Belt scraper

A scraper and belt technology, applied in the field of belt scrapers, can solve the problems of high maintenance rate and maintenance cost, high labor intensity for workers to clean up, and large amount of slag returned by the belt, so as to reduce cost consumption and reduce labor intensity of cleaning. , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

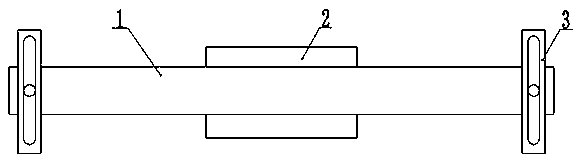

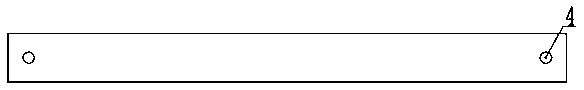

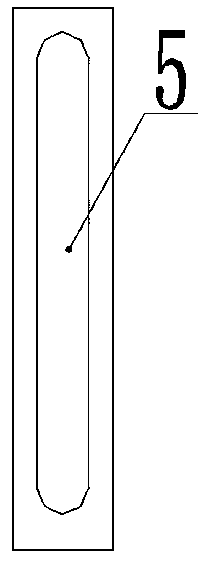

[0014] Embodiment 1: As shown in the figure, a belt scraper includes a splint 1 with positioning holes 4 at both ends, a scraper brush 2 arranged between the splints 1 and a vertically movable adjustment device at both ends of the splint 1. Plate 3 and scraper brush 2 are made of canvas rubber-surfaced conveyor belt. Adjusting plate 3 is provided with an adjusting hole 5 compatible with positioning hole 4. Adjusting plate 3 can be adjusted by positioning hole 4 on splint 1 and adjusting plate 3. The adjustment hole 5 is fixedly connected to the splint 1 by bolts, and the position of the splint 1 on the adjustment plate 3 can be adjusted by the bolts.

[0015] When in use, install the adjustment plate 3 on the bracket of the conveyor belt so that the scraper brush 2 is under the conveyor belt, and then adjust the position of the splint 1 on the adjustment plate 3 through bolts to adjust the distance between the scraper brush 3 and the conveyor belt 5. After adjusting the gap be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com