Double-groove wet-process flue gas desulfuration device and method operating on basis of two pH values

A wet flue gas desulfurization and desulfurization device technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of complex dual-circulation loop system, increased internal components of absorption towers, increased investment, etc. Operational safety and stability issues, strong load adaptability, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

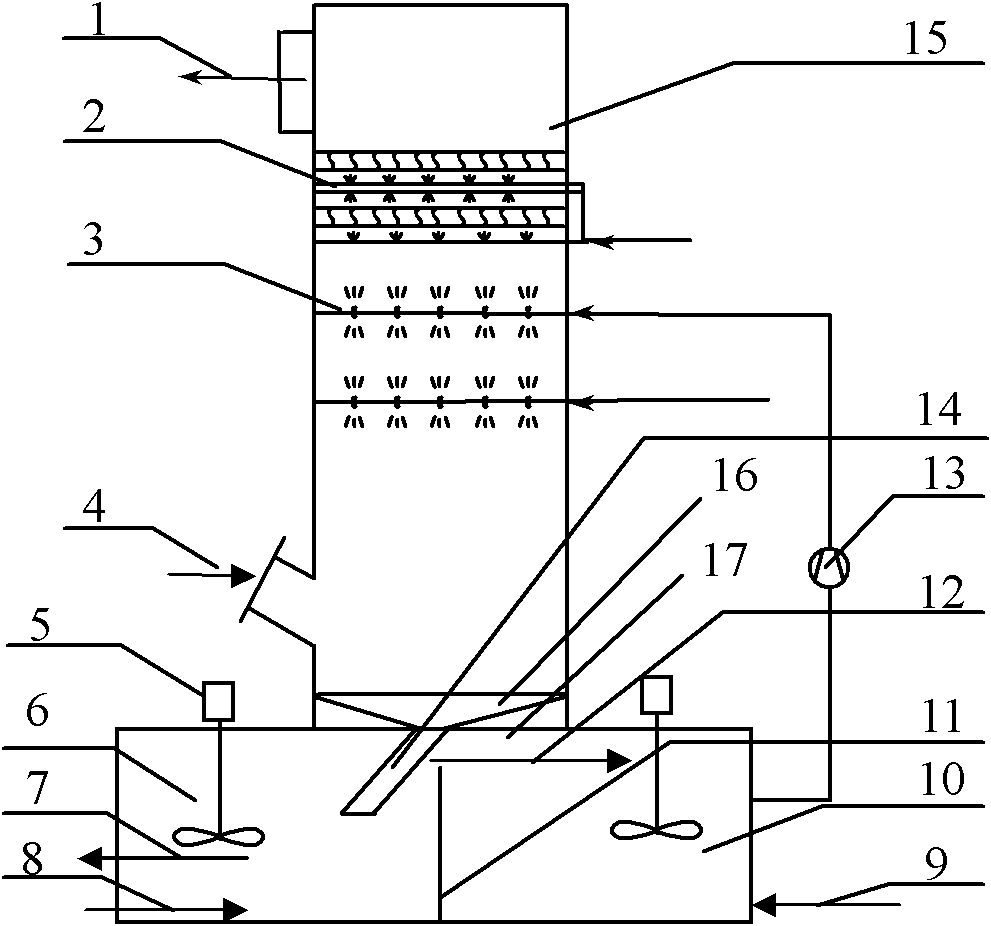

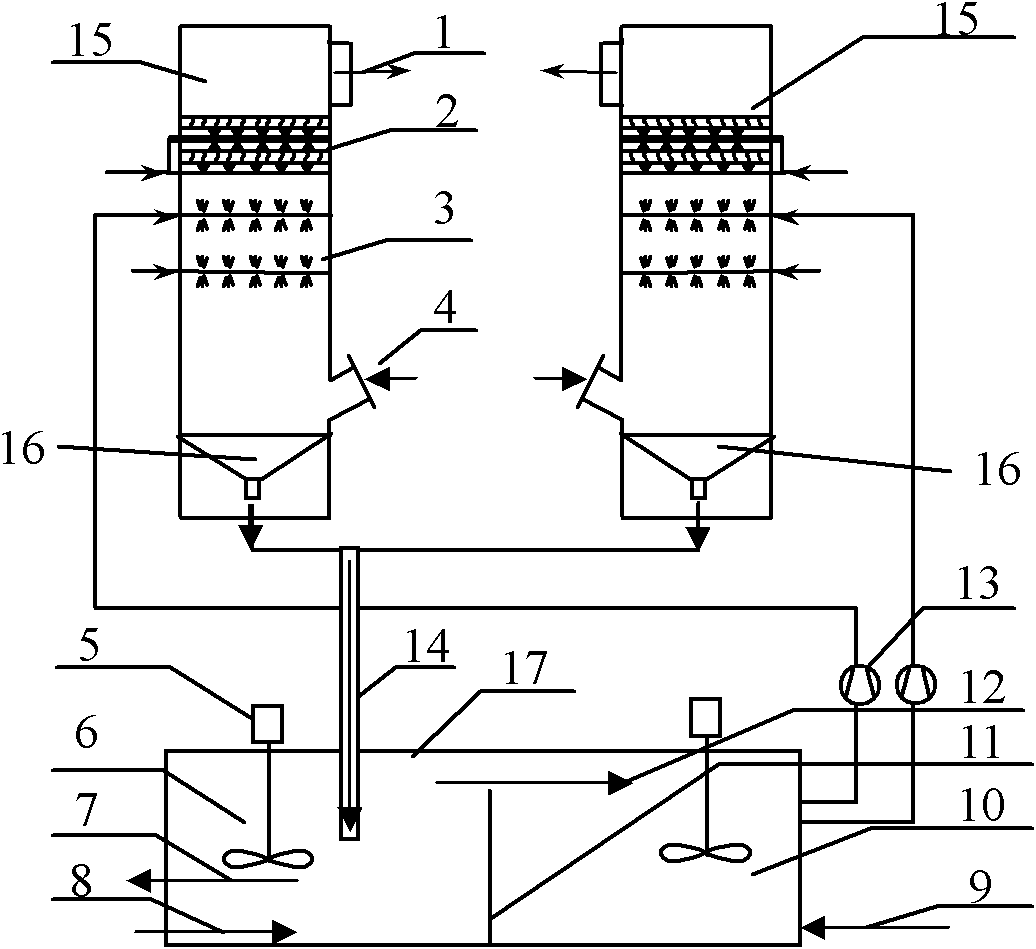

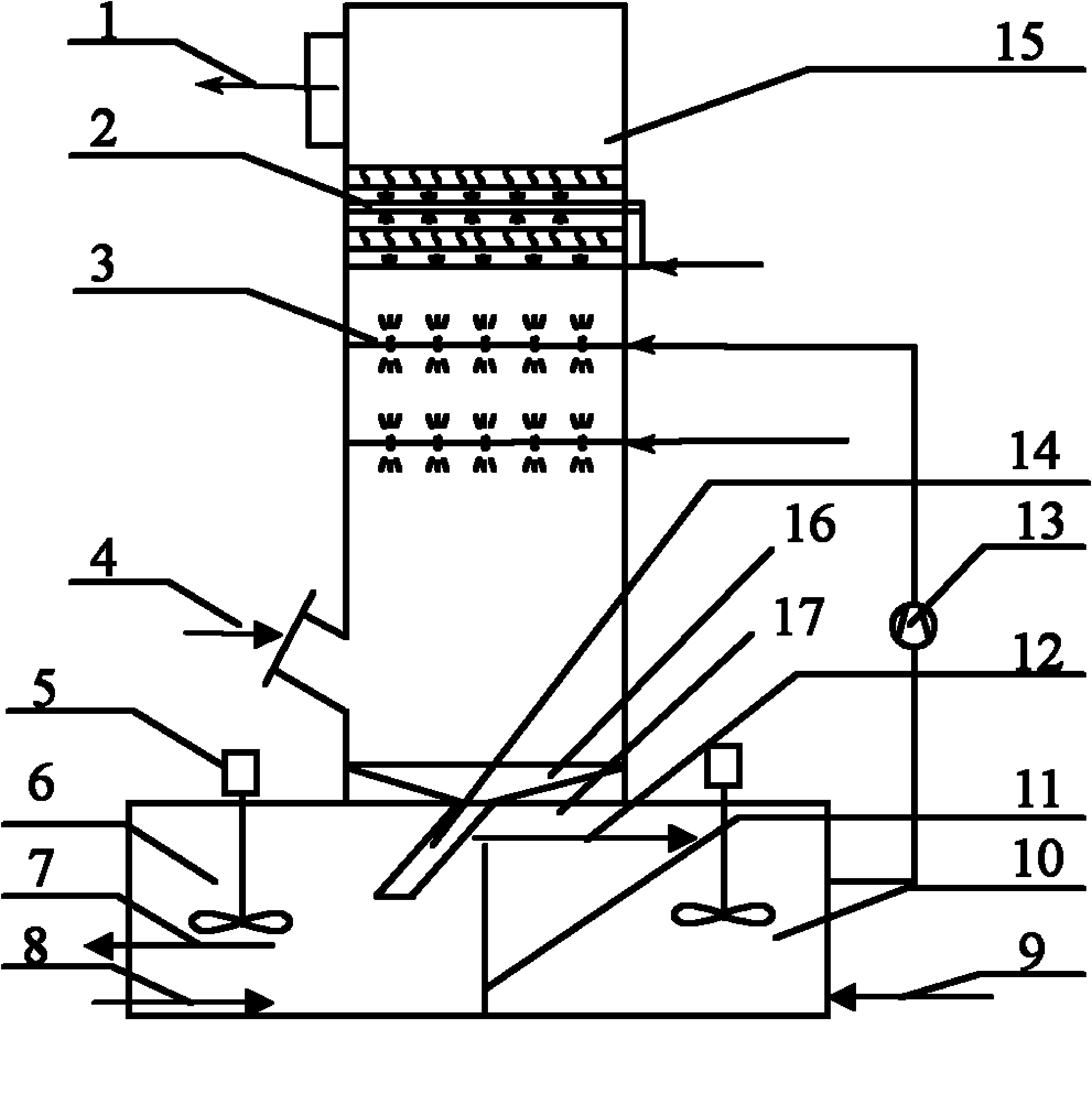

[0019] Specific implementation mode one: as figure 1 As shown, the double-slot wet flue gas desulfurization device based on dual-pH operation described in this embodiment includes an absorption tower body 15, a mist eliminator 2, a spray layer 3 and a circulation pump 13, the mist eliminator 2, spray The shower layer 3 is arranged in the upper part of the absorption tower body 15 from top to bottom. The lower end side wall of the absorption tower body 15 is provided with a raw flue gas inlet 4, and the upper end side wall of the absorption tower body 15 is provided with a clean flue gas outlet 1. It is characterized in that: the desulfurization device also includes an oxidation tank 6, a circulation tank 10 and a circulating slurry return pipe 14, the oxidation tank 6 and the circulation tank 10 are arranged below the absorption tower body 15, and the upper end of the oxidation tank 6 and the circulation The upper end of the tank 10 is connected; the absorption tower body 15 i...

specific Embodiment approach 2

[0022] Specific implementation mode two: as figure 1 As shown, the oxidation tank 6 and the circulation tank 10 in this embodiment are composed of a cuboid pool body 17 and a partition 11 arranged in the cuboid pool body 17, and the partition plate 11 divides the inner cavity of the cuboid pool body 17 along the Its length direction is divided into two parts used as the oxidation tank 6 and the circulation tank 10, and the height of the partition plate 11 is lower than the height of the cuboid pool body 17, so that the oxidation tank 6 and the circulation tank 10 are communicated. The cuboid design is adopted, and a top-entry agitator is designed on the top of each pool, which reduces the failure points that are prone to failure of the side-entry agitator of the conventional absorption tower. A partition 11 is set between the circulation tank 10 (circulation tank) and the oxidation tank 6 (oxidation tank), and the fully oxidized slurry of calcium sulfite contained in the desul...

specific Embodiment approach 3

[0023] Specific implementation mode three: as figure 1 As shown, the desulfurization device in this embodiment also includes two top-entry agitators 5, one top-entry agitator 5 is respectively arranged in the oxidation tank 6 and the circulation tank 10; the outlet of the circulating slurry return pipe 14 is It is installed below the liquid level of the oxidation tank 6 and above the jacking agitator 5 . Other components and connections are the same as those in the first embodiment.

[0024] Specific implementation mode four: as figure 1 As shown, the desulfurization device in this embodiment further includes a conical funnel 16, which is arranged in the lower part of the absorption tower body 15, and the liquid outlet of the conical funnel 16 is connected to the circulating slurry return pipe 14. Other compositions and connections are the same as those in the first, second or third embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com