Exopolysaccharide lactobacillus for improving fermented milk viscosity and application thereof

An extracellular polysaccharide, fermented milk technology, applied in the application, bacteria, dairy products and other directions, can solve the problems of not being used by consumers, low viscosity, thin product texture, etc., to improve the quality of yogurt and solve the effect of low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Strain acquisition:

[0025] The lactic acid bacteria ZLW-TM11 in the present invention is isolated from collected traditional fermented milk, and the strains of lactic acid bacteria with good fermented flavor isolated and screened from traditional fermented milk are respectively inserted into 12% reduced skim milk, After fermentation to pH 4.6, each fermented milk sample was taken to measure the viscosity of the fermented milk and the content of exopolysaccharide. The extraction of exopolysaccharide was carried out by the following method:

[0026] (1) Put the fermented fermented milk in a sterilizing pot, and inactivate the enzyme activity under the condition of 100°C for 10 minutes;

[0027] (2) Use double-layer ordinary filter paper to decompress and filter the sample after cross-gas to remove impurities;

[0028] (3) Collect the filtrate and centrifuge at 6000-8000g for 15min at 4°C;

[0029] (4) Collect the supernatant and perform microfiltration using a 0.45 μm...

Embodiment 2

[0041] Production and application of exopolysaccharide-producing lactic acid bacteria ZLW-TM11 direct input starter for improving the viscosity of fermented milk:

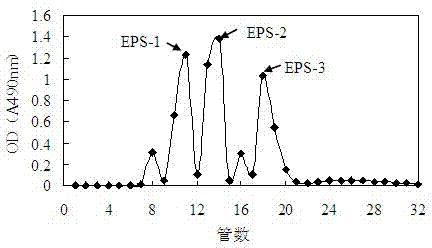

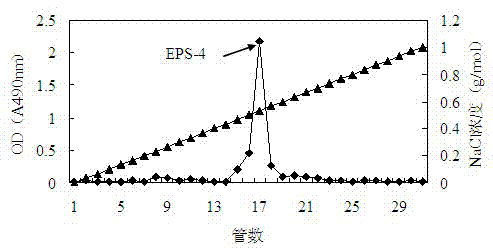

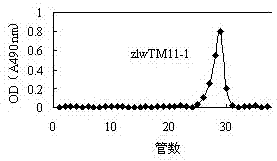

[0042] The extracellular polysaccharide fraction produced by ZLW-TM11 was separated and purified by two chromatographic columns ( Figure 1-6 ), obtained a polysaccharide component that contributes more to the viscosity of yoghurt, and determined the polysaccharide component by infrared spectroscopy. : 45.8 ratio composition, its structure is β-D-pyranose. The preserved Streptococcus thermophilus ZLW-TM11 was inoculated into the proliferation medium at an inoculation amount of 3%, and the proliferation medium consisted of 10% sterilized skim milk, 5% trypsin hydrolyzed whey powder, and 4% tomato Juice, 4% maltose, 2% lactose, 0.5% yeast extract or powder, 43 mg / kg formic acid and the rest of water, constant fermentation tank temperature 42 ° C, and constant fermentation broth with 12% sodium hydroxide The pH valu...

Embodiment 3

[0044] Production and application of exopolysaccharide-producing lactic acid bacteria ZLW-TM11 direct input starter for improving the viscosity of fermented milk:

[0045] The preserved Streptococcus thermophilus ZLW-TM11 was inoculated into the proliferation medium at an inoculation amount of 3%, and the proliferation medium consisted of 12% sterilized skim milk, 4% trypsin hydrolyzed whey powder, and 5% tomato Juice, 4% maltose, 1% lactose, 0.7% yeast extract or powder, 50 mg / kg formic acid and the rest of water, constant fermentation tank temperature 43 ° C, and constant fermentation broth with 10% sodium hydroxide The pH value is 6.0, fermented and cultured for 4.5 hours; then centrifuged at 10°C and 8,000 rpm to obtain a centrifugal precipitate; add a freeze-drying protective agent twice the weight of the centrifugal precipitate, and freeze-drying protection The agent is composed of 15% milk powder, 2% glycerin, 2% vitamin C, 0.8% glutamic acid or glycine, 5% sucrose, 1% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com