Intelligent cleaning control system for culture waterline

An intelligent cleaning and control system technology, which is applied in the transmission system, electrical program control, program control in sequence/logic controller, etc., can solve problems such as untimely cleaning, low bacteria and microorganism content, incomplete cleaning, etc., to prevent The generation of dirt and bacteria, the effect of small fluctuations in content, and the effect of low cleaning labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

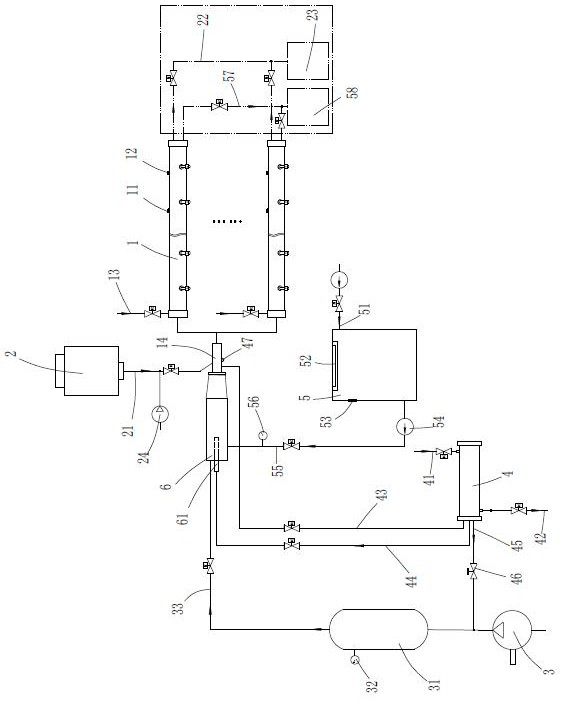

[0032]An exemplary embodiment according to the present invention will be described in detail below with reference to the accompanying drawings. Here, it should be noted that in the drawings, the same components are given the same components, and the components are substantially the same, and the redundancy description of the substantially identical components is omitted in order to make the specification more concise.

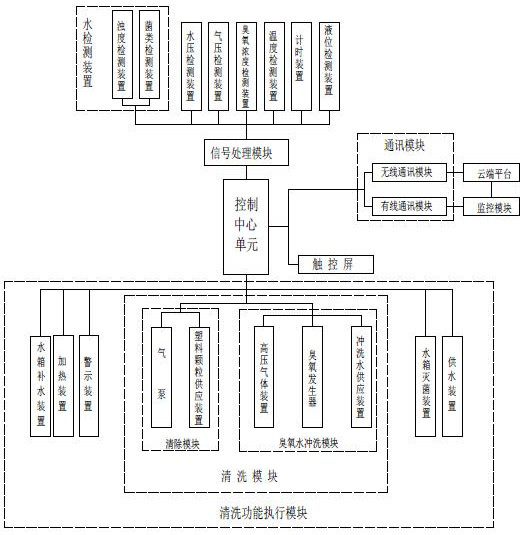

[0033]Such asfigure 1 As shown, a breeding water wire intelligent cleaning control system is used for the cleaning of the aquaculture water line 1, such as the cleaning of the aquaculture water 1 in the poultry breeding field, including

[0034]The control center unit can employ a central processor for receiving, processing, and transmitting data and operation instructions to achieve the normal conduction of the aquaculture water 1 cleaning;

[0035]The signal processing module may employ a signal processing circuit for receiving the data signal transmitted by each detecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com