Production technique of acetylene-free industrial cutting gas

A production process and industrial technology, applied in the field of acetylene-free industrial cutting gas production process and production equipment, can solve the problems of unfavorable industrial use, slow combustion speed, low combustion temperature, etc., achieve accelerated combustion speed, short warm-up time, The effect of high flame temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0087] As an embodiment of the present invention, the liquid fuel comprises in parts by weight:

[0088]

[0089]

[0090] Light hydrocarbon fuels:

[0091] "Hydrocarbons" are a series of substances composed of carbon and hydrogen mixed in different proportions. The lighter parts are called light hydrocarbons.

[0092] In the present invention, the light hydrocarbon fuel comprises in parts by weight:

[0093] 90 parts by weight of pentane;

[0094] 5 parts by weight of a mixture of methane, ethane and propane.

[0095] Pentane: Formula C 5 h 12 , There are two isomers of n-pentane: isopentane and neopentane.

[0096] Isopentane, also known as 2-methylbutane; neopentane, also known as 2,2-dimethylpropane, pentapentane.

[0097] As an embodiment of the present invention, the pentane in the present invention is a mixture of n-pentane, isopentane and neopentane in a weight ratio of 10:1:0.5.

[0098] Mixture of methane, ethane and propane: the methane, ethane and p...

Embodiment approach 1

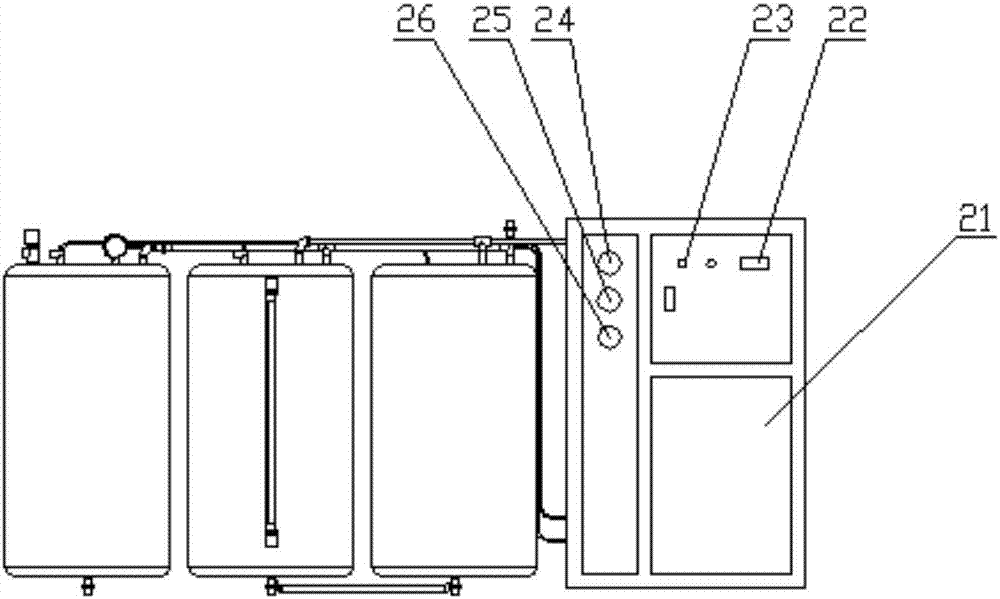

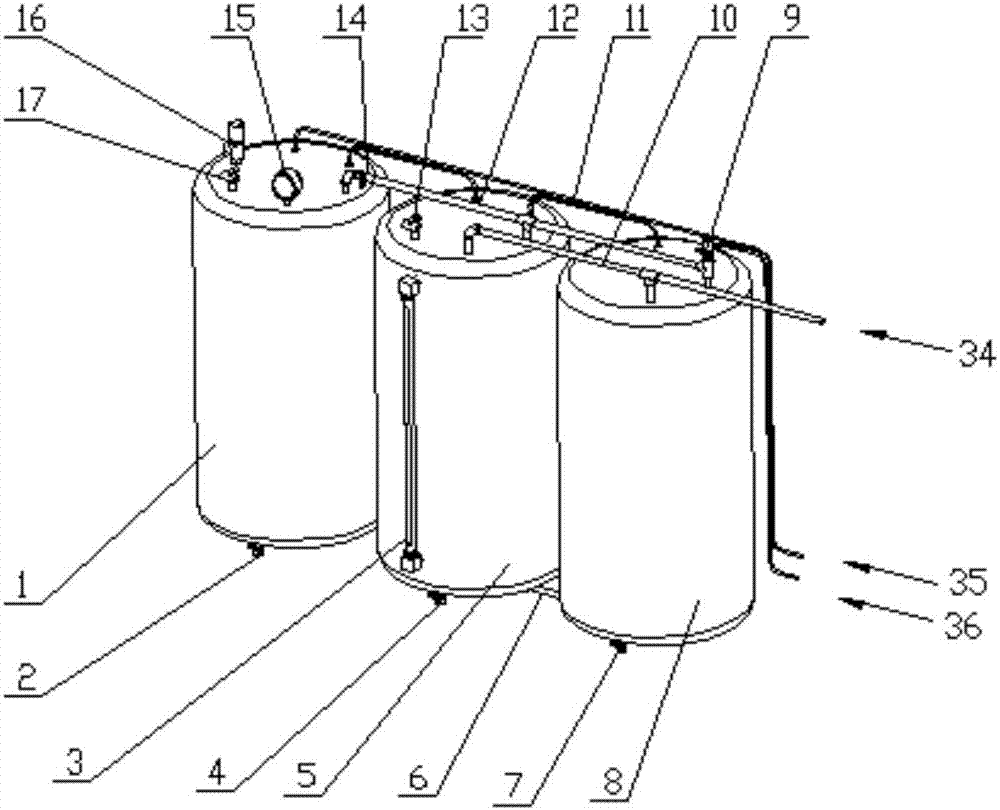

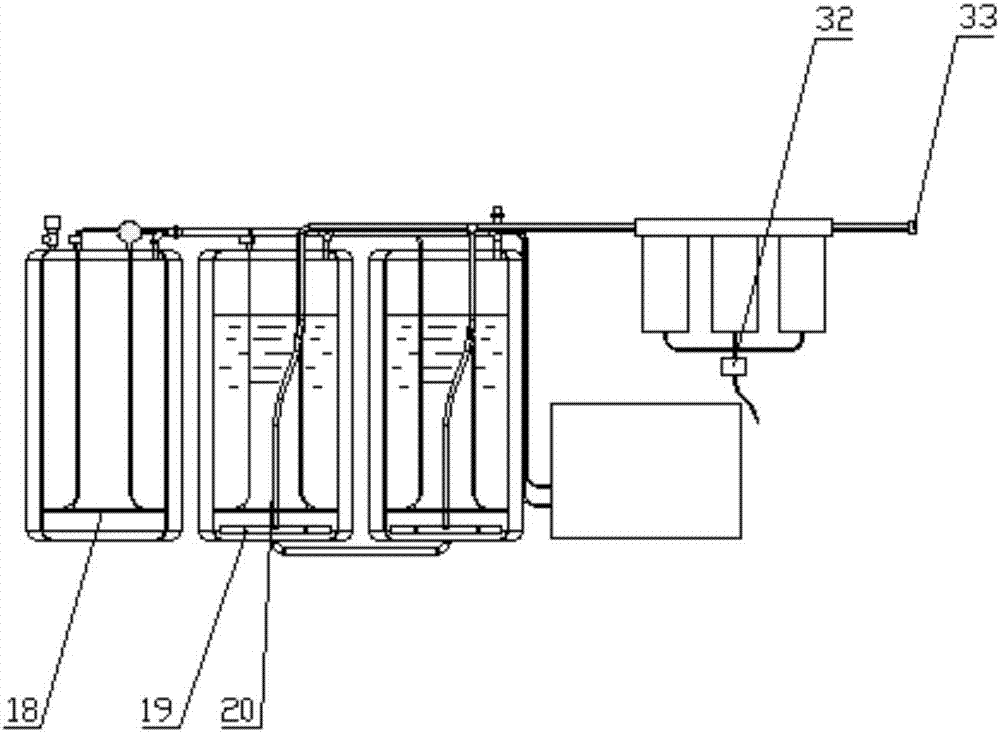

[0128] Embodiment 1: a kind of production process of acetylene-free industrial cutting gas, its step comprises:

[0129] (1) Pre-treatment of compressed air: After the compressed air is filtered, dried, and depressurized, it enters the storage tank through the compressed air inlet, and liquid fuel is stored in the storage tank;

[0130] (2) Preliminary gasification of liquid fuel: the compressed air entering the storage tank generates a large number of bubbles through the bubbling gasification device, which promotes the preliminary gasification of the liquid fuel, and at the same time heats the liquid fuel to generate preliminary gas;

[0131] (3) Secondary gasification of liquid fuel: the preliminary gas enters the gas collection tank through the gas outlet connecting pipe, and is heated for secondary gasification to obtain industrial cutting gas;

[0132] The liquid fuel includes light hydrocarbon fuel, combustion improver, dispersant, solubilizer, catalyst and solvent.

Embodiment approach 2

[0133] Embodiment 2: The production process of acetylene-free industrial cutting gas as described in Embodiment 1, the storage tank is provided with a heating system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com