Method for preventing scaling of controlled filtration equipment in titanium dioxide production process

A technology for controlling the filtration and production process, which is applied in the direction of chemical instruments and methods, titanium dioxide, titanium compounds, etc., can solve the problems of controlling the fouling and clogging of filtering equipment, and achieve the effect of solving fouling and clogging, simple process and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

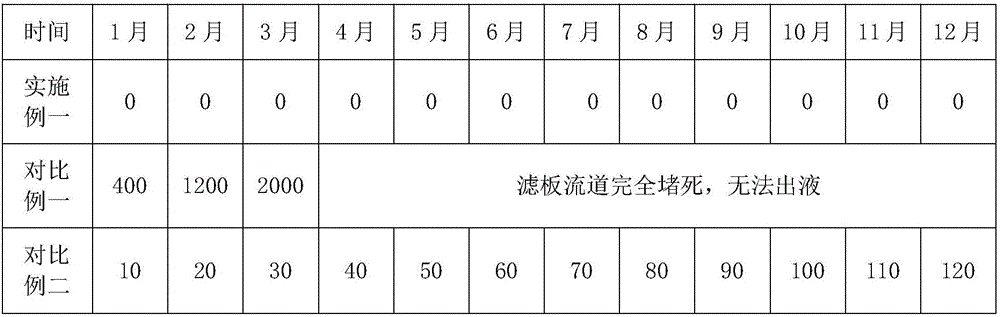

Embodiment 1

[0027] Control filtration equipment One set of plate and frame filter press, with a filtration area of 220 square meters (filter plate specification 1.5m×1.5m), add 500kg of diatomaceous earth and 10 square meters of filtrate (20°C) for beating and cloth after iron removal and crystallization, and then put After iron removal and crystallization, the filtrate is indirectly preheated to 77°C with a steam coil, and the filtrate (77°C) after preheating and iron removal crystallization is controlled and filtered to ensure that the titanium liquid-solid content after controlled filtration is less than or equal to 30ppm. When the overall pressure of the filter press When it reaches 0.4MPa, the filter-aid layer is replaced, and it is used reciprocally. The filter cloth is replaced every 15 days, and a filter plate is taken every 10 days, and the scale is thoroughly cleaned and weighed. The solid phase to be leached is added with water and the leaching temperature is 75°C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com