A production method of bulk molding compound (bmc) that can improve product performance

A technology of bulk molding compound and production method, which is applied in the field of bulk molding compound production technology, can solve problems such as unresolved bulk molding compound, water content reduction, product appearance and performance impact, etc., to eliminate pore defects and improve performance , Improve the effect of mechanical and appearance properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

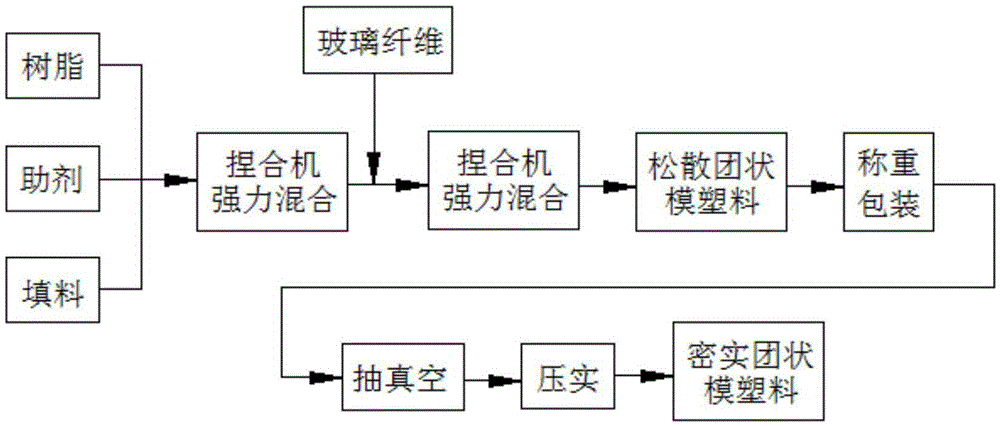

[0029] combine figure 1 and figure 2 A method for producing bulk molding compound (BMC) that can improve product performance in this embodiment comprises the following steps:

[0030] (1) Mixing: Add resin, fillers, additives and glass fiber into a kneader according to a certain formula ratio for intensive mixing to obtain a loose bulk molding compound; specifically, take component A: 70 parts of resin, low shrinkage resin 30 parts, 1.5 parts of tert-butyl peroxybenzoate and 4 parts of zinc stearate, component B: 300 parts of ground calcium carbonate, component C: 75 parts of 6mm chopped glass fiber;

[0031] (1.1) Fully mix component A in a high-speed mixer for 5 minutes, pour the mixed component A into the kneader containing component B and mix vigorously for 10 minutes. This step is the initial mixing of resin, filler and additives;

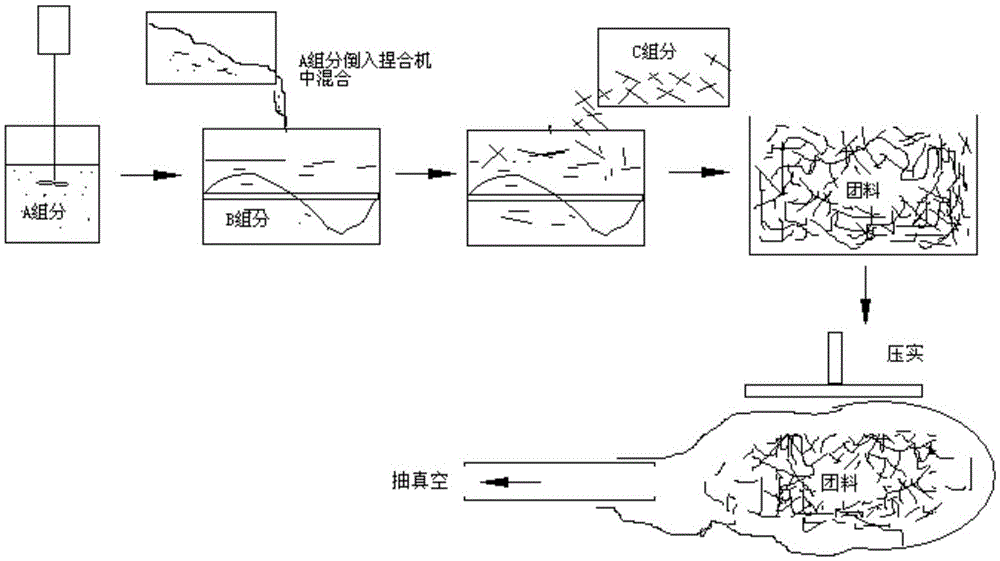

[0032] (1.2) After the initial mixing, add component C to the kneader, vacuumize to -0.08MPa~-0.1MPa, and knead vigorously for 5min to for...

Embodiment 2

[0039]A production method of bulk molding compound (BMC) that can improve product performance in this embodiment is basically the same as in embodiment 1, the difference is that in the step (1.1) of this embodiment, the mixed component A is poured into the containing component Mix vigorously in the kneader of part B for 25min; add component C to the kneader in step (1.2), and vacuumize to -0.08MPa~-0.1MPa, and knead vigorously for 10min to form a loose dough molding compound; step ( 2) The obtained loose bulk molding compound is weighed according to a certain weight and packed in airtight PP plastic bags. The PP plastic bags are low in cost, high in strength and not easy to be damaged, which ensures that the vacuum treatment can be successfully completed.

Embodiment 3

[0041] A production method of bulk molding compound (BMC) that can improve product performance in this embodiment is basically the same as in embodiment 1, the difference is that in the step (1.1) of this embodiment, the mixed component A is poured into the containing component Mix vigorously in the kneader of part B for 45min; in step (1.2), add component C to the kneader, and vacuumize to -0.08MPa~-0.1MPa, and knead vigorously for 15min to form a loose dough molding compound; step ( In 2), the obtained loose bulk molding compound is weighed and packed in airtight containers according to a certain weight.

[0042] Such as figure 2 Shown, a kind of Bulk Molding Compound (BMC) production method that can improve product performance of the present invention, after Bulk Molding Compound (BMC) production is finished, put into airtight nylon bag or PP plastic bag or airtight container , first remove the air in it by vacuuming, and at the same time extrude the BMC mass, so that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com