Laser cutting method and system used for amorphous thin belts

A technology of laser cutting and thin strip, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problem of inability to achieve high-quality cutting, and achieve the effect of good use effect, no slag hanging, and simple implementation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

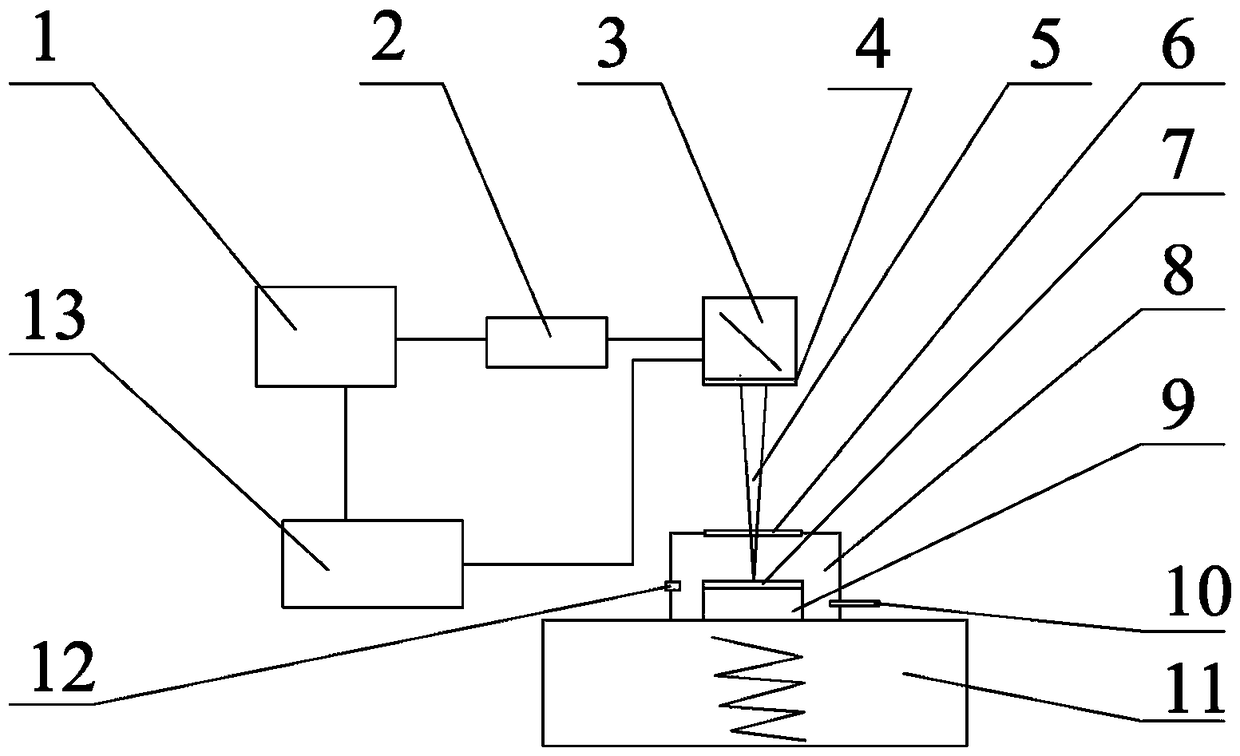

Method used

Image

Examples

Embodiment 1

[0035] For copper-based amorphous alloys with a thickness of 0.05mm, IPG pulse laser is used, with an average power of 20W, a pulse frequency of 40KHz, and a pulse width of 8μs. Scanlab scanning galvanometers are used with a scanning speed of 300mm / s. Argon gas is filled into the inflatable chamber with a flow rate of 10L. / min, the oxygen content is 6ppm, the focal length of the focusing lens is 163mm, the cutting results are as follows figure 2 shown.

Embodiment 2

[0037] For nickel-based amorphous alloys with a thickness of 0.01mm, IPG pulse laser is used, with an average power of 16W, a pulse frequency of 60KHz, and a pulse width of 8μs. Scanlab scanning galvanometers are used with a scanning speed of 500mm / s. Argon gas is filled into the inflatable chamber with a flow rate of 10L. / min, oxygen content 5ppm, focusing lens focal length 163mm, the cutting results are as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com