Ultrasonic high-energy density bead mill for biological cell wall breaking

A high energy density, ultrasonic technology, applied in grain processing and other directions, can solve the problems of low wall breaking rate, cell material damage, low grinding intensity, etc., to achieve uniform energy distribution, high energy density, and improve the effect of breaking rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

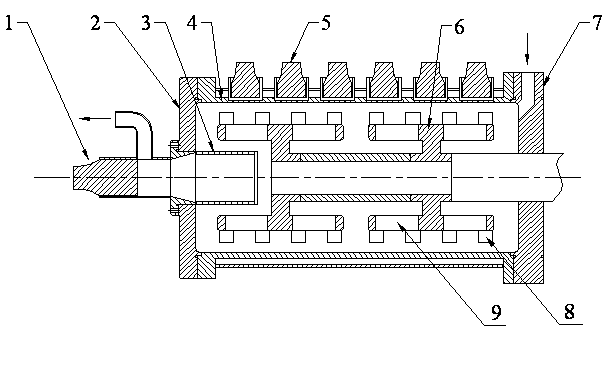

[0014] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0015] Such as figure 1 As shown, the ultrasonic high-energy bead mill for breaking biological cells of the present invention includes an ultrasonic emitting head 1 for breaking cells, a discharge cylinder cover 2, a bead separation net 3, a grinding cylinder 4, and a cleaning Ultrasonic emission head 5, lug pin turbine 6, feeding cylinder head 7.

[0016] Such as figure 1 As shown, the material enters the grinding cylinder from the feeding cylinder cover 7, and there are some evenly distributed convex pins on the outer circle of the convex pin turbine. The convex pins are arranged in a straight line in the axial direction, and a line with The vortex groove with a certain inclination, the convex pin of the rotating turbine acts as agitator, making the grinding beads rotate in a high-speed circular motion, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com