Method for utilizing bamboo forest waste to product edible mushrooms

A waste, edible fungus technology, applied in the fields of botanical equipment and methods, fertilizers made of biological waste, and applications, can solve problems such as environmental pollution, improve utilization, reduce production costs and waste disposal costs, The effect of eliminating the problem of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The invention discloses a method for producing edible fungi by using bamboo forest waste, which comprises the following steps:

[0044] Step 1, mother seed preparation

[0045] Step 1.1, mushroom selection

[0046] Among the first tide mushrooms, choose high-quality single mushrooms with typical appearance, moderate size, thick flesh, normal color, no spores, no pests and diseases, and 7 to 8 minutes of ripeness as seed mushrooms.

[0047] Mushrooms can also choose shiitake mushrooms, tea tree mushrooms and king oyster mushrooms.

[0048] Step 1.2, strain separation and purification

[0049] The tissue separation method was used for separation, and it was carried out on the ultra-clean workbench in the inoculation room.

[0050] (1) Surface sterilization: Cut off the base of the selected seed mushrooms, wipe the surface with 75% alcohol, rinse with sterile water, and dry the surface with sterile gauze or filter paper.

Embodiment 2

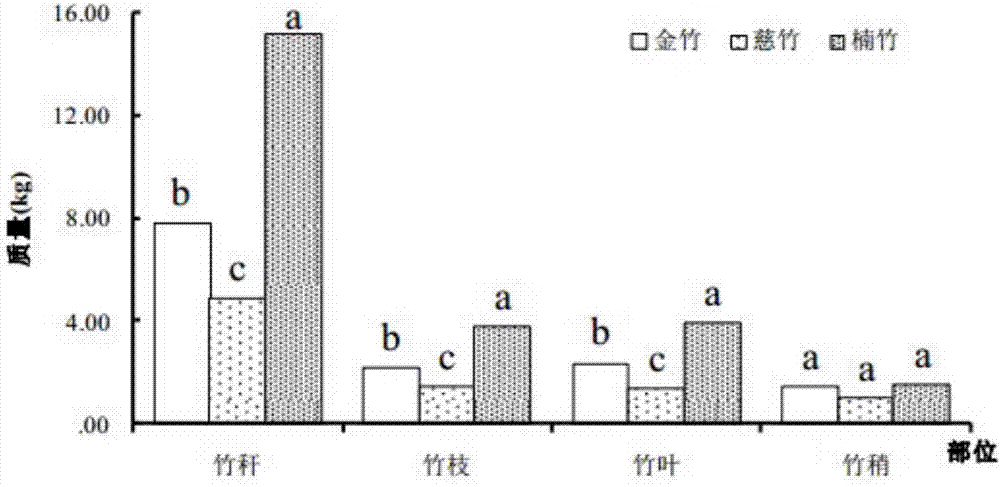

[0089] The culture medium formula is: 82% of bamboo chips, 16% of bran, and 2% of lime; wherein, the bamboo chips are selected from Phyllostachys osmanthus, Cizhu and golden bamboo respectively; the rest are the same as in Example 1.

Embodiment 3

[0091] The formula of cultivar medium is: 98% of bamboo chips, 0% of bran, and 2% of lime; wherein, the bamboo chips are respectively selected from Phyllostachys edulis, Cizhu, and Golden Bamboo; the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com