Treatment method for industrial wastewater

A technology for industrial wastewater and treatment methods, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve mass transfer resistance, increase operating load, block ammonia stripping equipment and Pipeline and other problems to achieve the effect of reduced mass transfer resistance, reduced operating costs, reduced power consumption and heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

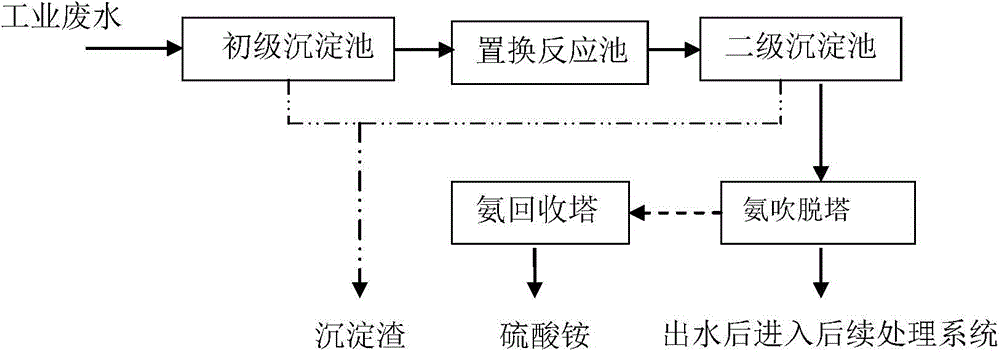

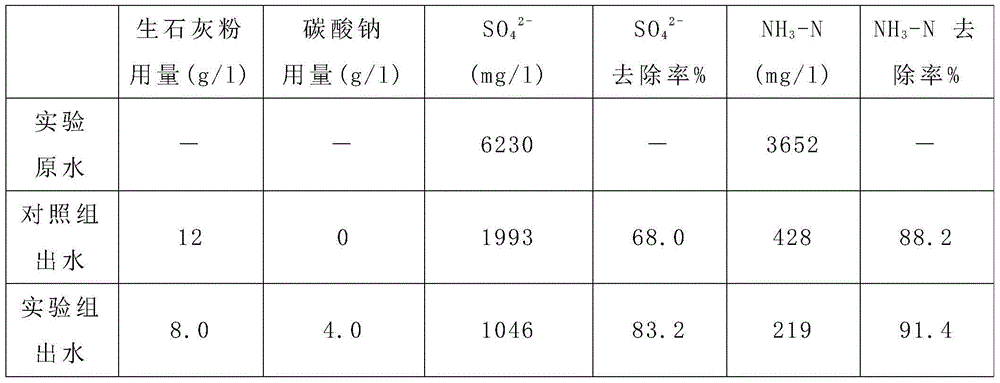

[0030] Embodiment 1 Contrast test of conventional precipitation treatment method and treatment method of the present invention

[0031] Taking the ammonium sulfate wastewater produced by a certain pharmaceutical company as the test object, the test is divided into two groups, namely the control group and the test group. "Primary precipitation, replacement reaction, secondary precipitation, ammonia stripping, ammonia recovery" treatment process, the comparative test results are shown in Table 1

[0032] Table 1: Comparative test results comparison

[0033]

[0034] From the data in Table 1, the following conclusions can be drawn:

[0035] Under the premise that the total mass of the dosage of the two groups of chemicals is the same, that is, the amount of quicklime powder in the control group is equal to the amount of SO in wastewater 4 2- The mass concentration ratio is 1.93, and the amount of quicklime powder in the experimental group is equal to that of SO in wastewate...

Embodiment 2

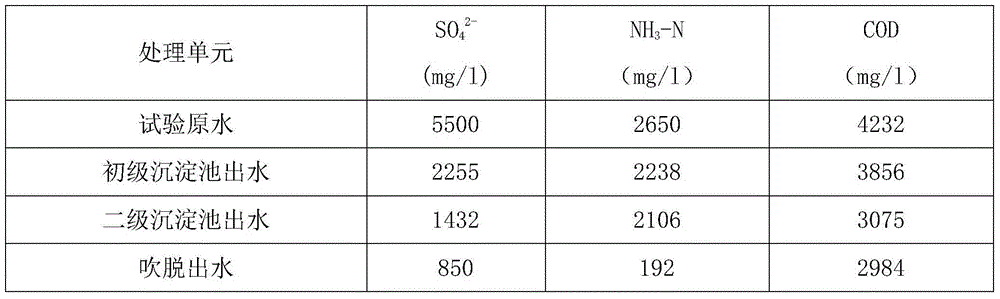

[0036] Embodiment 2 The pilot test of method of the present invention processing ammonium sulfate waste water

[0037] Ammonium sulfate wastewater from a chemical company was taken for pilot test. The wastewater SO 4 2- The concentration is 5500mg / L, NH 3 -N concentration is 2650mg / L, COD concentration is 4232mg / L, pH is 3.0, the test process is as follows:

[0038] The ammonium sulfate wastewater enters the primary sedimentation tank, and 6.5g / L of quicklime powder is added, and the stirring is started for reaction. After 20 minutes of reaction, the stirring is turned off, and the precipitation is allowed to stand for 1 hour. The generated calcium sulfate precipitates at the bottom of the tank, and the supernatant enters the replacement Reaction tank; Add 3.5g / L of sodium carbonate to the replacement reaction tank, turn on the stirring for the replacement reaction, turn off the stirring after 30 minutes of reaction, the waste water enters the secondary sedimentation tank, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com