Garbage treatment fermentation device

A technology for fermenting equipment and waste disposal, which is applied in the field of waste disposal and fermentation equipment, and can solve the problems of bending resistance, low torsional strength, overall dehydration device stuck, and potential safety hazards, and achieve low cost, low physical property requirements, and dehydration good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

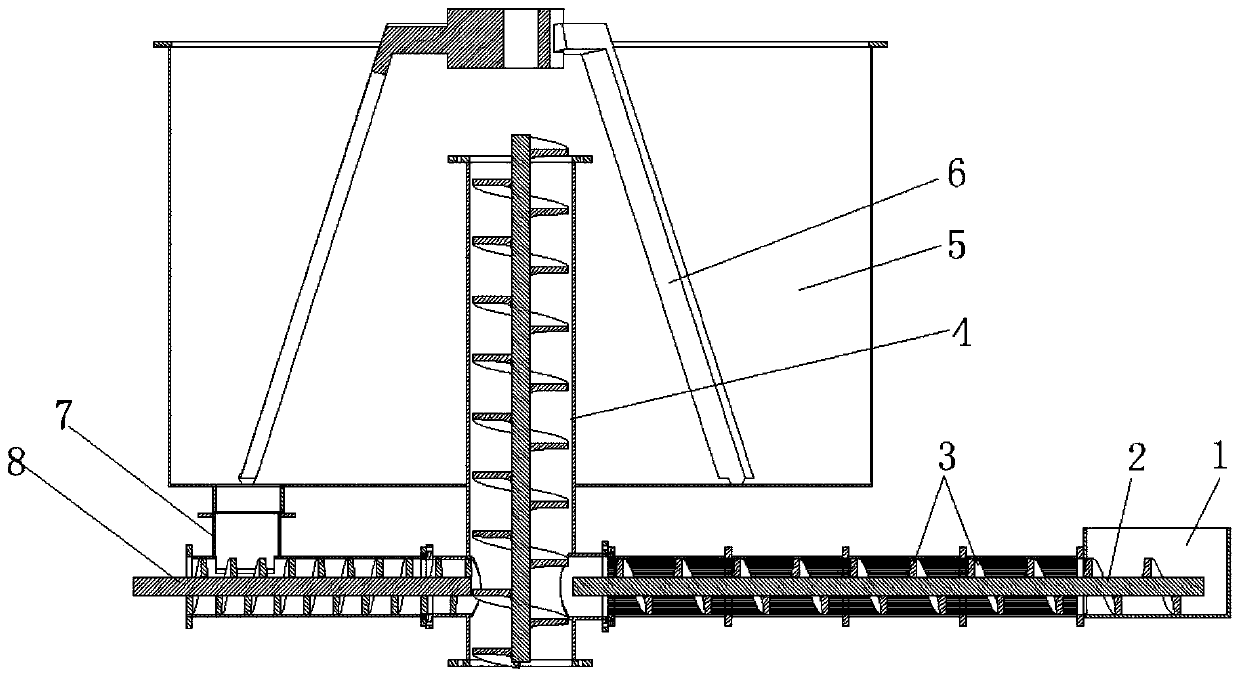

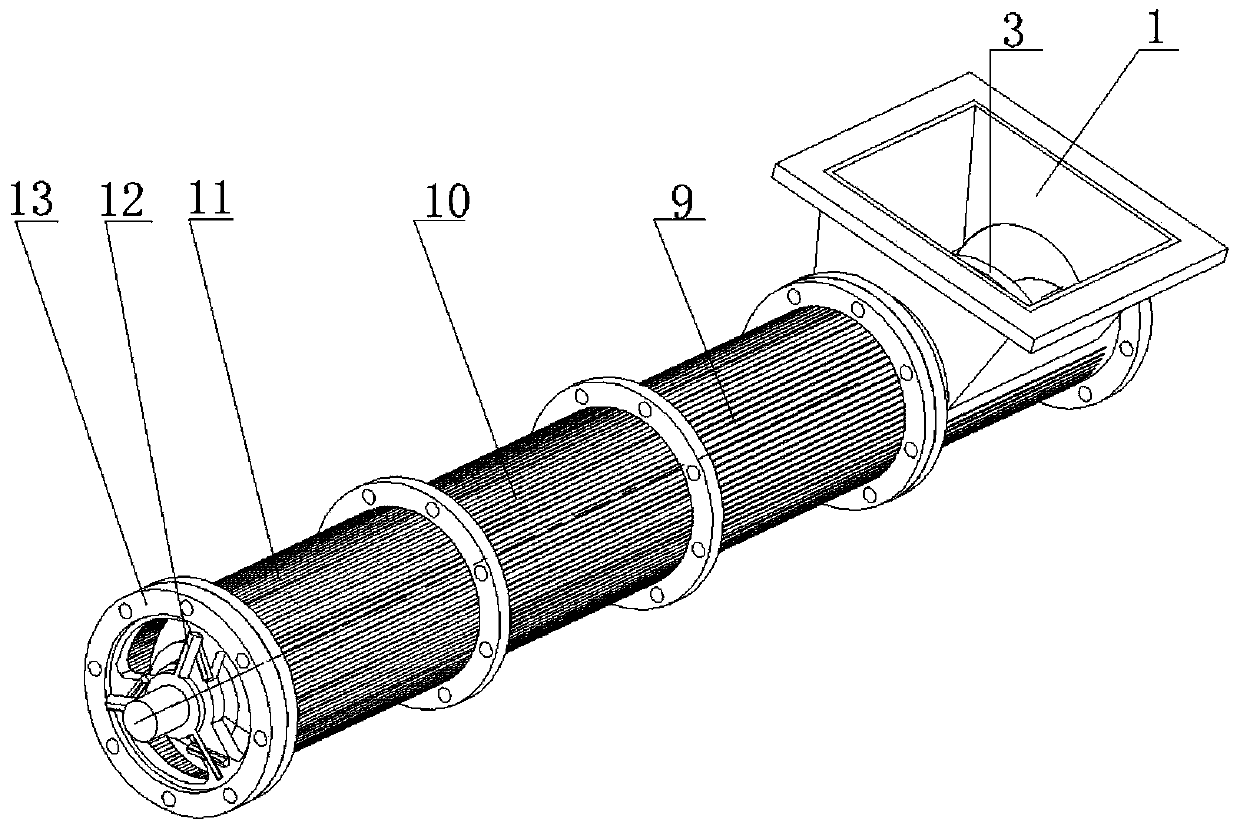

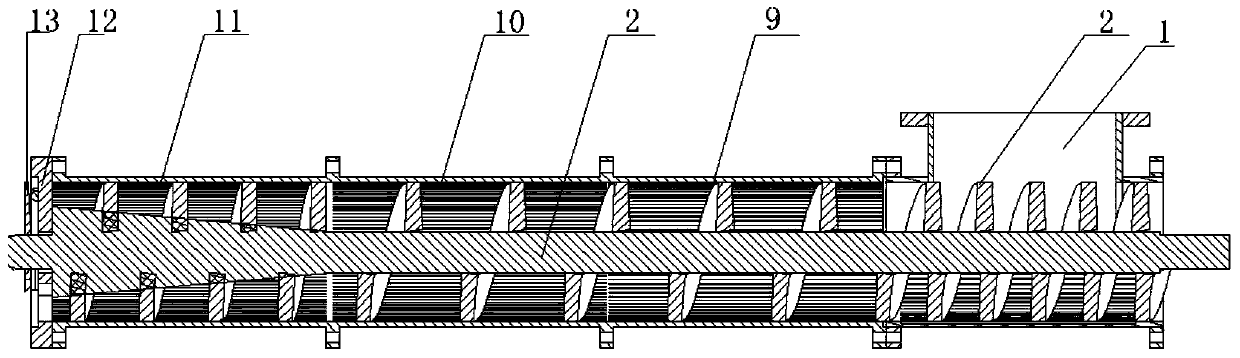

[0028] Such as Figure 1-Figure 6 A garbage treatment fermentation device shown includes a dehydration feeding device, a vertical feeding device 4, a circulating stirring device 6, a fermentation bin 5 and a circulating discharging device 8, the vertical feeding device includes a feeding cylinder 20, and the feeding The upper end of the cylinder is inserted into the fermentation chamber, and the center of the feeding cylinder is provided with a transmission shaft 19 that runs through the cylinder. The transmission shaft is provided with auger blades 21 from bottom to top, and the lower side of the feeding cylinder is A feed inlet is provided, and the feed inlet is connected to the outlet of the dehydration feeding device. The circulation stirring device is arranged in the fermentation chamber and includes a central rotating shaft 15, and a plurality of stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com