Tailing recycling device for cold-box core shooter and use method thereof

A technology of cold core box and core shooter, which is applied to molding machines, components of molding machines, casting molding equipment, etc., can solve the problems of difficulty in recycling and cleaning tailings, time consumption, etc., to reduce labor intensity of cleaning and improve The effect of cleaning efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

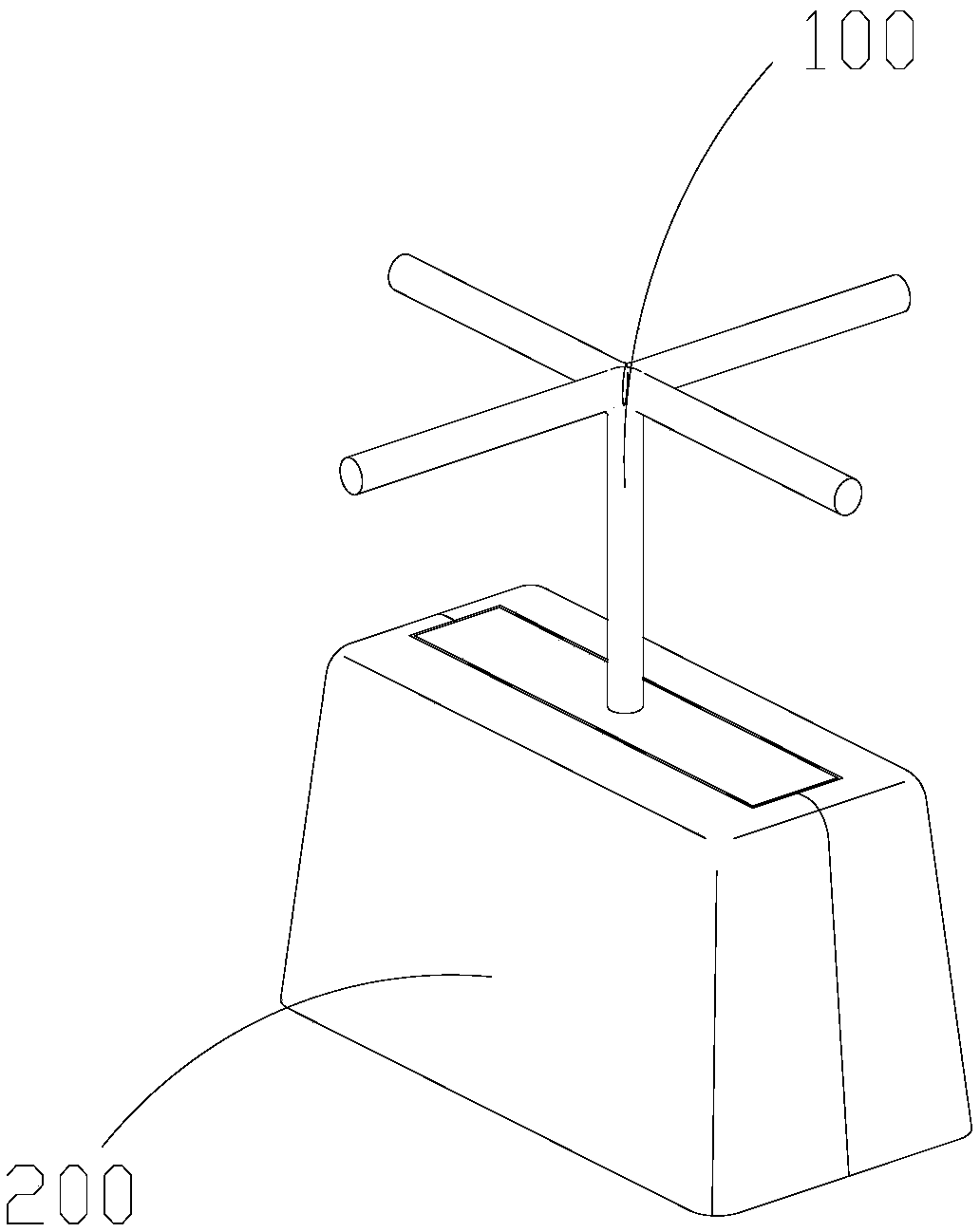

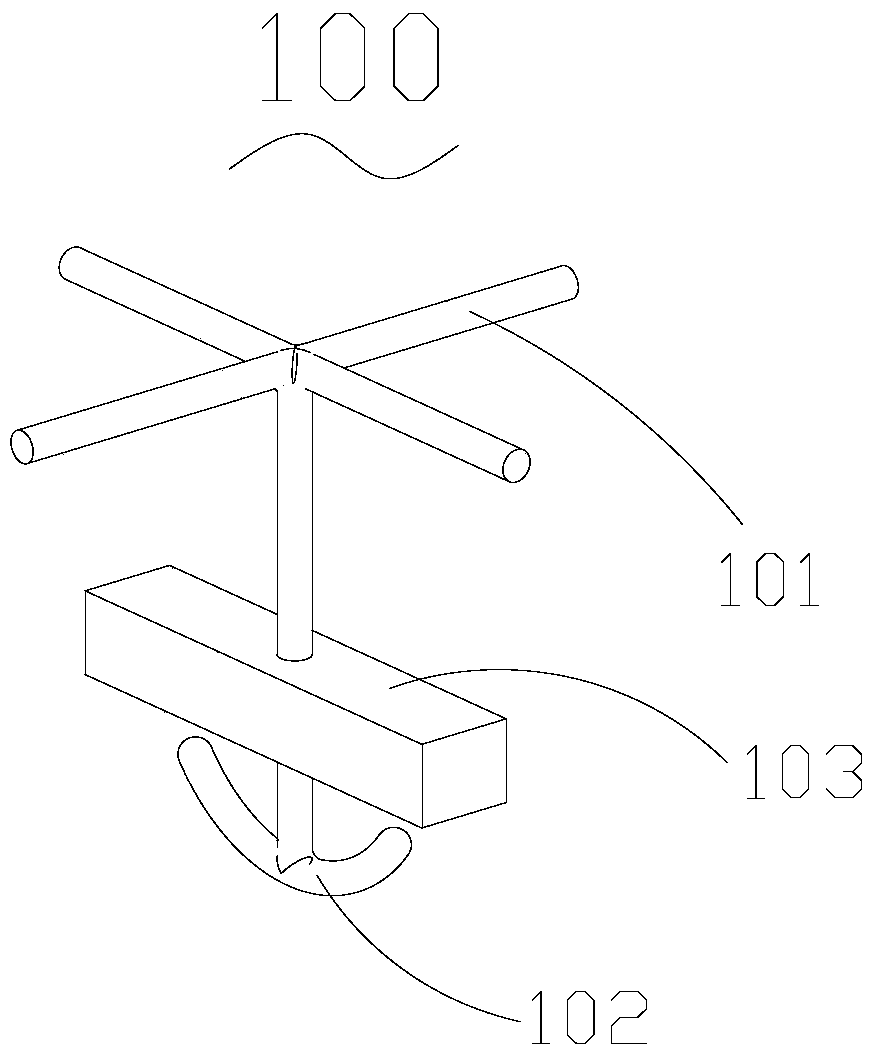

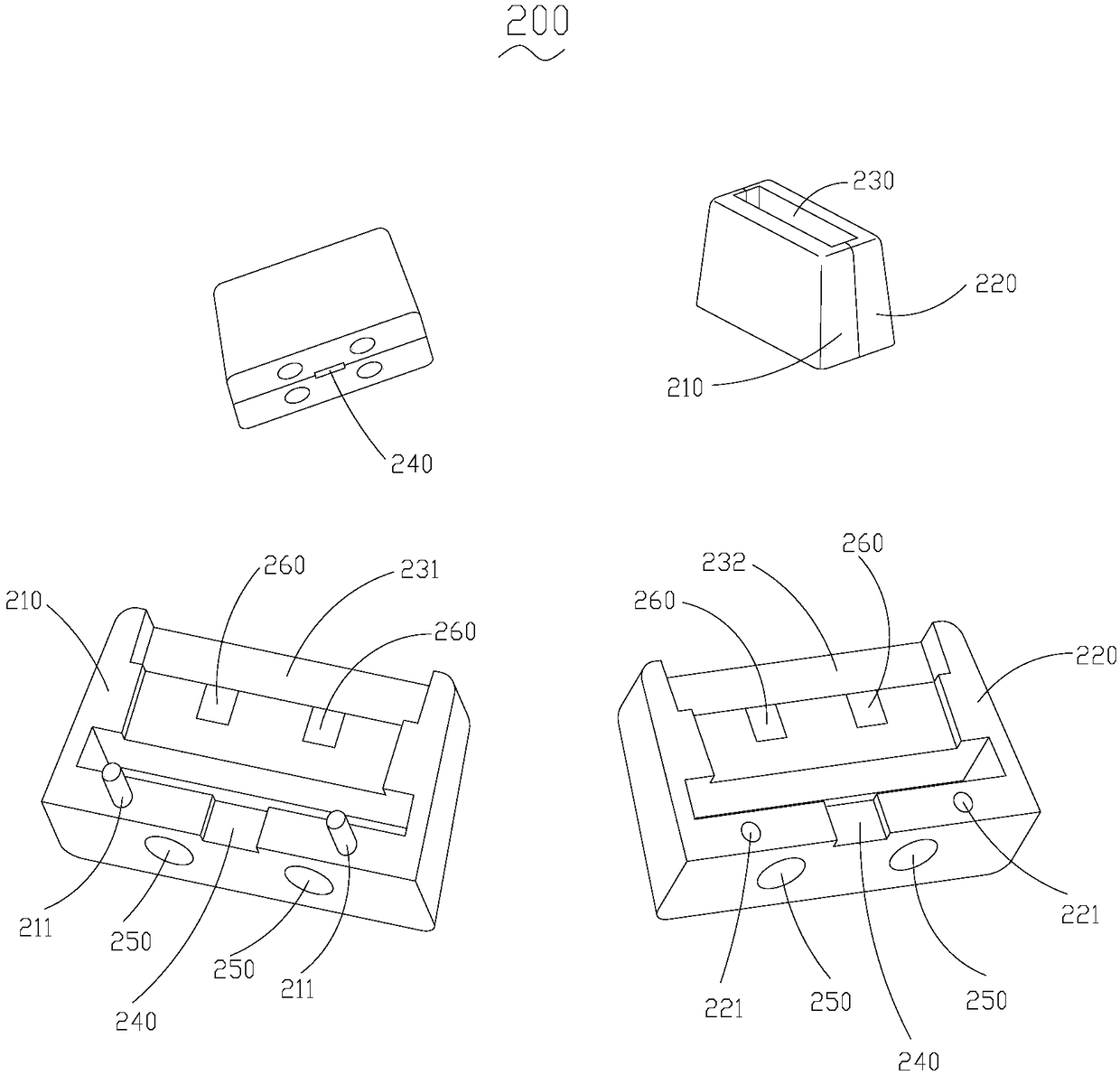

[0025] Such as figure 1 , figure 2 and image 3 In the tailings recycling device, one end of the main frame 100 is set on a cross-shaped sand-hanging piece 101, the middle part is set with a rectangular column-shaped clip 103, and the other end is set with a semi-arc-shaped lifting ear 102, and The height of the clamping member 103 in the shape of a rectangular parallelepiped column is twice the depth of the clamping position 230 on the blank 200 . The loose material 200 is made up of a loose material 1 210 and a loose material 2 220. The loose material 1 210 and the loose material 220 pass through the positioning rod 211 arranged on the loose material 210 and the positioning hole 221 arranged on the loose material 220. Cooperate with each other and fasten into a whole loose material 200; one end of the loose material 200 is provided with a card position 230 that cooperates with the clamp 103, and the clamp position 230 is a square groove opened on an end surface of the loo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com