Pneumatic packed rotating tower realizing self-distribution parallel flow

A technology of rotating tower and packing pressing plate, which is applied in the direction of separation method, dispersed particle separation, and the use of liquid separation agent, etc. It can solve the problems of increased pressure drop in the tower and low efficiency of the single plate, and achieves reduced operation and maintenance costs, gas-liquid The effect of uniform distribution and mixing, and simple tower structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

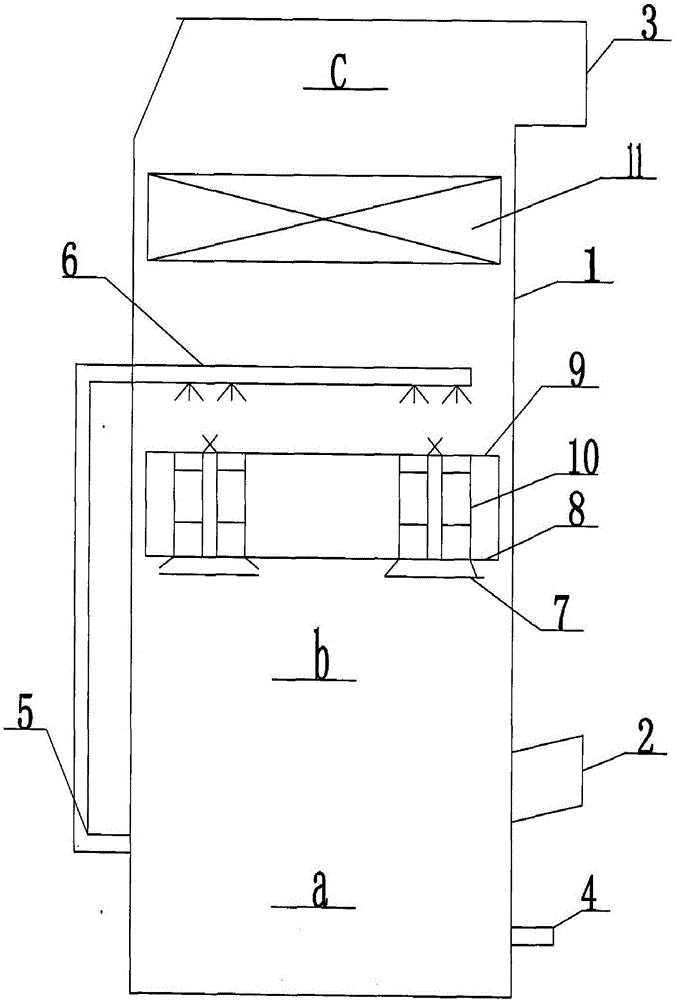

[0043] The purpose of the present invention is to provide a new type of wet flue gas purification device, which solves the problems of excessive investment and excessive operating costs in the current wet flue gas purification process, and realizes that the core equipment of the flue gas purification system has a simple structure and costs for manufacturing and installation. Low energy consumption, no fouling or blockage in the purification system, low energy consumption of the supporting system, and effectively solve the "amplification effect" of the absorption equipment.

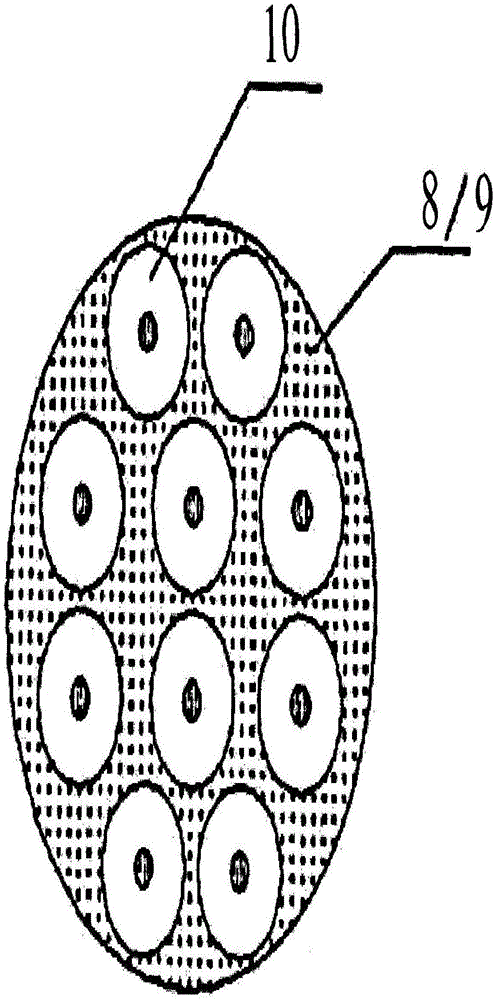

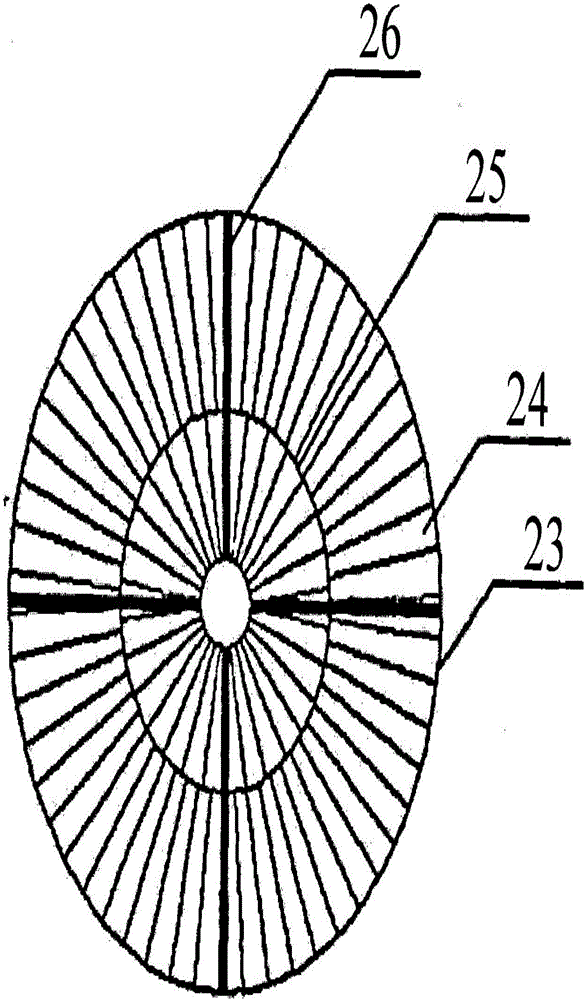

[0044] exist figure 1 In the invention, the present invention includes an absorption slurry pool section (A), a flue gas inlet and a diffusion adjustment section (B), a lower isolation plate (8) and an upper isolation plate (9), a parallel pneumatic desulfurization unit (10), and a spray pipe. A liquid distribution device (6), a mist removal and dehydration device (11), and a flue gas discharge section (C)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com