Treating and recycling method of tail gas generating in sulfonated naphthaldehyde water reducing agent production and special equipment

A sulfonated naphthalene formaldehyde and tail gas treatment technology, applied in chemical instruments and methods, separation methods, vapor condensation, etc., can solve the problems of secondary pollution, inability to discharge, environmental pollution, etc., and achieve high recycling rate and thorough treatment. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

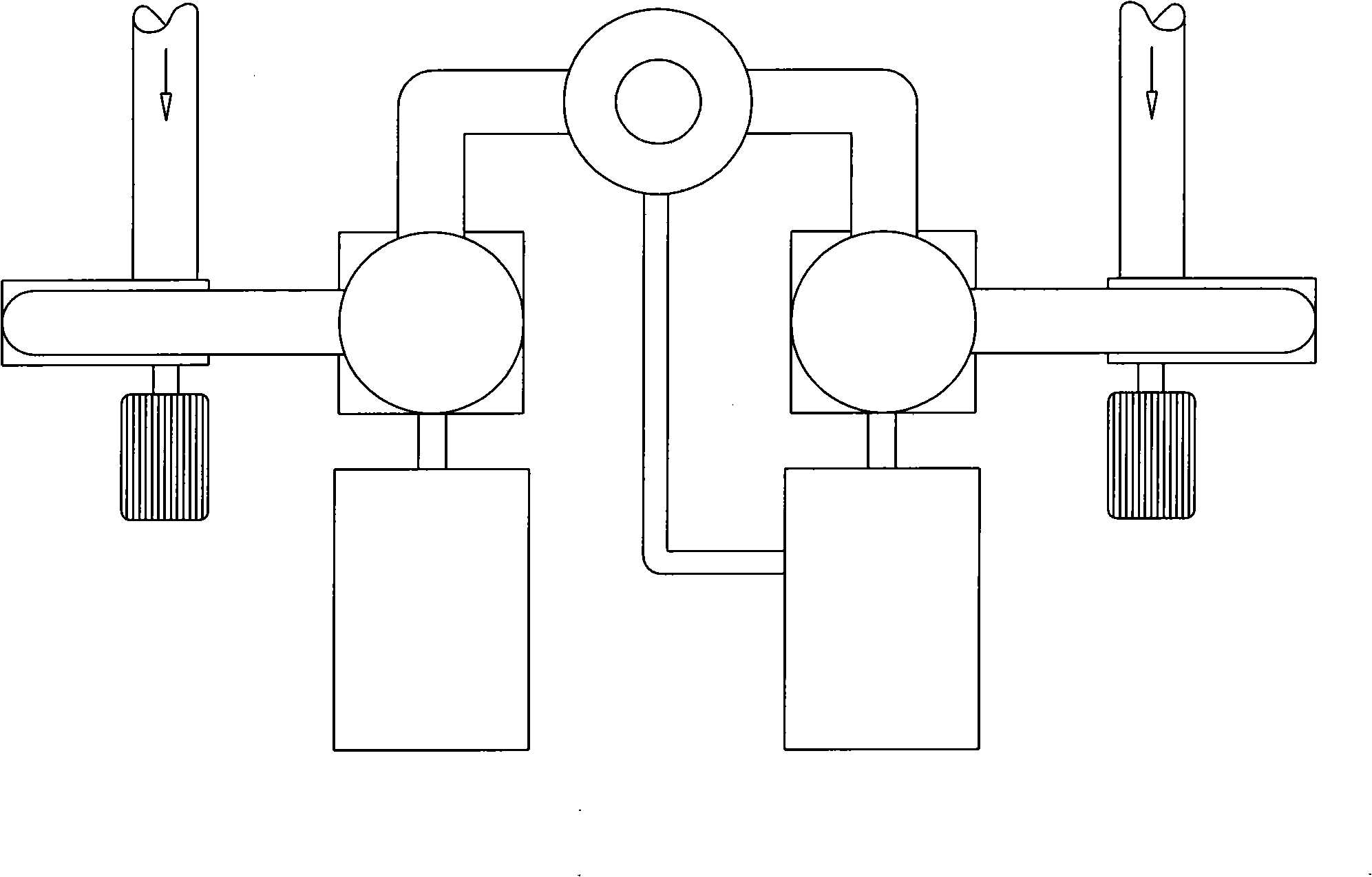

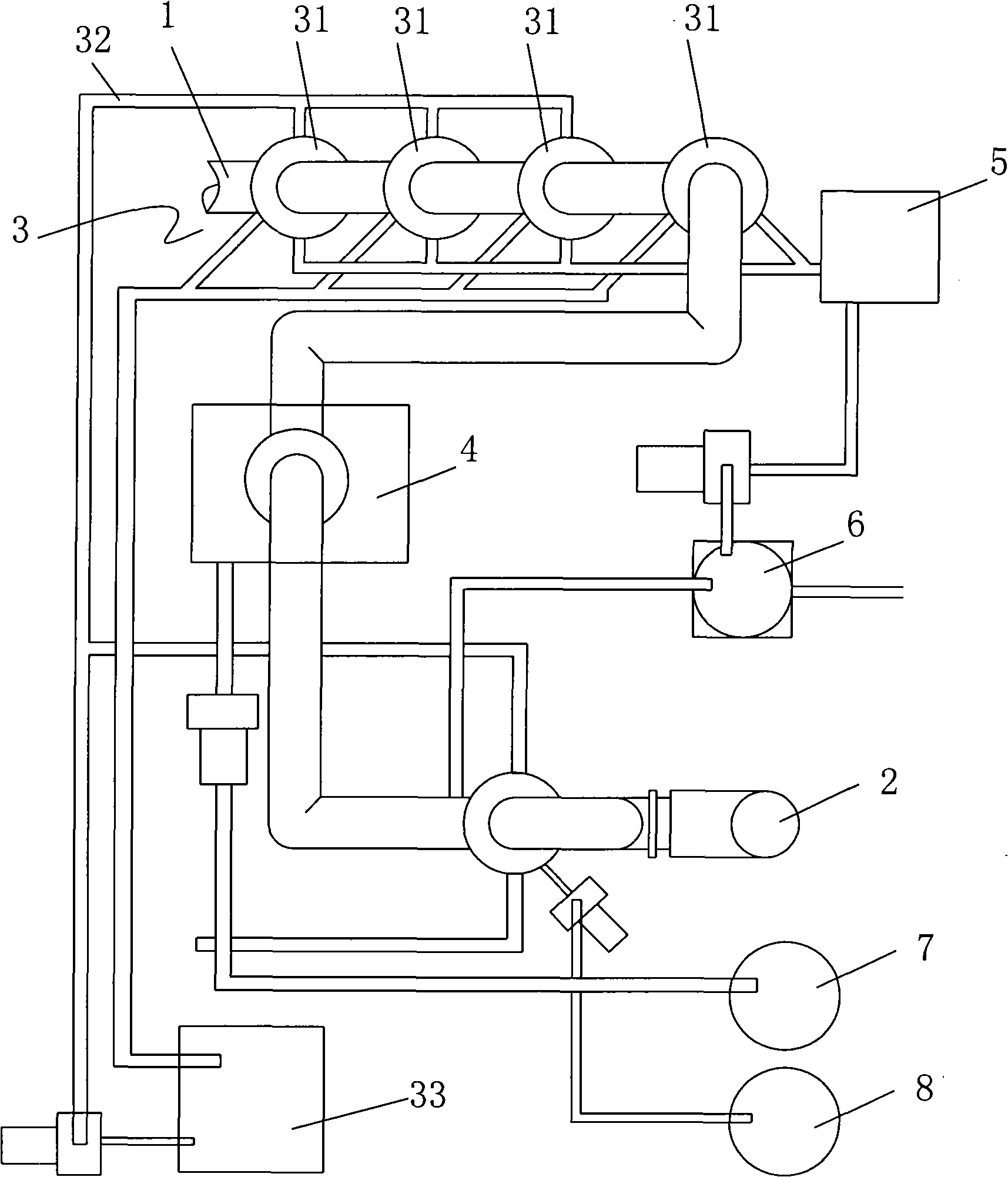

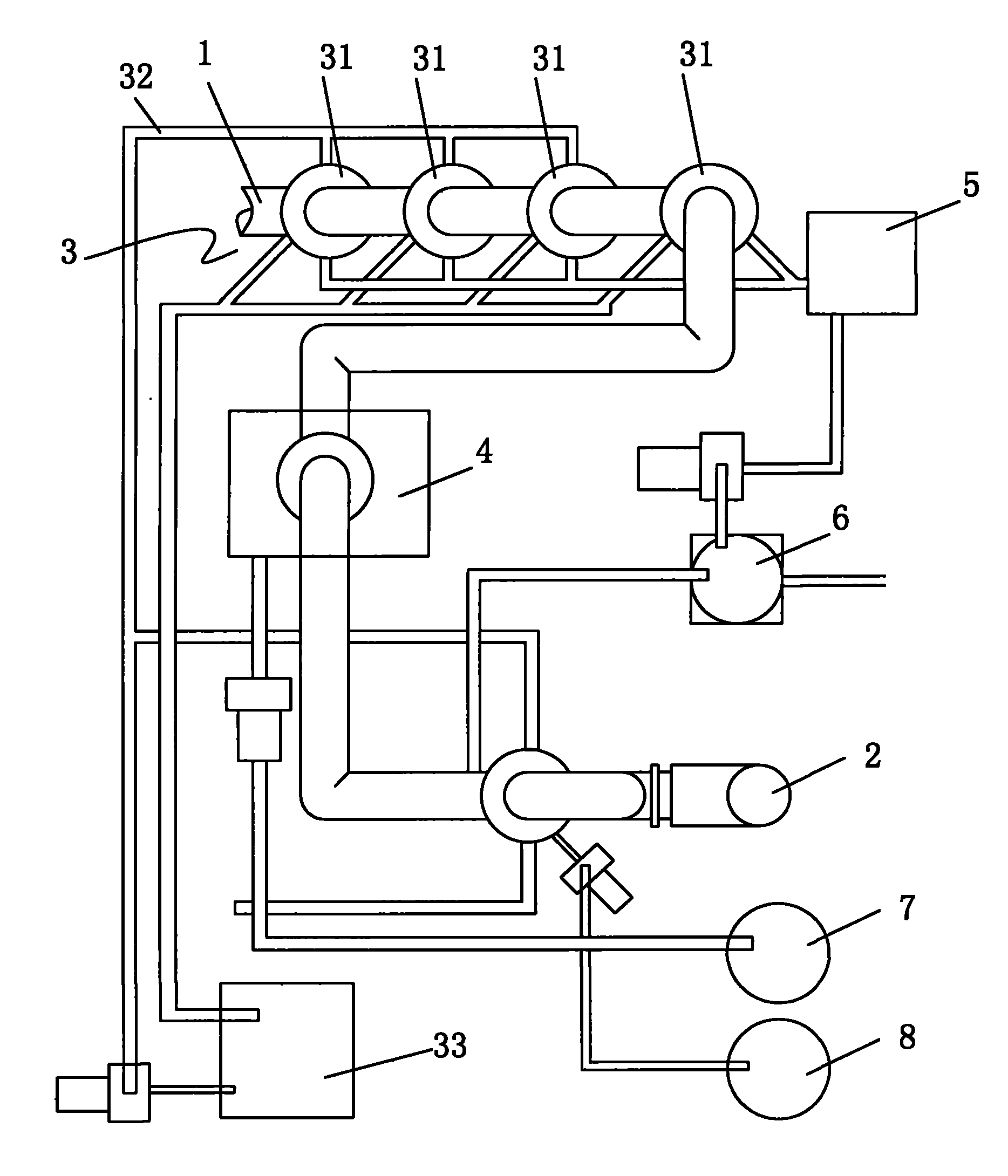

[0022] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

[0023] First of all, the present invention proposes a method for treating tail gas produced by sulfonated naphthalene formaldehyde water reducer, which has a better filtering and absorbing effect on harmful substances in tail gas, and can also lower production costs. The steps of this method are:

[0024] a, condensation, the naphthalene and SO in the tail gas 2 Acid gas condenses into naphthalene and acid coexisting liquid;

[0025] B, neutralization, neutralize the acidic liquid produced in the previous step;

[0026] c. Distillation, after the liquid is re-distilled in the process of a and b, the temperature reaches 180°C, the gas and liquid collected by distillation can be completely recovered after removing the components that interfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com