Stirring and defoaming device

A stirring defoaming and stirring chamber technology, which is applied in the direction of liquid degassing, transportation and packaging, mixers, etc., can solve the problems of stable current value, narrow dynamic range, easy to produce errors, etc., to achieve set time suppression, easy High-speed rotation to achieve the effect of working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Hereinafter, specific embodiments to which the present invention is applied will be described in detail with reference to the drawings.

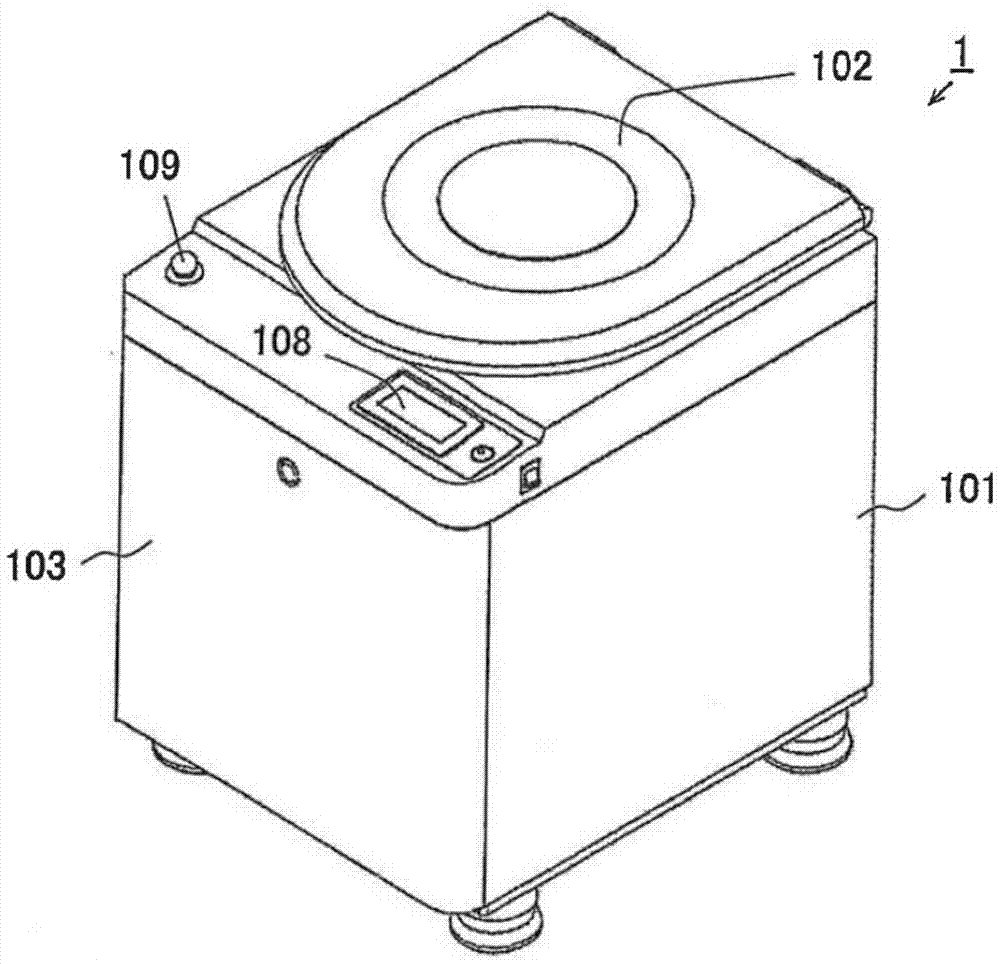

[0063] figure 1 It is a perspective view which shows the stirring degassing apparatus 1 to which the embodiment of this invention was applied. The stirring and degassing apparatus 1 of this embodiment has a cover 102 on the upper portion of a substantially cubic box 101 , and a control panel 108 and an emergency stop button 109 are arranged on the front side of the upper surface.

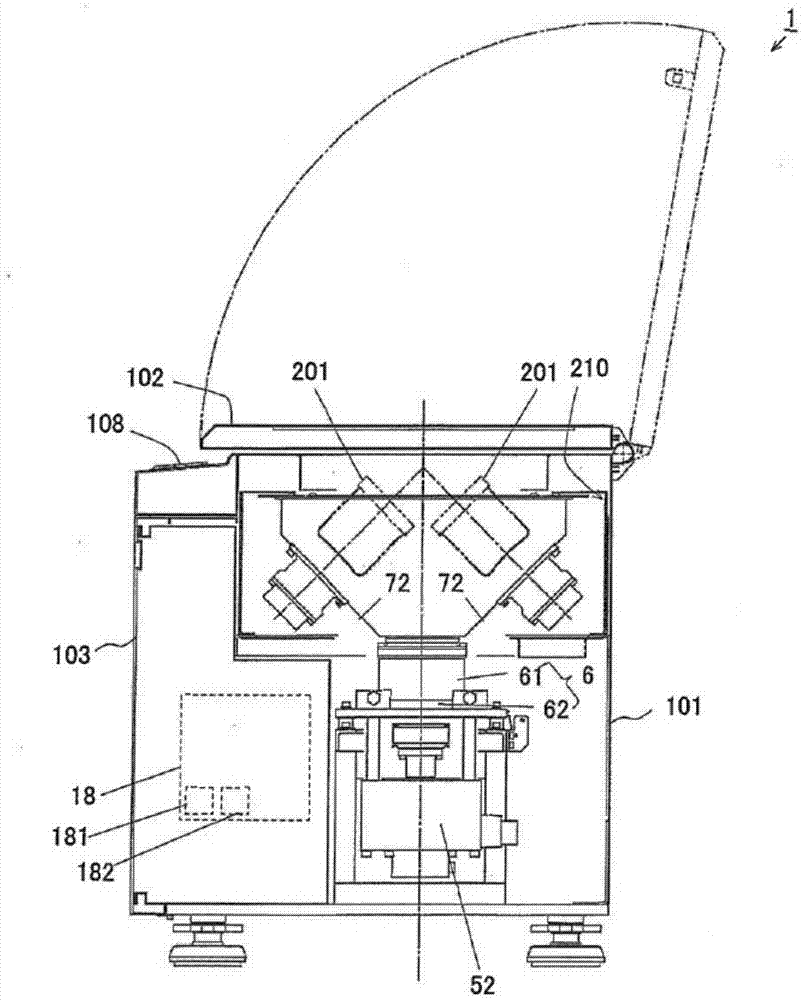

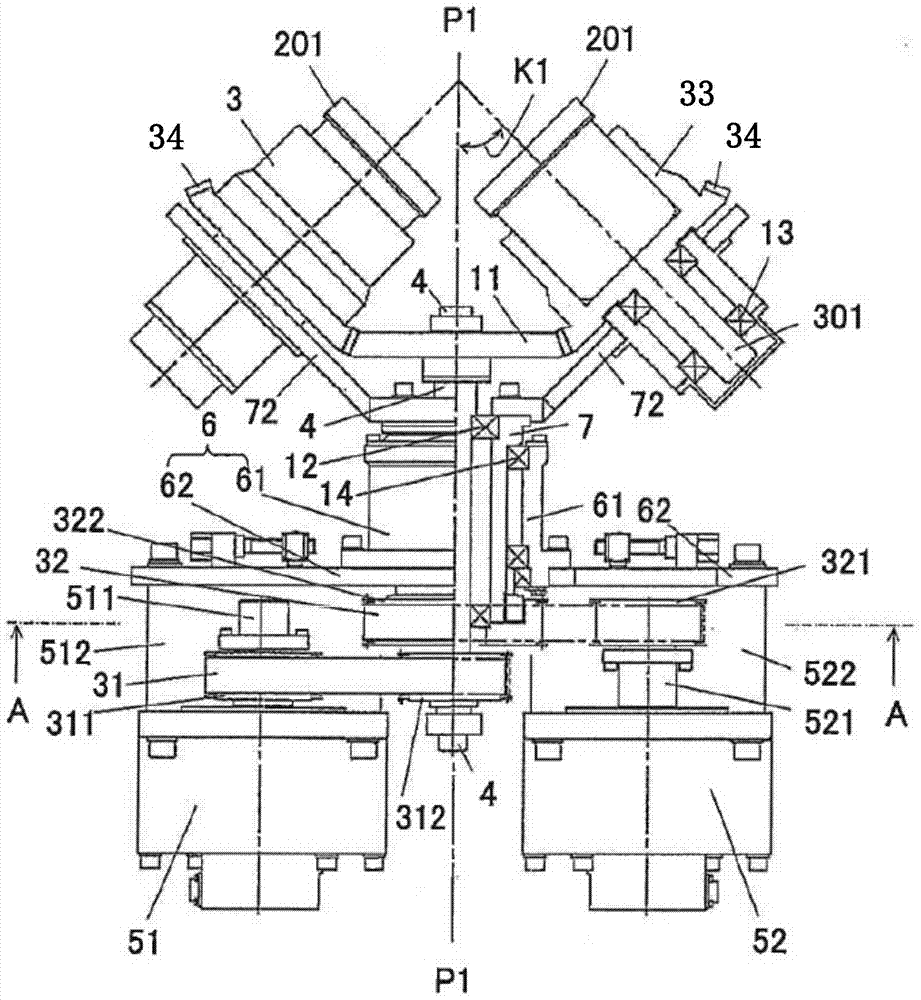

[0064] figure 2 It is a perspective view of main parts viewed from the side side of the stirring and degassing apparatus 1 of the present embodiment. In the stirring and degassing apparatus 1 of this embodiment, two raw material storage containers 201 are arranged in a rotationally symmetrical manner, and the shape above the base 6 serves as a stirring chamber 210 for storing the raw material storage containers 201 . Furthermore, a control circuit 18 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com