Melt desulfurization turbine agitator

A turbine type and agitator technology, applied in the field of molten iron pretreatment desulfurization equipment, can solve the problems of slow desulfurization reaction speed, single stirring force direction, insufficient stirring force, etc., and achieve the effect of improving desulfurization efficiency and meeting production needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The refractory protective layer of the present invention includes fused mullite, andalusite, white corundum, α-Al 2 o 3 Micropowder, 95# flake graphite, binder, steel fiber, kyanite, spinel fine powder and burnt gem; the mass ratio of the above raw materials is: 35:30:9:3:2:1:1:1 :1:1.

Embodiment 2

[0025] The refractory protective layer of the present invention includes fused mullite, andalusite, white corundum, α-Al 2 o 3 Micropowder, 95# flake graphite, binder, steel fiber, kyanite, spinel fine powder and burnt gem; the mass ratio of the above raw materials is: 41:40:12:6:3:5:3:2 :2:2.

Embodiment 3

[0027] The refractory protective layer of the present invention includes fused mullite, andalusite, white corundum, α-Al 2 o 3 Micropowder, 95# flake graphite, binder, steel fiber, kyanite, spinel fine powder and burnt gem; the mass ratio of the above raw materials is: 37:36:10:5:2.5:3:2:1.5 :1.5:1.5.

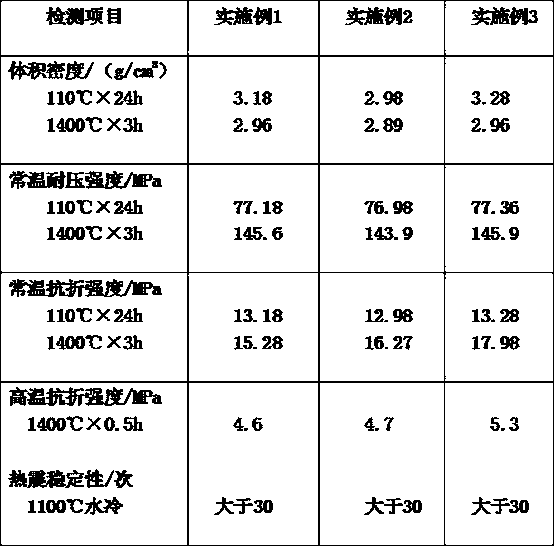

[0028] Physical and chemical performance data of the device of the present invention

[0029]

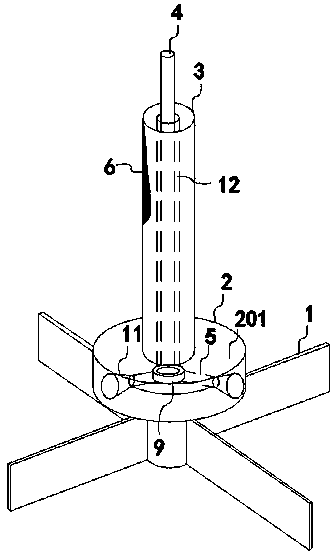

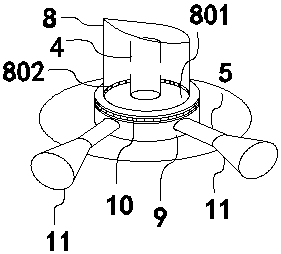

[0030] The cooling medium gas of the present invention is introduced into the annular cooling gas channel 801 through the cooling gas channel 12, and then the cooling gas is sent into the annular cooling gas through the air supply hole 802 at the bottom of the cooling jacket 8 and the exhaust grille 10 at the top of the distributor 9. In the cavity 201, after the cooling gas exchanges heat with the first special-shaped horn nozzle 11, it returns to the cooling gas channel 12 through the exhaust grill 10, the air supply hole 802 and the annular cooling gas channel 801 to complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com