Method for producing succinic acid through fermentation by utilizing lemna minor

A technology of succinic acid and duckweed, applied in the field of microbial fermentation, can solve the problem of high cost of raw materials, and achieve the effects of reducing production cost, being environmentally friendly, and reducing the amount of nitrogen source added.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment is a specific example of the method for producing succinic acid by fermentation of duckweed according to the present invention, including the following operation steps and control technical conditions: raw materials of duckweed are collected from Xingning District, Nanning City, Guangxi Zhuang Autonomous Region.

[0025] 1. Crushing and sizing of duckweed raw materials: Duckweed dried at 70°C to a constant weight is pulverized, passed through a 60-mesh sieve, and water is added to adjust the total sugar concentration to 30-70g / L to obtain a duckweed mash ;

[0026] 2. Fermentation culture and preparation: adjust the pH value of duckweed mash to 5.5, add medium temperature α-amylase according to 10u / g duckweed powder, hydrolyze at 85℃ for 30min, adjust the pH to 4.5 by cooling, and float at 105u / g Add saccharifying enzyme to the powdered sugar, hydrolyze at 60℃ for 2h, add corn steep liquor 0-20g / L, KH 2 PO 4 2g / L, CaCl 2 0.3g / L, MgCl 2 0.5-1g / L, basic magnesi...

Embodiment 2

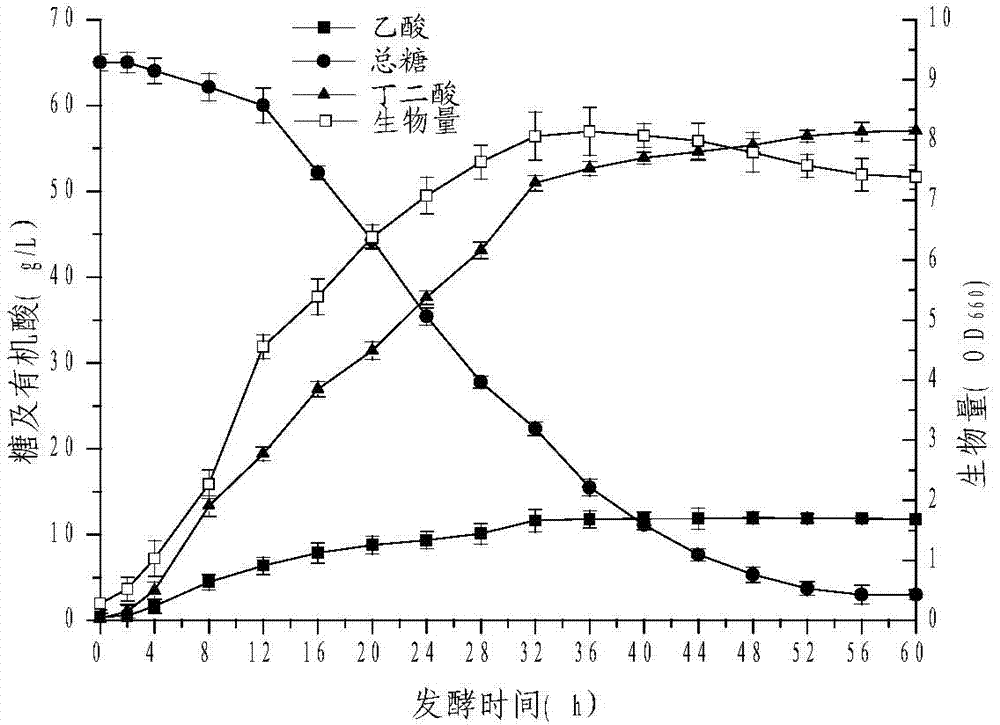

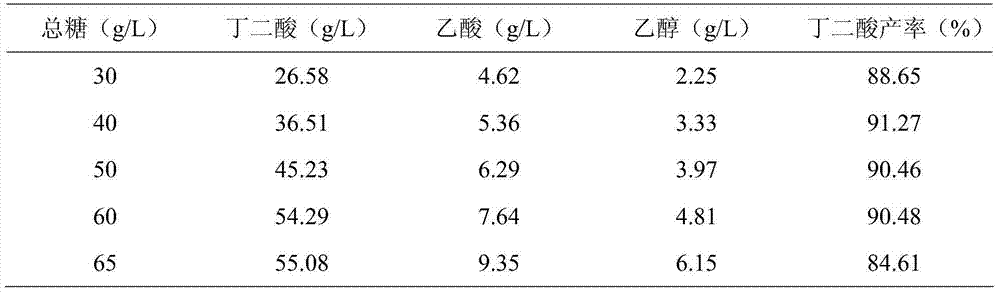

[0039] The Actinobacillus succinate-producing strains were connected to the seed culture medium, cultured in an anaerobic incubator or ordinary incubator at 37°C for 16 hours, and then subjected to secondary propagation and culture for 8 hours according to the 5% (V / V) inoculum. The liquid seed is obtained. Put 8% (V / V) inoculum into a 250mL Erlenmeyer flask containing fermentation medium, with a liquid volume of 150mL, add 20g / L corn steep liquor as a nitrogen source, and add 50g / L basic magnesium carbonate Adjust the pH to 6.0-7.0 and place it in an anaerobic incubator for fermentation at 37°C for 60 hours. Anaerobic box culture conditions: anaerobic box (Don Whitley Scientific DG250anaerobic workstation), mixed gas N 2 : CO 2 : H 2 =8.5: 1.0: 0.5, temperature 37°C. The experimental results are shown in Table 1.

[0040] Table 1 The effect of duckweed with different total sugar concentration on the yield of succinic acid

[0041]

[0042] It can be seen from Table 1 that duckw...

Embodiment 3

[0044] According to the method of Actinobacillus succinate-producing fermented duckweed to produce succinic acid in Example 1, the initial total sugar concentration was 65g / L, and different kinds of nitrogen sources were added. The total nitrogen was added at 1.5g / L. The control did not add anything. Nitrogen source, the inoculum amount is 8% (V / V), the 250mL Erlenmeyer flask of the fermentation medium, the liquid volume is 150mL, placed in an anaerobic incubator at 37°C for 60h fermentation, HPLC is used to determine succinic acid and main by-products Content, the results are shown in Table 2.

[0045] Table 2 Effects of different nitrogen sources on the fermentation of duckweed to produce succinic acid

[0046]

[0047]

[0048] It can be seen from Table 2 that the most suitable nitrogen source for succinic acid fermentation is yeast powder, followed by corn steep liquor. When urea is the nitrogen source, the effect is poor (34.77g / L), but even if no nitrogen source is added The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com