Flexible fiber spiral line demisting device

A flexible fiber and defogging device technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of corrosion, large floor area, and low defogging efficiency, and achieve good water absorption and high efficiency. The effect of gas-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

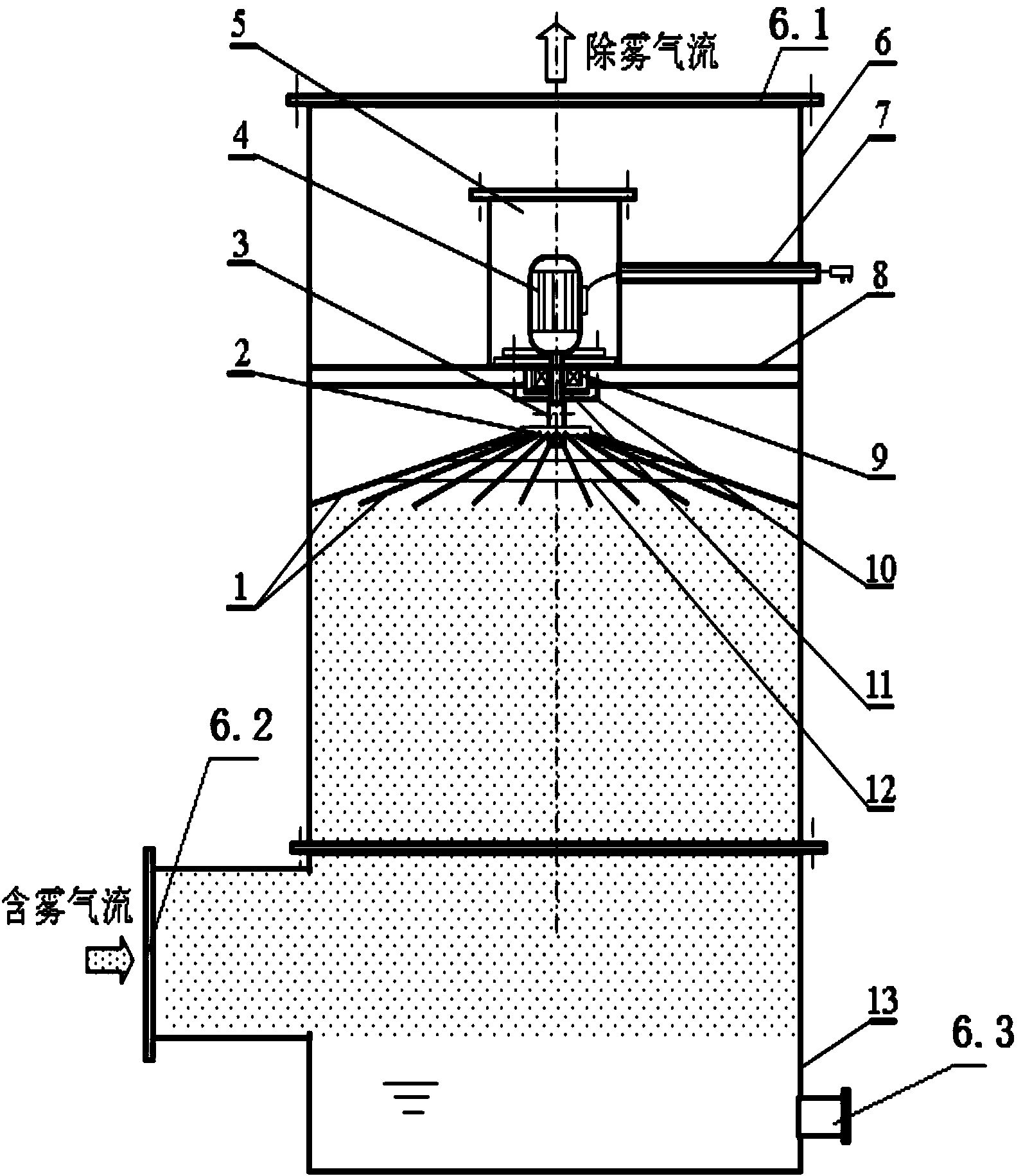

[0041] In embodiment 1, the flexible fiber spiral in the flexible fiber spiral defogging device installed on the vertical center line of the exhaust cylinder 6 is a single layer, and its structure is as follows: figure 1 Shown: including warp 1, disc 2, motor shaft sleeve 3, motor 4, sealing chamber 5, plastic conduit 7, support beam 8, bearing 9, sealing end cover 10, motor shaft 11 and weft 12.

[0042] Wherein, the top of the exhaust tube 6 is provided with an air outlet 6.1, the lower section is provided with an air inlet 6.2, and the bottom is provided with a water tank 13, and the water tank 13 communicates with the drain pipe 6.3, and the vertical center line of the upper section of the exhaust tube 6 is A motor 4 located in the sealed chamber 5 is provided, and the sealed chamber 5 passes through the cylinder wall of the exhaust cylinder 6 to communicate with the outside world through the conduit 7, so that the power supply wire of the motor 4 can pass through the condu...

Embodiment 2

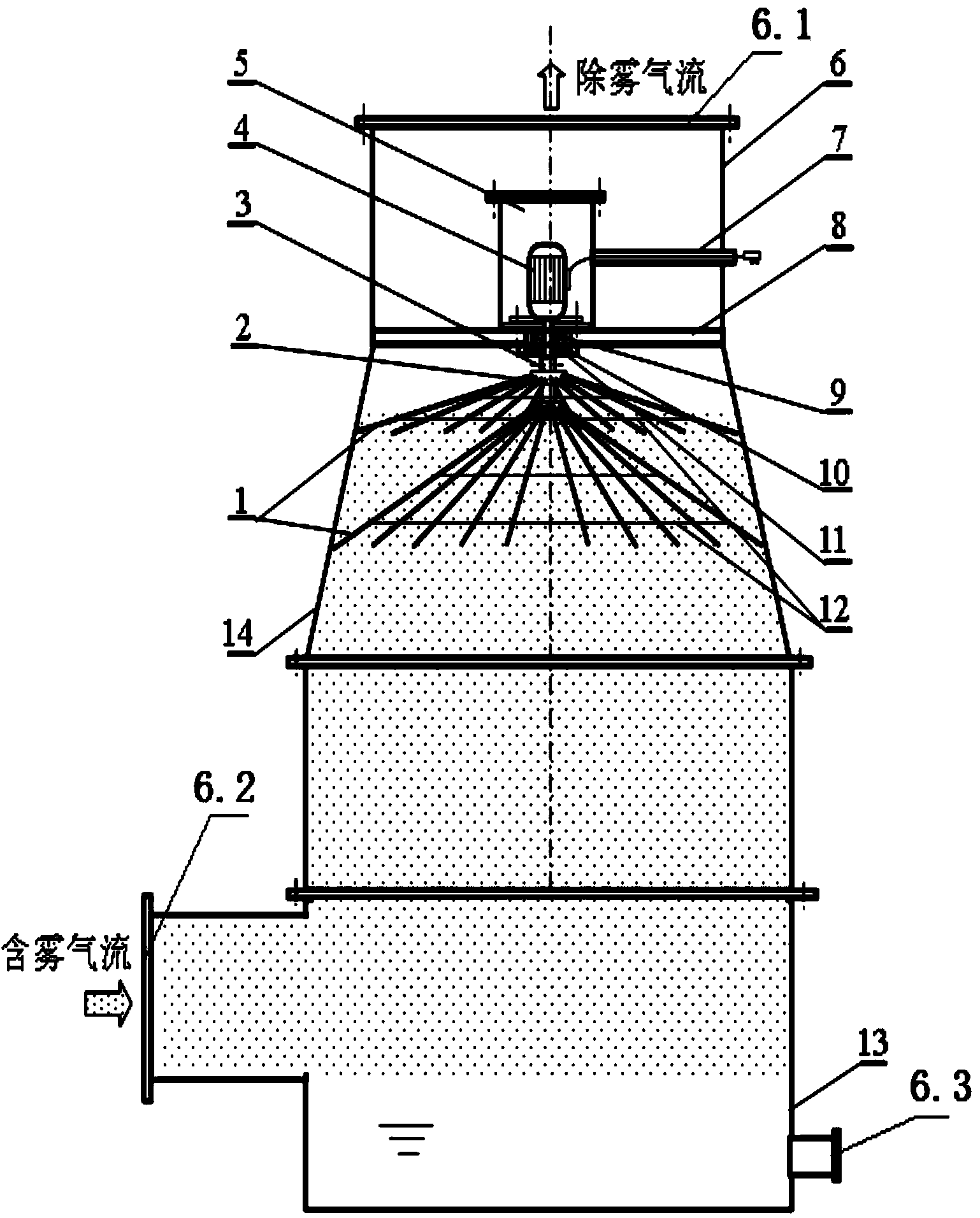

[0049] The number of layers of the flexible fiber spiral can be designed into multiple layers, but when it exceeds 5 layers, the pressure loss will increase significantly, and although the flexible fiber spiral is very light, if there are too many layers and it is a wet fiber thread, the weight will increase significantly . Therefore, the number of flexible fiber spirals is preferably 1-5 layers, and one layer of discs 2 is correspondingly installed with one layer of flexible fiber spirals.

[0050] In addition, when the exhaust cylinder 6 is a straight pipe, the warps in the multilayer flexible fiber spirals can have the same length; The increase or decrease of the cylinder diameter increases or shortens accordingly, and the control of its length is still "when the warp 1 rotates at a high speed, it is better for the free end to be in contact with the cylinder wall of the exhaust cylinder 6 or to be slightly longer",

[0051] In this example, if figure 2 As shown, the exha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com