Molten-iron desulphurization spraying gun

A technology of molten iron desulfurization and spray gun, which is applied in the field of molten iron desulfurization spray gun, which can solve the problems of slow desulfurization reaction speed, low desulfurization efficiency, insufficient stirring force, etc., and achieve the effect of meeting production needs, low sulfur return, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

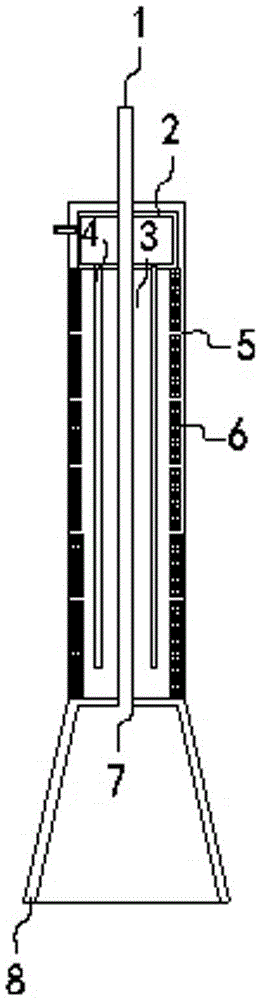

[0012] As shown in the figure, the molten iron desulfurization spray gun includes a spray gun body; the spray gun body includes a central nozzle 1, a gas storage chamber 2 and a gas distribution bin 3; the central nozzle 1 passes through the gas storage chamber 2 and is fixedly connected to it ; The gas distribution chamber 3 is provided with a gas injection pipe 4; the upper port of the gas injection pipe 4 communicates with the gas storage chamber 2, and its lower port communicates with the gas distribution chamber 3; on the side of the gas distribution chamber 3 The wall is provided with several gas injection ports 5; a vaporization chamber 8 is provided at the lower port of the central nozzle 1; the lower port of the central nozzle 1 communicates with the vaporization chamber 8; Refractory protective layer 6.

[0013] In the present invention, the lower end of the central nozzle 1 is fixedly provided with a refractory protective cover 7 . Compared with the traditional sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com