Method for producing succinic acid by using ferment of molasses raw material

A technology of succinic acid and molasses, applied in microorganism-based methods, biochemical equipment and methods, fermentation, etc., to achieve the effect of reducing the cost of culture medium and alleviating the shortage of petrochemical resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

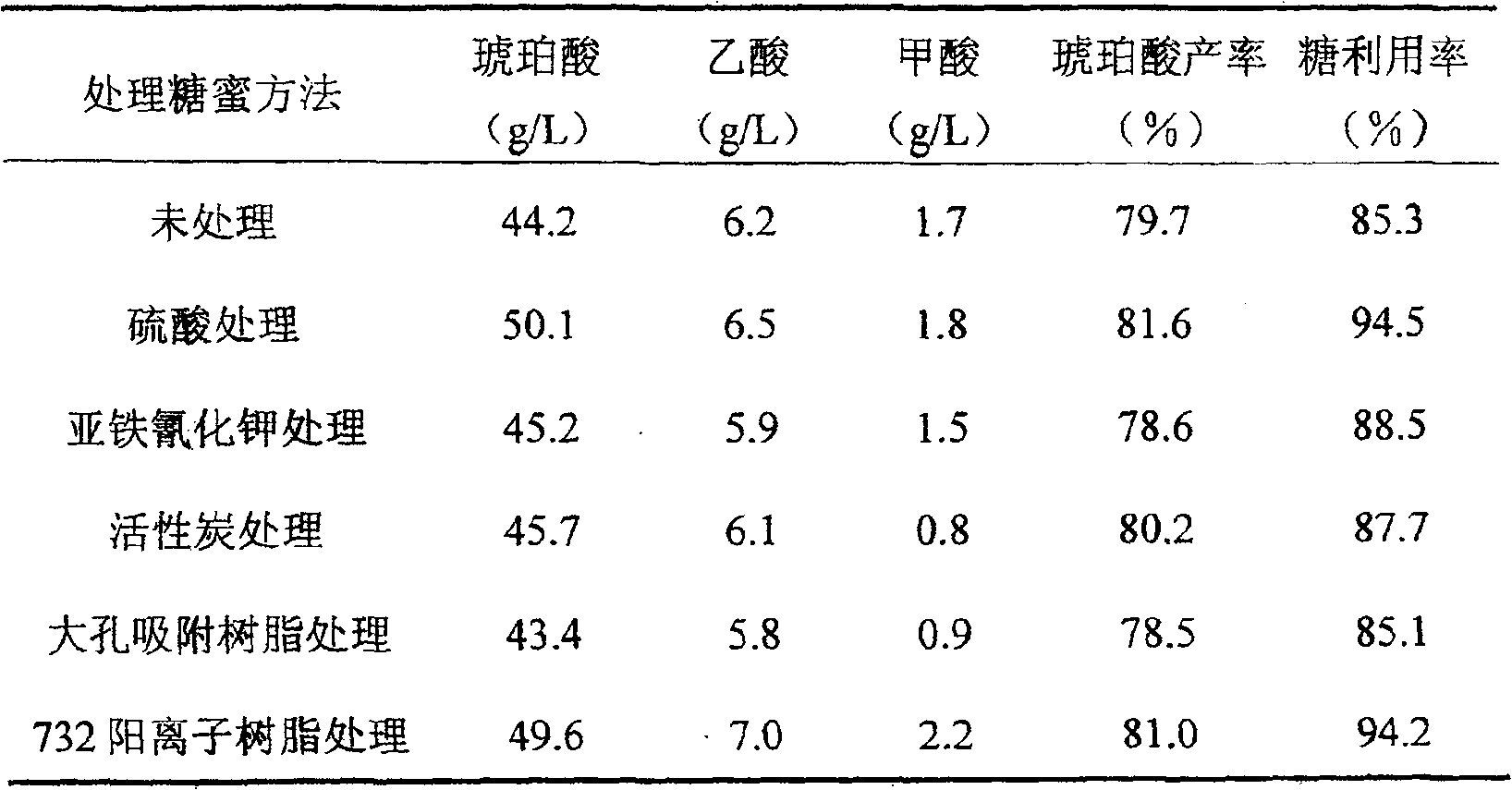

Embodiment 1

[0032] Seed medium (per L): glucose 5g, yeast extract 5g, K 2 HPO 4 ·3H 2 O 1.0 g, NaH 2 PO 4 ·2H 2 O1.0g, mixed with vitamin 1ml, pH7.0. Anaerobic culture at 37°C for 24h.

[0033] Fermentation medium (per L): processed cane molasses (total reducing sugar) 65g, yeast extract 15g, corn steep liquor 20g, MgCl 2 0.2g, Na 2 HPO 4 ·12H 2 O 1.5g, NaH 2 PO 4 ·2H 2 O 1.5g, pH 6.5. Anaerobic incubation at 37°C for 48h.

[0034] Molasses is processed as follows:

[0035] First, the raw molasses (about 510 g / L reducing sugar) was diluted with tap water to a sugar concentration of 300 g / L (hereinafter referred to as the diluted molasses), and then processed by the following methods.

[0036] (1) Sulfuric acid treatment: The diluted molasses was adjusted to pH 3.5 with 1 mol / L sulfuric acid solution, kept at rest for 6 h, centrifuged, and the supernatant was taken and adjusted to pH 6.5 with 5 mol / L NaOH.

[0037] (2) Potassium ferrocyanide treatment: add 0.1 g of potassium ...

Embodiment 2

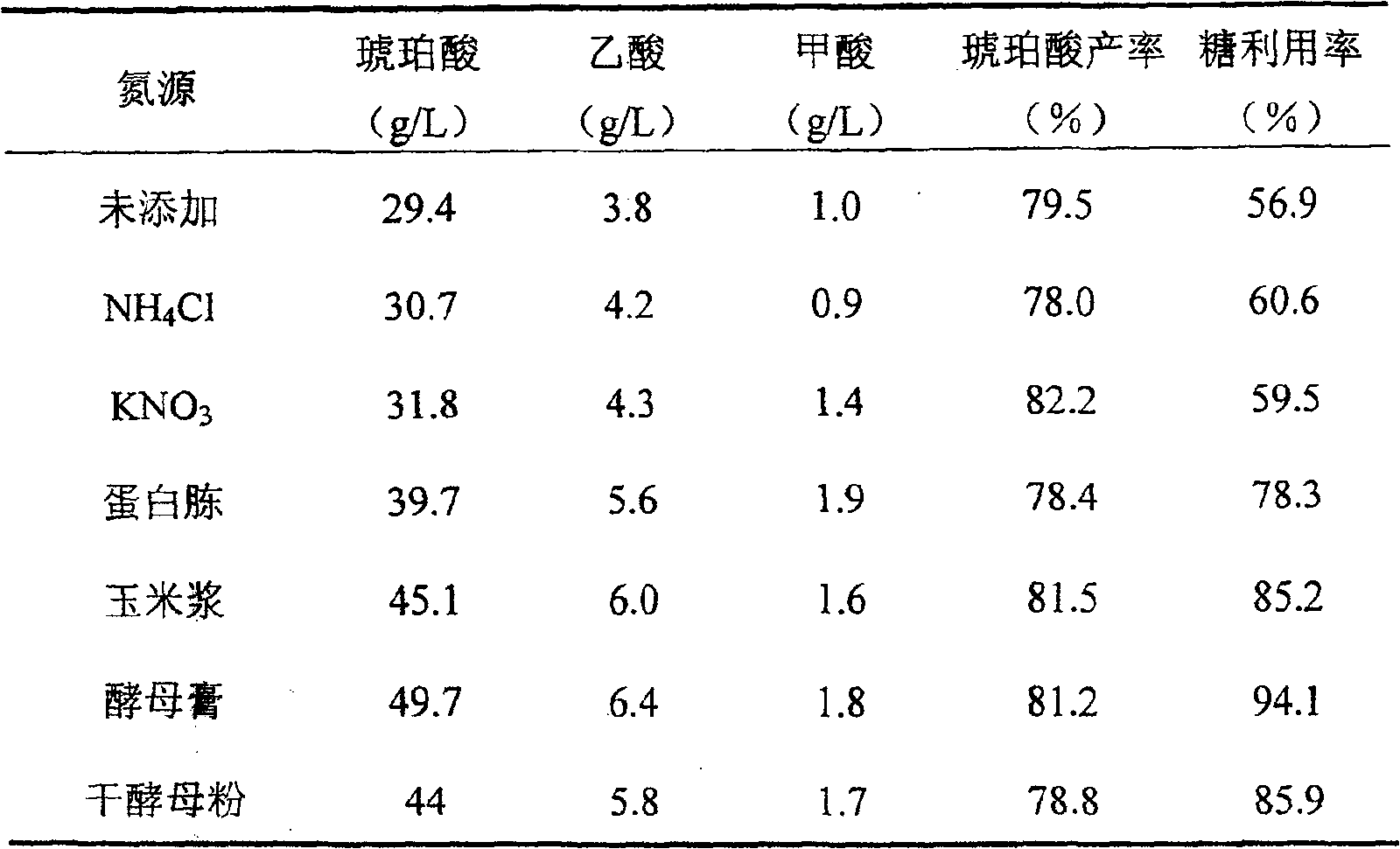

[0045] According to the method of Example 1, in the anaerobic flask fermentation experiment, the sugar cane molasses was treated with sulfuric acid, and the initial reducing sugar concentration was 65 g / L, and different inorganic and organic nitrogen sources were added to the fermentation medium (the total nitrogen content was basically similar), their contents are (per L): NH 4 Cl 5.3g, KNO 3 9.6g, peptone 12g, corn steep liquor (solid content ≥55%) 25g, yeast extract 15g and dry yeast powder 12g. The effects of various nitrogen sources on the production of succinic acid from fermented sugarcane molasses are shown in Table 2.

[0046] Table 2 Effects of adding different nitrogen sources on the production of succinic acid from fermented sugarcane molasses (fermented in anaerobic flasks)

[0047]

[0048] Comparing the above nitrogen sources, yeast extract is the best. When the concentration of yeast extract is 15g / L, the output of succinic acid reaches 49.7g / L, the yield...

Embodiment 3

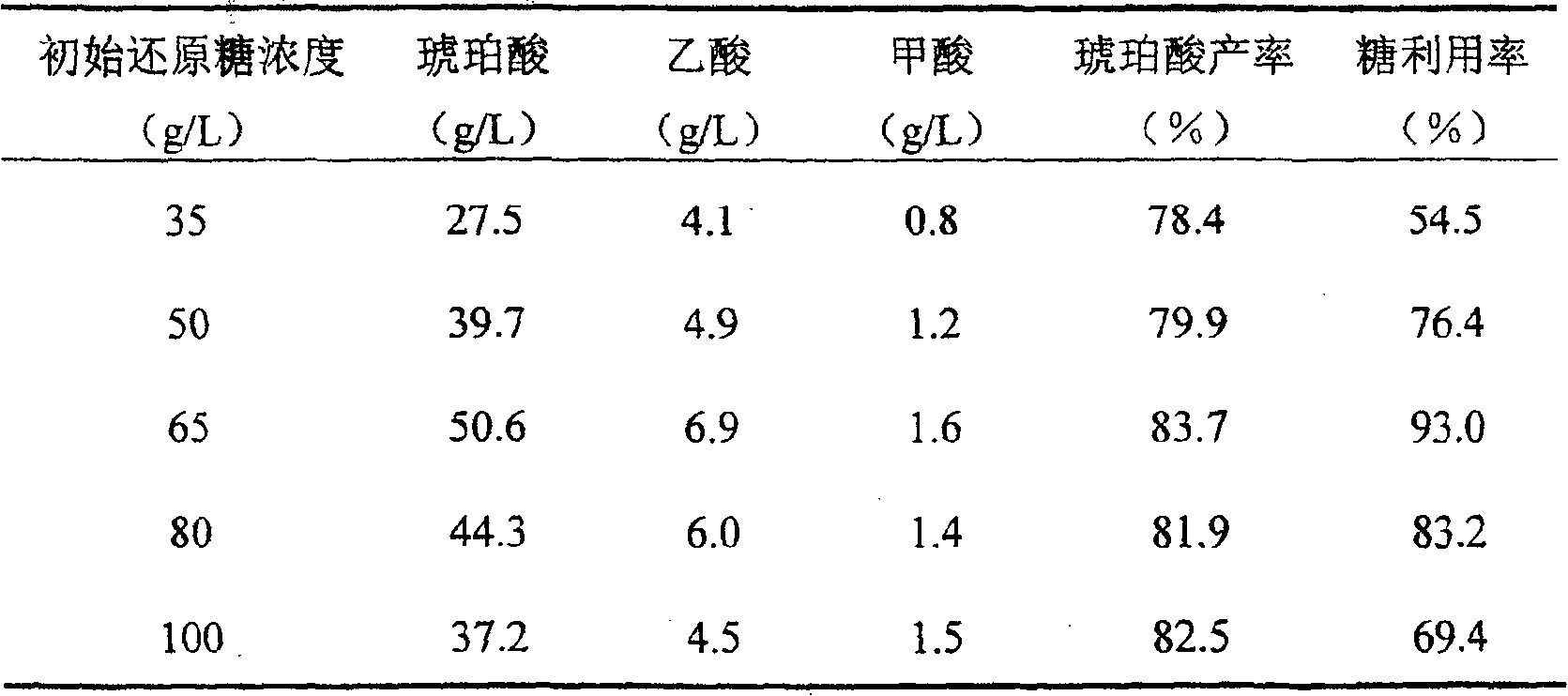

[0050] According to the method of Example 1, in the anaerobic flask fermentation experiment, the sugarcane molasses was treated with sulfuric acid. When the initial reducing sugar concentrations were 35, 50, 65, 80, and 100 g / L, the results were shown in Table 3:

[0051] Table 3 Effects of different initial reducing sugar concentrations on the production of succinic acid from fermented sugarcane molasses (anaerobic flask fermentation)

[0052]

[0053] As can be seen from the above table, when the initial reducing sugar concentration is 65g / L, the output of succinic acid is the highest, reaching 50.6g / L, the yield of succinic acid to consumed sugar is 83.70%, the utilization rate of sugar is 93.0%, and the production strength is 1.05g. / L·h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com