Eletromagnetic stirring supporting roller

A technology of electromagnetic stirring and supporting rolls, which is applied in the field of metallurgical continuous casting equipment, can solve the problems of reducing electromagnetic stirring force, slab bulging deformation, and affecting the quality of slab, so as to prolong service life, reduce deflection deformation, and reduce maintenance volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

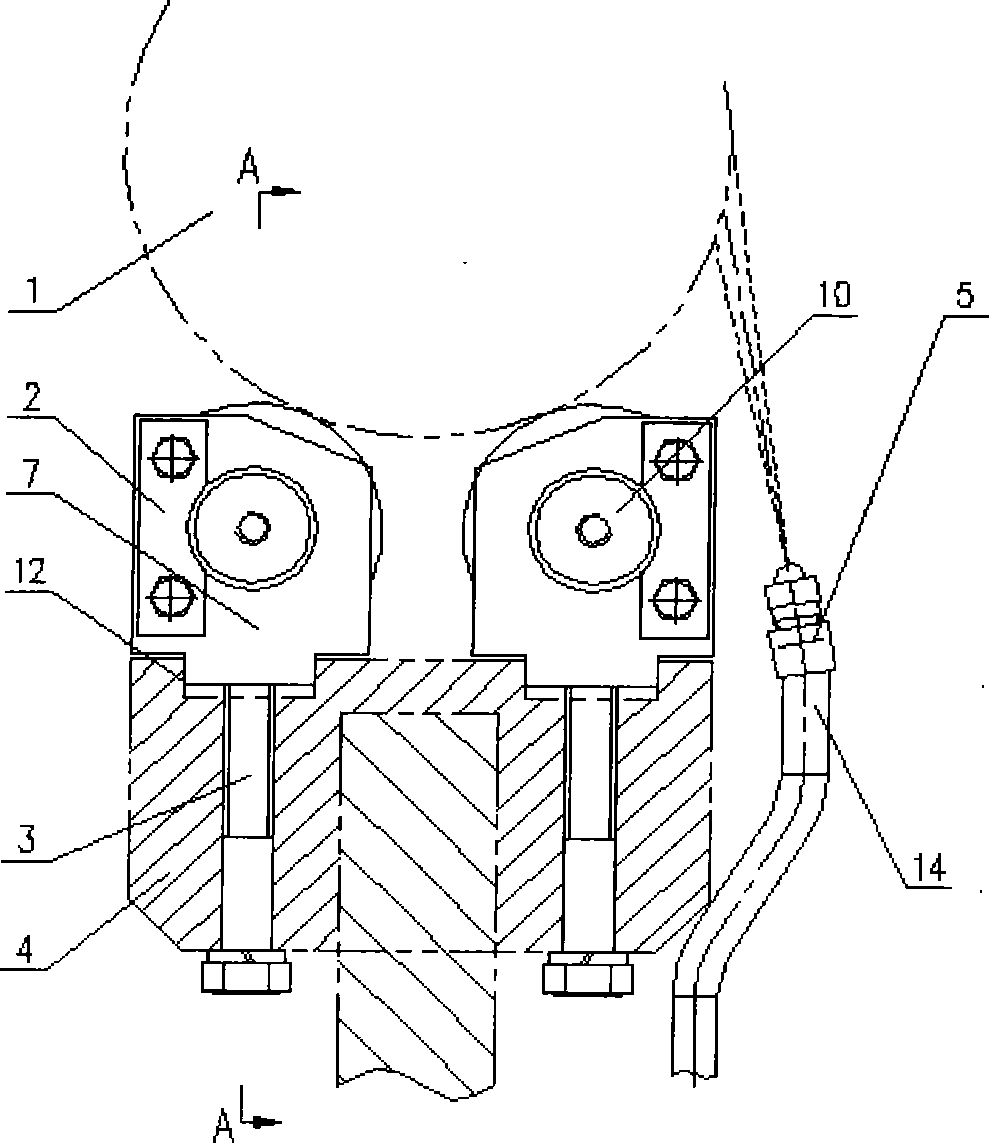

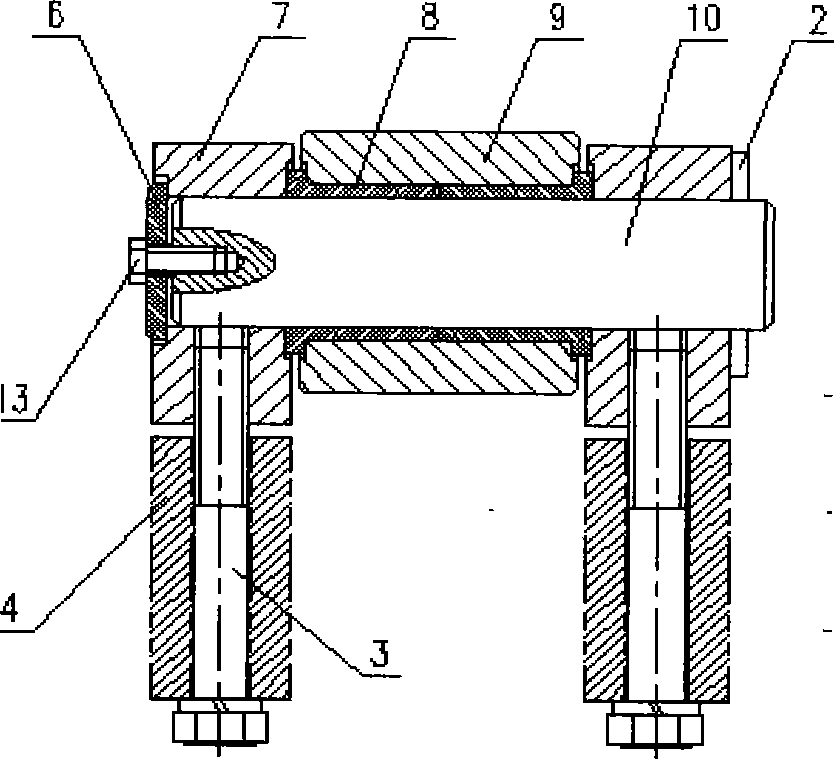

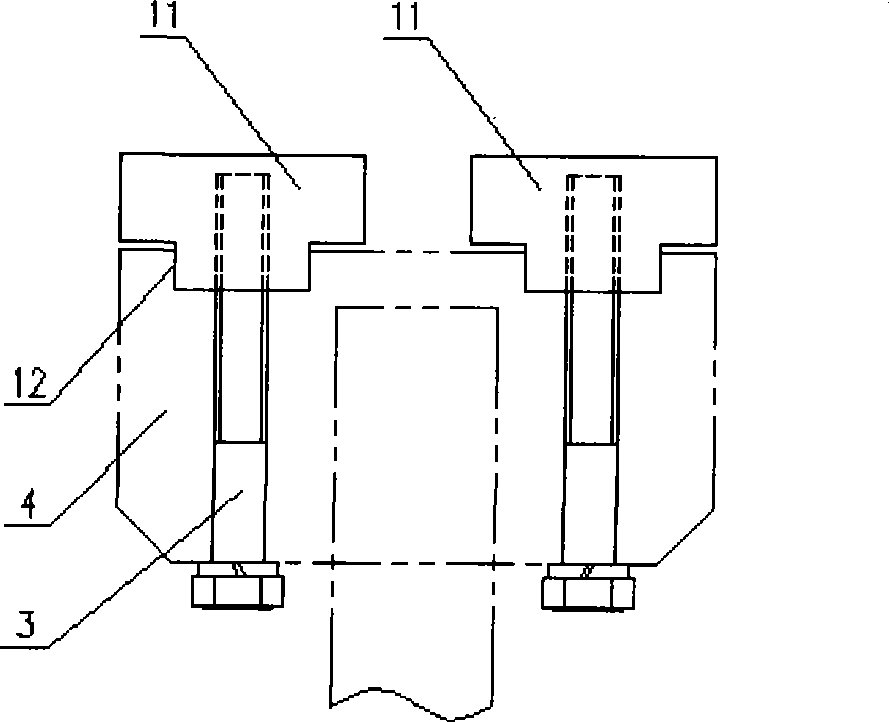

[0015] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] refer to figure 1 , figure 2 , an electromagnetic stirring support roller device, installed on the bottom of the stirring roller 1, including a support roller 9, the support roller 9 is installed in the notch 12 of the inner and outer arc frame 4 of the sector, and the notch 12 and the protruding part of the bearing seat 7 adopt Clearance fit, and fixed on the frame 4 with high-strength bolts 3, the support roller 9 penetrates the mandrel 10 in the middle and is assembled with the bearing seat 7, and one end of the mandrel 10 is connected with the bearing seat 7 through the end cover 6 and the bolt 13 to prevent The mandrel 10 moves relative to the bearing seat 7; the other end uses the shaft end baffle 2 to fix the mandrel 10 to prevent axial movement and rotation. A high-strength self-lubricating bearing 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com