Method and device for continuously cooking rice

A rice and cooking technology, applied in application, food preparation, food science and other directions, can solve the problems of difficult to accurately control the rice gelatinization process, difficult mechanical cleaning, complicated operation steps, etc., and achieves convenient continuous production and process conditions. Change and control, the effect of temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

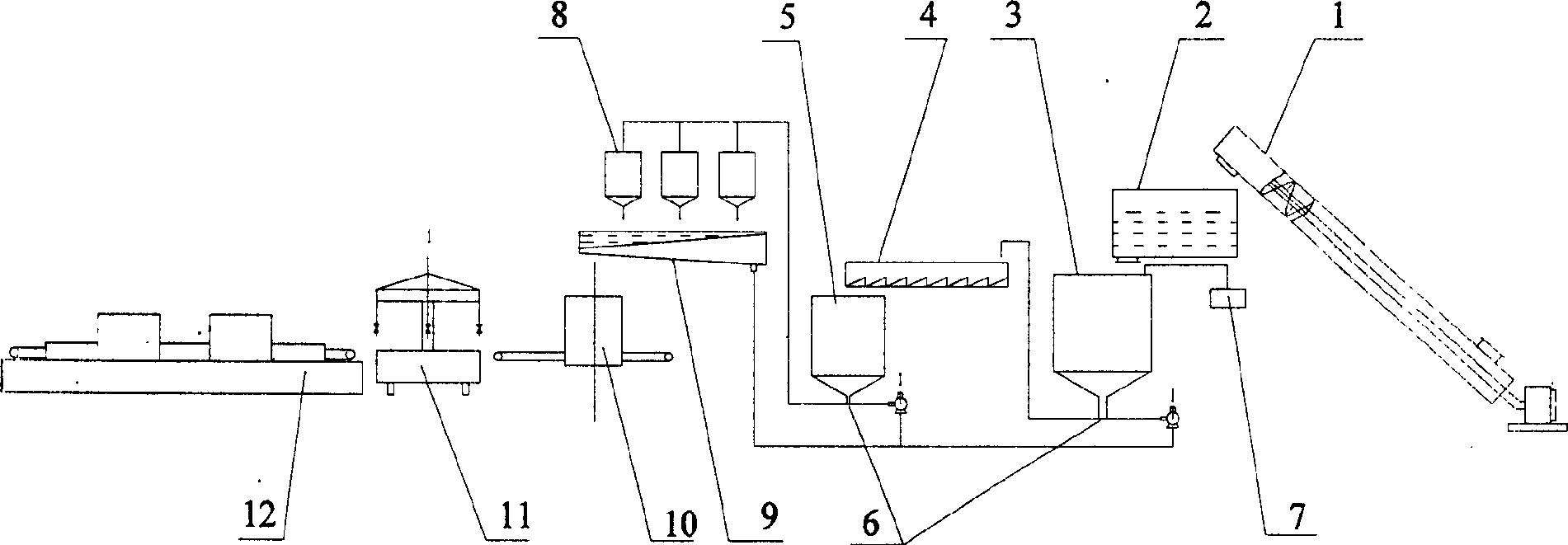

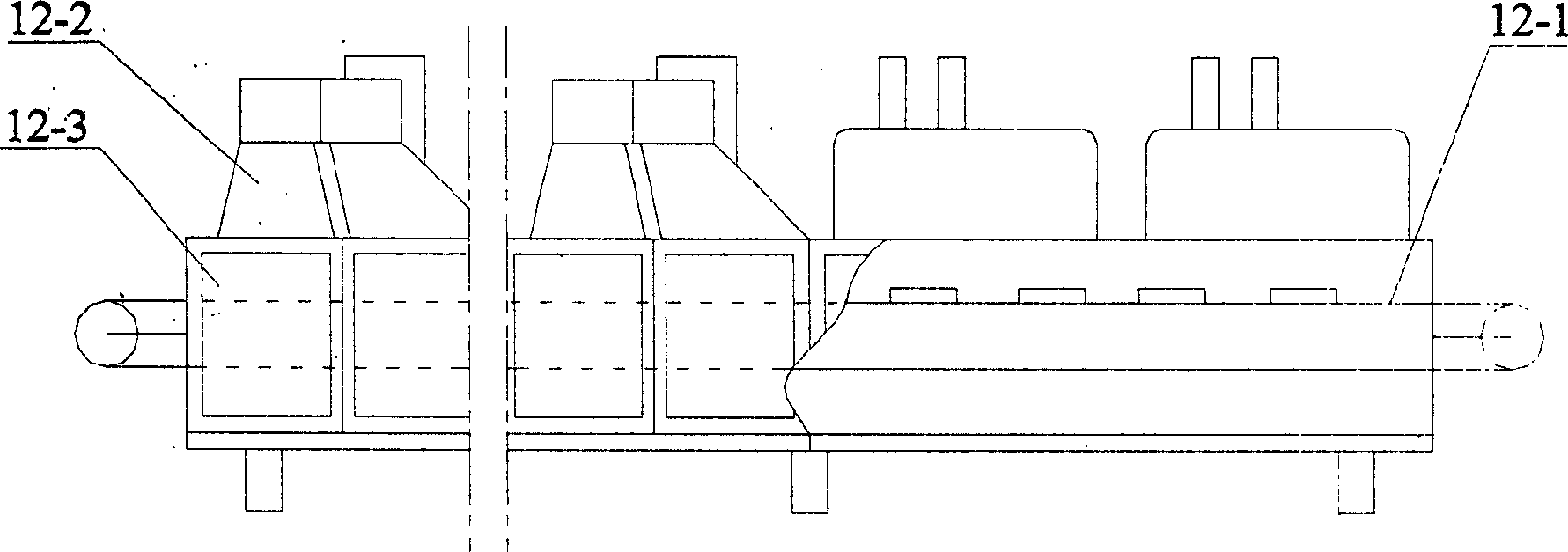

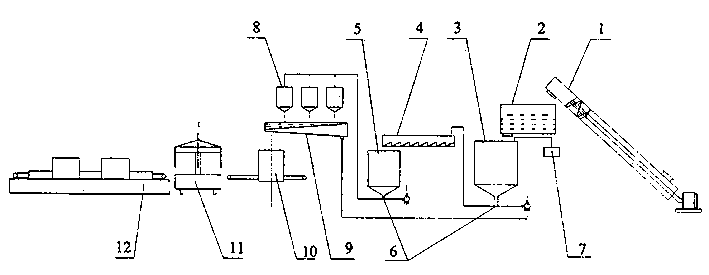

[0019] figure 1 shows the concrete structure of the present invention, by figure 1 It can be seen that the continuous rice cooking device includes a screw conveyor 1, a high-level rice storage tank 2, a cleaning rice washing device 3, a stepped impurity removal tank 4, a redox rice washing device 5, a jet injector 6, and a strongly acidic oxidized ionized water generator 7 , rice soaking tank 8, inclined rice falling tank 9, rice quantitative filling machine 10, water replenishment filling machine 11, microwave continuous rice cooking machine 12; the output end of the screw conveyor 1 is located on the high-level rice storage tank 2, and the high-level storage The outlet at the lower end of the rice tank 2 is connected to the inlet of the cleaning rice washing device 3, and the inlet of the cleaning rice washing device 3 is connected to the strongly acidic oxidized ionized water generator 7 at the same time, and the outlet at the lower end of the cleaning rice washing device 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com