Patents

Literature

246 results about "Lactobacillus strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lactobacillus GG is a strain of good-for-you bacteria that was first discovered in 1985. Now, over 30 years later, it has been the subject of over 1,000 clinical studies, making it the number one most studied probiotic strain. 1†† But what is it about this beneficial bacteria strain that keeps scientists...

Novel strain of lactobacillus crispatus

The invention provides a naturally occurring strain of Lactobacillus crispatus with advantageous characteristics. The strain colonizes mucosal surfaces, particularly vaginal surfaces. The strain is also capable of rapid growth in a number of conditions and is highly viable after desiccation. Moreover, the strain is capable of preventing and reducing pathogenic infection of vaginal mucosa.

Owner:OSEL

Brewing method for a fruit wine

The invention discloses a method for brewing a fruit wine. The raw materials of the fruit wine comprise the following components by weight percentage: 71wt%-86wt% of fruit crude juice, 9wt%-21wt% of white sand sugar, 4wt%-6wt% of yeast strain amplification culture solution and 1wt%-2wt% of lactobacillus strain amplification culture solution. The technological process of the method comprises the steps as follows: (1) juicing fruits, filtering and adding sulfur dioxide (SO2); (2) clarifying the fruit juice; (3) carrying out the primary fermentation; (4) carrying out the secondary fermentation; (5) clarifying the crude wine; (6) blending; (7) carrying out the cold treatment; and (8) sterilizing and canning. The method has the advantages that the strain amplification culture solution is subjected to the primary fermentation and the secondary fermentation, therefore, the fermentation speed is high, the fermentation time is short, and the fruit wine has good original taste and good stability; and the bentonite-loaded chitosan is adopted to carry out the clarifying treatment and a diatomite filter is used for filtering, thereby the fruit wine has pure original taste; and the 6-second flash sterilization at the high temperature of 105 DEG C is carried out to prolong the shelf life of the fruit wine.

Owner:海南省工业研究所

Preparation of freeze-dried Lactobacillus acidophilus powder

ActiveCN101486986AActivity is not affectedStability is not affectedBacteriaMicroorganism based processesBiotechnologyFreeze-drying

The invention discloses a preparation method of freeze dried microbial powder of Lactobacillus acidophilus, which comprises the technical processes of fermented cultivation of Lactobacillus acidophilus, separation of a fermented fluid, emulsification of microbial soil and vacuum freeze drying of an emulsified solution. The preparation method is characterized in that the strain fermented cultivation comprises the steps as follows: a lactobacillus strain is inoculated into a fluid culture medium in a triangular flask, cultivated at the temperature of 30 to 40 DEG C for 10 to 30 hours, inoculated into a large fermentation flask and fermentation cultivated at the temperature of 35 to 40 DEG C for 10 to 30 hours, and sterilized at the temperature of 115 DEG C for 15 minutes; and fermentation and augmentation cultivation is carried out for 10 to 30 hours, the pH value of the fermented fluid is 5.5 to 6.5, and OD600 is over 2.0; the vacuum freeze drying of the emulsified solution comprises the steps: the emulsified solution is pre-frozen at the temperature of minus 60 to minus 40 DEG C for 1 to 5 hours, and then vacuum frozen and dried at the temperature of minus 60 DEG C and with the vacuum degree of 1 to 8 Pa for 10 to 30 hours. The freeze dried microbial powder of Lactobacillus acidophilus with the total plate count of 1.0 multiplied by 10 cfu / g can be preserved for 18 months at the temperature of minus 18 DEG C with unaffected liveness and stability.

Owner:方曙光

Stirring type corn yoghourt and preparation method thereof

ActiveCN101455236ARetain nutritionImprove exudation rateMilk preparationFood preparationAbsorption rateBiology

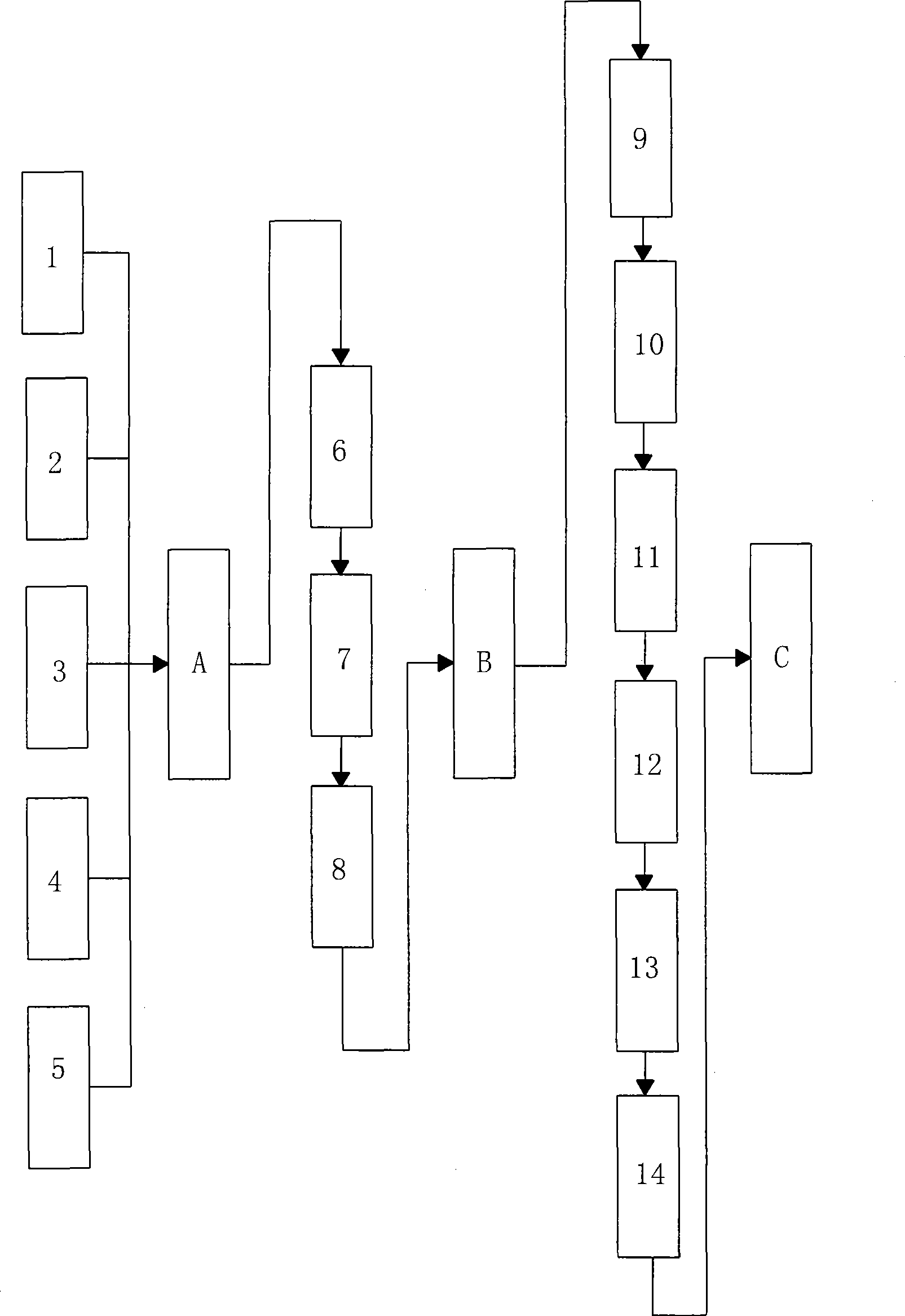

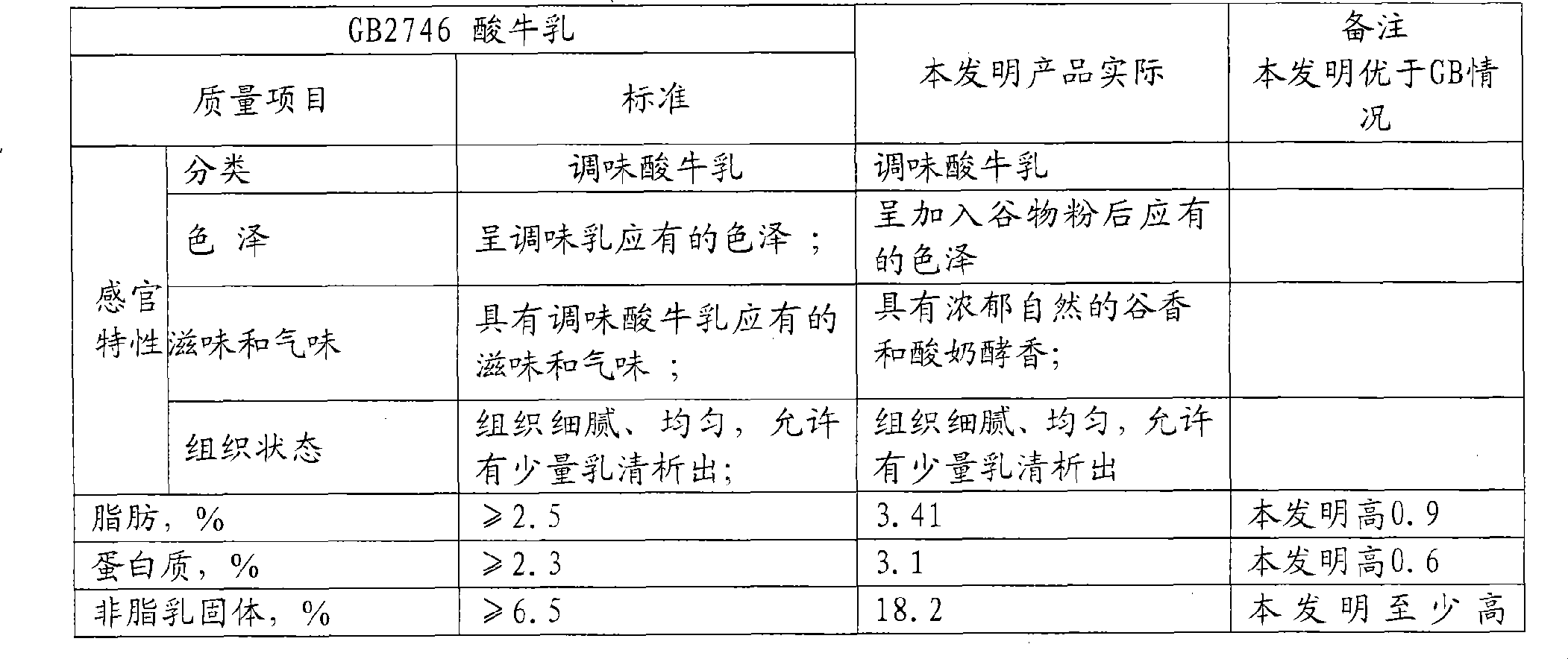

The invention relates to a stirring type cereal sour milk and a method of preparing the same. The cereal sour milk is made through lactobacillus and probiotics ferment by using raw materials with the following weight components: raw fresh milk of 700-875 parts, cereal powder 1-30 parts; additive agent for dairy food of 5-44 parts; lactobacillus strain / functionality probiotics strain of 0.2-0.8 parts; corrective of 48-82 parts; stabilizing thickening agent of 3-10 parts; homogeneous pourable dense quasi-fluid which is the external appearance showing the color of added cereal powder with suspended corresponding cereal powder; the tissue is fine, smooth and uniform and a few whey is allowed to be precipitated; organoleptic attribute, nutritive index, health indicator and content of lactobacillus series of the cereal sour milk are all better than that in the GB2746 cultured milk quality index. The present invention is characterized in that the cereal powder that is formed by pulverizing and swelling processes reserves the nutrient of cereal to the utmost extent and improves the hot water leaching rate and absorption rate of its nutrient components; the technique is more compact and the operation is easy; the production efficiency is high and the consumption human populations of the products are widened; the cereal sour milk is easy to digested and absorbed, and the taste is better.

Owner:SHANDONG DEYI DAIRY IND

Lactobacillus plantarum bb9 capable of adhering to gastrointestinal tract and cholesterol removal

InactiveUS20110117629A1Good acidGood bile toleranceBacteriaFood ingredient functionsTolerabilityIn vitro test

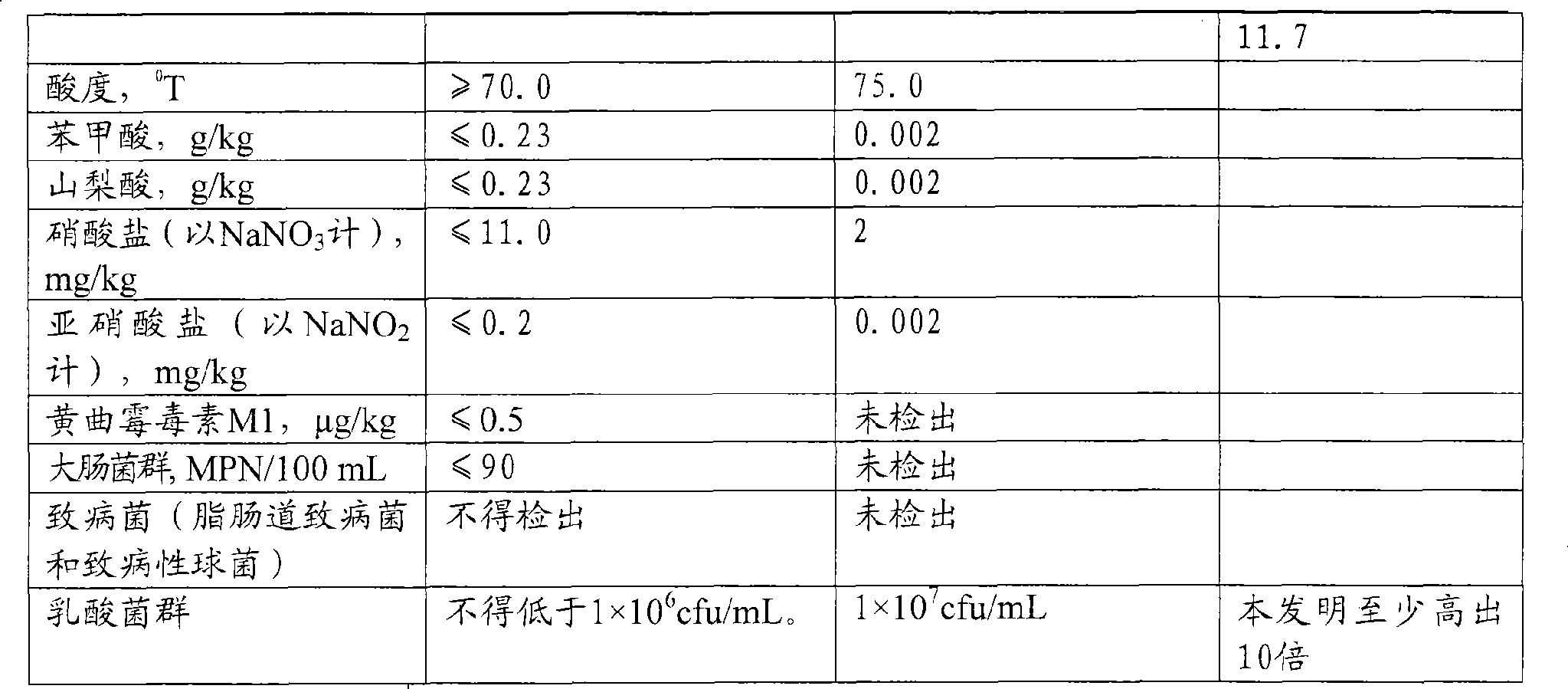

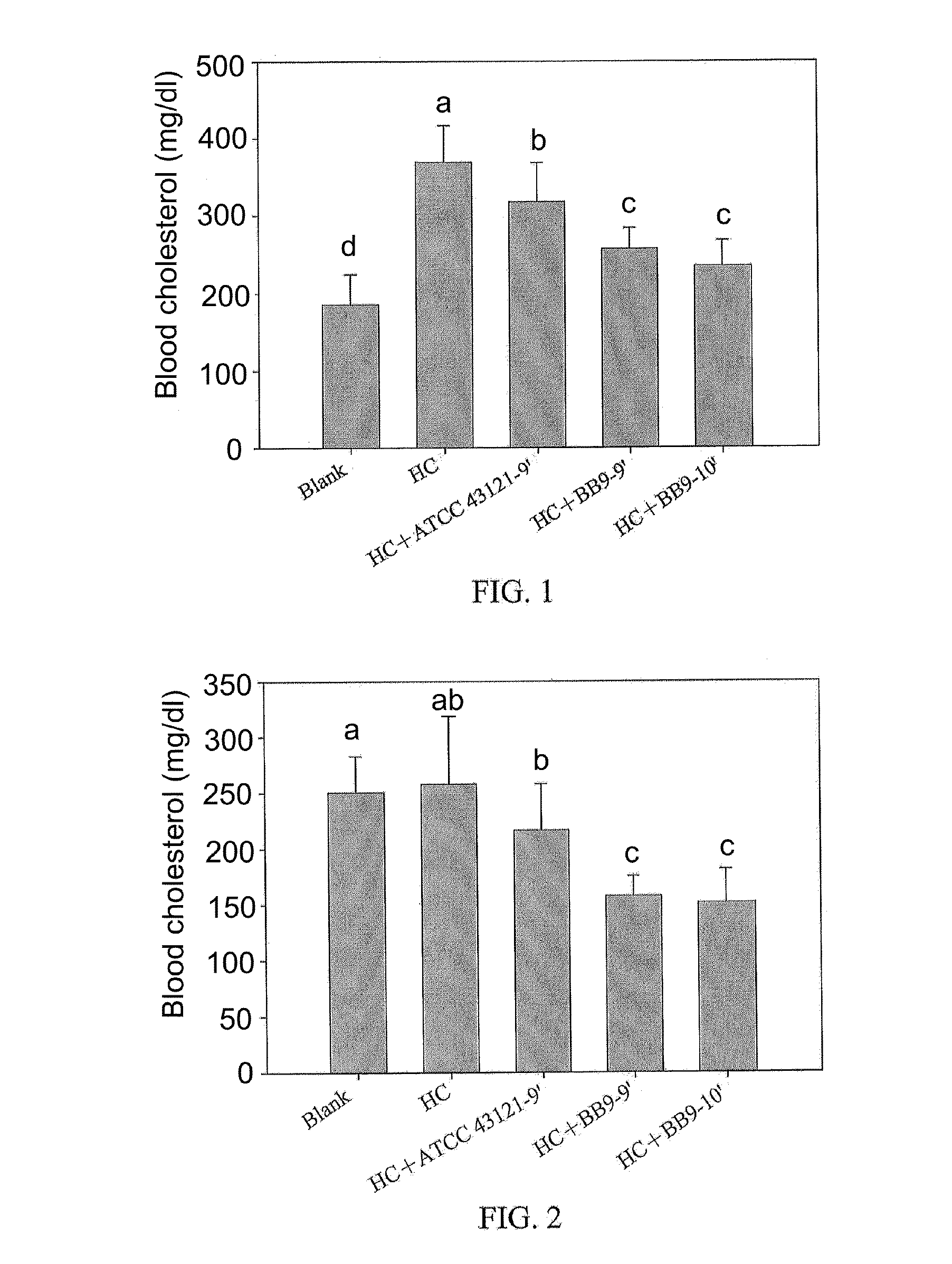

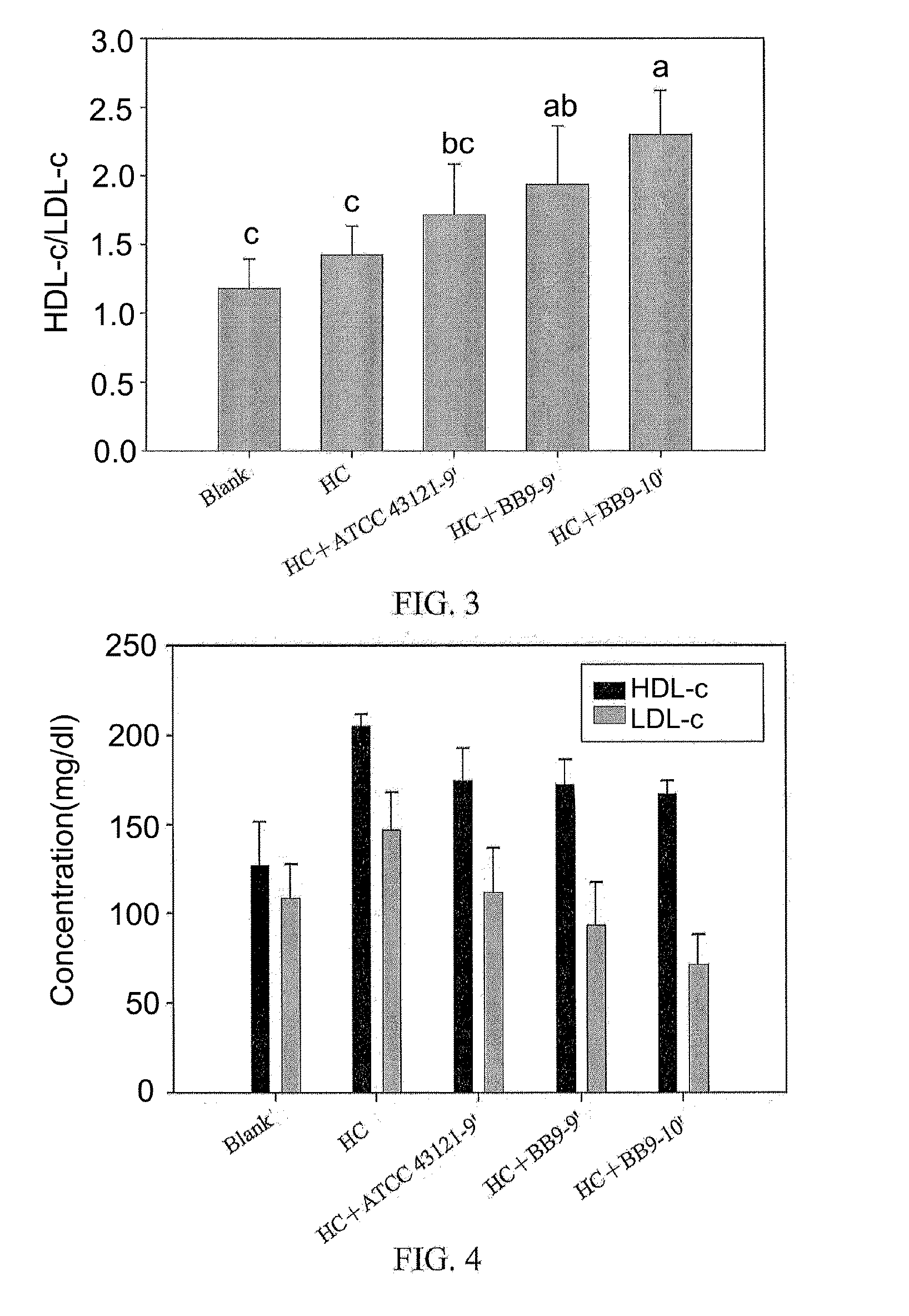

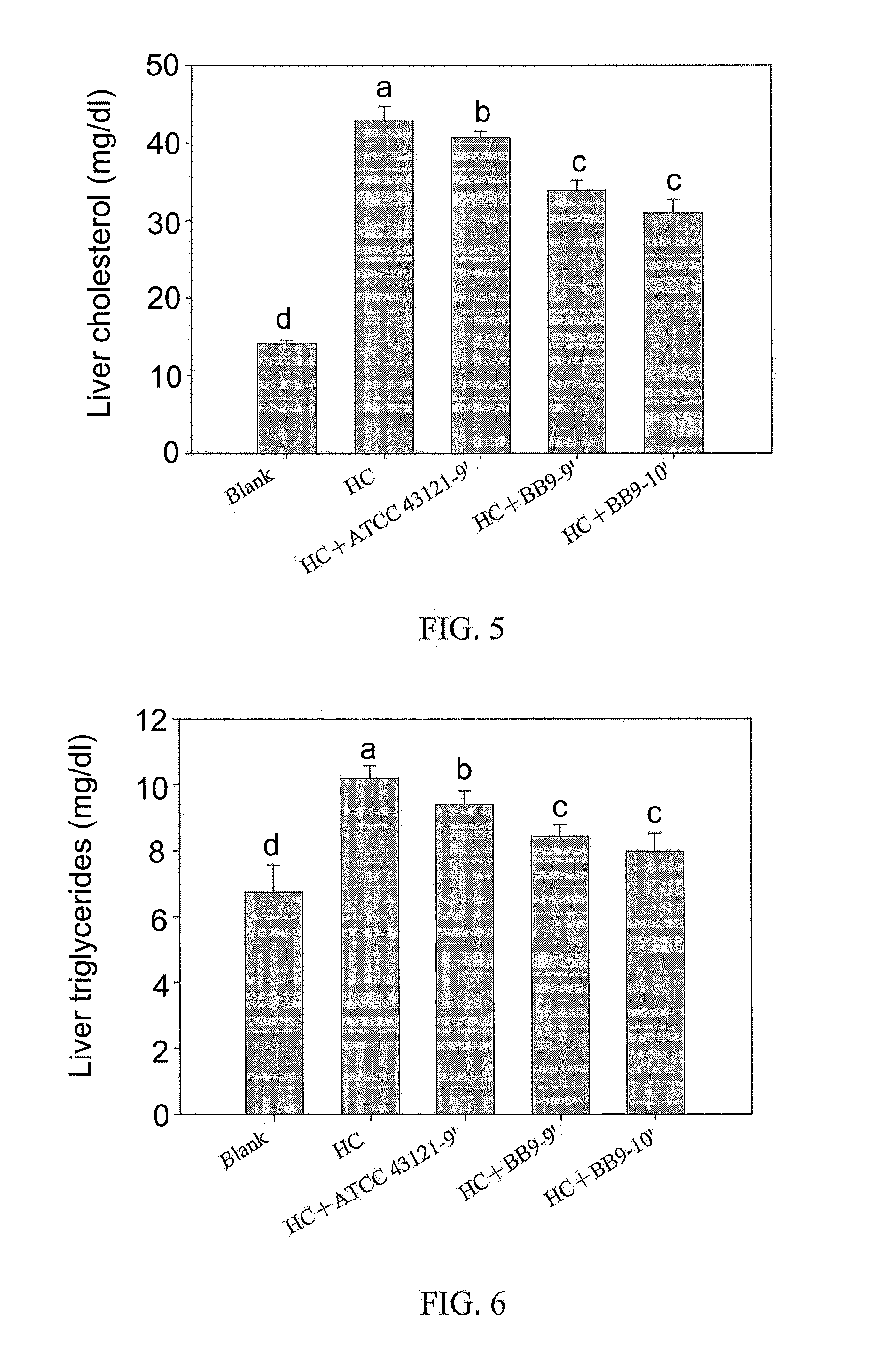

A Lactobacillus plantarum BB9 capable of adhering to gastrointestinal tract and cholesterol removal is isolated from fruits and exhibits high BSH activity. In-vitro tests demonstrate that Lactobacillus plantarum BB9 has good acid and bile tolerance, and strong ability to adhere to intestinal cells. In-vivo tests show that hamsters fed high cholesterol diets added with BB9 strain have cholesterol and triglycerides in blood and liver effectively reduced, and their HDL-c / LDL-c ratios in blood are significantly higher than those of hamsters fed Lactobacillus acidophilus ATCC 43121 strain. It is hoped that the excellent acid and bile tolerance and intestinal adherence of the lactobacillus strain provided herein could produce cholesterol-lowering effect in humans.

Owner:FAMILY MEDICINE INTERANTIONAL

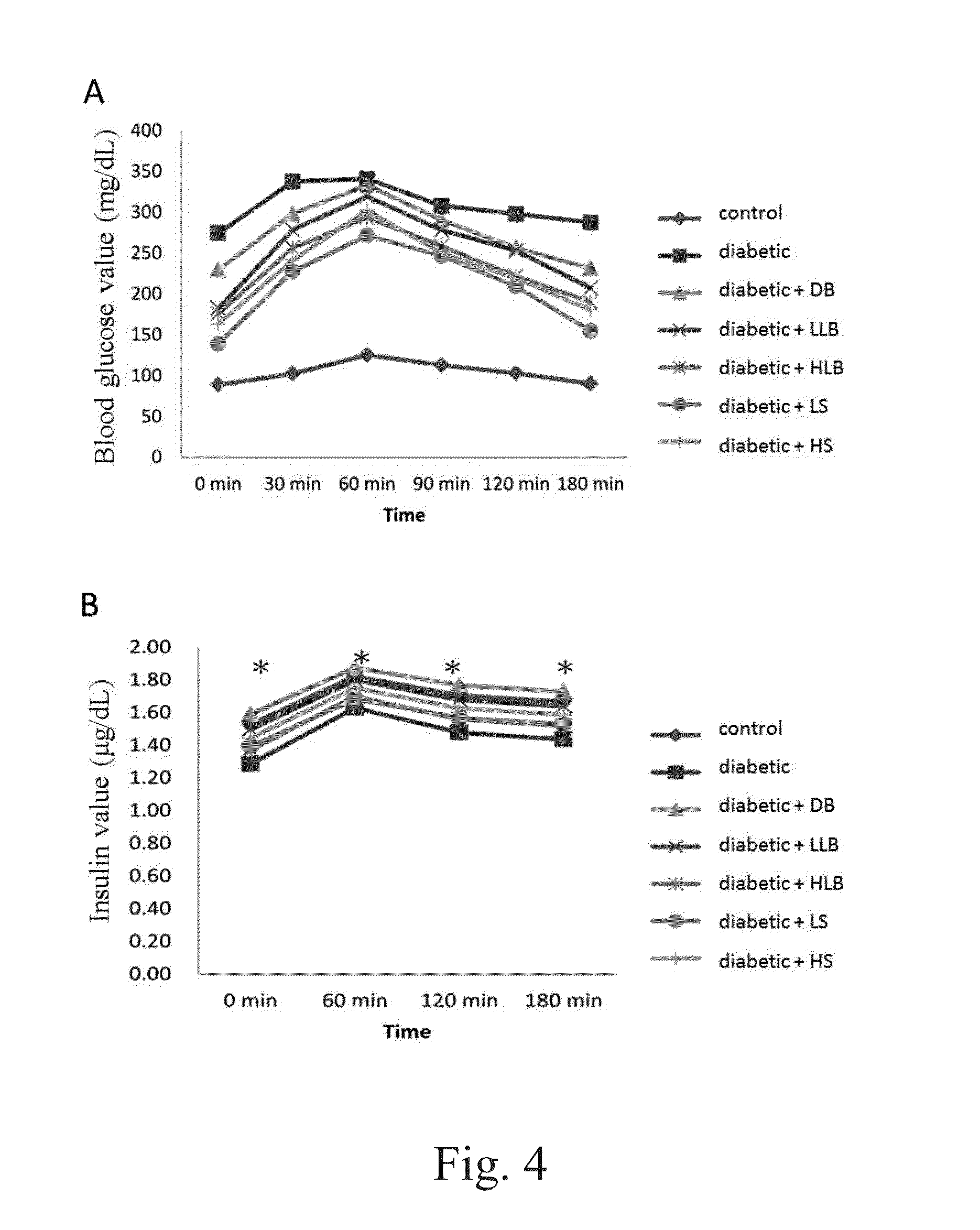

Composition and method of lactobacillus reuteri gmnl-89 in treating type 2 diabetes

ActiveUS20150250835A1Improve the level ofRaise the ratioBiocideBacteria material medical ingredientsBacteroidesBacilli

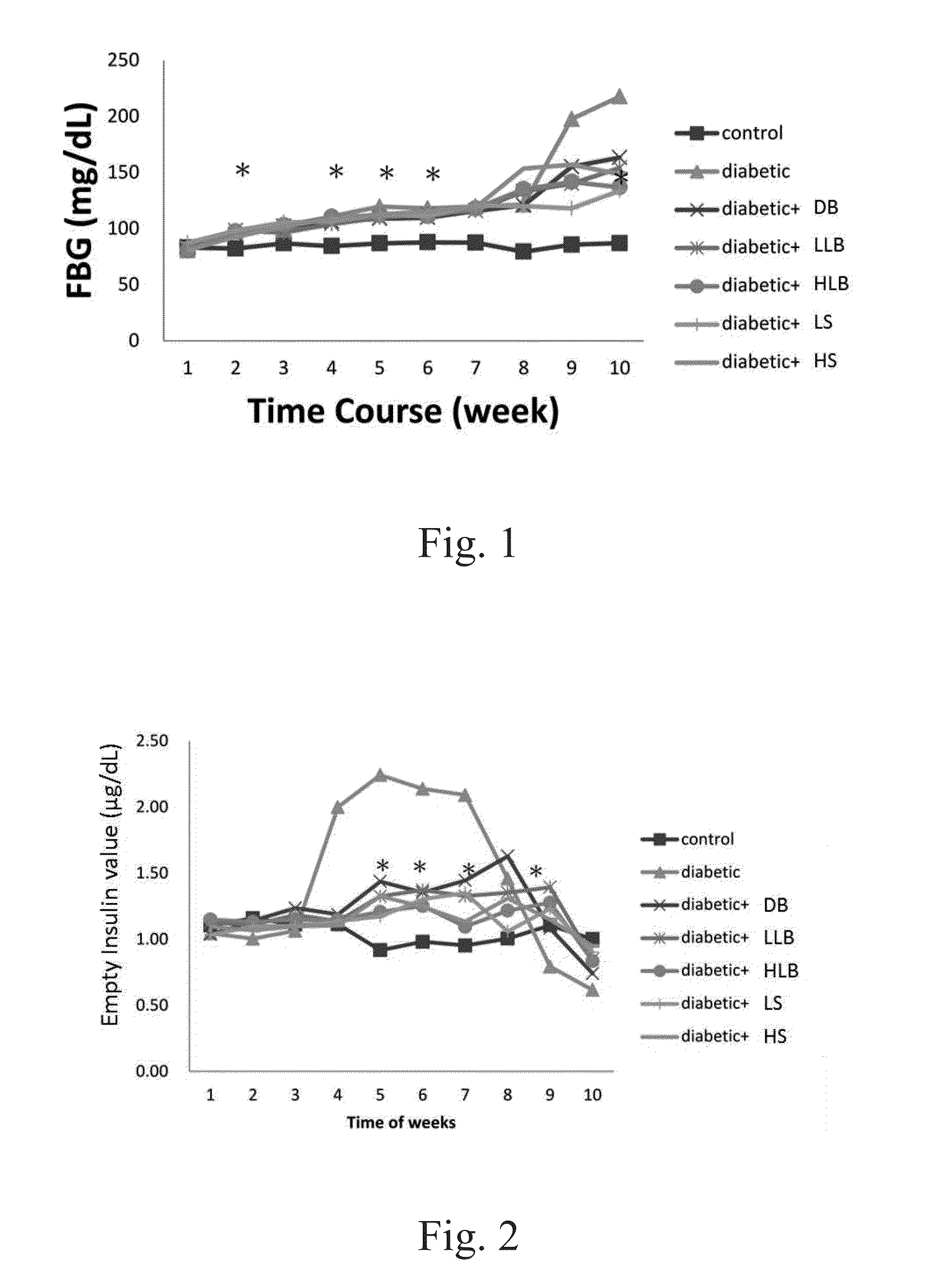

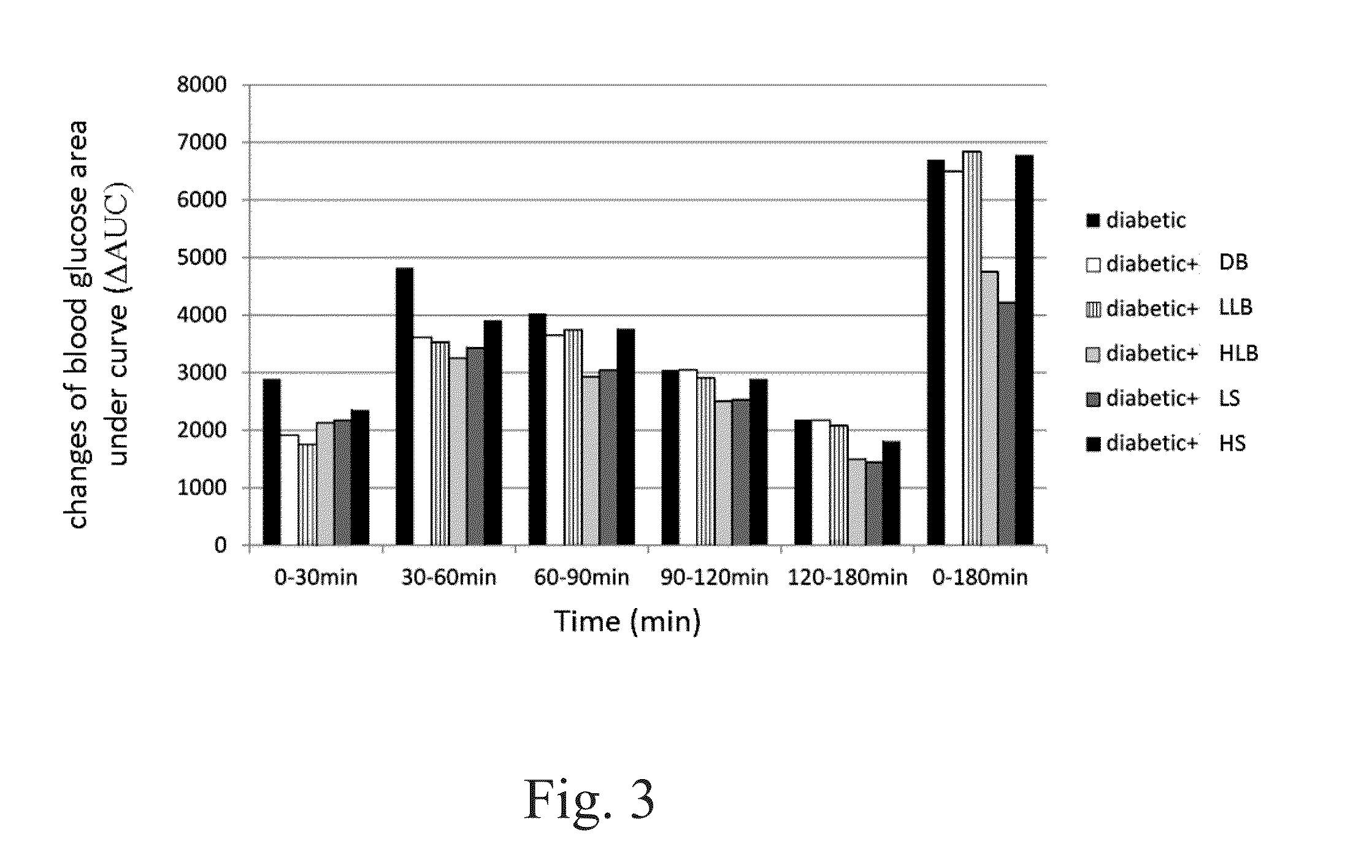

Present invention features a novel use of Lactobacillus for treating type 2 diabetes, wherein the Lactobacillus is Lactobacillus reuteri GMNL-89 with the deposition numbers of BCRC 910340 and CCTCC M 207154 and comprises of live, dead bacteria or supernatant of the bacterial culture(s) and a pharmaceutically acceptable vehicle. The invention also discloses the efficacies of the indicated Lactobacillus strain including anti-oxidative enzyme activity, anti-inflammation, reduction of blood glucose level, reduction of triglycerides, reduction of total cholesterol, reduction of LDL, increase of HDL and improve insulin utilization.

Owner:GENMONT BIOTECH

Acidproof and bile-salt-resisting rhamnose lactobacillus strain with anti-enterovirus and antioxidant functions

ActiveCN1982437AImprove adhesionResistantBacteriaBacteria material medical ingredientsEnterovirusMicroorganism

Lactobacillus rhamnosus and the use for it and its metabolin are disclosed. The strain is sieved and obtained from excrement of long-lived old. It's safe, has excellent antibacterial, acid-resisting and antioxidant performances. It can be used in dairy process and functional food production.

Owner:PRESIDENT ENTERPRISES (CHINA) INVESTMENT CO LTD +1

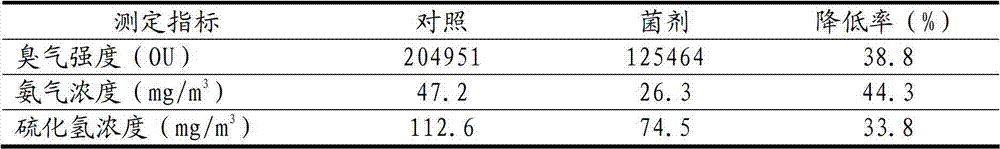

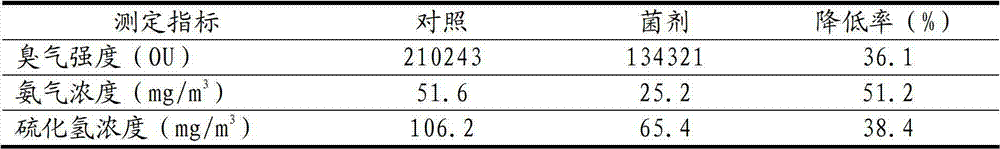

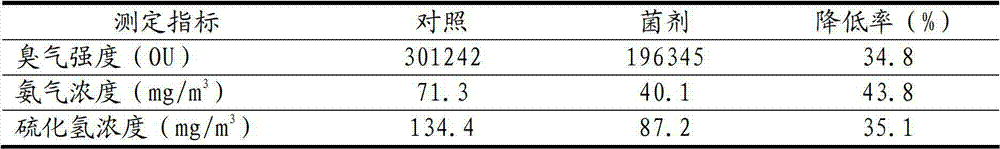

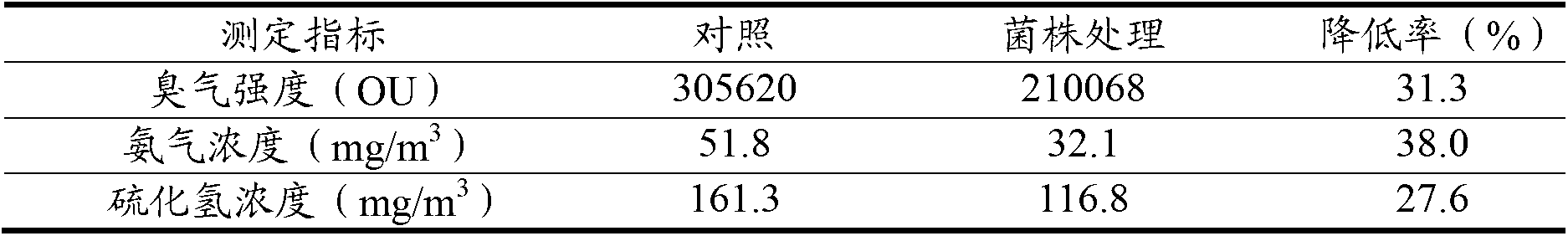

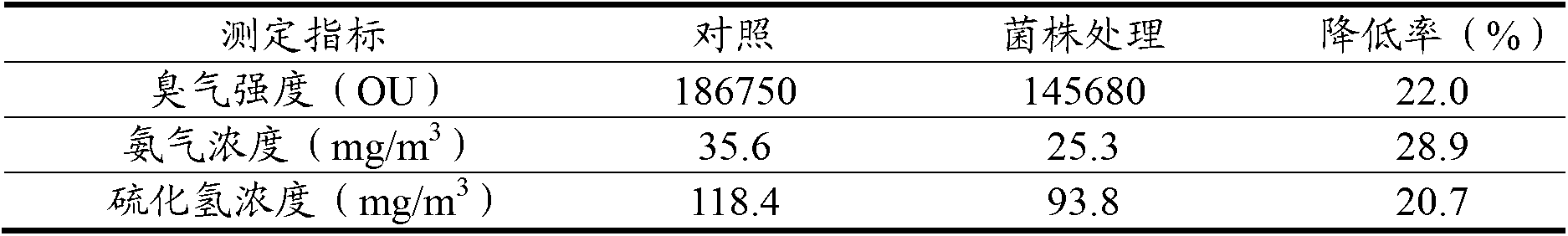

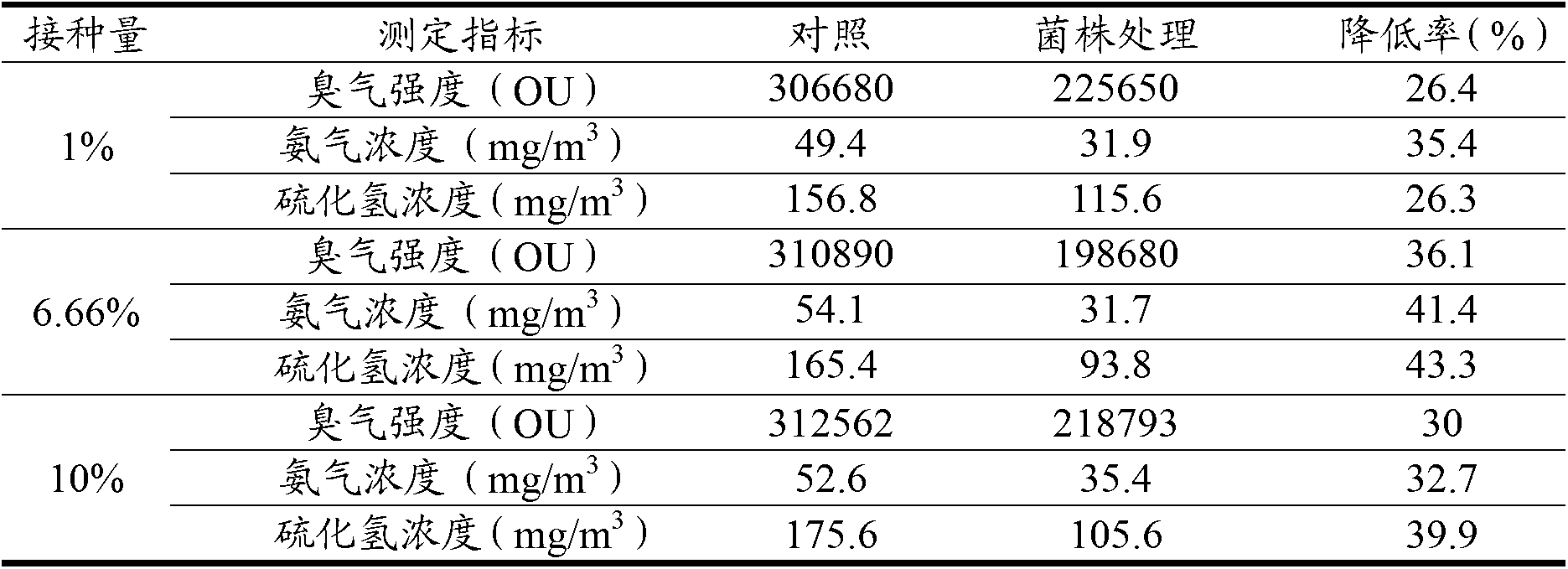

Livestock and poultry excrement microbial deodorizing agent, and preparation method and application thereof

ActiveCN102851210AInhibition of growth and reproductionEasy to controlFungiMicroorganism based processesMicroorganismMicrobiology

The invention relates to a livestock and poultry excrement microbial deodorizing agent, and a preparation method and an application thereof. The invention discloses a composite biological preparation used in public toilet deodorization. The composite biological preparation comprises a lactobacillus strain which is lactobacillus sp with a collection number of CGMCC NO: 5983, a lactobacillus strain which is streptococcus thermophilus with a collection number of CGMCC NO: 5985, and an orange peel extraction liquid. The invention also discloses the preparation method of the composite biological preparation. The method comprises preparation methods of a liquid composite biological preparation and a solid biological preparation. The invention also discloses a purpose of the composite biological preparation.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

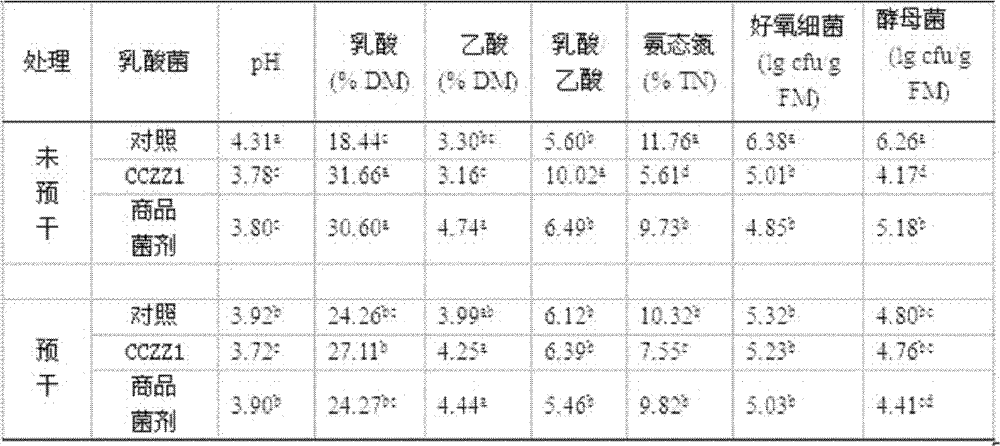

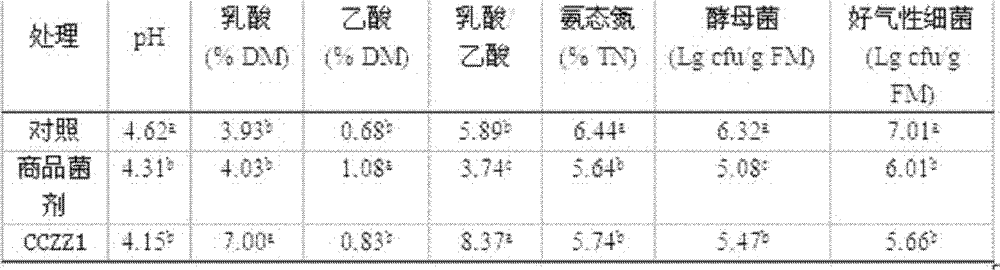

Low-temperature-resistant lactobacillus strain lactobacillus plantarum CCZZ1 and application thereof

ActiveCN102851233AStrong acid resistanceFast growthBacteriaAnimal feeding stuffMicrobiological cultureStain

The invention discloses a low-temperature-resistant lactobacillus strain which is lactobacillus plantarum CCZZ1, and an application thereof. The lactobacillus strain provided by the invention is collected at China General Microbiological Culture Collection Center with an address of Institute of Microbiology, Chinese Academy of Sciences, No.3, Court 1, West Beichen Road, Chaoyang District, Beijing. The strain has a collection number of CGMCC NO. 6078. A collection date is May 3rd, 2012. The lactobacillus strain provided by the invention is a Gram stain positive bacilli. The lactobacillus strain is glucose-homofermentative, and is acid-resisting. The strain has high growth speed and wide reproductive temperature range. With the strain, under a low-temperature or normal-temperature environment, silage fermentation quality can be substantially improved.

Owner:SOUTH CHINA AGRI UNIV

Plant lactobacillus strain and its application

InactiveCN1888051AImprove cleanlinessImprove adhesionBacteriaBacteria material medical ingredientsEscherichia coliStaphylococcus cohnii

The present invention discloses one plant lactobacillus strain and its application. The plant lactobacillus, Lactobacillus plantarum L323 CGMCC No. 1329, is separated from Chinese pregnant woman's vaginal secretion, and has relatively high bacteriotasis on common vaginal pathogens, such as staphylococcus aureus, candida albicans, colibacillus and vaginal Gardnar bacillus, and acid producing and H2O2 producing capacity higher than other lactobacillus. The plant lactobacillus, Lactobacillus plantarum L323 CGMCC No. 1329, may be used in preparing vaginal microbial preparation for preventing and / or treating vaginal infectious diseases.

Owner:TIANYOUDA BIO ENG SCI & TECH BEIJING +1

Natural yeast powder and preparation method therefore

ActiveCN102613265ADoes not interfere with flavorAdd flavorPre-baking dough treatmentBiotechnologyVitamin C

The invention discloses a natural yeast powder, which is prepared by the method comprising the following steps of: preparing a yeast solution soaking fruit, grains or plant flowers into honey, malt extract and purified water, and extracting the yeast solution of the fruit, grains or plant flowers containing saccharomyces cerevisiae strains and lactobacillus strains after placing; preparing yeast paste: kneading rye flour, the malt extract and the purified water into the yeast paste to be cultivated for four stages; cultivation of microzyme: combining the yeast solution with the yeast paste into wet cenobium for cultivation; enlarging cultivation of the microzyme: mixing the wet cenobium with an enlarging cultivation medium according to a certain ratio to carry out enlarging cultivation of the microzyme multiplying 100-10000 times, and preparing a mixed yeast solution; and concocting yeast powder: mixing dry substances such as glucose, alpha dry rice meal, vitamin C, corn starch, and cane sugar into the mixed yeast solution to finally obtain the natural yeast powder. The natural yeast powder is completely prepared by natural products, does not contain a preservative, and has the advantages of ageing resistance, anti-mildew and long retention period.

Owner:福建省麦都食品发展有限公司

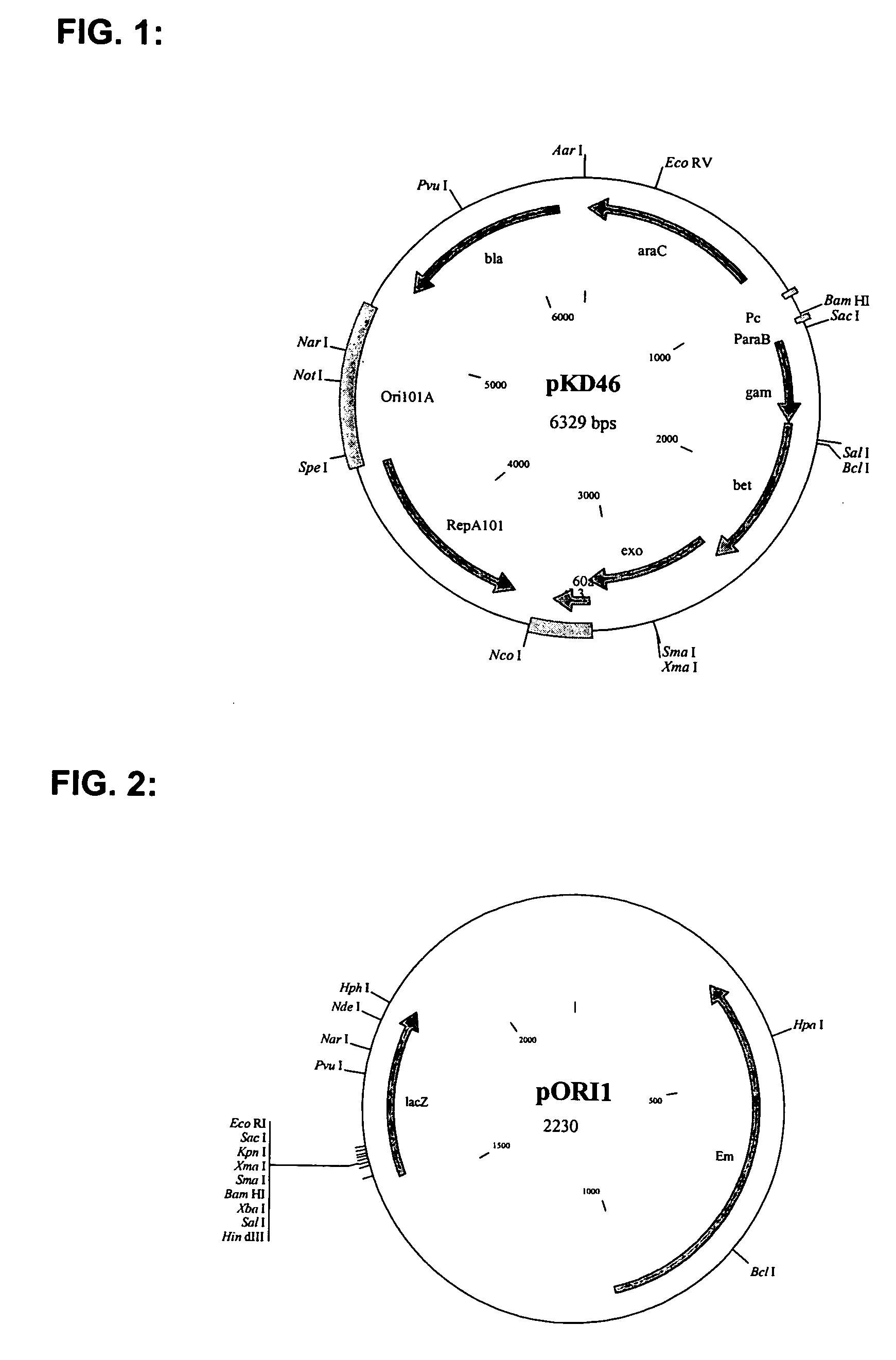

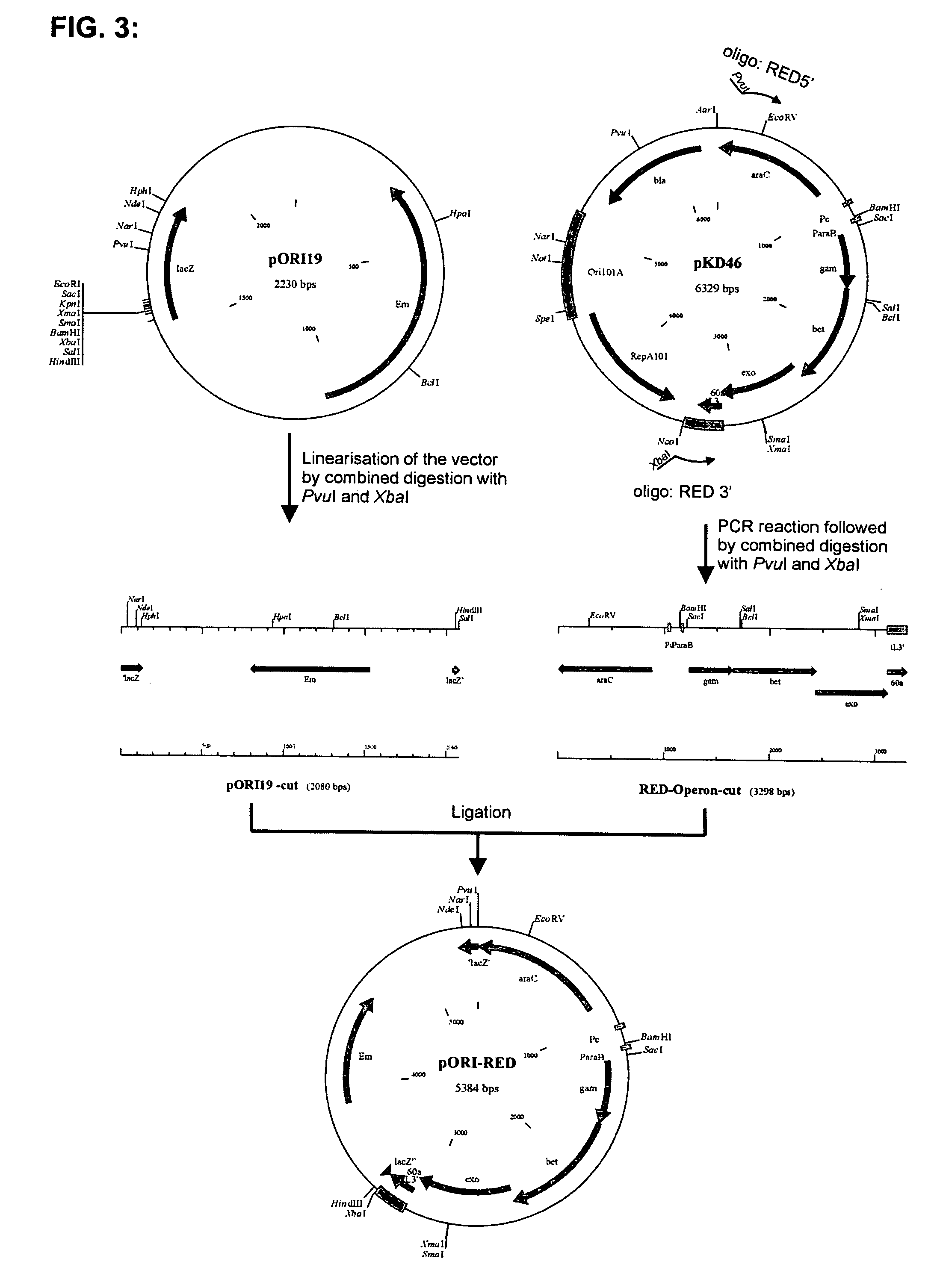

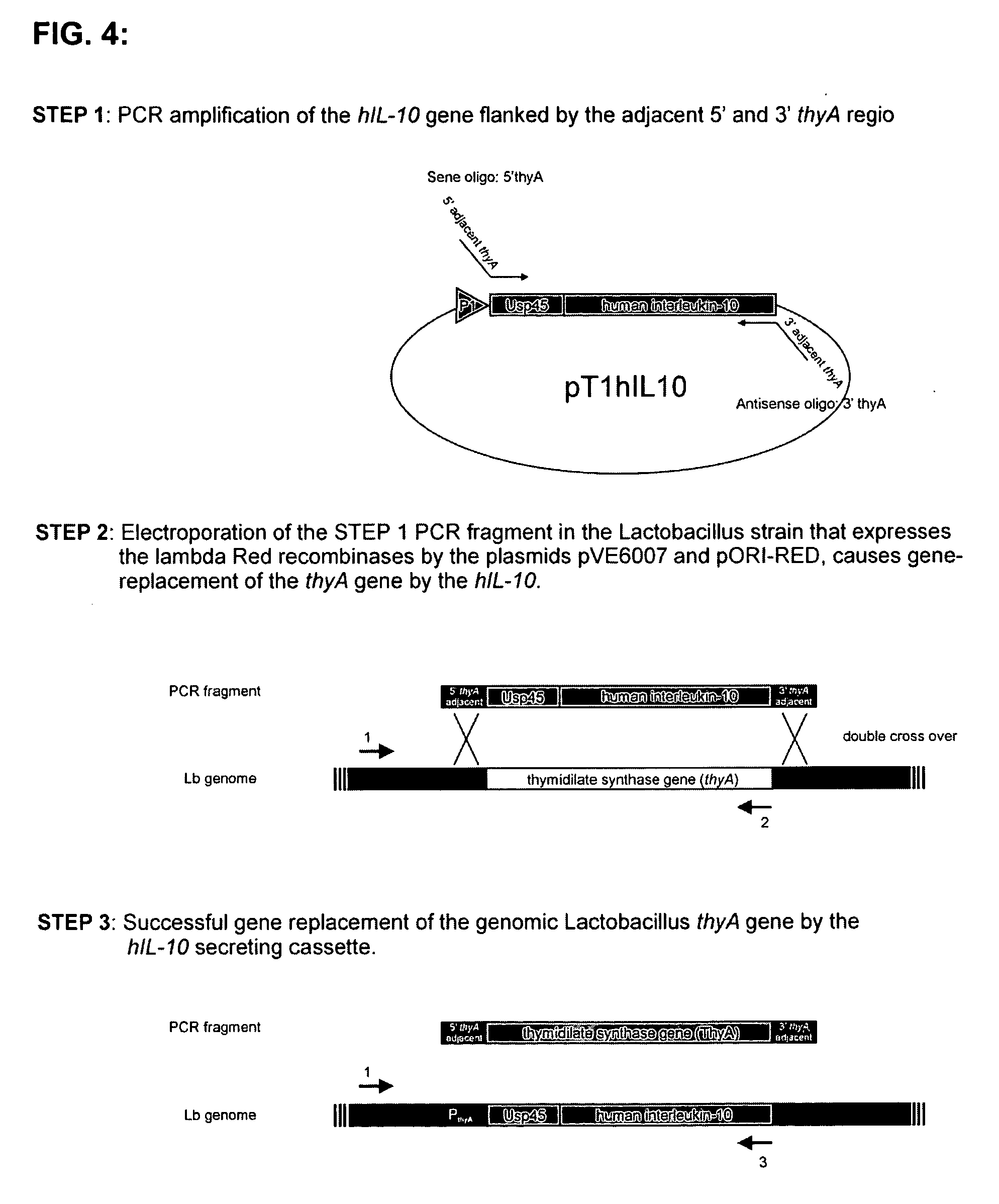

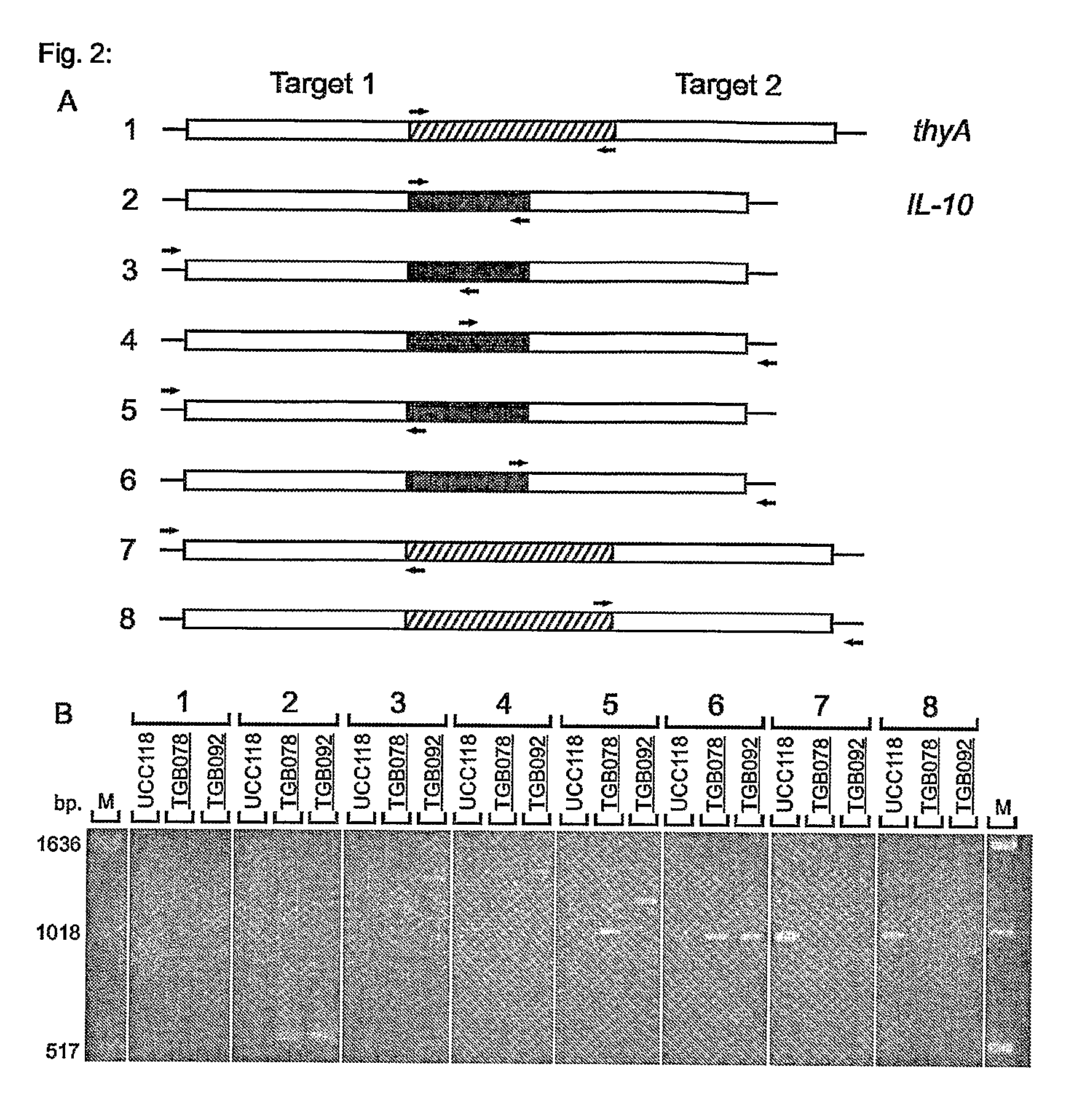

Self-containing lactobacillus strain

The invention relates to a recombinant Lactobacillus strain, with limited growth and viability in the environment. More particularly, it relates to a recombinant Lactobacillus that can only survive in a medium, where well-defined medium compounds, preferably thymidine or thymine, are present. A preferred embodiment is a Lactobacillus that may only survive in a host organism, where the medium compounds are present, but cannot survive outside the host organism in absence of the medium compounds. Moreover, the Lactobacillus strain can be transformed with prophylactic and / or therapeutic molecules and can, as such, be used to treat diseases such as, but not limited to, inflammatory bowel diseases.

Owner:VLAAMS INTERUNIVERSITAIR INST VOOR BIOTECHNOLOGIE VZW +1

Method for quick producing pickled Chinese cabbage by adding lactic acid strain

InactiveCN1537455AInhibition of growth and reproductionHas a fragranceFood preparationLactic acid bacteriumLiquid medium

A process for quickly preparing high-quality pickled Chinese cabbage includes such steps as preparing culture media, sterilizing, activating excellent lactobacillus strain, constant-temp culturing in ordinary liquid culture medium, culturing in another liquid medium to obtain bacterial liquid, loading the cleaned Chinese cabbage in a container, compressing, adding said bacterial liquid, edible salt and warm water, sealing and anaerobic fermenting for 10-15 days. Its advantages are delicious taste, high crispness and without destroy of nutrients.

Owner:郝欣欣

Method for preparing Rhodotorula benthica fermentation feed

InactiveCN101433275AImprove digestion and absorption rateHigh nutritional valueFood processingAnimal feeding stuffNutritive valuesMicrobial transformation

The invention relates to a method for preparing ocean rhodotorula fermentation feed. The method comprises the preparation of solid fermentation base stock of soybean meal, the mixing of a nutrition replenishing agent and the preparation of a solid fermentation medium. The feed is characterized in that ocean rhodotorula and a lactobacillus strain are inoculated in the solid fermentation medium and are subjected to solid fermentation to obtain the ocean rhodotorula fermentation feed. The method has the advantages: 1. macromolecular protein in the soybean meal is decomposed into small molecular peptide which improves the digestive absorption rate of the protein and further balances the composition of amino acid through microbial transformation; 2. the fermentation feed is replenished with astaxanthin and other biological active substances introduced by the metabolism of rhodotorula glutinis, thereby improving the nutritive value of the feed; 3. lactobacillus in the fermentation feed has positive function on improving a microecological flora of intestinal tracts of bred animal; and 4. the method has low fermentation cost, low fermentation condition and equipment requirement, simple operation of process flow and small investment and is suitable for small-scale production of breeding households and feed processing factories.

Owner:OCEAN UNIV OF CHINA

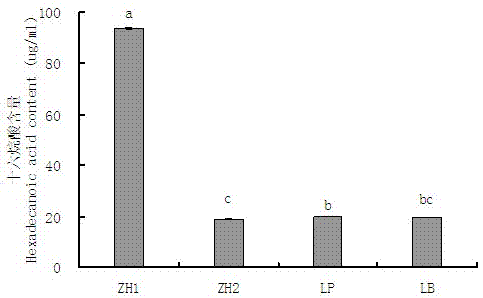

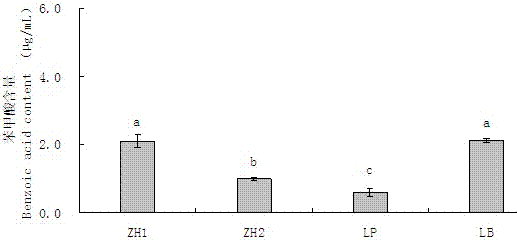

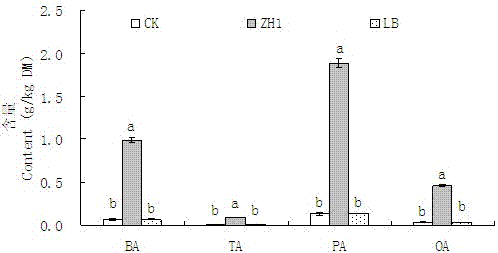

Lactobacillus strain lactobacillus parafarraginis ZH1 and application thereof

ActiveCN102851232AInhibition of aerobic deteriorationLow costBacteriaAnimal feeding stuffBiotechnologyBenzoic acid

The invention discloses a lactobacillus strain which is lactobacillus parafarraginis ZH1, and an application thereof. The lactobacillus strain provided by the invention is collected at China General Microbiological Culture Collection Center with an address of Institute of Microbiology, Chinese Academy of Sciences, No.3, Court 1, West Beichen Road, Chaoyang District, Beijing. The strain has a collection number of CGMCC NO.6079. A collection date is May 3rd, 2012. The lactobacillus strain provided by the invention is a Gram stain positive bacilli. The lactobacillus strain is glucose-heterofermentative, and is acid-resisting. The strain has high growth speed and wide reproductive temperature range. The strain has high yield of benzoic acid and palmitic acid. With the strain, silage fermentation aerobic deterioration can be substantially inhibited.

Owner:SOUTH CHINA AGRI UNIV

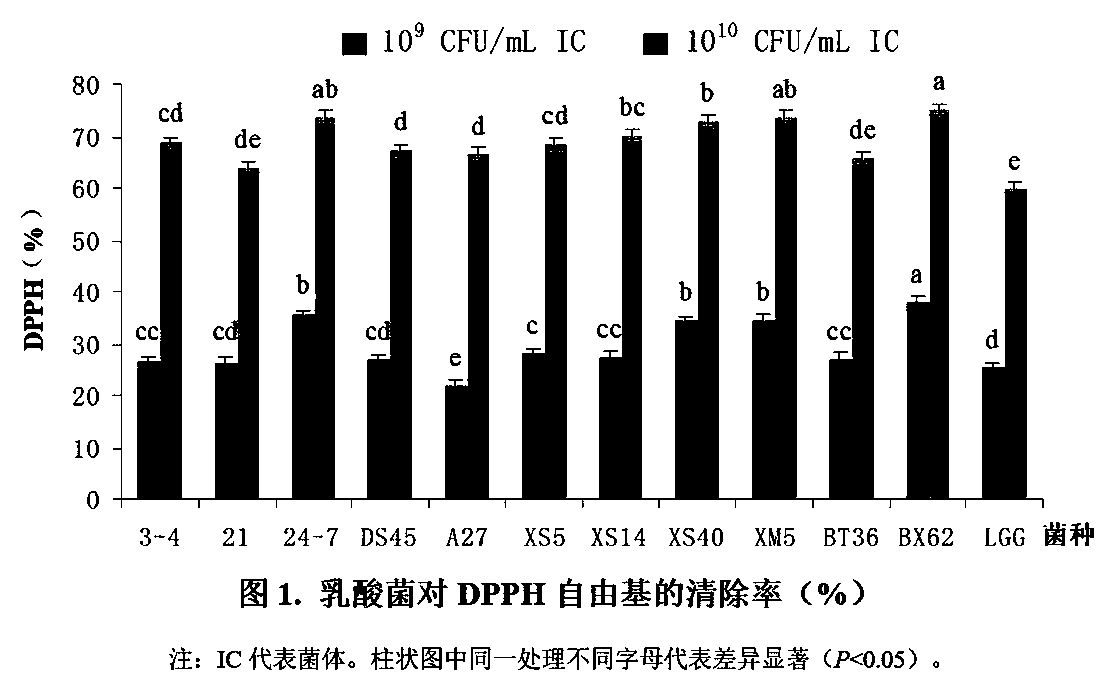

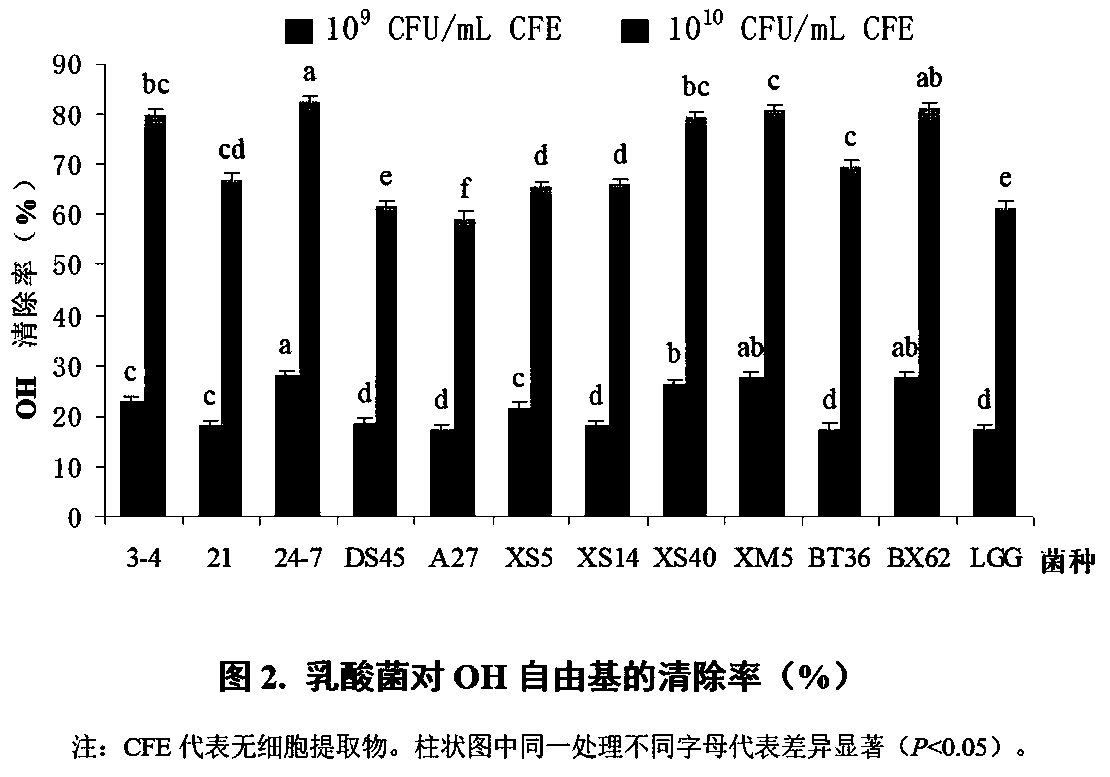

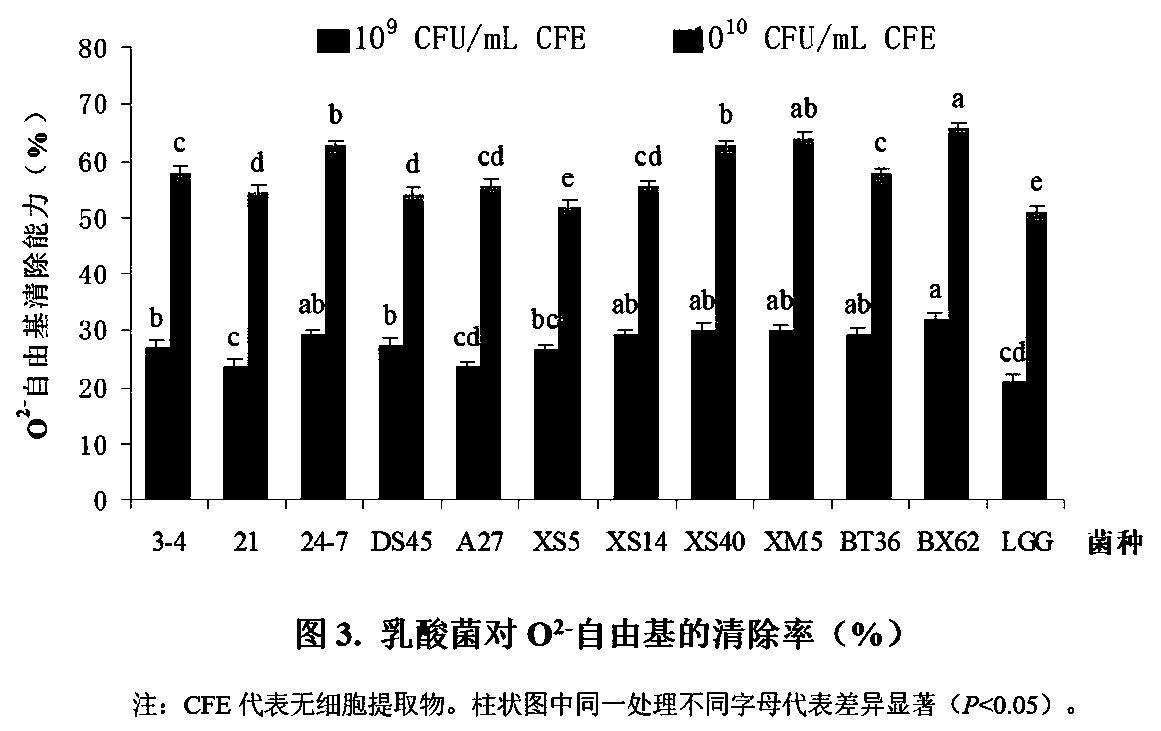

Lactobacillus plantarum with oxidation resistance and application thereof

ActiveCN109182162AGood probiotic propertiesAvoid damageCosmetic preparationsMilk preparationIntestinal wallsSide effect

The invention discloses lactobacillus plantarum with oxidation resistance and preservation number of CGMCC15780, and application of the lactobacillus plantarum. The lactobacillus plantarum is a lactobacillus strain with high oxidation resistance, which is screened from traditional fermented yak yogurt and silage in the Qinghai-Tibet Plateau. In vivo and in vitro tests prove that the lactobacillusplantarum has relatively good oxidation resistance, and can be used for effectively promoting increase of the activity of antioxidative enzyme in a body. The lactobacillus plantarum having relativelygood hydrophobic performance can increase the opportunity of adhering to the intestinal walls and achieving the probiotic effect, does not have toxic or side effect, and can be used as health-protecting foods or medicines to enhance the body immunity, relieve senescence, beautify, regulate intestinal flora and the like.

Owner:哈尔滨美华生物技术股份有限公司

Novel lactobacillus strains and uses thereof

ActiveUS20070148149A1Suitable for productionImprove microbiomeAntibacterial agentsMilk preparationHelicobacter pyloriBiology

The invention concerns new isolated Lactobacillus cells, which are capable to aggregate Helicobacter pylori under culture conditions of the human digestive tract, in particular of the stomach, and to the uses of such cells.

Owner:NOVOZYMES AS

Method for preparing environment-friendly enzymes by food waste

InactiveCN105671086ANo irritating smellEasy to manufactureNon-surface-active detergent compositionsFermentationContinuous fermentationEnvironmental resistance

The invention discloses a method for preparing environment-friendly enzymes by food waste. The method comprises the following concrete steps of 1, picking fresh food waste such as fruit peels and leftovers, and performing decontamination cleaning treatment; 2, crushing the processed food waste into dices or slices; 3, uniformly mixing the crushed food waste, putting the mixture into a fermentation container, and adding pure water, wherein the weight ratio o the food waste to the pure water is 1:3; 4, after the fermentation for one week, opening the container for gas exhausting; performing stirring; closing a container opening after no gas exists after the uniform stirring; 5, after the fermentation for 10 to 15 days, adding lactobacillus strains accounting for 10 to 15 percent of the food waste for continuous fermentation; 6, after the fermentation for 20 to 25 days, adding brown sugar accounting for 15 percent of the weight of the food waste for continuous fermentation for one week; 7, filtering, filling, sealing and storing the fermented environment-friendly enzymes. The method has the advantages that the preparation process is simple; the preparation materials can be easy obtained; the garbage quantity can be obviously reduced; the social garbage treatment load and cost can be reduced; the prepared environment-friendly enzymes do not have pungent smell, have ultra-strong decontamination capability and belong to a good helper for cleaning work in the life.

Owner:SHANGQIUYINZHIJIANFOODCO LTD

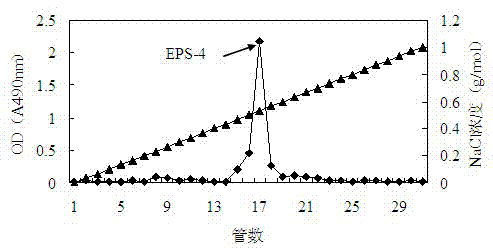

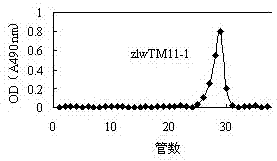

Exopolysaccharide lactobacillus for improving fermented milk viscosity and application thereof

The invention discloses exopolysaccharide lactobacillus for improving fermented milk viscosity and an application thereof, and belongs to the field of processing of dairy products. The exopolysaccharide lactobacillus strain provided by the invention is a streptococcus thermophilus ZLW-TM11 strain, and preserved at the China General Microbiological Culture Collection Center; the preservation number is CGMCC No.3819; the preservation date is May 7, 2010. The exopolysaccharide content of the strain provided by the invention is about 43 mg / L; the viscosity of the single-bacteria fermented milk is 7716 mPa / s; the exopolysaccharide lactobacillus can be applied to yogurt as a yoghurt starter, so as to improve the quality of the yoghurt. A direct vat starter culture prepared by using the exopolysaccharide lactobacillus ZLW-TM11 for improving fermented milk viscosity is applied to the fermented milk, and can be mixed with any strain or direct vet starter culture for the fermented milk, so that the original acid production rate and flavor of the fermented product are not changed; the exopolysaccharide content in the prepared product can be up to 40-45 mg / L. Thus, the product has good vicidity, and is free of thickeners such as gelatin and the like.

Owner:HARBIN INST OF TECH

Feed additive, preparation method and application of feed additive

InactiveCN103843972AIncrease profitHigh nutritional valueBacteriaFood processingFood additiveNutrition

The invention discloses a feed additive, a preparation method and application of the feed additive. The preparation method of the feed additive comprises the steps of transferring activated lactobacillus strains to a sterilized MRS culture medium from glycerinum for culture to obtain a seed solution; carrying out primary and secondary enlarged cultivation on the seed solution in the MRS culture medium, inoculating into the sterilized solid culture medium for solid feed fermentation through an intermittent oxygen-introduction facultative anaerobic fermentation mode, and drying to obtain the feed additive. According to the preparation method of the feed additive, lactobacillus fermented soybean meal, bran, rice bran, straw, cottonseed cake, corncob powder, bagasse and other agricultural wastes are utilized for effectively reducing the antinutritional factor level in the raw materials, and the nutrition utilization rate is increased; the prepared feed additive is rich in antimicrobial peptide and other prebiotic substances secreted by lactobacillus through fermentation and metabolic processes, thereby having a prebiotic function and being healthy. The feed additive can be applied to an animal feed.

Owner:GUANGZHOU YOURUI BIOSCI

Method for preparing lysine-rich fermented soybean meal

ActiveCN102763769AAddress nutrient contentSolve two key problems to make up for the lack of lysine in fermented soybean mealFood processingAnimal feeding stuffBrevibacillus borstelensisSaccharomyces

The invention discloses a method for preparing lysine-rich fermented soybean meal, which is simple and can effectively improve the content of nutrients of the soybean meal. The method is technically characterized by comprising the following steps: (1) preparing strains: a, inoculating the brevibacterium flavum into the brevibacterium flavum liquid culture medium, and vibrating and culturing at 28-37 DEG C to obtain the first-level brevibacterium flavum strain when the OD590 value of the brevibacterium flavum liquid is 0.25-0.30; b, the inoculating the saccharomycetes into the saccharomycetes liquid culture medium, and vibrating and culturing at 28-37 DEG C to obtain the first-level saccharomycetes strain when the OD590 value of the saccharomycetes liquid is 0.25-0.30; and c, inoculating the lactobacillus into the lactobacillus liquid culture medium, and vibrating and culturing at 30-37 DEG C to obtain the first-level lactobacillus strain when the OD590 value of the lactobacillus liquid is 0.25-0.30; (2) preparing a fermentation substrate; and (3) inoculating the fermentation substrate. The method for preparing the lysine-rich fermented soybean meal belongs to the technical field of feed preparation.

Owner:广东希普生物科技股份有限公司

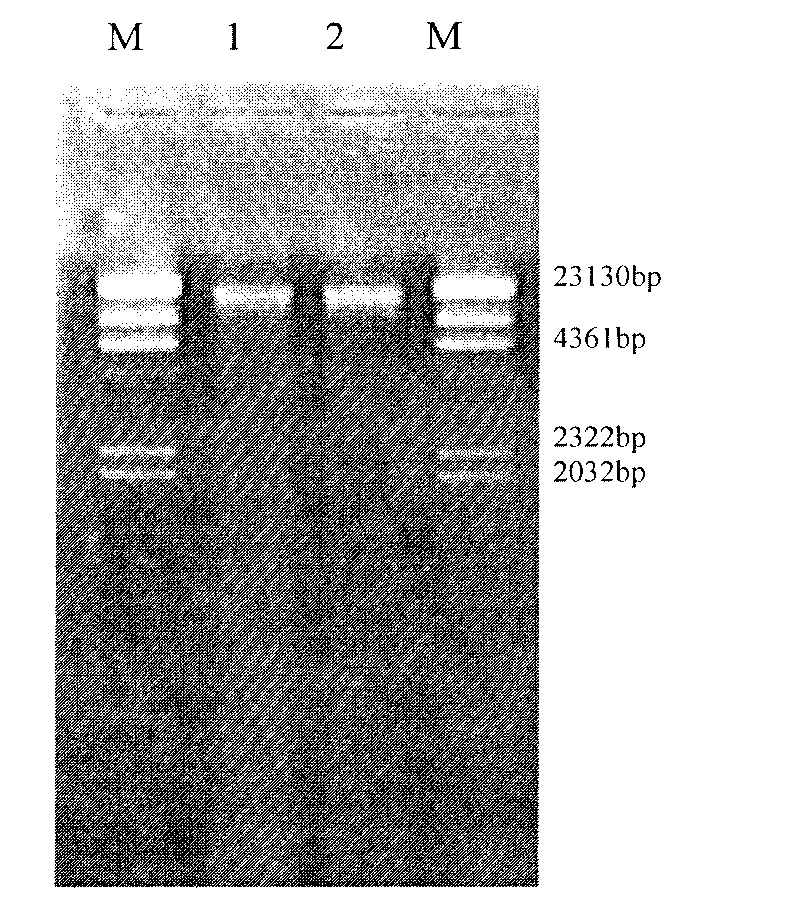

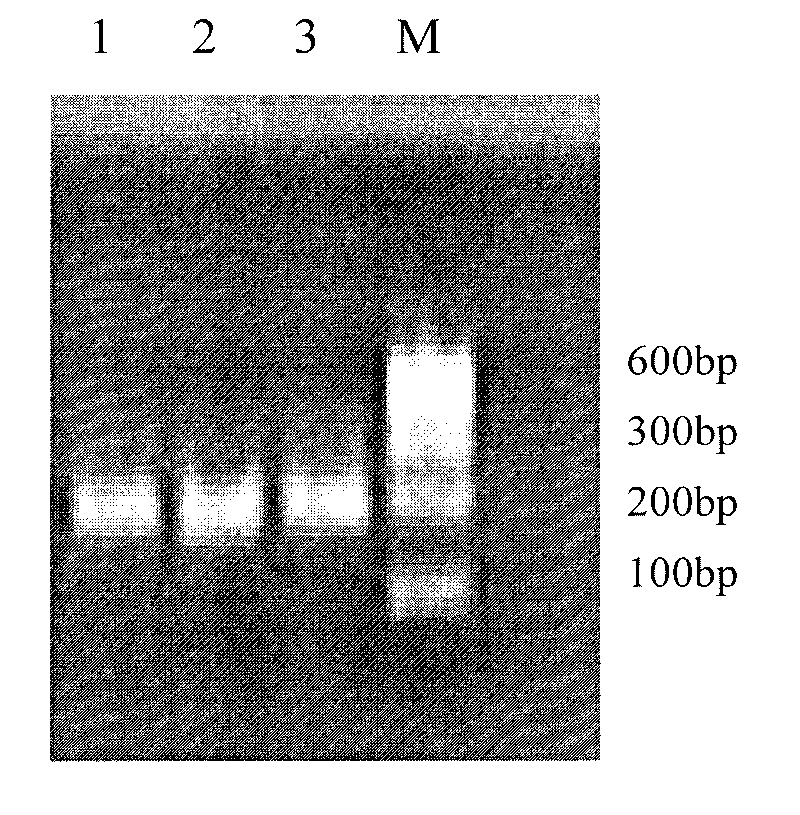

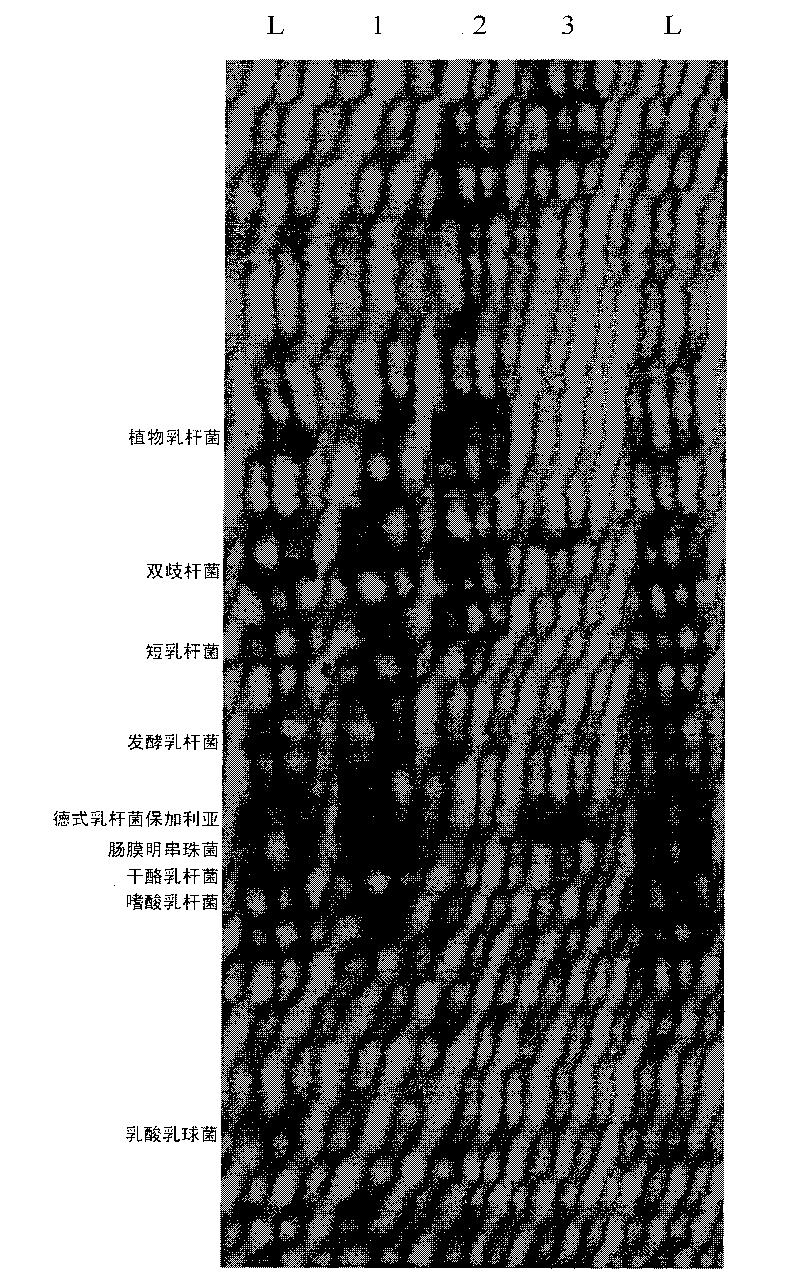

Method for rapidly detecting kinds of lactobacillus in fermented dairy product

InactiveCN101717828AEasy to detectImprove quality supervisionMicrobiological testing/measurementGel electrophoresisBiology

The invention relates to a method for rapidly detecting the kinds of lactobacillus in a fermented dairy product. In the method, a method combing a polymerase chain reaction technique with a denatured gradient gel electrophoresis technique is applied; the existence of lactobacillus strains is determined by amplifying a lactic acid 16S rDNA V3 variable region and analyzing a polyacrylamide gel electrophoresis pattern so as to rapidly finish the detection of the kinds of lactobacillus in the fermented dairy product in two workdays.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

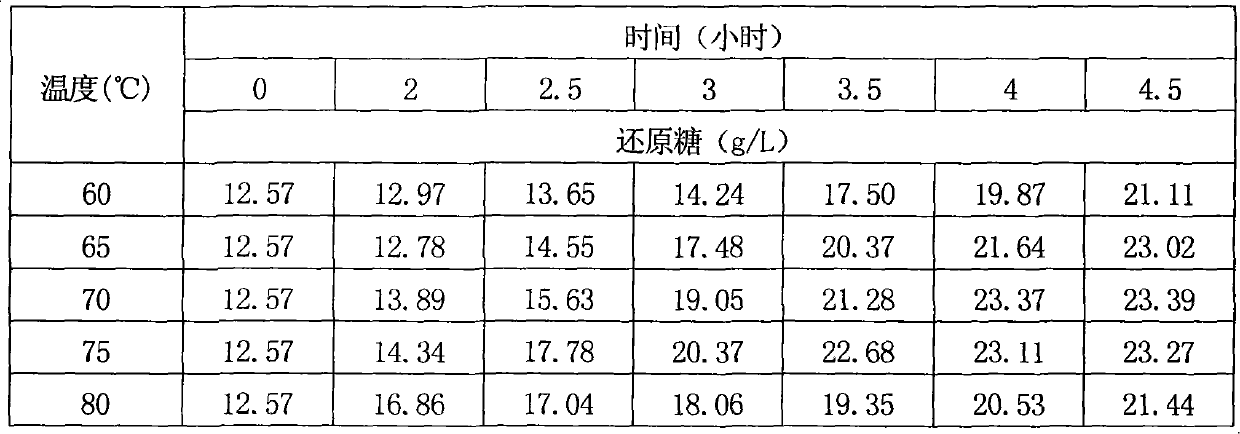

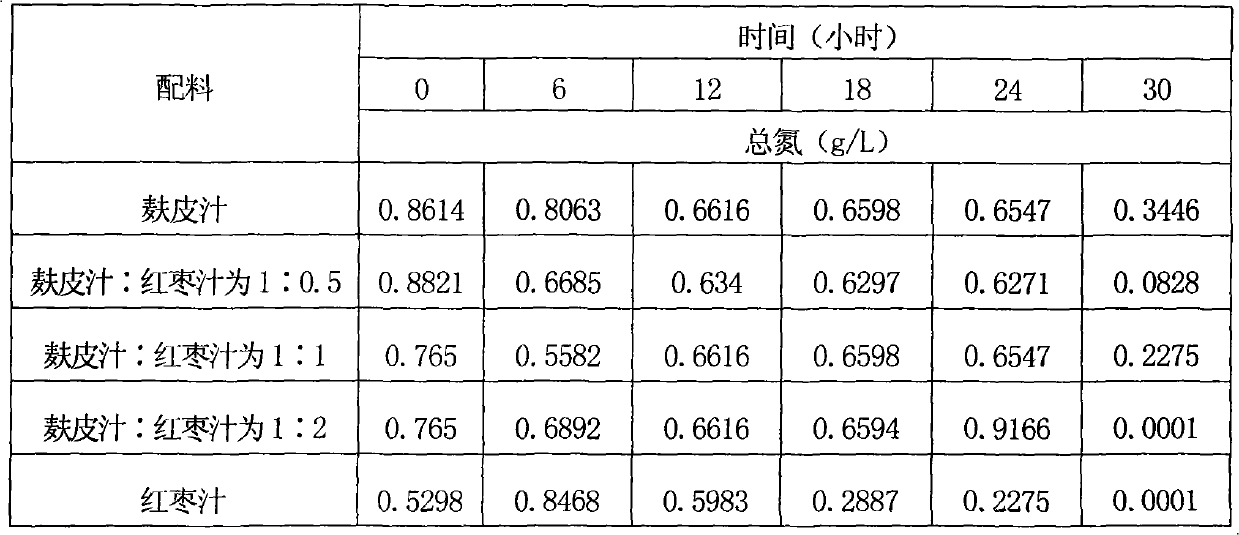

Bran and red jujube juice lactic acid fermentation beverage and preparation method thereof

InactiveCN101946933AImprove palatabilityPromote digestion and absorptionFood preparationSolubilityGlycerol

The invention relates to a bran and red jujube juice lactic acid fermentation beverage prepared from the following raw materials in percentage by weight: 59%-65% of bran juice, 29%-34% of red jujube juice, 1.5%-2.5% of protein sugar, 1.2%-1.8% of sodium chloride, 0.2%-0.6% of glycerol and 2%-5% of lactobacillus strains liquid, wherein the bran juice contains 4.1% of soluble solid matters; and thered jujube juice contains 7% of the soluble solid matters. The bran and red jujube juice lactic acid fermentation beverage produced by enabling sweet and palatable red jujubes to be compatible with bran has very good palatability; meanwhile, the red jujube juice which is easy to culture microbes is added and the solubility of certain effective components contained in the bran is enhanced through lactic acid fermentation, thus the bran and red jujube juice lactic acid fermentation beverage is easier to digest and absorb; and in addition, the bran and red jujube juice lactic acid fermentation beverage is detected to have the reducing sugar content of 4.77 g / L, the lactic acid content of 1.51 g / L, the total nitrogen content of 0.31 g / L, a physicochemical index and a microbial index both achieving the GB19297-2003 'fruit and vegetable juice beverage' hygienic standard, thereby being used as a beverage.

Owner:SHAANXI NORMAL UNIV

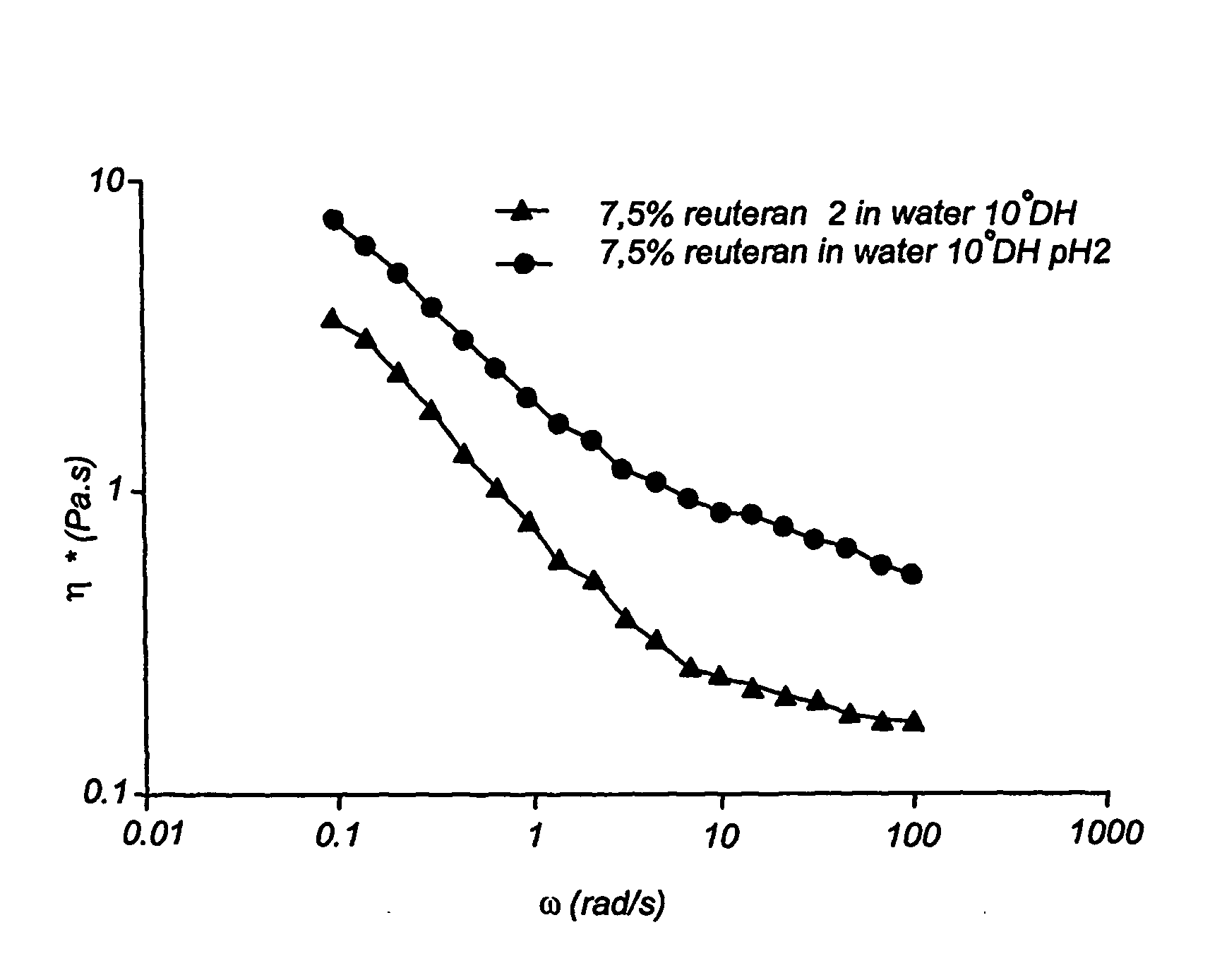

Branched alpha-glucans for weight management

Highly branched α-glucan having an average molar weight of at least 105 Da can be used for inducing or enhancing satiety and / or satiation in humans or animals by incorporation of the α-glucan into a liquid nutritional or pharmaceutical composition, preferably together with a food protein. The α-glucan induces a viscosity increase upon lowering the pH. The degree of branching of the α-glucan is at least 8%. Such α-glucans can be obtained e.g. by fermentation of lactobacillus strains having glucosyltransferase activity on a sucrose substrate.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

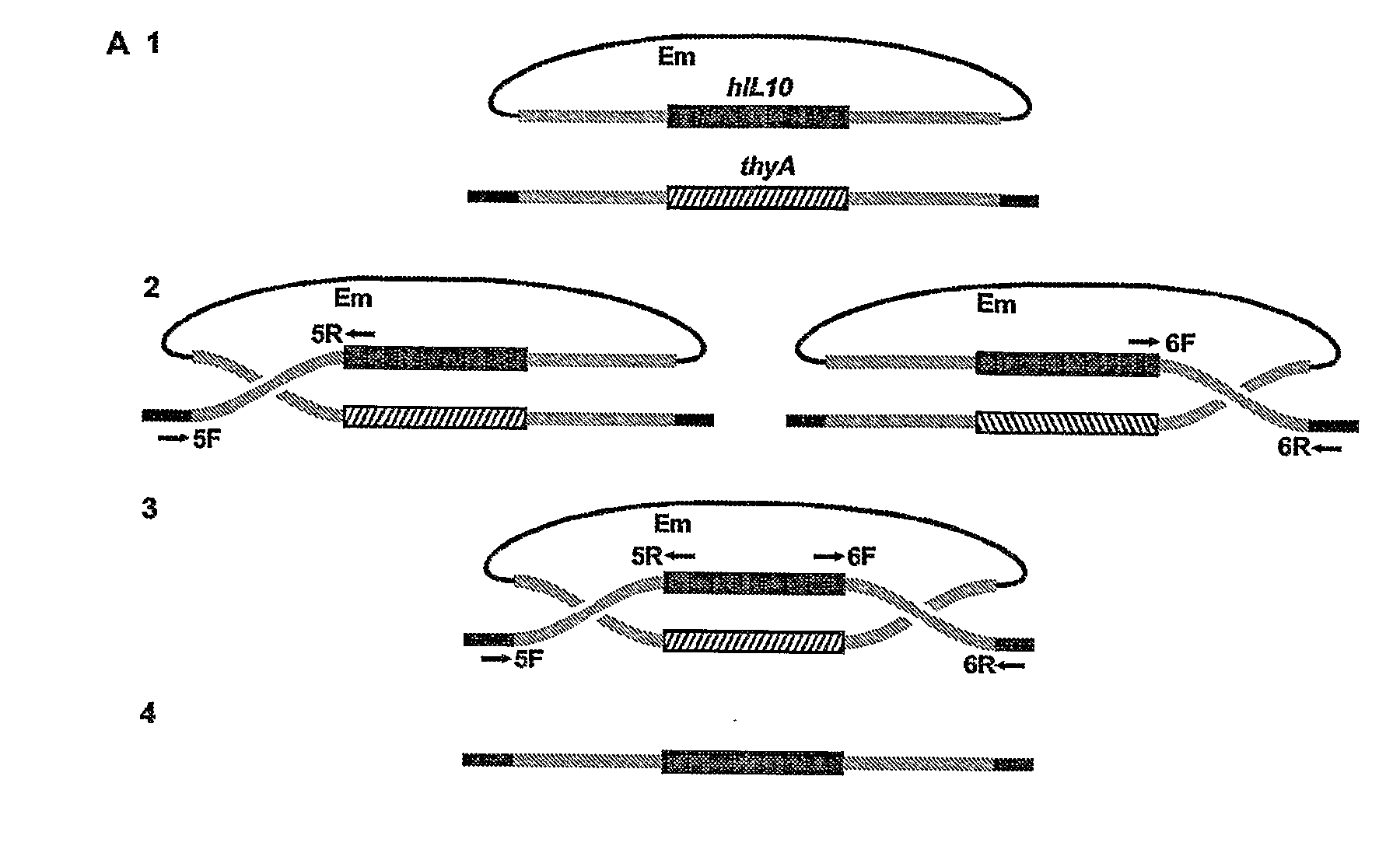

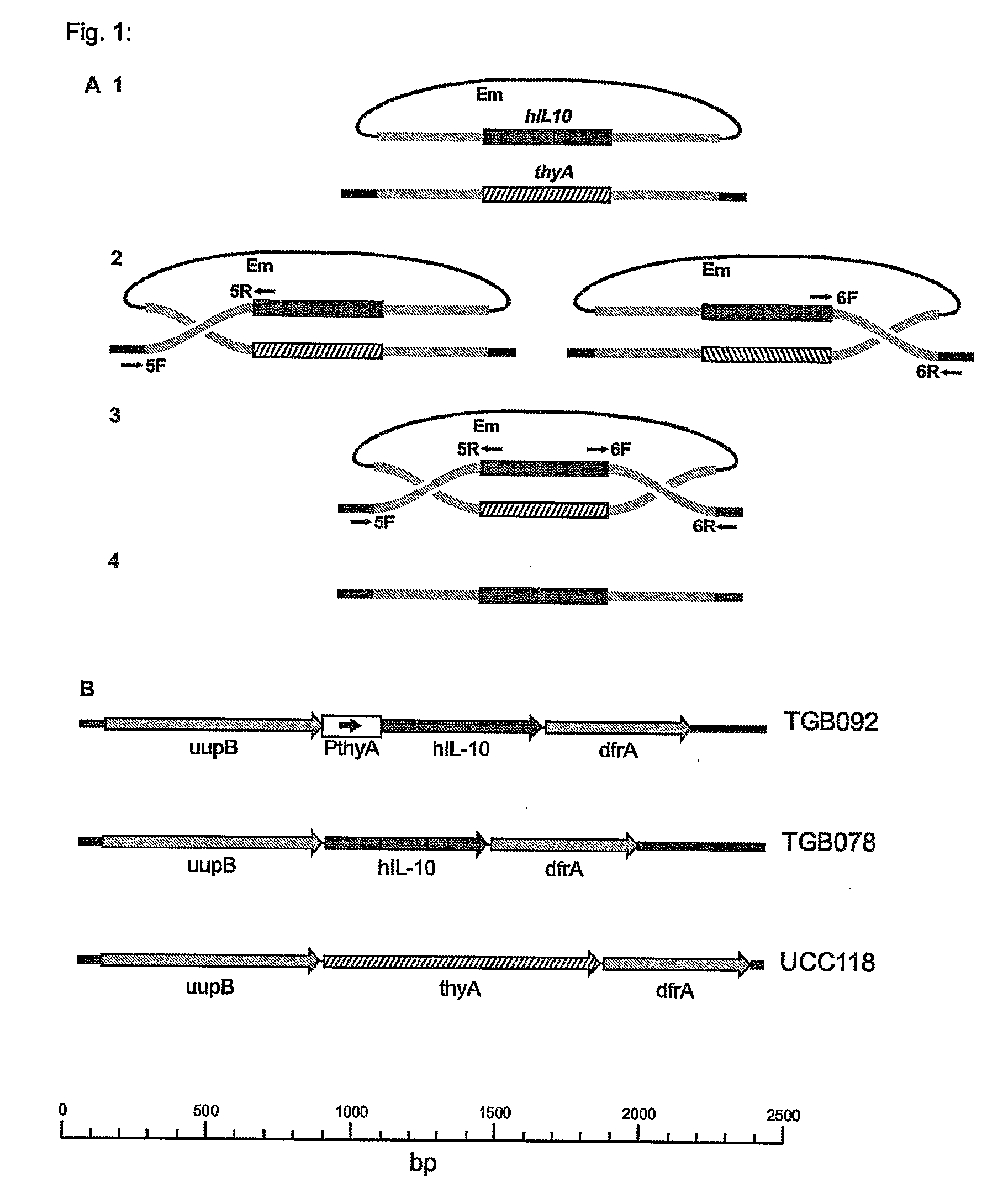

Self-Containing Lactobacillus Strain

InactiveUS20080253990A1Enhanced inhibitory effectBiocideBacteriaInflammatory bowel diseaseHost organism

The invention relates to a recombinant Lactobacillus strain, with limited growth and viability in the environment. More particularly, it relates to a recombinant Lactobacillus that can only survive in a medium where thymidine is present. By this strict dependency upon thymidine, thymidineless death is rapidly induced in this recombinant strain. A preferred embodiment is a Lactobacillus that may only survive in a host organism where thymidine is present, but cannot survive outside the host organism in absence of this medium compound. Moreover, the Lactobacillus strain can be transformed with prophylactic and / or therapeutic molecules and can, as such, be used to treat diseases such as, but not limited to, inflammatory bowel diseases.

Owner:UNIV COLLAGE COOK

Processing method of enzyme stoste

InactiveCN106235320ARegulate nutritional balancePurify the environmentFood scienceAlcohol contentSugar

The invention discloses a processing method of enzyme stoste. The processing method includes following steps: (1), weighing raw materials; (2), cleaning the raw materials, naturally air-drying, and slicing; (3), adding 16 parts of traditional brown sugar, stirring well, pouring into a 304 stainless steel vat or a porcelain vat, adding 0.1 part of saccharomycetes culture liquid after amplified culture, stirring well, and primarily fermenting for 6 months; (4), using a filtering machine to filter the raw materials obtained in the step (3) to remove impurities to obtain liquid, sequentially adding 0.1 part of acetic bacteria culture liquid after amplified culture and 1.5 parts of isomalto-oligosaccharide into the liquid to increase sugar content to 40%, and secondarily fermenting at temperature of 32 DEG C for 3 months; (5), detecting alcohol content of liquid obtained in the step (4), adding a lactobacillus strain, and fermenting at temperature of 34 DEG C for the third time; (6), sealing for static fermentation for more than 1 month. The processing method is scientific and reasonable in material selection and proportioning and simple and convenient in preparation process.

Owner:黄玉捷

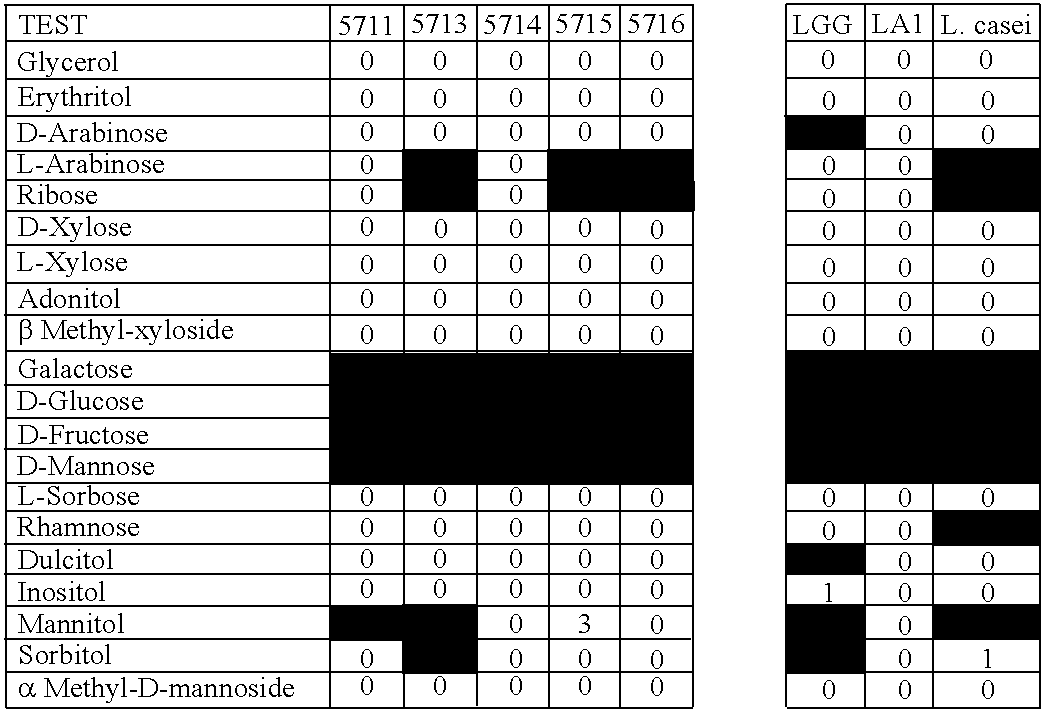

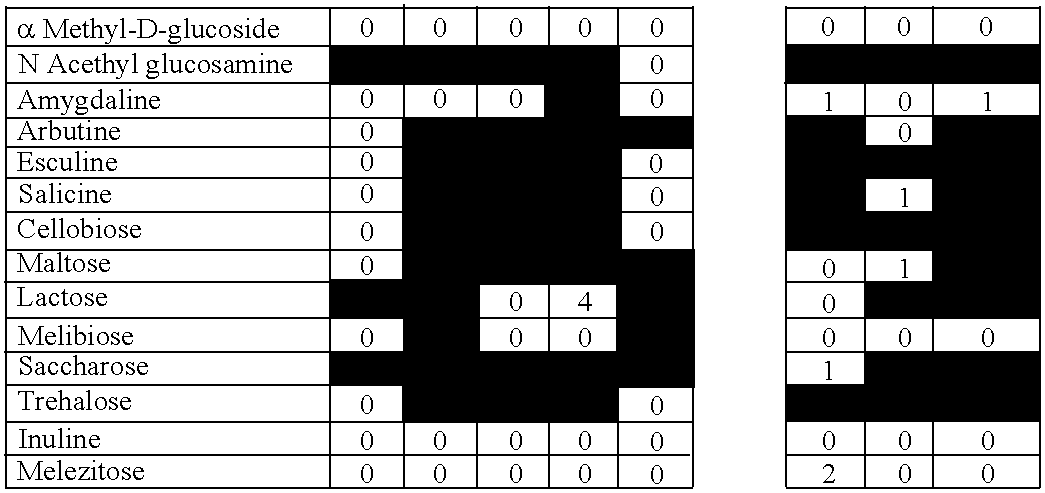

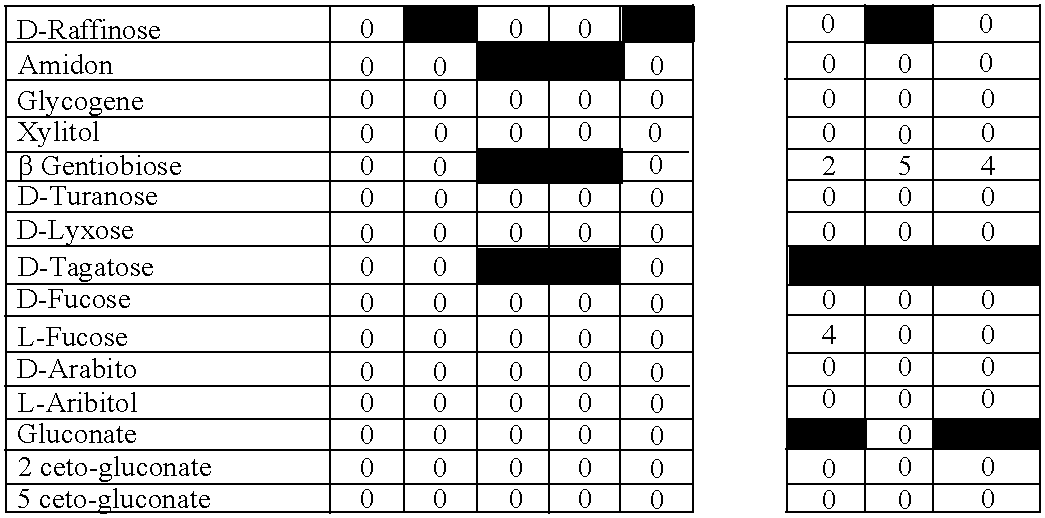

Probiotic strains, a process for the selection of them, compositions thereof, and their use

ActiveUS20050244392A1Antibacterial agentsNervous disorderLactobacillus fermentumLactobacillus salivarius

The present invention relates to a novel process for the selection of new probiotic strains which comprises the following steps: a) selecting for non-pathogenic strains which are capable of surviving in breast milk and / or amniotic fluid, and b) selecting for non-pathogenic strains which are able to be transferred to breast milk and / or amniotic fluid after oral intake in healthy individuals without colonizing other internal organs except mucousas. The invention also provides new Lactobacillus strains, which are: CECT5711 (Lactobacillus coryniformis), CECT5713 (Lactobacillus salivarius subsp. salivarius), CECT5714: (Lactobacillus gasseri, formerly L. acidophilus), CETC5715: (Lactobacillus gassen), and CECT5716: (Lactobacillus fermentum); and refers to their use for the prophylaxis or treatment against digestive, infective, neuro-degenerative and immune related diseases such as allergies or inflammatory diseases.

Owner:BIOSEARCH SA

Lactobacillus strain and application thereof

ActiveCN103173384ANo harmCompliance with Biosafety RegulationsBacteriaMicroorganism based processesMicroorganismFeces

The invention discloses a lactobacillus strain and application thereof. The lactobacillus CGMCC6495 is separated from pickled vegetable wastewater and stored in a common microorganism center of China Committee for Culture Collection of Microorganisms with the collection date of September 3, 2012 and the collection number of CGMCC No.6495. The strain can be applied to biological deodorization of excrement through the conventional activation culture and enlargement fermentation cultivation; the lactobacillus CGMCC 6495 can be used as a single strain for in-situ deodorization of the human excrement, so that the deodorization effect is stable and the temperature influence is small. Under the normal-temperature condition, the lactobacillus strain has a better deodorization effect in both a laboratory environment and a public toilet site environment.

Owner:杨凌未来中科环保科技有限公司

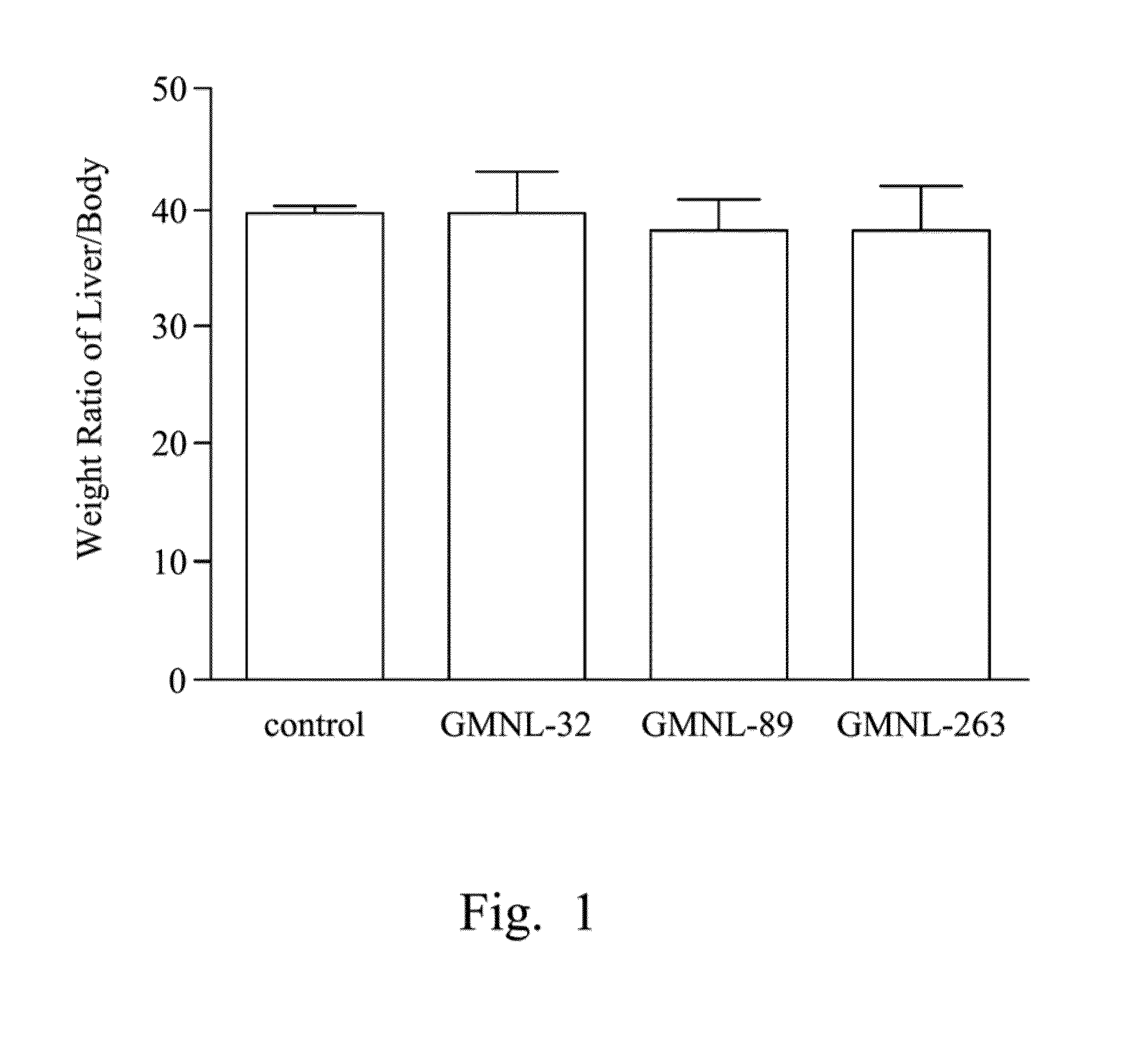

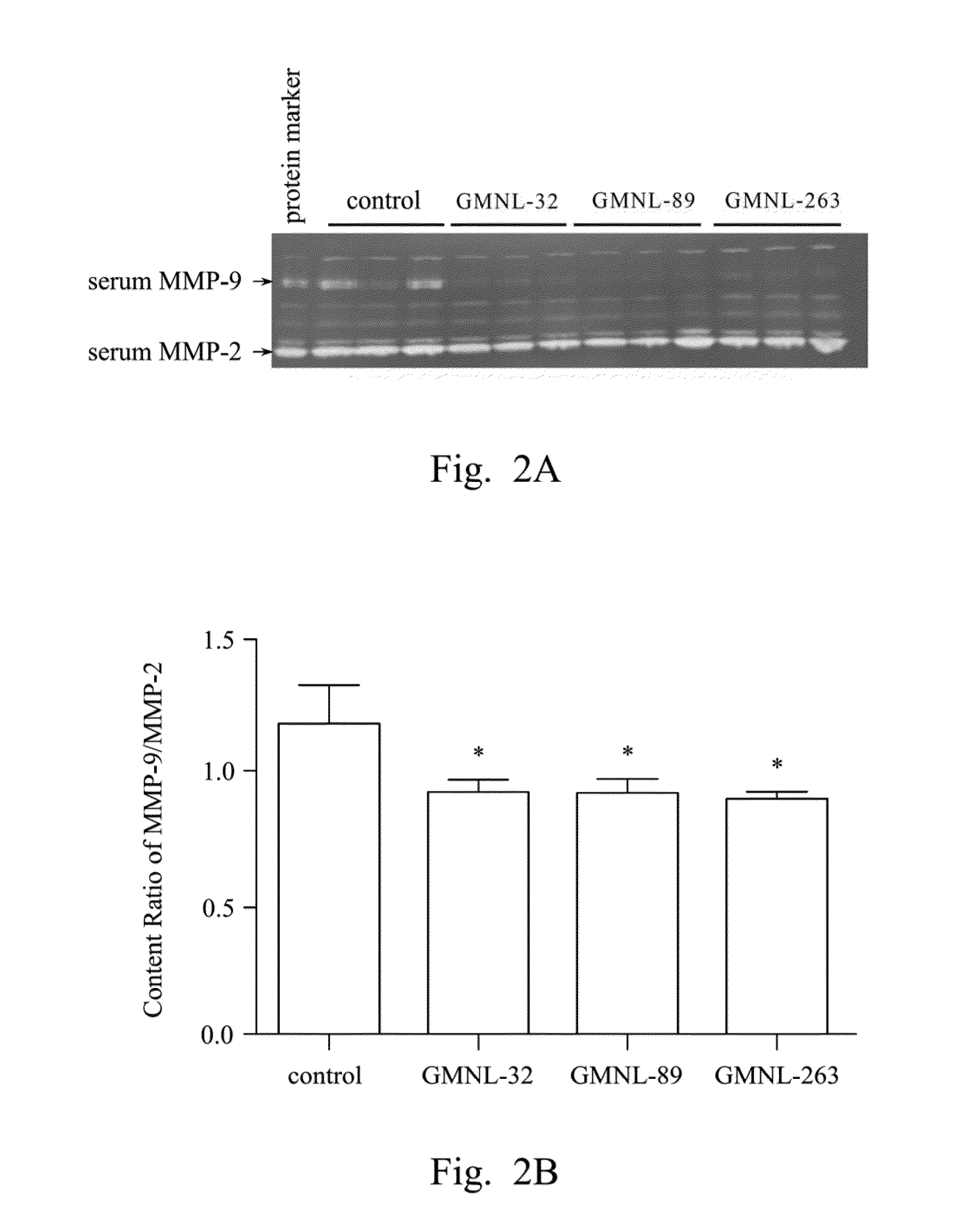

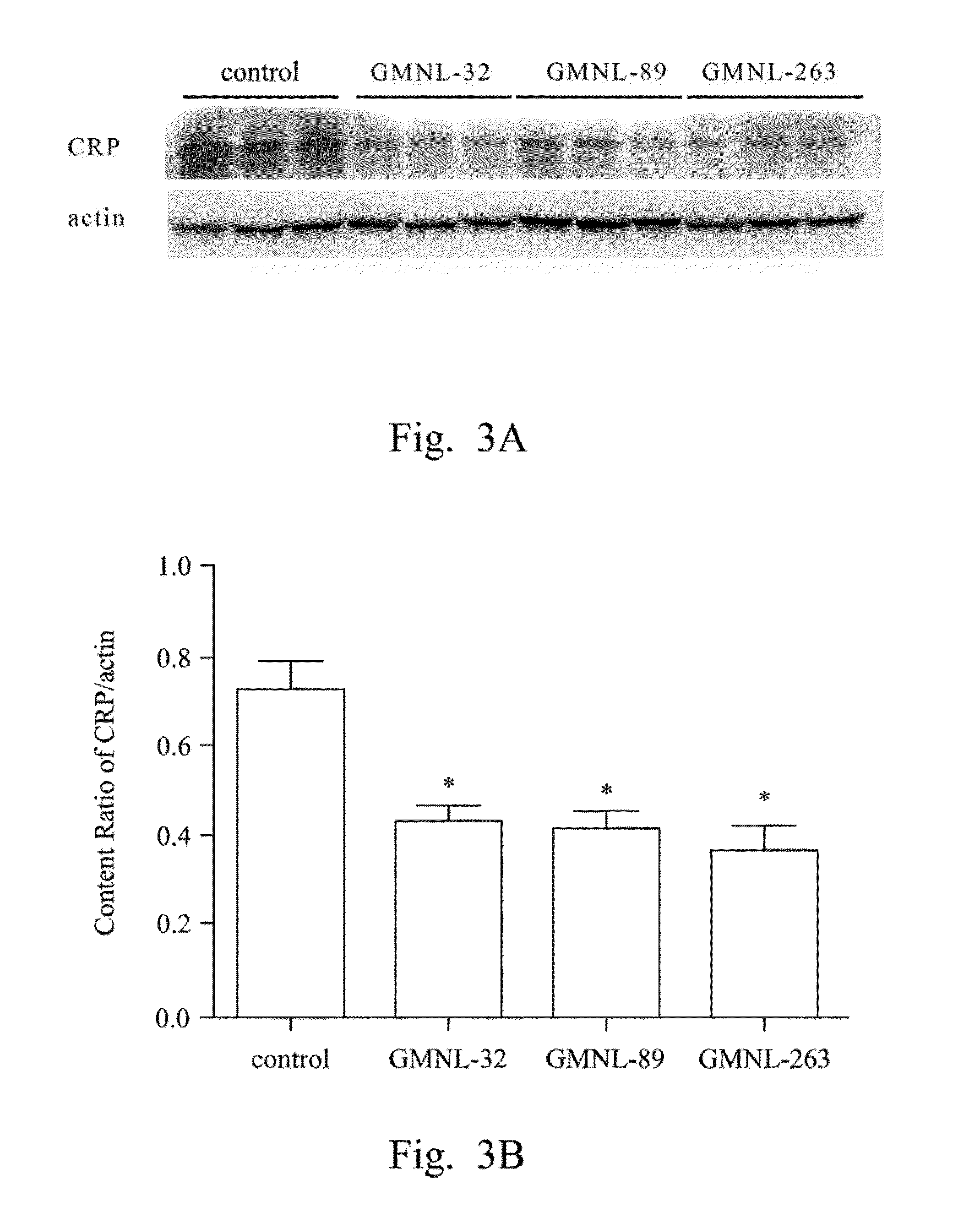

Lactobacillus strain, composition and use thereof for treating syndromes and related complications of autoimmune diseases

The present invention is related to a Lactobacillus strain, composition and use thereof for treating autoimmune disease and related complications. The composition comprises at least one isolate of Lactobacillus paracasei strain GMNL-32, L. reuteri strain GMNL-89 or L. reuteri strain GMNL-263, and a pharmaceutical carrier, for treating syndromes and related complications of the autoimmune diseases.

Owner:GENMONT BIOTECH

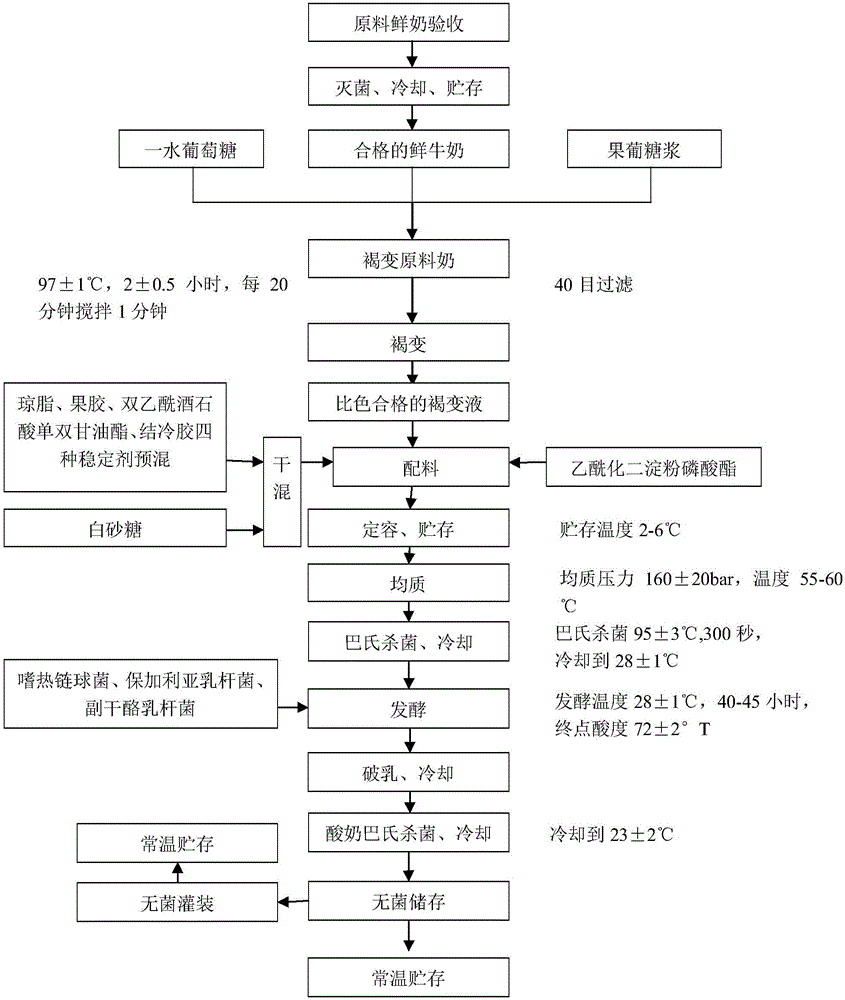

Normal-temperature brown yoghurt and manufacturing method thereof

InactiveCN106259928AWith room temperature shelf lifeHas a burnt flavorMilk preparationMilk preservationDextrose MonohydrateBiotechnology

The invention discloses normal-temperature brown yoghurt and a manufacturing method thereof. The normal-temperature brown yoghurt is prepared from fresh milk, dextrose monohydrate, a compound stabilizer, acetylated distarch phosphate, white granulated sugar and lactobacillus strains, wherein compound strains added proportionally according to activity include streptococcus thermophilus, lactobacillus bulgaricus and lactobacillus paracasei. The method includes steps: controlling quality of fresh cow milk, preparing browning material milk, matching materials, browning, cooling, adding the compound stabilizer and the white granulated sugar, premixing, performing dry mixing, adding the acetylated distarch phosphate, pasteurizing, performing ultralow-temperature ultralong-time inoculated fermentation, matching the strains, inoculating, fermenting, demulsifying, cooling, sterilizing, cooling, filling and storing. By means of ultralow-temperature ultralong-time inoculated fermentation, the problem of normal-temperature storage and transport of the brown yoghurt is solved while problems of quality and flavor of the normal-temperature yoghurt are solved as well. By improvement of technical formulations and processes of conventional yoghurt, high freshness and long shelf lives of products are achieved, and application to the technical field of dairy products is realized.

Owner:辽宁辉山生物科技研究有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com