Normal-temperature brown yoghurt and manufacturing method thereof

A production method and normal temperature technology, applied in the direction of milk preparations, dairy products, milk preservation, etc., can solve the problems of different fermentation strain formulas and fermentation conditions, single color, flavor and nutritional performance, long shelf life of normal temperature yogurt, etc., to achieve Resolution of texture and flavor issues, wide distribution, and smooth cohesive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

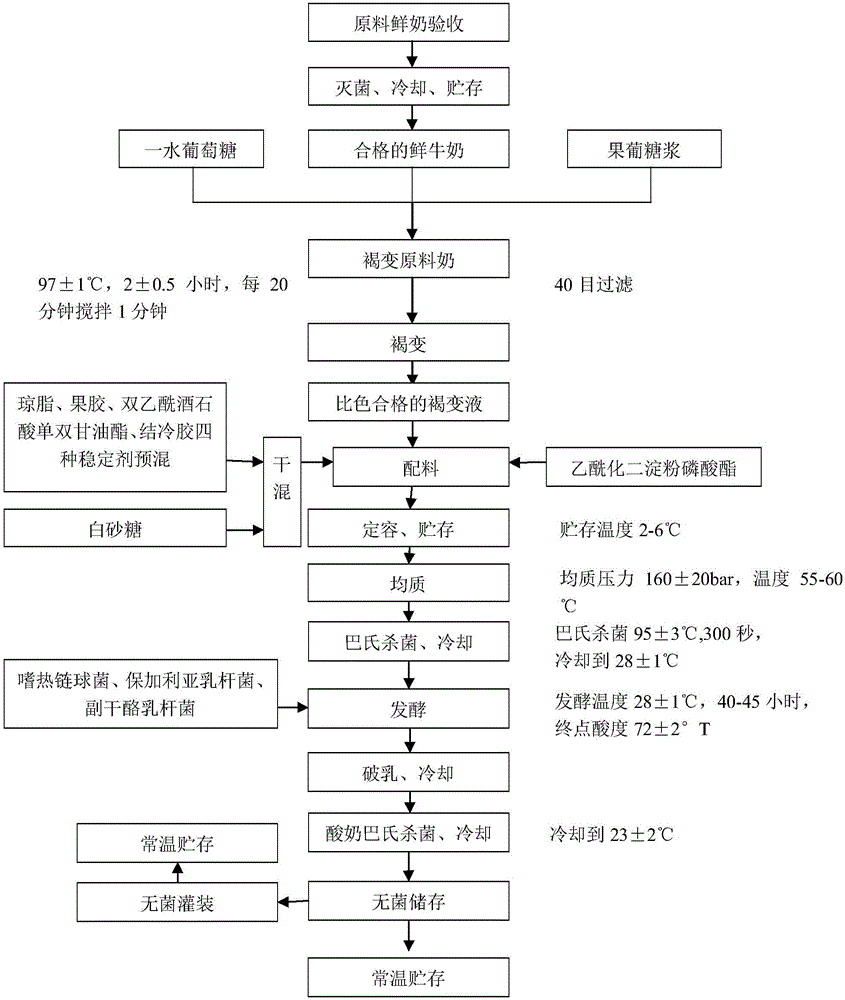

Image

Examples

Embodiment 1

[0035] (1) Quality control of fresh milk: fat ≥ 3.85%, protein ≥ 3.35%, acidity 12-16 oT, homogenization, pre-sterilization, homogenization pressure 190bar, and 137 ° C, 4 seconds ultra-high temperature sterilization treatment, the raw milk filter mesh is 80 mesh, cooled to 6 ° C for use;

[0036] (2) Browning raw milk preparation:

[0037] Ingredients: Put 87.68 kg of sterilized fresh milk into the mixing tank, put 1.9 kg of glucose monohydrate and 5.6 kg of fructose syrup into the blender in turn, filter the mesh to 40 mesh, fresh milk, fructose syrup, Water glucose three kinds of raw materials account for the mass percent of total formula;

[0038] Browning: Heat up the mixed browning milk raw materials to 96°C and keep the temperature constant for 2.5 hours to prepare browning raw milk, stir for 1 minute every 20 minutes during the browning process, and the final browning color is controlled in yellow-brown The light color MS-39W in the color card - the dark color MS-28W...

Embodiment 2

[0054] (1) Quality control of fresh milk: fat ≥ 3.85%, protein ≥ 3.35%, acidity 12-16 o T Homogenization, pre-sterilization, homogenization pressure 190bar, and 137 ° C, 4 seconds ultra-high temperature sterilization treatment, raw milk filter mesh requirement is 80 mesh, cooled to 6 ° C for use;

[0055] (2) Browning raw milk preparation:

[0056] Ingredients: Put 87.46 kg of sterilized fresh milk into the mixing tank, put 1.9 kg of glucose monohydrate and 5.6 kg of fructose syrup into the blender in turn, filter the mesh to 40 mesh, fresh milk, fructose syrup, Water glucose three kinds of raw materials account for the mass percent of total formula;

[0057] Browning: Heat up the mixed browning milk raw materials to 96°C and keep the temperature constant for 2.5 hours to prepare browning raw milk, stir for 1 minute every 20 minutes during the browning process, and the final browning color is controlled in yellow-brown The light color MS-39W in the color card - the dark colo...

Embodiment 3

[0073] (1) Quality control of fresh milk: fat ≥ 3.85%, protein ≥ 3.35%, acidity 12-16 o T, homogenization, pre-sterilization, homogenization pressure 190bar, and 137 ° C, 4 seconds ultra-high temperature sterilization treatment, the raw milk filter mesh is 80 mesh, cooled to 6 ° C for use;

[0074] (2) Browning raw milk preparation:

[0075] Ingredients: Put 87.23 kg of sterilized fresh milk into the mixing tank, put 1.9 kg of glucose monohydrate and 5.6 kg of fructose syrup into the blender in turn, filter the mesh to 40 mesh, fresh milk, fructose syrup, Water glucose three kinds of raw materials account for the mass percent of total formula;

[0076] Browning: Heat up the mixed browning milk raw materials to 96°C and keep the temperature constant for 2.5 hours to prepare browning raw milk, stir for 1 minute every 20 minutes during the browning process, and the final browning color is controlled in yellow-brown The light color MS-39W in the color card - the dark color MS-28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com