Honeycomb chilling block

A honeycomb type, cold iron technology, applied in the field of foundry, can solve the problems of small air permeability of molding sand or coating layer, inability to exhaust cold iron, less cleaning and grinding amount, etc. Handling convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

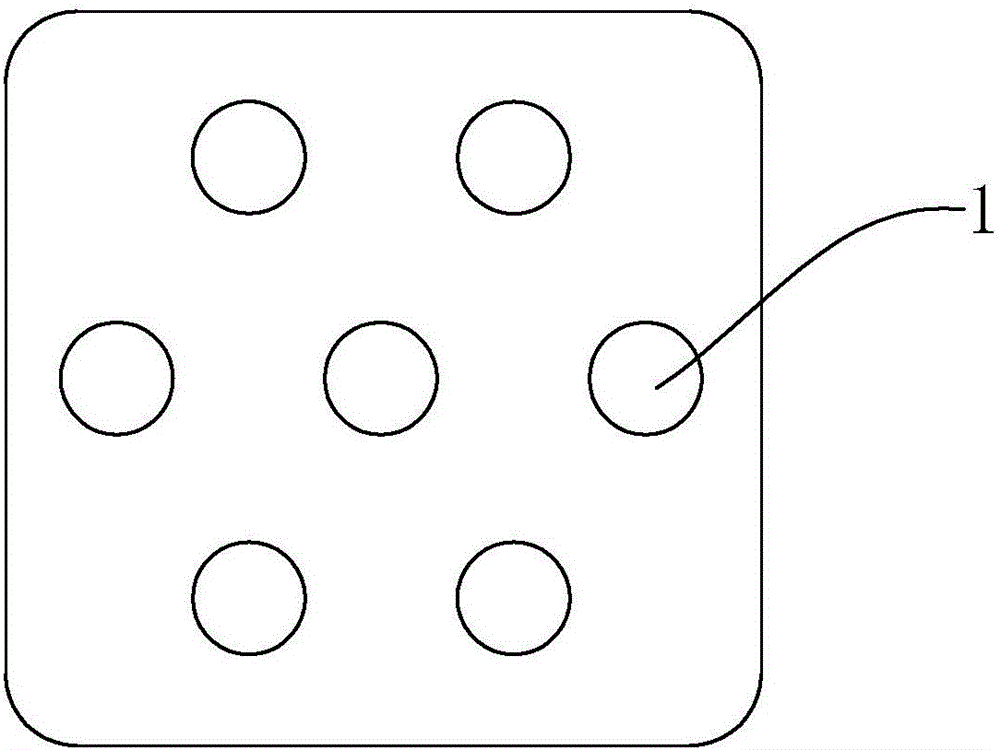

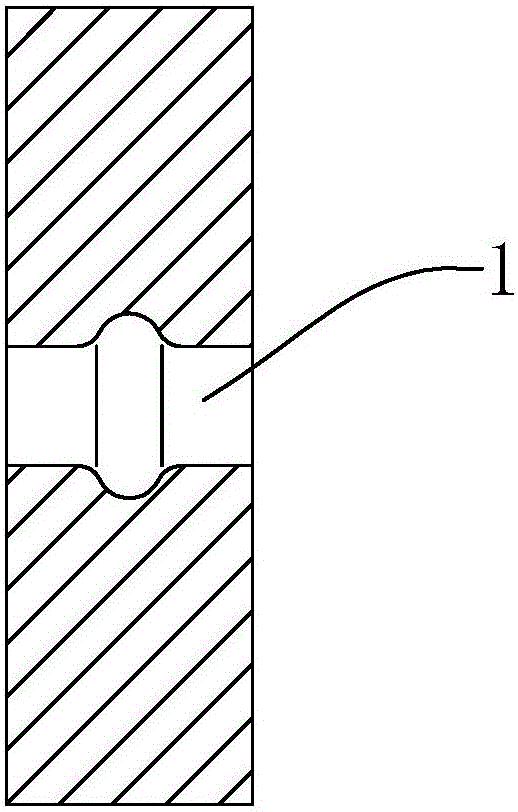

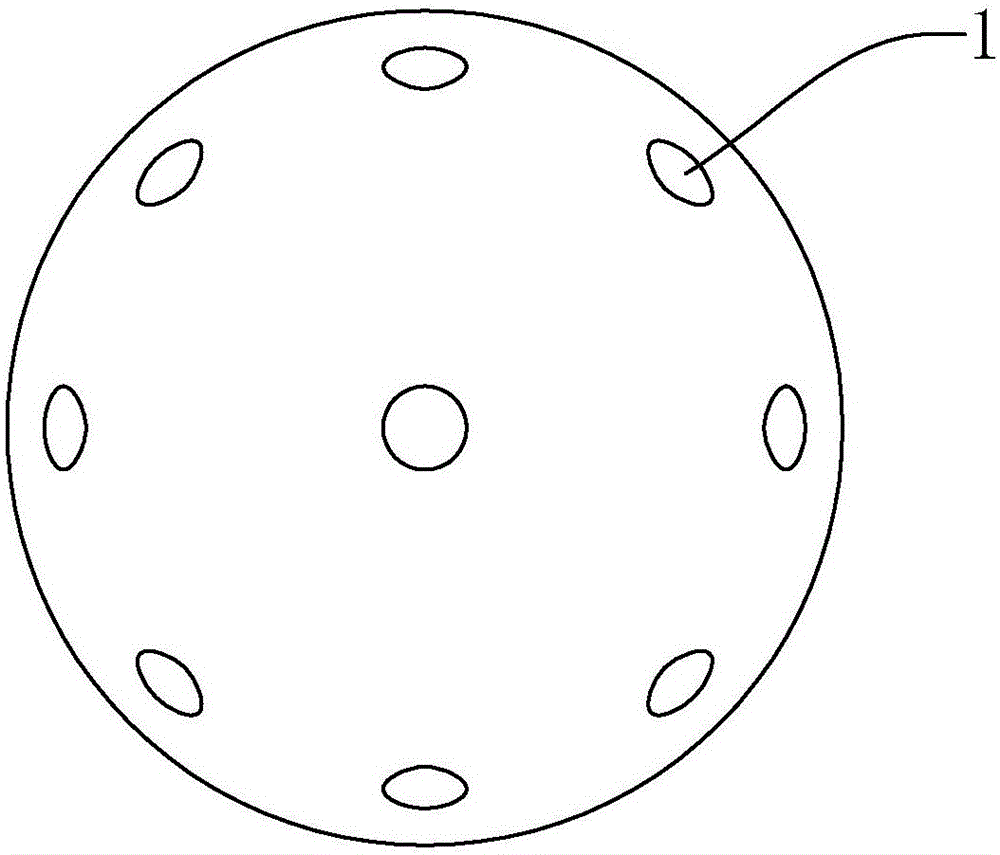

[0017] refer to figure 1 , figure 2 , figure 1 , figure 2 It is a structural schematic diagram of the first specific embodiment of the present invention. As shown in the figure, the honeycomb chiller includes a chiller body, and the chiller body includes a cooling surface for being close to the casting to be cooled. The cooling surface A number of exhaust holes 1 are opened through the body of the cold iron to form a honeycomb structure. Through the exhaust holes 1, the surface gas or oxides that are not properly treated on the surface of the cold iron can be effectively discharged and the gas generated by decomposition at high temperature can be effectively eliminated. Casting porosity defects, through the use of new cold iron in casting production, not only easy to handle, easy to set up, improve casting yield, reduce casting cleaning labor intensity, and can eliminate the porosity defects that may occur due to traditional chilled iron, casting pass rate It can be incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com