Combined blowing dephosphorization method of converter

A dephosphorization and converter technology, which is used in the manufacture of converters and other directions, can solve the problems of increasing the explosion venting of electrostatic precipitators, electric field venting, and insufficient dephosphorization effect, and achieves the promotion of dephosphorization reaction rate and increase of gas Stirring force, avoiding the effect of electrostatic precipitator and explosion venting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

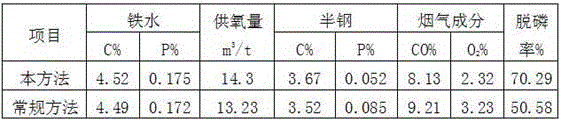

[0021] Embodiment 1: The method for reblowing and dephosphorization of the converter adopts the following specific processes.

[0022] Implemented in a 120-ton converter, 131.6 tons of molten iron was put into the furnace, 3.95 tons of scrap steel, and 4.56wt% of C and 0.176wt% of P were put into the furnace. Blowing under the gun, the oxygen flow rate in the early stage is 4.17Nm 3 / s, adjust the nitrogen flow rate to 1.11Nm after blowing for 1 minute 3 / s; after the slag is melted, adjust the oxygen flow rate to 5Nm 3 / s, the temperature rises significantly, adjust the nitrogen flow rate to 1.67Nm 3 / s; in the later stage of blowing, the oxygen flow rate is 6.39Nm 3 / s, nitrogen flow rate 1.39Nm 3 / s. During the blowing process, the total oxygen supply is 14.19m 3 / t steel, temperature controlled at 1320-1350°C, fan speed 1500rpm; semi-steel C 3.45wt%, P 0.038wt%, sampling slag alkalinity 1.96; CO 8.6wt%, O 2 3.56wt%, did not reach the mixing ratio.

Embodiment 2

[0023] Embodiment 2: The method for reblowing and dephosphorization of the converter adopts the following specific process.

[0024] It is implemented in a 120-ton converter, with 134 tons of molten iron and 4.3 tons of scrap steel, C 4.41% and P 0.162%. Blowing under the gun, the oxygen flow rate in the early stage is 4.44Nm 3 / s, adjust the nitrogen flow rate to 0.97Nm after blowing for 2 minutes 3 / s; slag melting, adjust oxygen flow to 5.28Nm 3 / s, the temperature rises obviously, adjust the nitrogen flow rate to 1.39Nm 3 / s; in the later stage of blowing, the oxygen flow rate is 6.11 Nm 3 / s, nitrogen flow rate 1.94 Nm 3 / s. During the blowing process, the total oxygen supply is 12.8m 3 / t steel, temperature controlled at 1320-1350°C, fan speed 1600rpm; semi-steel C 3.39%, P 0.041%, sampling slag alkalinity 2.1; CO content in flue gas 9.1%, O 2 The amount is 2.56%, and the gas mixing ratio has not been reached.

Embodiment 3

[0025] Embodiment 3: The method for reblowing and dephosphorization of the converter adopts the following specific processes.

[0026] It is implemented in a 120-ton converter, with 133 tons of molten iron and 6 tons of scrap steel, and the C 4.63% and P 0.181% into the furnace. Blowing under the gun, the oxygen flow rate in the early stage is 5Nm 3 / s, adjust the nitrogen flow rate to 1.11Nm after blowing for 3 minutes 3 / s; slag melting, adjust oxygen flow to 5.56Nm 3 / s, the temperature rises obviously, adjust the nitrogen flow to 1.67Nm 3 / s; in the later stage of blowing, the oxygen flow rate is 6.11Nm 3 / s, nitrogen flow rate 1.67Nm 3 / s. During the blowing process, the total oxygen supply is 12.1m 3 / t steel, the temperature is controlled at 1320-1350°C, the fan speed is 1600rpm; semi-steel C 3.53%, P 0.045%, sampling slag alkalinity 2.2; CO content in flue gas 7.23%, O 2 The amount is 2.89%, and the gas mixing ratio has not been reached.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com