Graphite-oxide composite solid lubricant for hot-rolled seamless steel pipe and preparation method thereof

A technology of solid lubricants and seamless steel pipes, applied in lubricating compositions, petroleum industry, etc., can solve the problems of alloy carburization performance, uneven distribution, and low wear life, and achieve good friction and wear performance and wear resistance The effect of long life and high load carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Take the following raw materials for use: 50g of graphite, 35g of boric acid, 6g of serpentine, 3g of potassium titanate whiskers, 5g of mica, 0.5g of sodium dodecylsulfonate, and 0.3g of simethicone;

[0019] (2) Evenly mix graphite, boric acid, serpentine, potassium titanate whiskers, and mica to obtain mixed powder;

[0020] (3) join mixed powder and sodium lauryl sulfonate and simethicone jointly in the water glass solution, the ratio of the mass fraction of added solid and the mass fraction of water glass is 1: 1;

[0021] (4) Stir at high speed (above 8000 rpm) for 2 hours, and the obtained uniform solution is the solid lubricant for graphite-oxide composite hot-rolled seamless steel pipe.

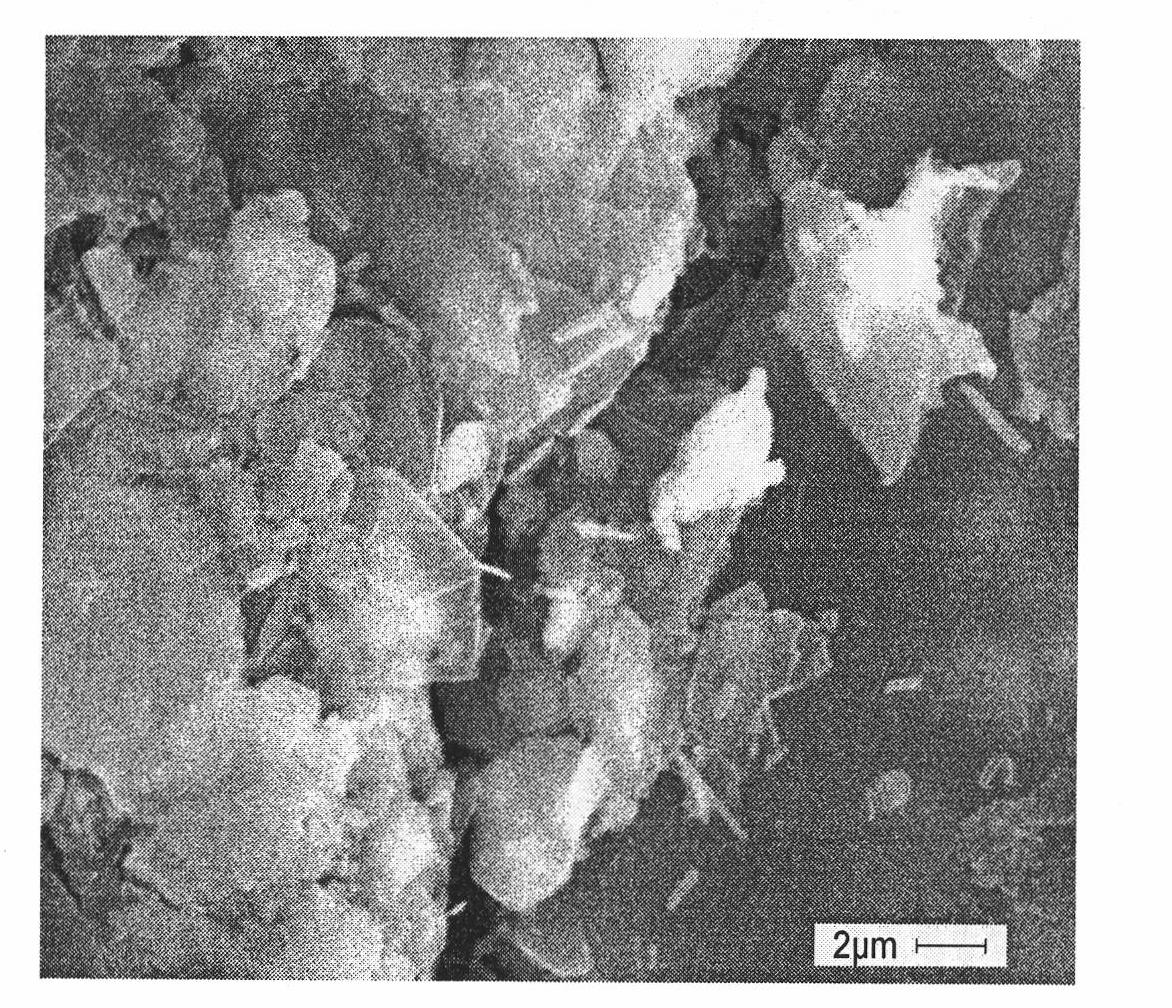

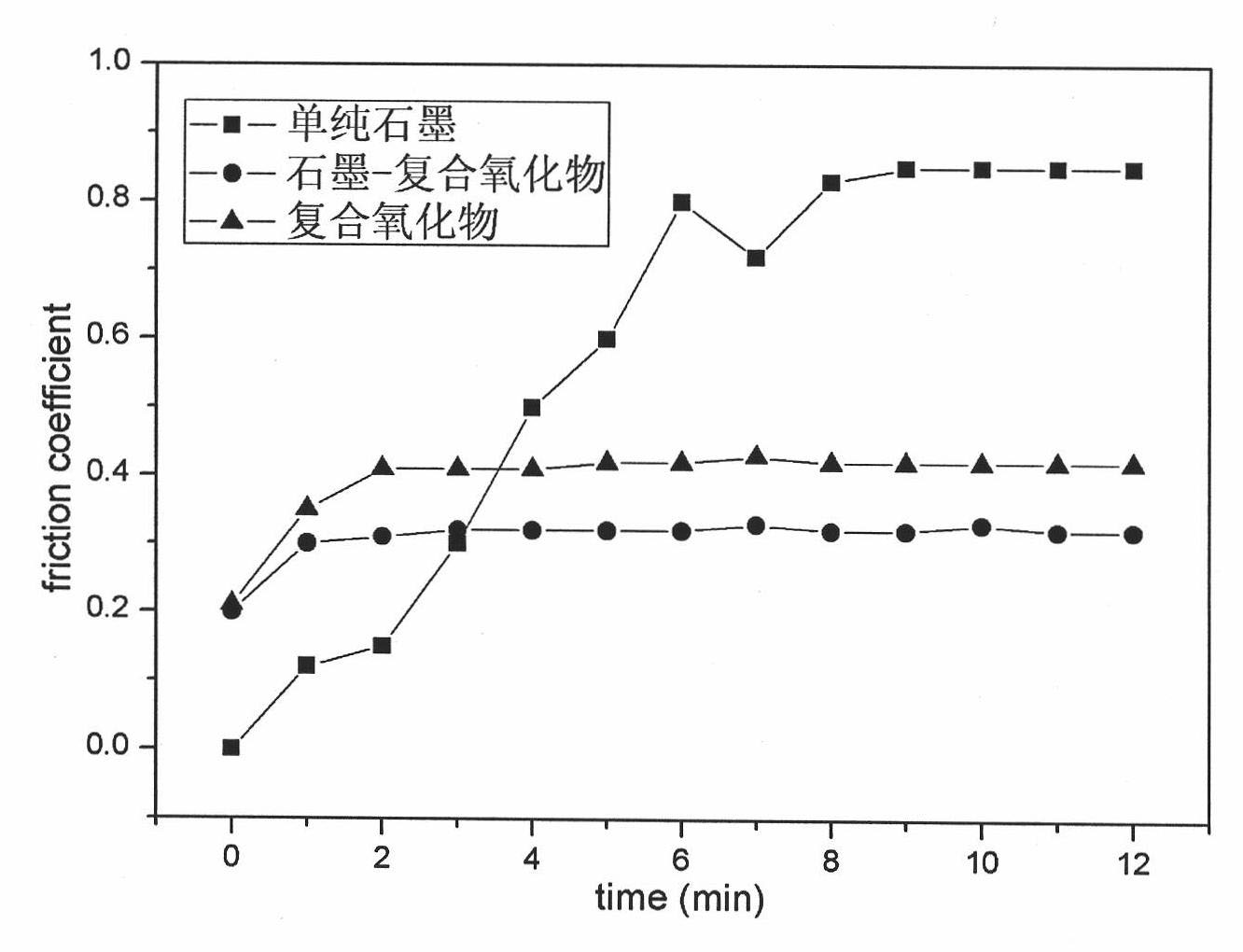

[0022] The product of this embodiment is scanned by electron microscope to observe its microscopic appearance, and the obtained SEM pictures are as follows: figure 1 As shown, it can be seen that the layered materials are graphite and MoS 2 , can play a role of solid lub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com