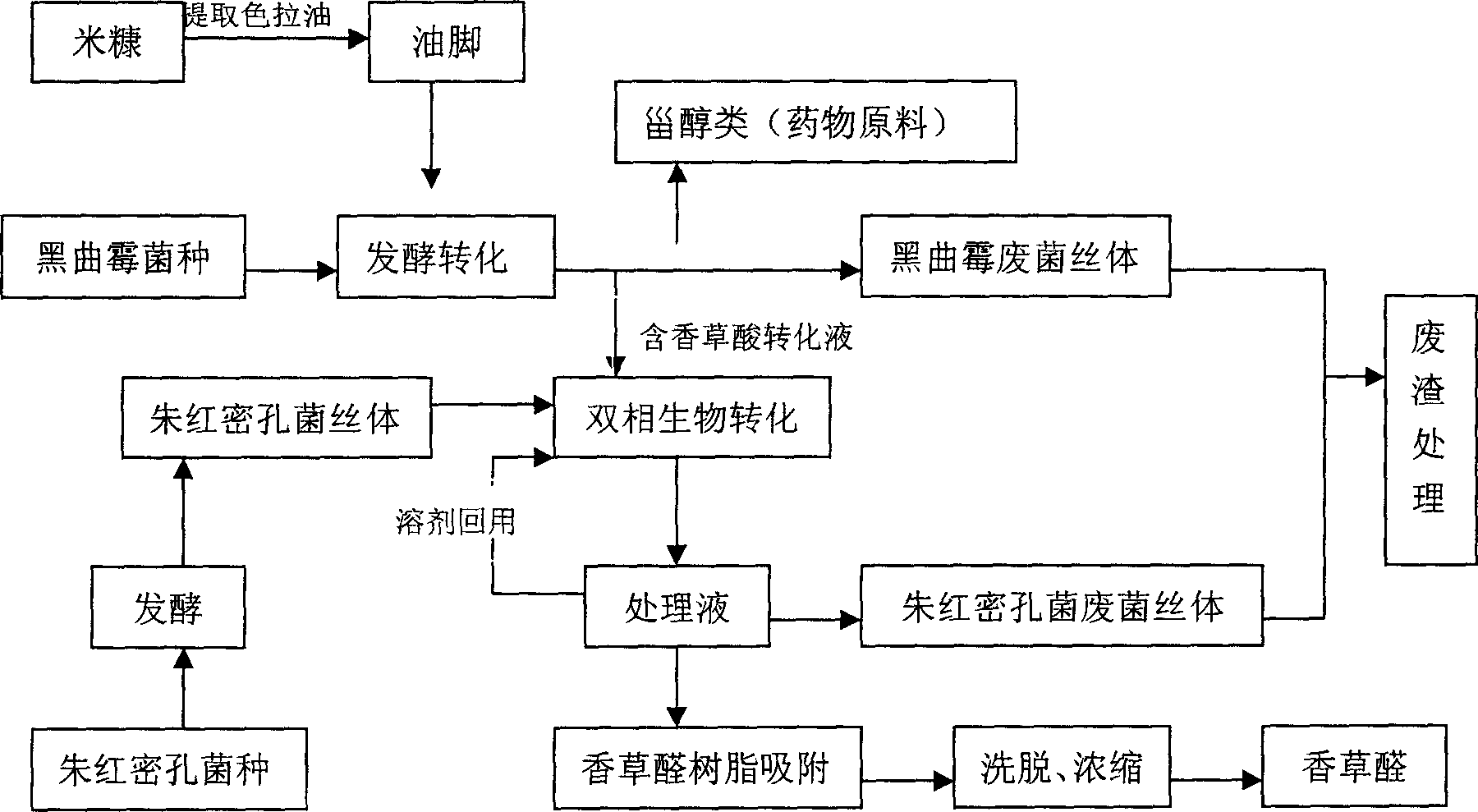

Process for producing vanillic acid and vanillic aldehyde by fermentation transforming bran foots

一种香草醛、香草酸的技术,应用在生物催化领域,能够解决副产物多、不利于转化产物分离提取、未提及阿魏酸和香草酸来源等问题,达到有害物质含量低、缓解石化资源紧张问题、解决产物抑制问的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Scrape off a certain amount of bacterium block from the Asp.niger CGMCC 0774 slant that grows freshly and be placed in the aseptic water that 100mL glass beads are housed, smash 20min under the rotating speed of 180r / min, the concentration of the spore liquid that obtains is about for 10 6 1 / mL, according to 10% inoculation amount, received into 800mL seed medium, cultivated at 30°C, 170r / min for 2 days, crushed the seed liquid for 20min, and finally put the seed liquid into the sterilized at 120°C for 20-50 minutes, In the cooled fermentation medium, the components of the fermentation medium are maltose 20g / L, diammonium tartrate 10g / L, yeast extract 2g / L, potassium dihydrogen phosphate 1g / L, calcium chloride 5g / L, magnesium sulfate 0.5g / L, the pH value is 7.0. The fermentation conditions are 100ml / 250ml Erlenmeyer flask, 10% inoculum size, 35°C, and 120r / min shaker flask rotation speed. After 40 hours of culture and growth of the bacteria, 10 g / 100 ml of rice bran ...

Embodiment 2

[0042] Cultivate Aspergillus niger A5p niger CGMCC 0774 by embodiment 1, seed liquid is placed in specific inoculation bottle, inserts in the 15L fermenter in the solid tank sterilization fermentation medium that 8L is housed, at 37 ℃, 200r / min, 1vvm ventilation, under 0.1Mpa tank pressure condition, thalline growth 44h, add the aseptic ferulic acid solution (sodium salt solution, pH7.0) 1L that obtains by embodiment 1 10g / L, carry out under the same condition For conversion, regular sampling was followed by thin-layer chromatography. After 34 hours of conversion, the ferulic acid was basically exhausted, the concentration of vanillic acid was 0.506g / L, and the corresponding molar conversion rate was 83.32%. The biomass (dry weight of bacteria) can reach 4.8g / L.

Embodiment 3

[0044] Cultivate Aspergillus niger Asp.niger CGMCC 0774 by embodiment 1, receive in 1.6L seed culture medium by 10% inoculum amount, 30 ℃, 170r / min cultivate 2d, seed solution is placed on specific inoculation bottle and inserts In a 25L fermenter in a 16L solid tank sterilized fermentation medium, the bacteria were grown at 37°C, 200r / min, 1vvm ventilation, and 0.1Mpa tank pressure. After 41 hours of growth, the pH dropped to the lowest point of pH3.1 , add 1L of 36g / L aseptic ferulic acid sodium salt solution (pH7.0) that obtains by embodiment 1, adjust through concentrating or crystallization, record the concentration of ferulic acid in the transformation liquid and be 2.0g / L, in the same Transformation was carried out under fermenter conditions. At 36 hours of transformation, 1 L of sterile ferulic acid sodium salt solution (pH 7.0) adjusted by 33 g of ferulic acid was added, and the concentration of ferulic acid in the transformation liquid was measured to be 2.3 g / L, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com