Continuous strengthened blender

A kind of mixer, powerful technology, applied in the field of coal powder gangue mixture, continuous mixing and conveying of cement sand and gravel slurry, which can solve the problems of easily polluted environment, large equipment space, high noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

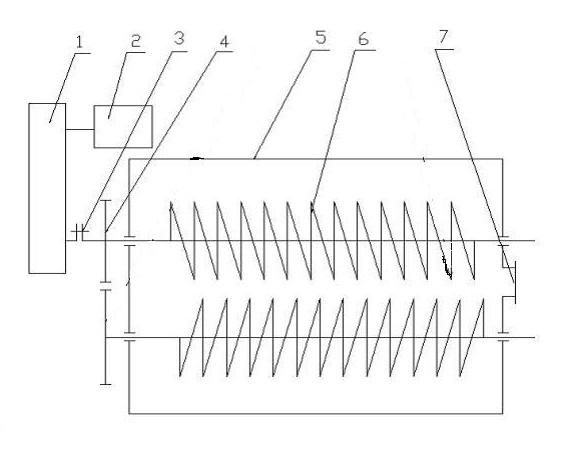

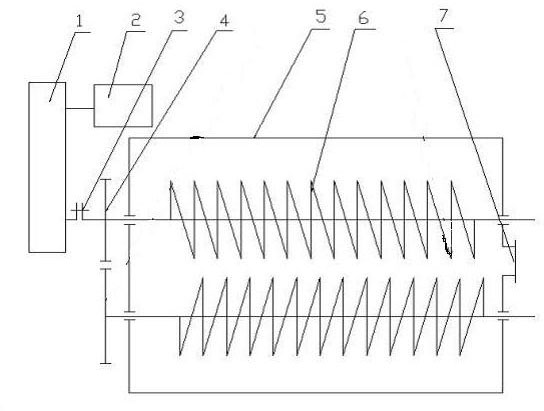

[0009] In the figure, the continuous strong mixer includes a reducer 1, a frequency conversion motor 2, a coupling 3, a transmission gear 4, a cylinder 5, a screw shaft 6, and a valve 7. The two screw shafts with the same parameters 6 is symmetrically installed in the cylinder body 5, on the shaft ends of the two screw shafts 6 extending out of the cylinder body 5, a corresponding transmission gear 4 is respectively installed, and the two transmission gears are meshed with each other, and the output shaft of the reducer 1 is connected through the connection. The shaft 3 is connected with one of the screw shafts 6 , the output shaft of the variable frequency motor 2 is connected with the input shaft of the reducer 1 , and the valve 7 is fixedly installed in the middle of the two screw shafts 6 on the bottom of the cylinder 5 . After the material is loaded into the cylinder body 5, the frequency conversion motor 2 drives the reducer 1 to rotate, and the reducer 1 drives on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com