Preparation method of biological activated carbon filter

A biological activated carbon, activated carbon filter technology, applied in chemical instruments and methods, biological water/sewage treatment, special treatment targets, etc., can solve environmental and human health hazards, filter operation and maintenance obstacles, etc. The effect of cost, good effluent quality, extensive development and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a preparation method of a biological activated carbon filter, including the test process flow as follows: pre-ozonation+coagulation, precipitation, filtration+ozone-biological activated carbon, wherein,

[0022] The cross-sectional size of the activated carbon filter is 500×500mm, the height is 4.92m, and the interior is divided into two compartments. It adopts a small resistance water distribution system and is filled with ZJ-15 columnar activated carbon. The iodine value of the carbon and the methylene blue adsorption value are respectively 961. and 187mg / g, the biological activated carbon filter adopts the downward flow type, and the filter adopts two-stage air-water backwashing, that is, first scrubbing with air, and then backwashing with non-chlorinated sand filter water, and the backwashing cycle is 7 days .

[0023] The ozone contact pool is divided into five pools with an effective water depth of 6. Among them, air is used as the gas sourc...

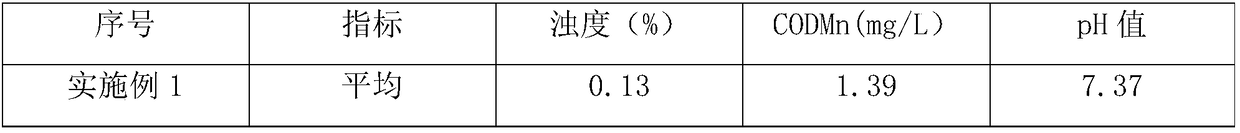

Embodiment 1

[0034] Embodiment 1: The preparation method of this bioactivated carbon filter, conventional treatment process parameters are basically constant, that is, the amount of water to be treated is 3~3.5m3 / h, the mixing time is 6~6.5s, the reaction time is 23.2~19.9min, and the rising flow rate in the clear water area of the sedimentation tank 1.39~1.62mm / s, ascending flow rate in the inclined pipe is 1.60~1.87mm / s, filter rate is 6.49~7.57m / h, coagulant and pH regulator are respectively liquid alkali aluminum and sodium hydroxide, and the concentration They are about 2.5mg / L and 6mg / L respectively, which is the biological activated carbon filter. Indicators, ammonifying bacteria: This method uses the MPN method to mix the sample to be tested with sterile water. After shaking and ultrasonic treatment, the water sample is diluted to the required dilution by the 10-fold dilution method, and the samples with different dilutions are respectively Inoculate into sterile peptone ammoniat...

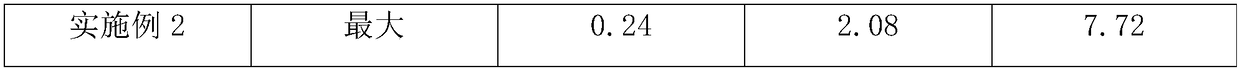

Embodiment 2

[0035] Embodiment 2: The preparation method of this bioactivated carbon filter, the routine treatment process parameter is constant basically, and promptly handles water volume 4~5.5m3 / h, mixing time 6~7.5s, reaction time 20~22min, sedimentation tank clear water area ascending flow velocity 1.03 ~1.09mm / s, ascending flow rate in the inclined pipe is 1.80~2.07mm / s, filter rate 6.49~8.50m / h, coagulant and pH regulator are respectively liquid alkali aluminum and sodium hydroxide, and the dosing concentration is respectively 2.5mg / L and 6mg / L, that is, a biological activated carbon filter. The detection method of biological activated carbon filter includes: ammonifying bacteria, nitrosifying bacteria, heterotrophic bacteria, several biological indicators of dehydrogenase activity, ammonification Bacteria: This method adopts the MPN method. Mix the sample to be tested with sterile water. After shaking and ultrasonic treatment, the water sample is diluted to the required dilution by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com