Combustion synergist for industrial fuel gas

An industrial gas and synergist technology, which is applied in the petroleum industry, fuel, gas fuel, etc., can solve the problems that the gas flame temperature cannot reach the predetermined level, the liquid phase synergist has many components, and the propane gas cannot be guaranteed, etc., to achieve cutting Fast speed, good for environmental protection, good cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

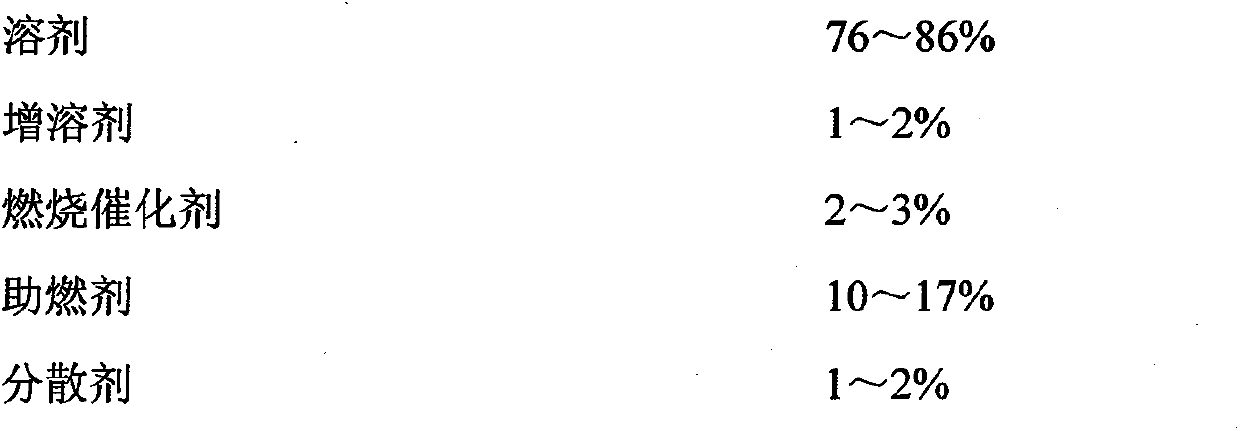

[0028] A kind of component of industrial gas combustion synergist and mass percent thereof are:

[0029]

[0030] Wherein: described solvent is mixed solvent 1 (namely described mixed solvent 1 is made up of acetone, methanol and benzene, and its acetone: methanol: the mass ratio of benzene is 1: 0.75: 0.35); Described solubilizer is mixed solubilizer 2 (that is, the mixed solubilizer 2 is composed of isopropanol and 120 # Solvent oil composition, its isopropanol: 120 #The mass ratio of solvent oil is 1: 0.35); The combustion catalyst is a mixed combustion catalyst 1 (that is, the mixed combustion catalyst 1 is composed of ferrocene and zirconium naphthenate, and its ferrocene: the quality of zirconium naphthenate is 1:0.7); the combustion-supporting agent is a mixed combustion-supporting agent 2 (that is, the mixed combustion-supporting agent 2 is composed of hydrazine hydrate and 2,6-lutidine, and its hydrazine hydrate: 2,6-lutidine The mass ratio is 1:0.35); the disper...

Embodiment 2

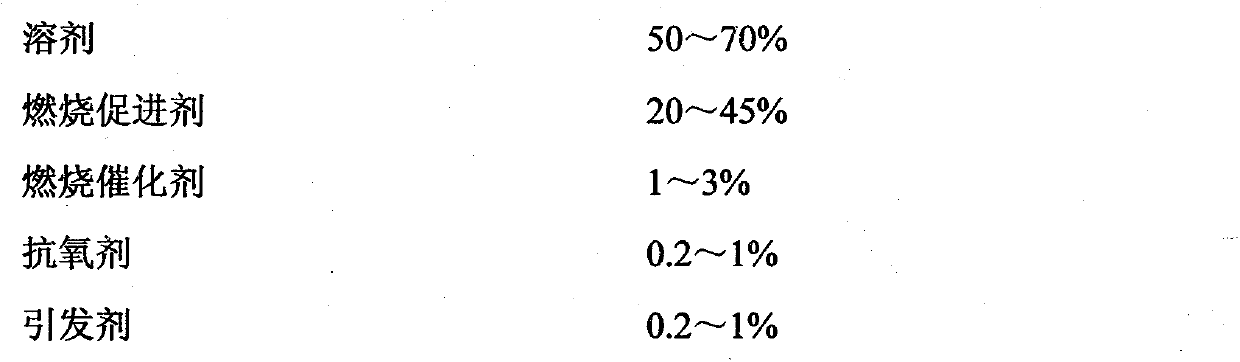

[0032] A kind of component of industrial gas combustion synergist and mass percent thereof are:

[0033]

[0034]

[0035] Wherein: described solvent is mixed solvent 1 (namely described mixed solvent 1 is made up of acetone, methanol and benzene, and its acetone: methanol: the mass ratio of benzene is 1: 0.5: 0.5); Described solubilizer is mixed solubilizer 2 (that is, the mixed solubilizer 2 is composed of isopropanol and 120 # Solvent oil composition, its isopropanol: 120 # The mass ratio of solvent oil is 1: 0.2); The combustion catalyst is a mixed combustion catalyst 1 (that is, the mixed combustion catalyst 1 is composed of ferrocene and zirconium naphthenate, and its ferrocene: the quality of zirconium naphthenate is 1:1); the combustion enhancer is a mixed combustion enhancer 2 (that is, the mixed combustion enhancer 2 is composed of hydrazine hydrate and 2,6-lutidine, and its hydrazine hydrate: 2,6-lutidine The mass ratio is 1:0.5); the dispersant is diethyl p...

Embodiment 3

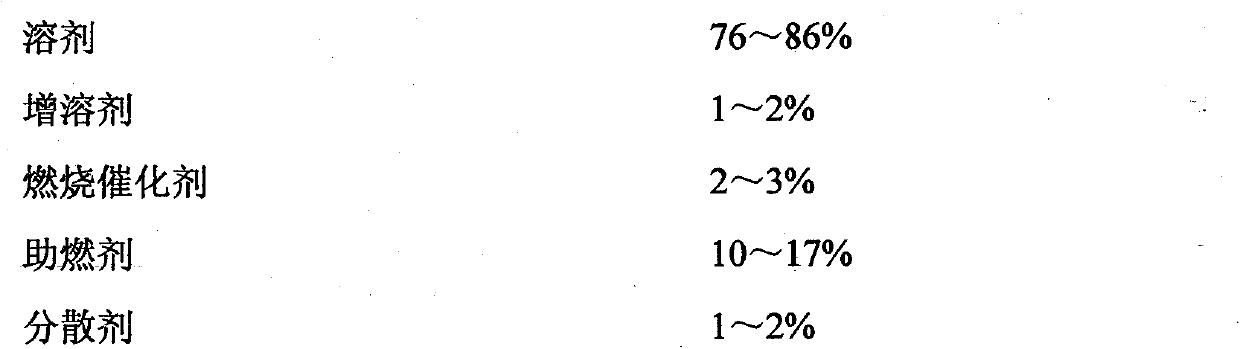

[0037] A kind of component of industrial gas combustion synergist and mass percent thereof are:

[0038]

[0039] Wherein: described solvent is mixed solvent 1 (namely described mixed solvent 1 is made up of acetone, methanol and benzene, and its acetone: methanol: the mass ratio of benzene is 1: 1.5: 0.2); Described solubilizer is mixed solubilizer 2 (that is, the mixed solubilizer 2 is composed of isopropanol and 120 # Solvent oil composition, its isopropanol: 120 # The mass ratio of solvent oil is 1: 0.5); The combustion catalyst is a mixed combustion catalyst 1 (that is, the mixed combustion catalyst 1 is composed of ferrocene and zirconium naphthenate, and its ferrocene: the quality of zirconium naphthenate is 1:0.25); the combustion-supporting agent is a mixed combustion-supporting agent 2 (that is, the mixed combustion-supporting agent 2 is composed of hydrazine hydrate and 2,6-lutidine, and its hydrazine hydrate: 2,6-lutidine The mass ratio is 1:0.25); the dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com