Siding joinery with fastener

a fastener and joinery technology, applied in the field of panel systems, can solve the problems of gap deflecting away from the building at the seam section, irregular seam section between two adjacent panels, etc., and achieve the effect of less apparent seams and a smoke-free seam section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The following description is intended to convey a thorough understanding of the embodiments by providing a number of specific embodiments and details involving a siding panel assembly. It is understood, however, that the invention is not limited to these specific embodiments and details, which are exemplary only. It is further understood that one possessing ordinary skill in the art, in light of known devices, systems and methods, would appreciate the use of the invention for its intended purposes and benefits in any number of alternative embodiments.

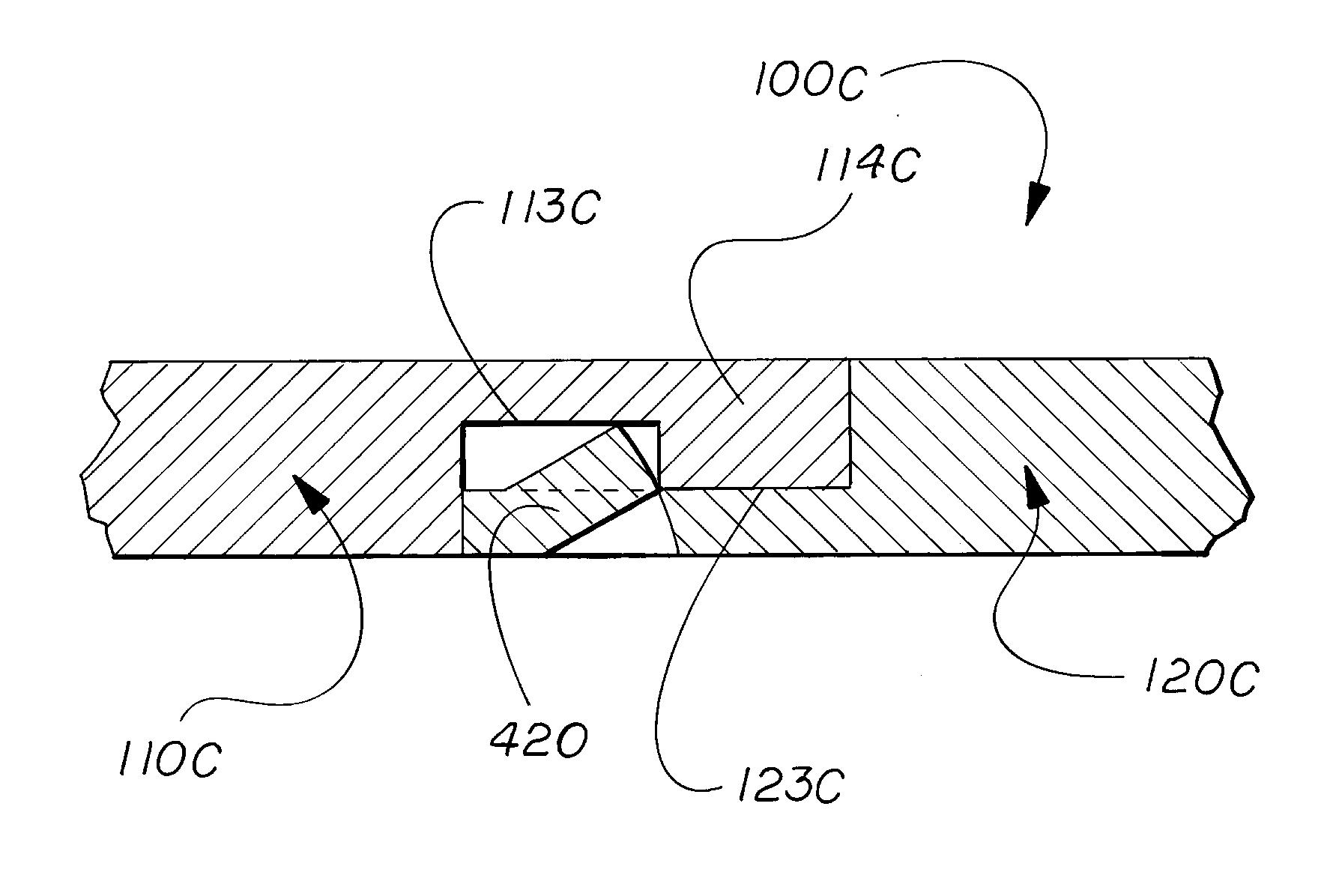

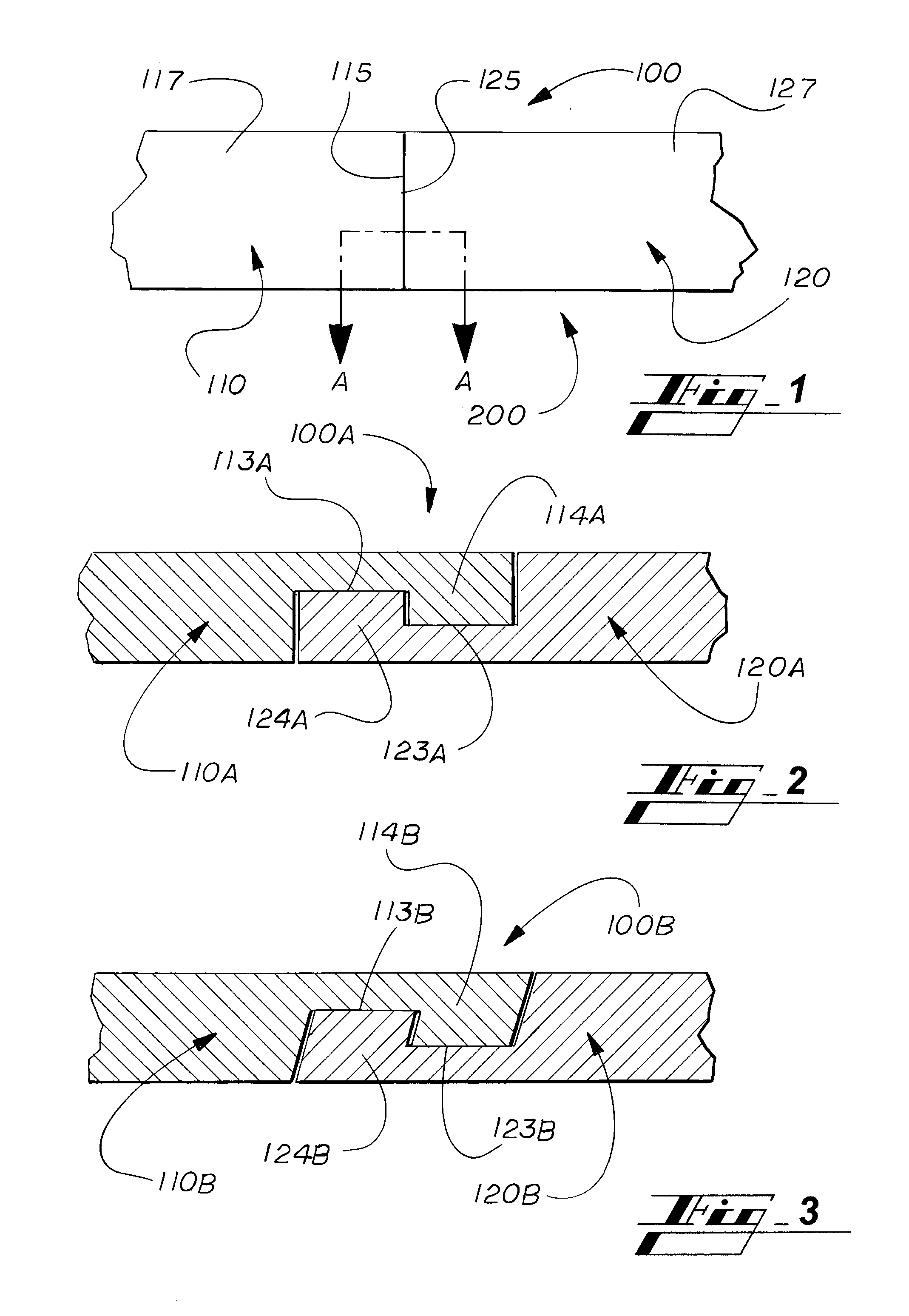

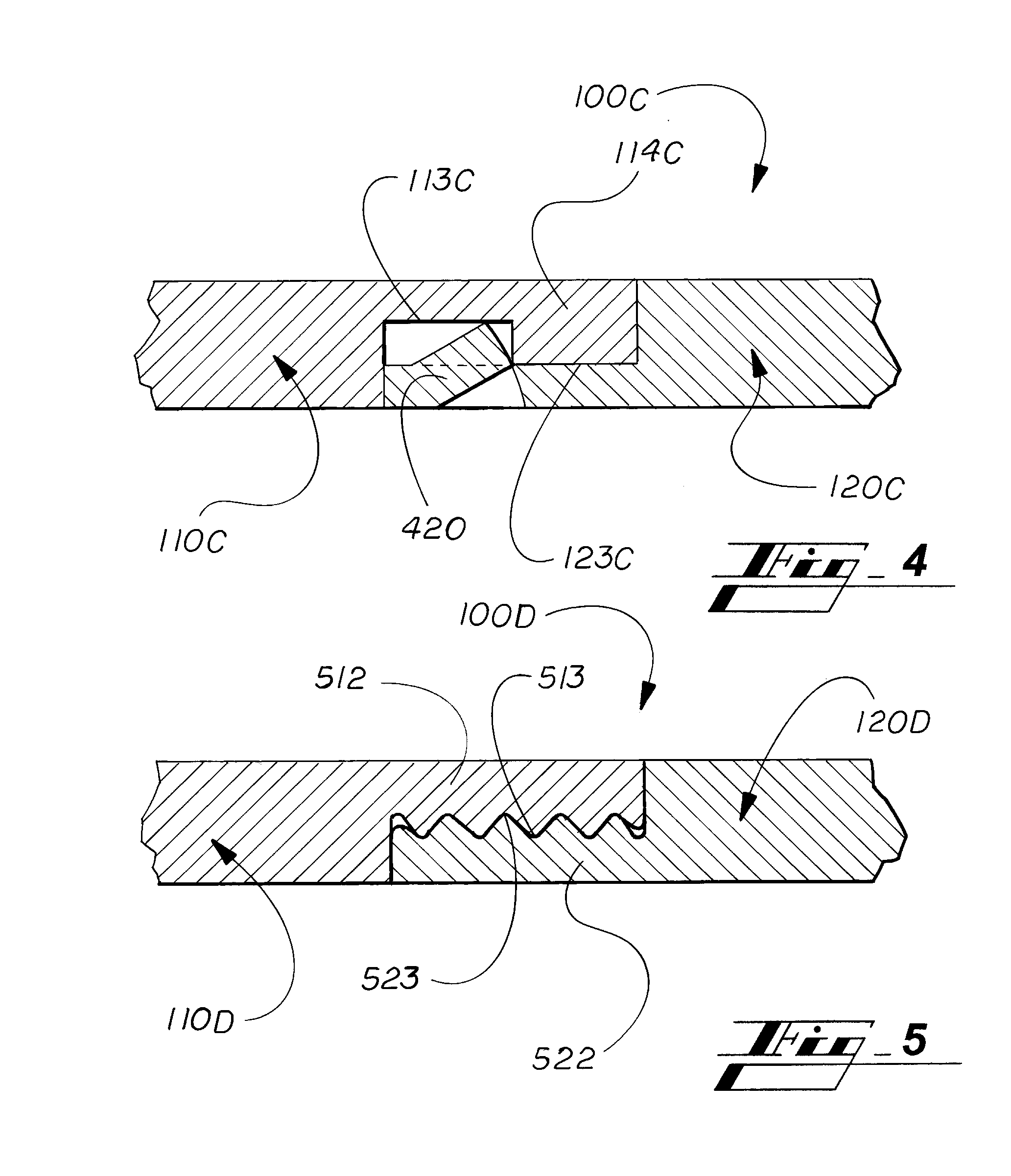

[0026]Generally speaking, as shown in FIG. 1, panel systems 100 of the present invention are generally flat sections used in building, construction and other applications, including in walls, siding, flooring, tiling, shelving, furniture and like. In one described but non-limiting embodiment, a panel system 100 of the invention includes siding panels 110 that have a plurality of horizontally adjacent siding panels 120 that are int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com