Production technology for smelting ferronickel from laterite-nickel ore

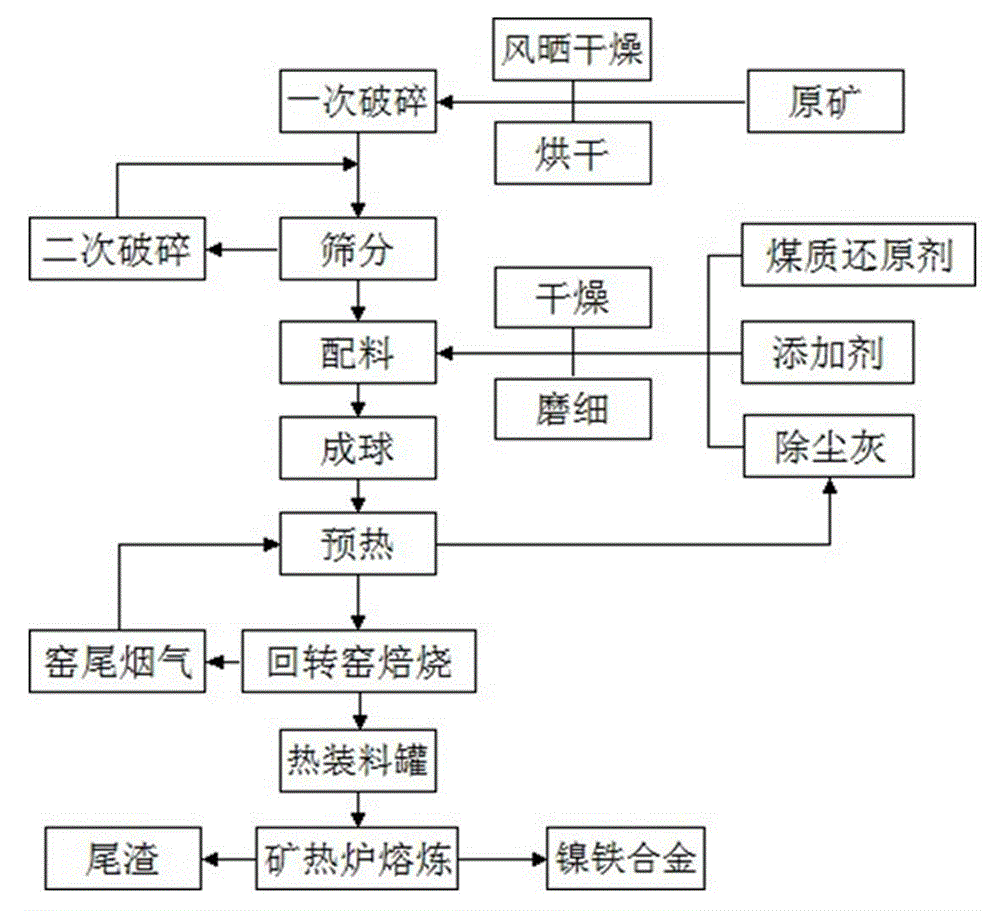

A technology of laterite nickel ore and production process, which is applied in the field of production process of using laterite nickel ore to smelt ferronickel, can solve the problems of low nickel recovery rate and high energy consumption, and achieve the goal of increasing roasting temperature, recovery rate and reduction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A production process for smelting ferronickel using laterite nickel ore, the steps are:

[0030] (1) The laterite nickel ore used as raw material contains 1.76% nickel and 21.7% iron, which is ground to 99%≤5mm and dried to a moisture content of 12%;

[0031] Based on the weight of laterite nickel ore, add 3% bentonite, 6% limestone, and 6% fluorite as additives. After drying and crushing, the water content is 8%, and the particle size is ≤5mm, accounting for 96%;

[0032] The reducing agent is coke with 10% weight of laterite nickel ore. The coke composition is 80.6% fixed carbon, 13.5% volatile matter, and 5.9% ash content. After drying and crushing, the moisture content is 10%, and the particle size is ≤5mm, accounting for 96%;

[0033] Use a cold press briquetting machine to make balls with a diameter of 30-50mm;

[0034] (2) Preheat in a preheater at a temperature of 300-400°C for 2 hours, and then enter a rotary kiln at a temperature of 1150-1200°C for 6 hours to...

Embodiment 2

[0039] A production process for smelting ferronickel using laterite nickel ore, the steps are:

[0040] (1) The laterite nickel ore used as raw material contains 2.5% nickel and 27% iron, which is ground to 95%≤5mm and dried to a moisture content of 10%;

[0041] Based on the weight of laterite nickel ore, add 4% bentonite, 5% lime, and 10% sodium fluoride as additives. After drying and crushing, the water content is 10%, and the particle size is ≤5mm, accounting for 95%;

[0042] The reducing agent is 15% by weight of lateritic nickel ore, of which 60% is coke and 40% is dust. After drying and crushing, the water content is 8%, and the particle size is ≤5mm, accounting for 97%;

[0043] Use a cold press briquetting machine to make balls with a diameter of 30-50mm;

[0044] (2) Preheat in a preheater at 420-500°C for 1 hour, then enter a rotary kiln at 1190-1250°C for 4 hours to obtain reduced calcine;

[0045](3) Send the reduced calcine and 1% coke, 2% lime, and 3% fluorit...

Embodiment 3

[0048] A production process for smelting ferronickel using laterite nickel ore, the steps are:

[0049] (1) The laterite nickel ore used as raw material contains 1.97% nickel and 16.8% iron, which is ground to 96%≤5mm and dried to a moisture content of 15%;

[0050] Based on the weight of laterite nickel ore, add 5% bentonite, 10% limestone, and 5% magnesium fluoride as additives. After drying and crushing, the water content is 9%, and the particle size is ≤5mm, accounting for 98%;

[0051] The reducing agent is 20% of the weight of the laterite nickel ore, of which coal powder accounts for 40%, dedusting ash accounts for 60%, after drying and crushing, the water content is 8%, and the particle size is ≤5mm accounting for 95%;

[0052] Use a cold press briquetting machine to make balls with a diameter of 30-50mm;

[0053] (2) Preheat in a preheater at a temperature of 380-450°C for 3 hours, and then enter a rotary kiln at 1150-1200°C for 8 hours to obtain reduced calcined san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com