Combined storage hopper easy to clean

A storage hopper and small bucket technology is applied in the field of easy-to-clean combined storage hoppers, which can solve the problems of inability to disassemble, low cleaning efficiency, and high labor intensity, and achieve the effects of rapid positioning, strength assurance, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

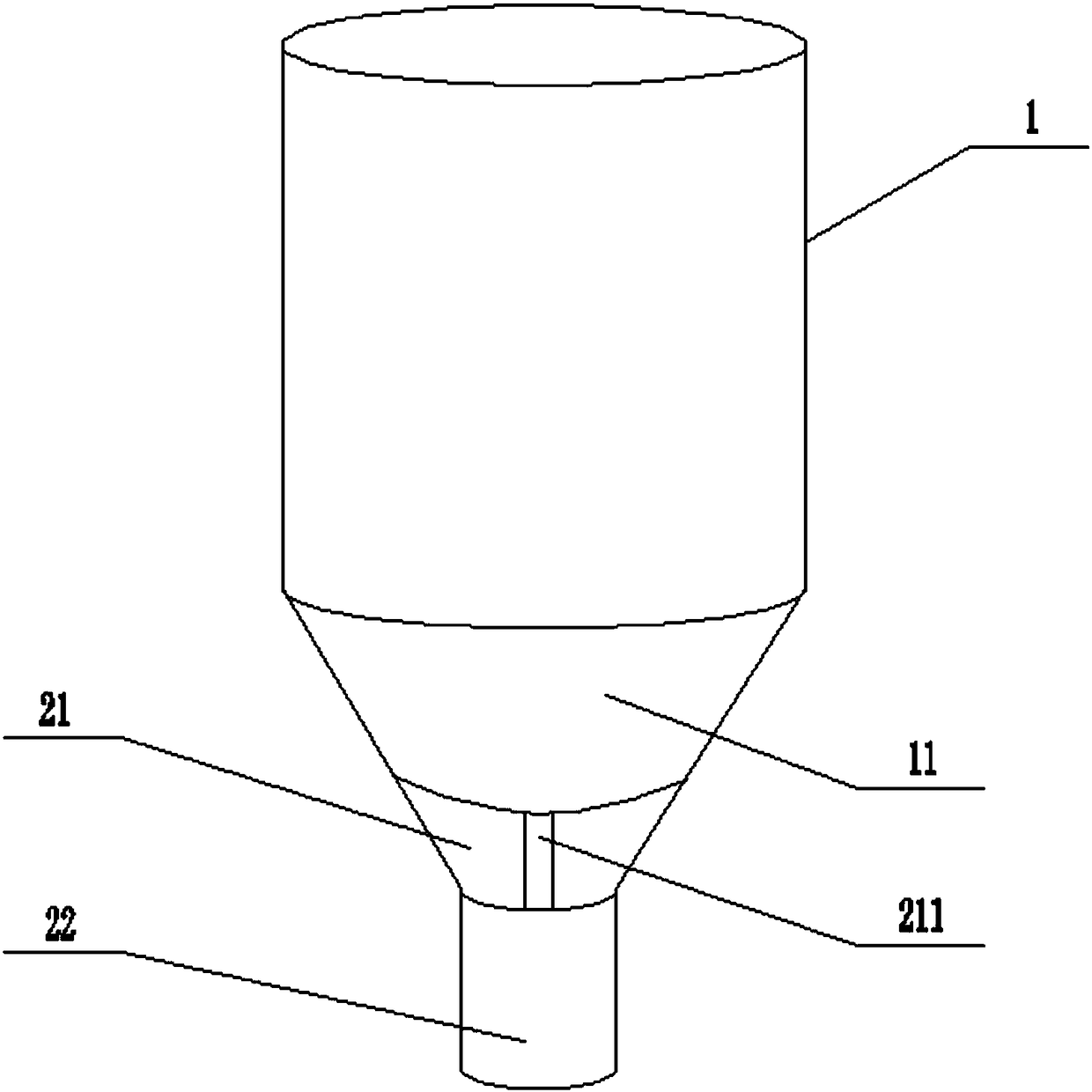

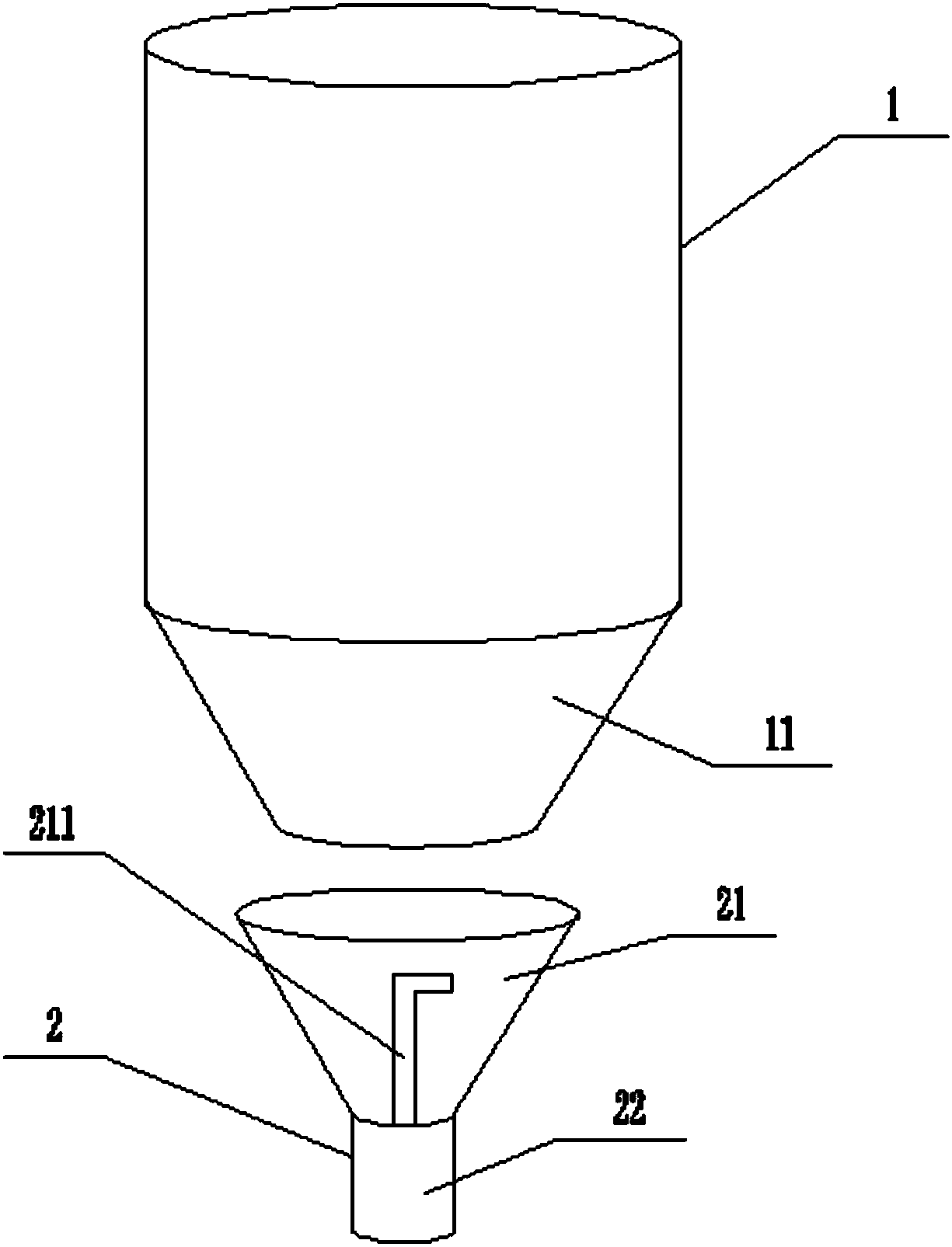

[0044] Such as figure 1 and figure 2As shown, the discharge end of the main body storage hopper 1 is provided with a boss structure 11, the boss structure 11 is in the shape of a circular platform with a large upper end and a small lower end, the inner wall surface of the boss structure 11 is a conical surface, and the outer wall shape of the feeding part 21 Cooperate with the boss structure 11, and restrict the small discharge hopper 2 from falling away from the main storage hopper 1 through the boss structure 11. Wherein, the outer wall surface of the feeding part 21 is provided with a limiting groove 211, and the inner wall surface of the discharge end of the main body storage hopper 1 is provided with a limiting column that cooperates with the limiting groove 211. The limiting groove 211 is an inverted L-shaped structure. The feed end of the hopper 1 is provided with a positioning mark corresponding to the limit column. When assembling, the limit groove 211 is aligned w...

Embodiment 2

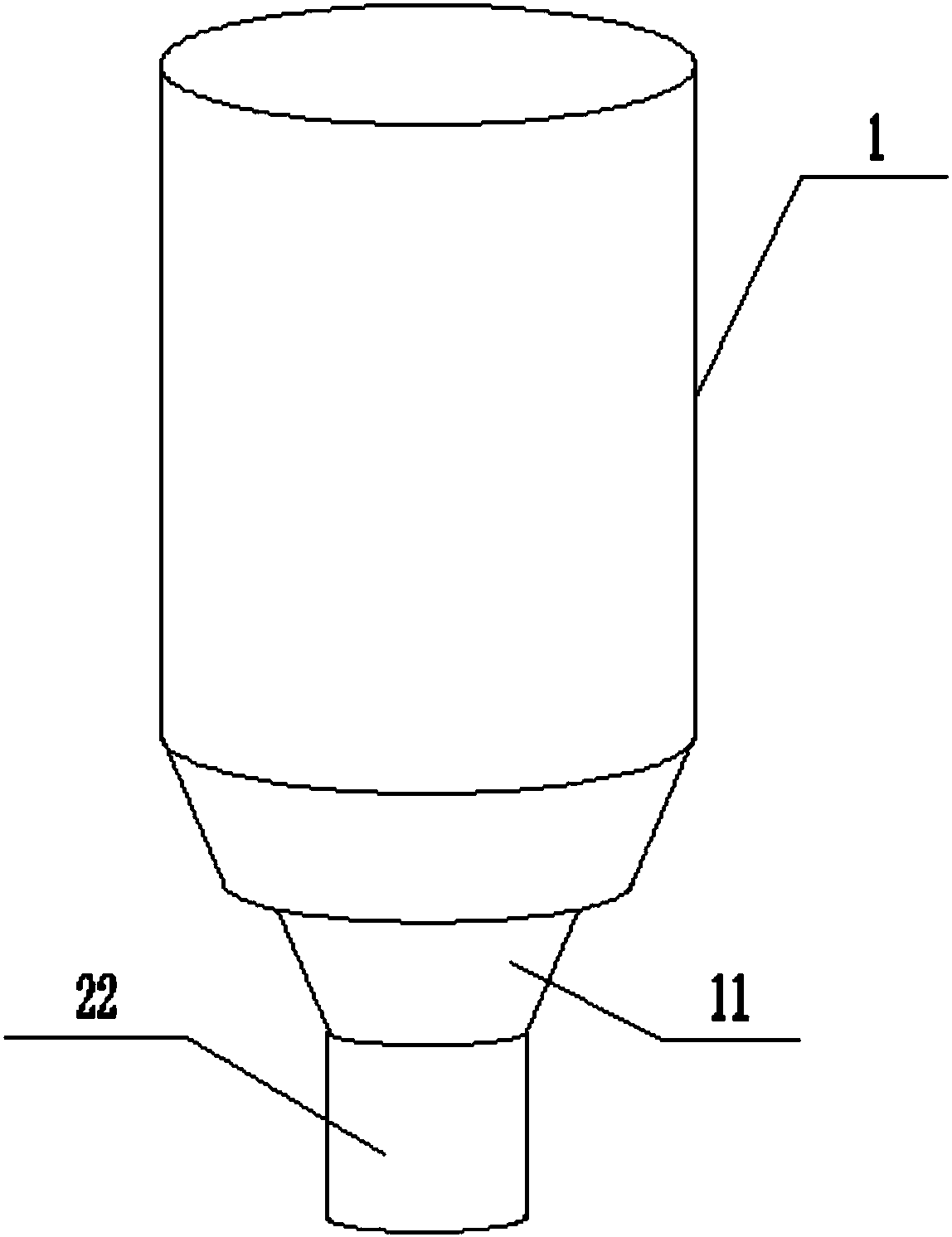

[0046] Such as image 3 and Figure 4 As shown, the discharge end of the main body storage hopper 1 is provided with a boss structure 11, the boss structure 11 is in the shape of a circular platform with a large upper end and a small lower end, the inner wall surface of the boss structure 11 is a conical surface, and the outer wall shape of the feeding part 21 Cooperate with the boss structure 11, and restrict the small discharge hopper 2 from falling away from the main storage hopper 1 through the boss structure 11. The inside of the boss structure 11 is provided with a stepped hole, and the outer wall of the feeding part 21 is provided with a stepped surface that matches the stepped hole. The tapered surface, that is, the inner wall surface of the feeding part 21 is not provided with a step surface, so that the material can be conveyed smoothly, which is conducive to preventing the accumulation of material sedimentation, and the material cleaning operation on the inner wall...

Embodiment 3

[0049] Such as Figure 5 to Figure 8 As shown, the main body storage hopper 1 is a cylindrical structure, the discharge end of the main body storage hopper 1 is provided with an inward flanging structure 12, and the upper end of the discharge part 21 is provided with an outward flanging structure. 212 , the inner flange structure 12 is bonded to the outer flange structure 212 , and restricts the small discharge hopper 2 from falling away from the main storage hopper 1 . The lower surface of the outer flange structure 212 is provided with a raised portion 213, and the upper surface of the inner flanged structure 12 is provided with an inner concave portion 121 that cooperates with the raised portion 213, and the raised portion 213 falls into the inner concave portion 121 to limit the discharge. Bucket 2 rotates. During assembly, the small discharge hopper 2 is extended from the feed end of the main body storage hopper 1, and the end of the discharge part 22 away from the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com