Device and method for reducing pressing-in of iron sheet ash during strip steel production through hot tandem rolling unit

A technology of hot continuous rolling and strip steel, which is applied in the field of steel rolling, can solve the problems of heavy workload and little effect, and achieve the effects of improving quality, eliminating hidden safety hazards, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

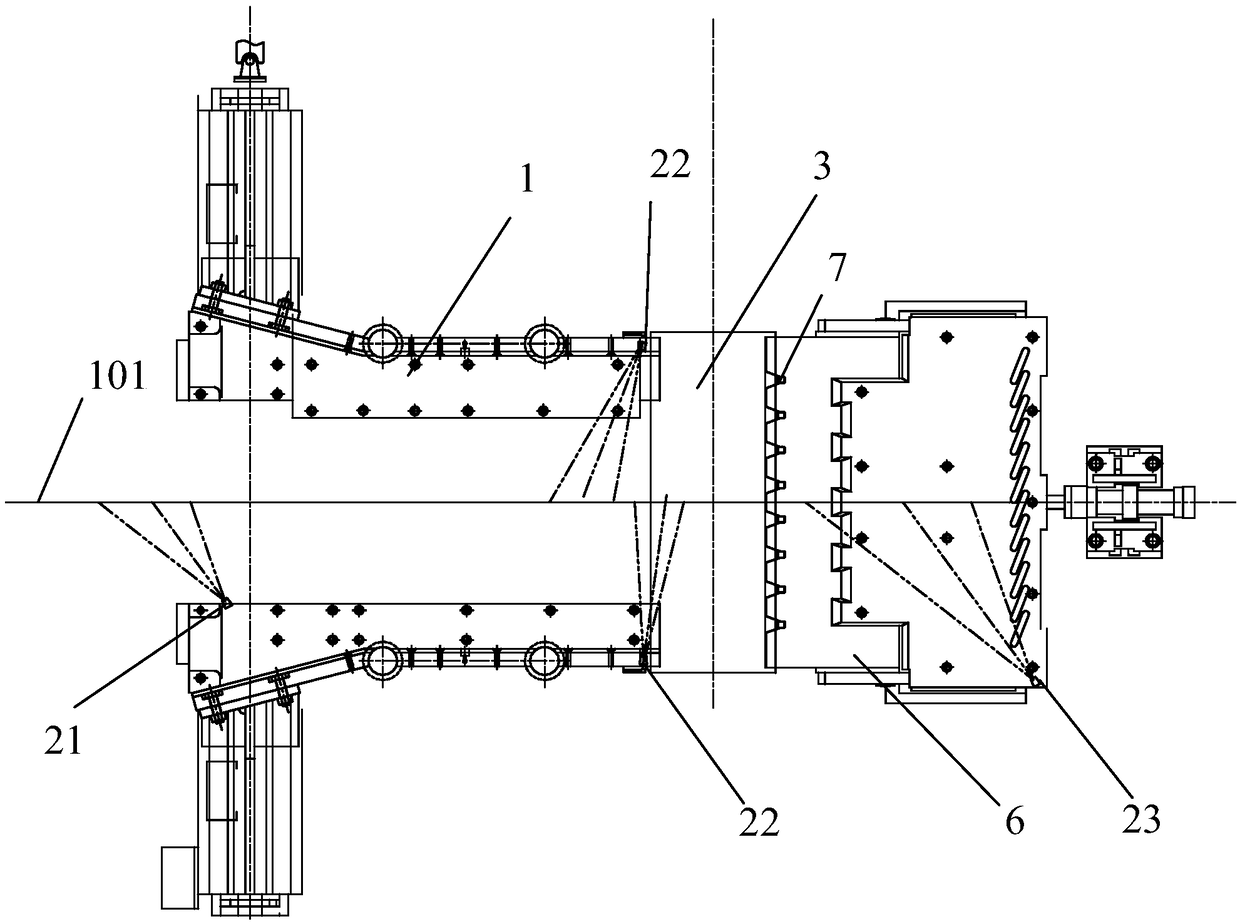

[0052] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

[0053] see Figure 3-Figure 4 , the equipment for reducing iron sheet ash to be pressed in when the hot tandem rolling mill of the present invention produces strip steel comprises:

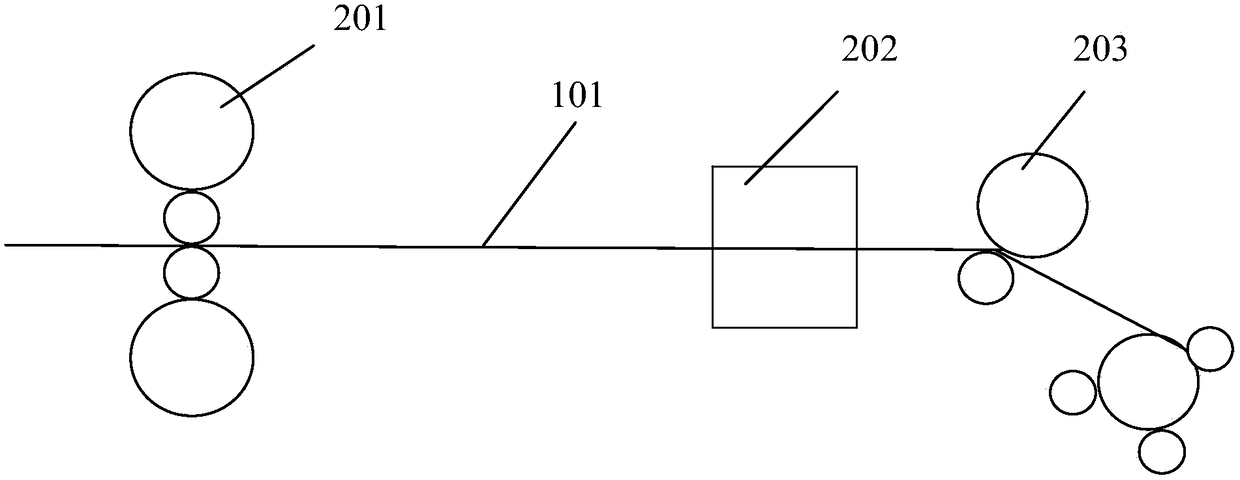

[0054] Side water spray equipment at the entrance of the finishing mill, such as image 3As shown, the entrance of the finishing mill 3 is provided with two sets of side water spray equipment, the first group of entrance side water spray equipment 21 is installed on the outer end of the side guide plate 1 of the finish rolling mill, and the entrance side spray water of its ejection is in the The upper surface of the strip steel 101 is purged at the looper roll, usually on one side, or on both sides; the second group of side water spray equipment 22 at the entrance is installed on the inner end of the side guide plate 1 of the fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com