Efficient molten iron desulfurization spray gun

A high-efficiency technology for hot metal desulfurization, applied in the field of high-efficiency hot metal desulfurization spray guns, can solve the problems of slow desulfurization reaction speed, single direction of stirring force, and low desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

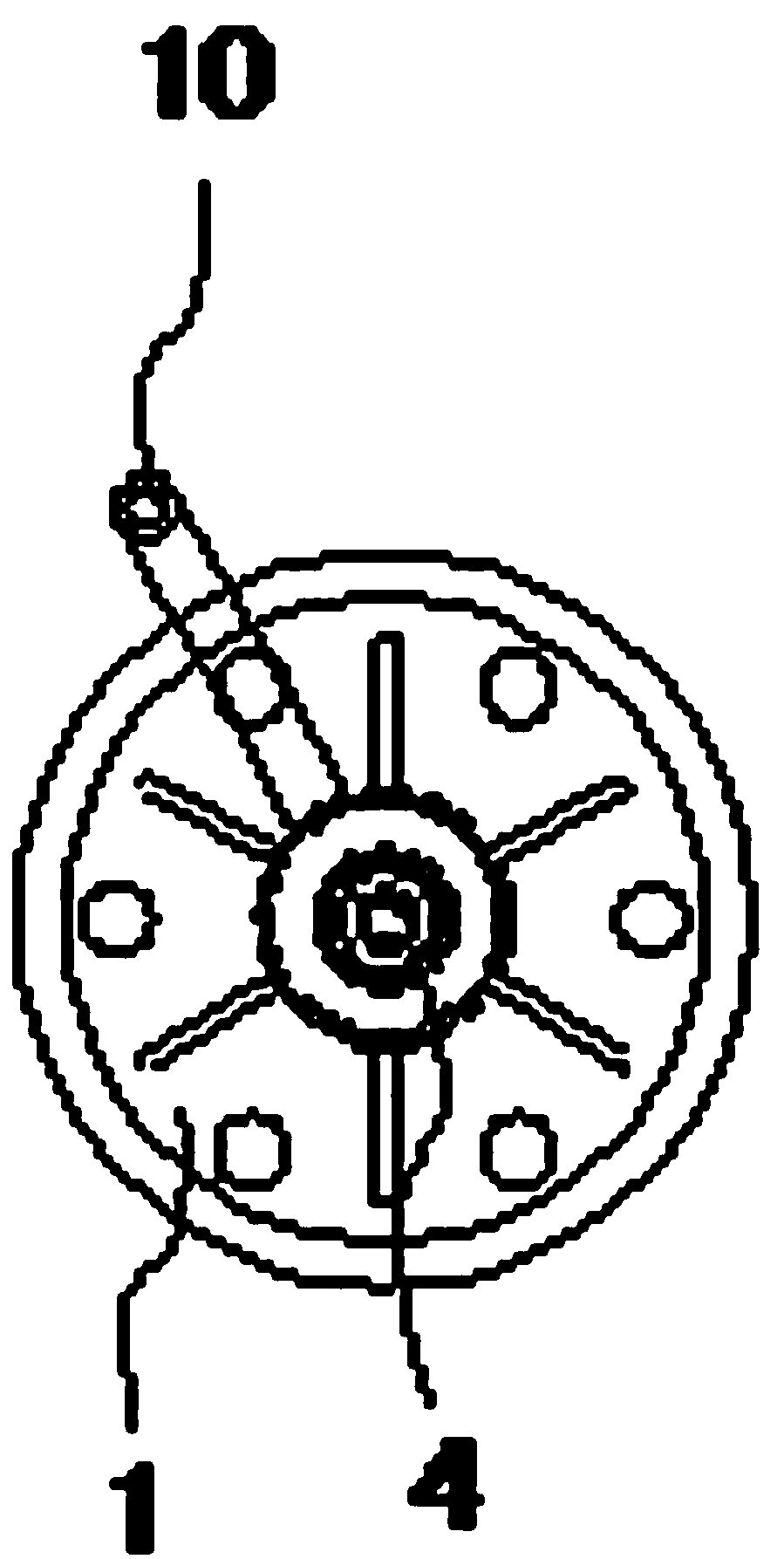

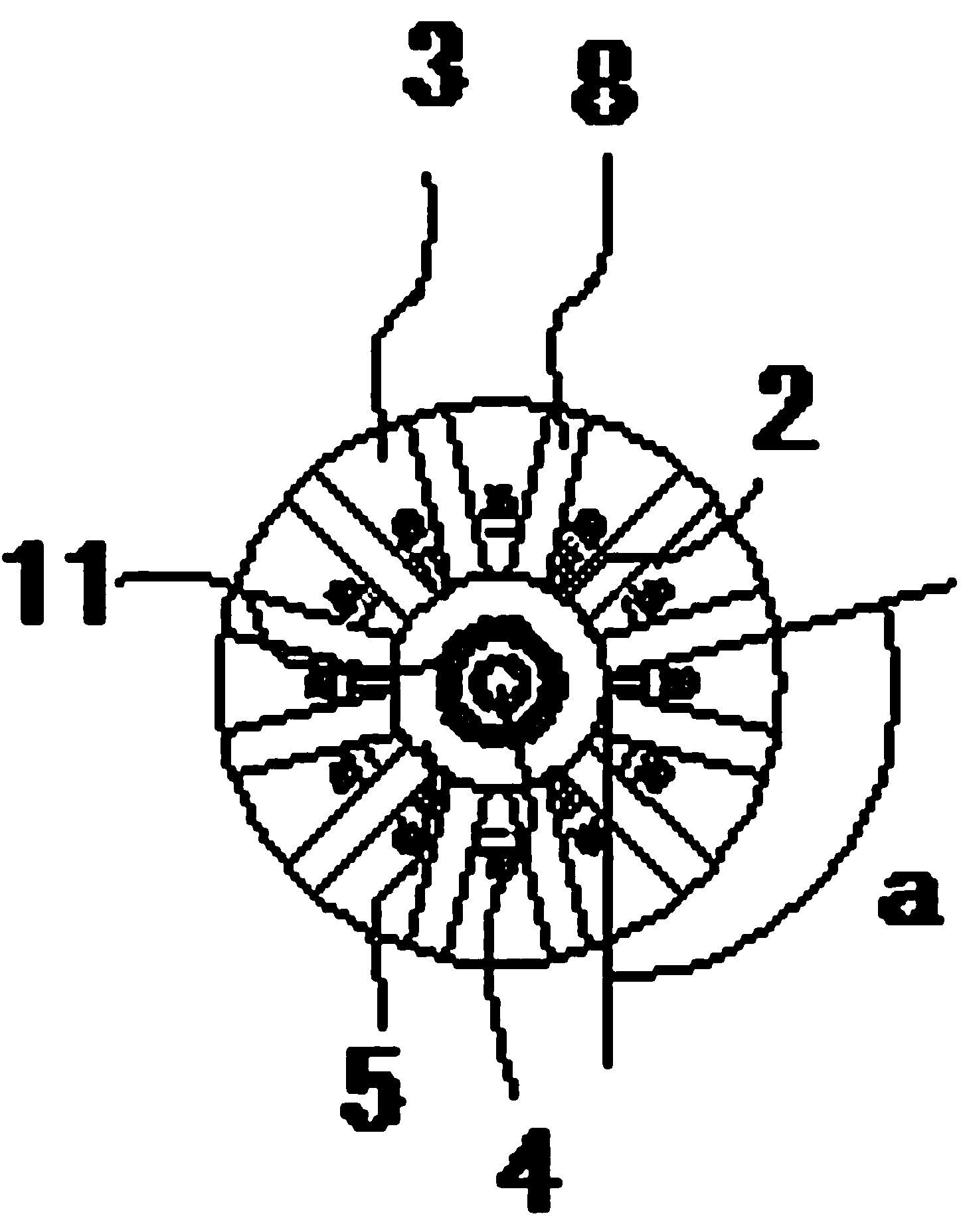

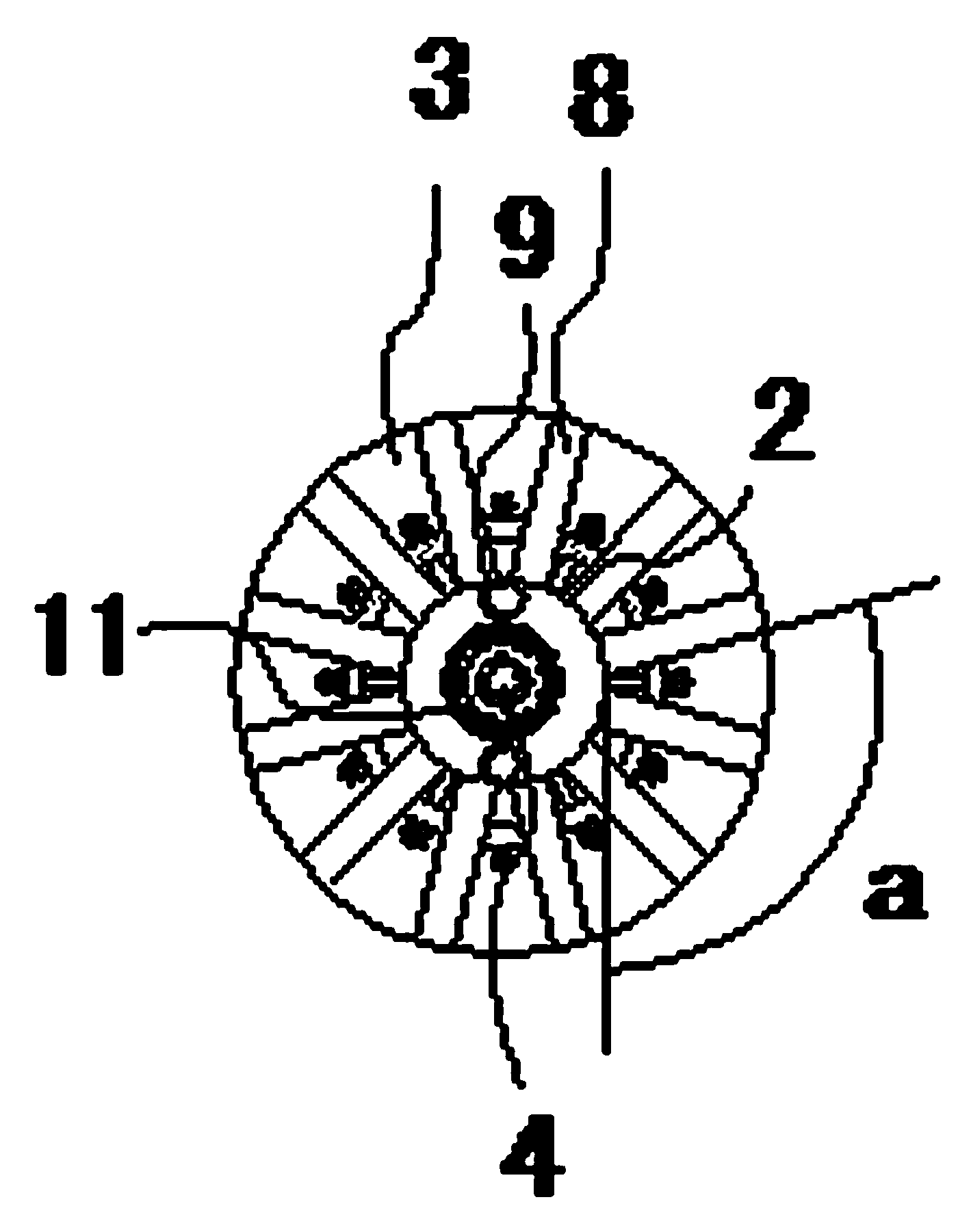

[0020] like figure 1 As shown, the high-efficiency molten iron desulfurization spray gun includes 1, an outer protective pipe 2, a central desulfurizing agent nozzle 4 and a refractory protective layer 3; the central desulfurizing agent nozzle 4 is fixedly placed in the outer protective pipe 2; the central The desulfurizing agent nozzle 4 and the outer protection pipe 2 are fixedly connected with the assembly flange 1; the injection medium input pipe 10 is fixed in the area of the assembly flange 1; the outer protection pipe 2 and the central desulfurization agent nozzle 4 There is a blowing medium gap 5 between them; the port of the blowing medium input pipe 10 communicates with the blowing medium gap 5; a blowing medium gas distribution mechanism 6 is fixed laterally in the tail area of the outer protective tube 2; The blowing medium distribution mechanism 6 includes an air supply cavity 7 and a blowing medium nozzle 8 ; the blowing medium gap 5 communicates with the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com