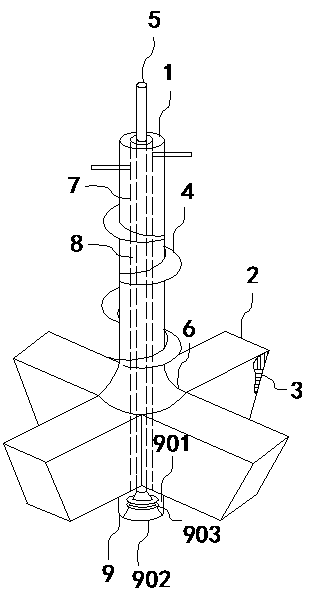

KR screw mixer

A stirrer and spiral technology, which is applied in the field of desulfurization devices in the metallurgical casting industry, can solve the problems such as the unsatisfactory desulfurization stirring effect of the stirring head, achieve ideal desulfurization stirring effects, reduce manufacturing costs, and improve desulfurization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

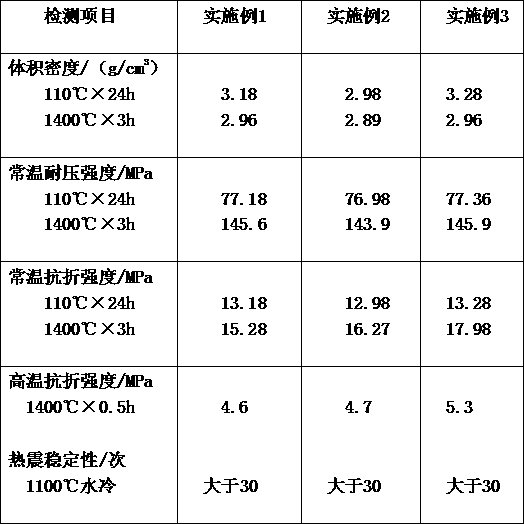

Embodiment 1

[0022] The refractory protective layer of the present invention includes fused mullite, andalusite, white corundum, α-Al 2 o 3 Micropowder, 95# flake graphite, binder, steel fiber, kyanite, spinel fine powder and burnt gem; the mass ratio of the above raw materials is: 35:30:9:3:2:1:1:1 :1:1.

Embodiment 2

[0024] The refractory protective layer of the present invention includes fused mullite, andalusite, white corundum, α-Al 2 o 3 Micropowder, 95# flake graphite, binder, steel fiber, kyanite, spinel fine powder and burnt gem; the mass ratio of the above raw materials is: 41:40:12:6:3:5:3:2 :2:2.

Embodiment 3

[0026] The refractory protective layer of the present invention includes fused mullite, andalusite, white corundum, α-Al 2 o 3 Micropowder, 95# flake graphite, binder, steel fiber, kyanite, spinel fine powder and burnt gem; the mass ratio of the above raw materials is: 37:36:10:5:2.5:3:2:1.5 :1.5:1.5.

[0027] Physical and chemical performance data of the device of the present invention

[0028]

[0029] The cooling medium gas of the present invention enters the cooling chamber 901 in the blowing mechanism 9 through the cooling medium channel 8 , and returns through the cooling medium channel 8 after completing heat exchange with the special-shaped horn blowing port 902 and taking away part of the heat. Through the above-mentioned structural design, the present invention can ensure that the nozzle of the desulfurization agent (passivation granular magnesium can be used) is blocked during the use of the device.

[0030] In the present invention, by adjusting the outlet st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com