Novel worktable structure of overlocking machine

A technology of locomotive table and sewing machine, applied in sewing machine components, textiles and papermaking, sewing equipment, etc., can solve the problems of running crooked, uncomfortable, affecting the quality of garments, etc., and achieve the effect of uniform stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

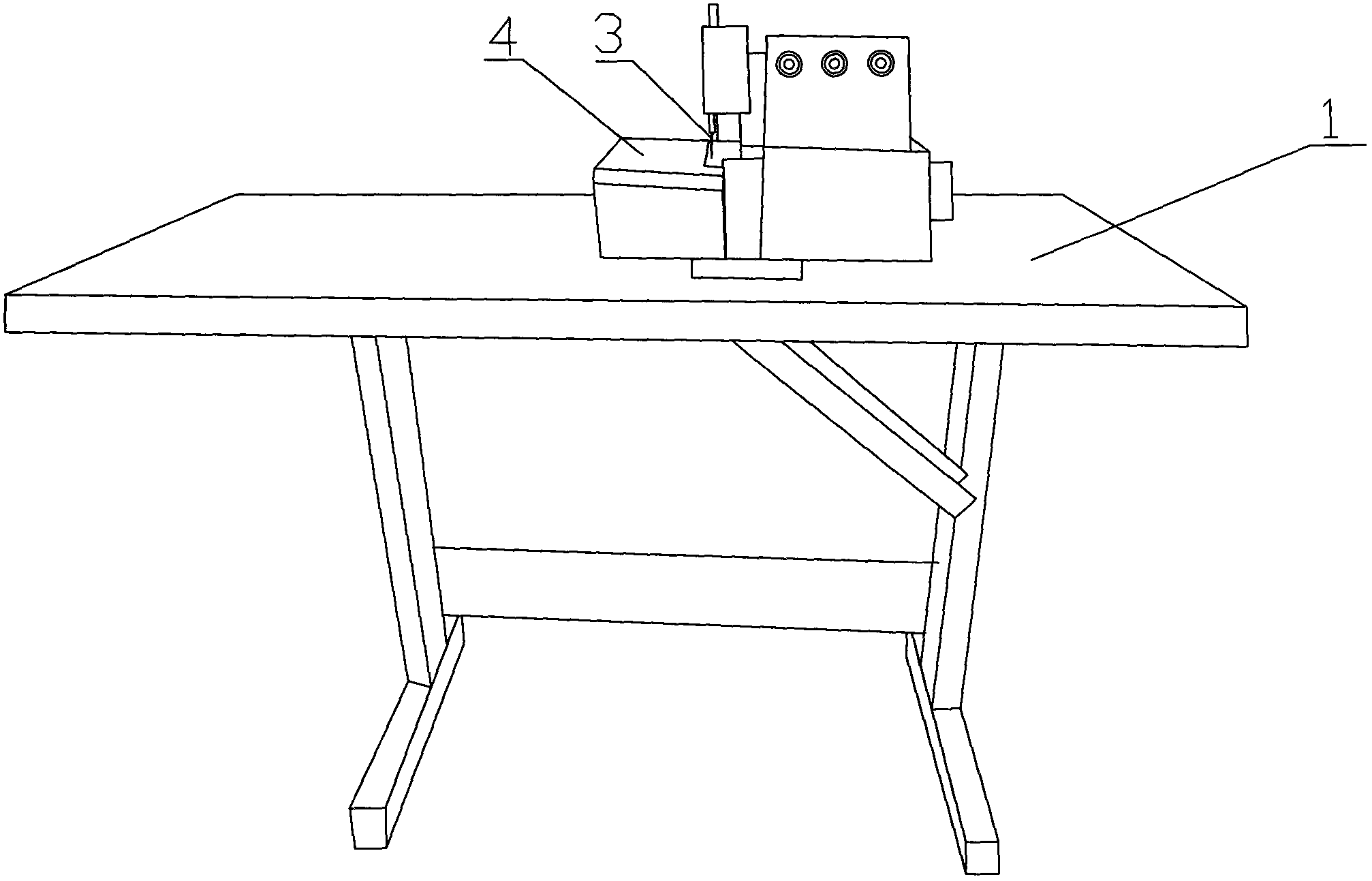

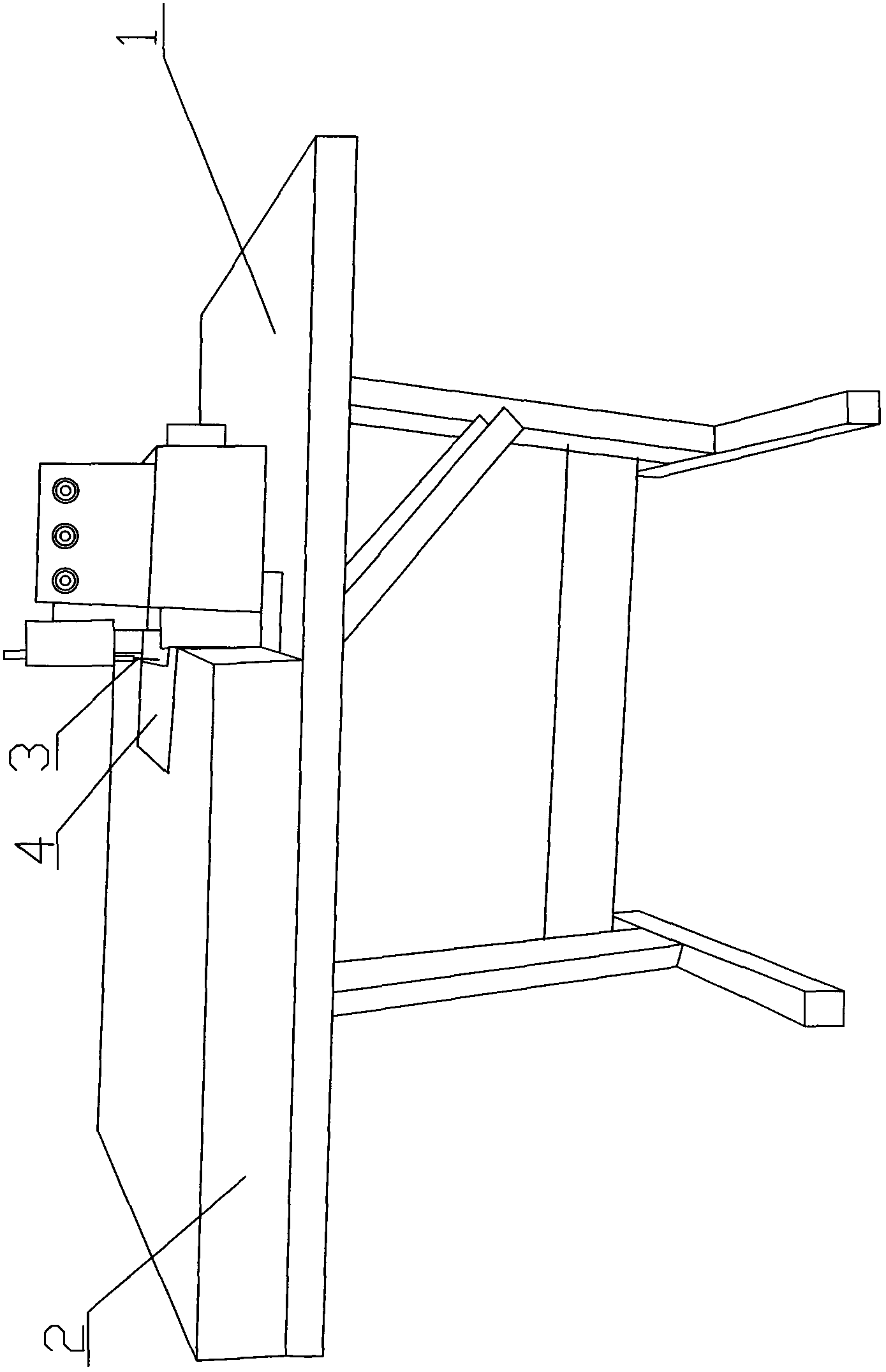

[0010] Such as figure 2 As shown, a new type of overlock locomotive platform structure is characterized in that: it includes a flat vehicle platform 1 and a protrusion 2 located on the plane vehicle platform 1, the protrusion 2 is located on the side of the machine needle 3 for overlocking, The height of the small platform 4 on which the needle 3 works on the above-mentioned protruding part 2 is consistent with that of the overlock machine, so that the small platform 4 and the protruding part 2 form a larger platform together.

[0011] When in use, because the cloth is supported by the protruding part 2, it no longer falls or tilts up, and the operator does not need to press the cloth hard on the small platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com