A sewing machine characterized by smooth cloth feeding

A sewing machine and smooth technology, which is applied in the field of sewing machines with smooth cloth feeding, can solve the problems of unsmooth cloth, uneven stitching of sewing stitches, insufficient pressure, etc., and achieve the effect of smooth feeding of cloth, uniform stitching and smooth sewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described in conjunction with the following examples.

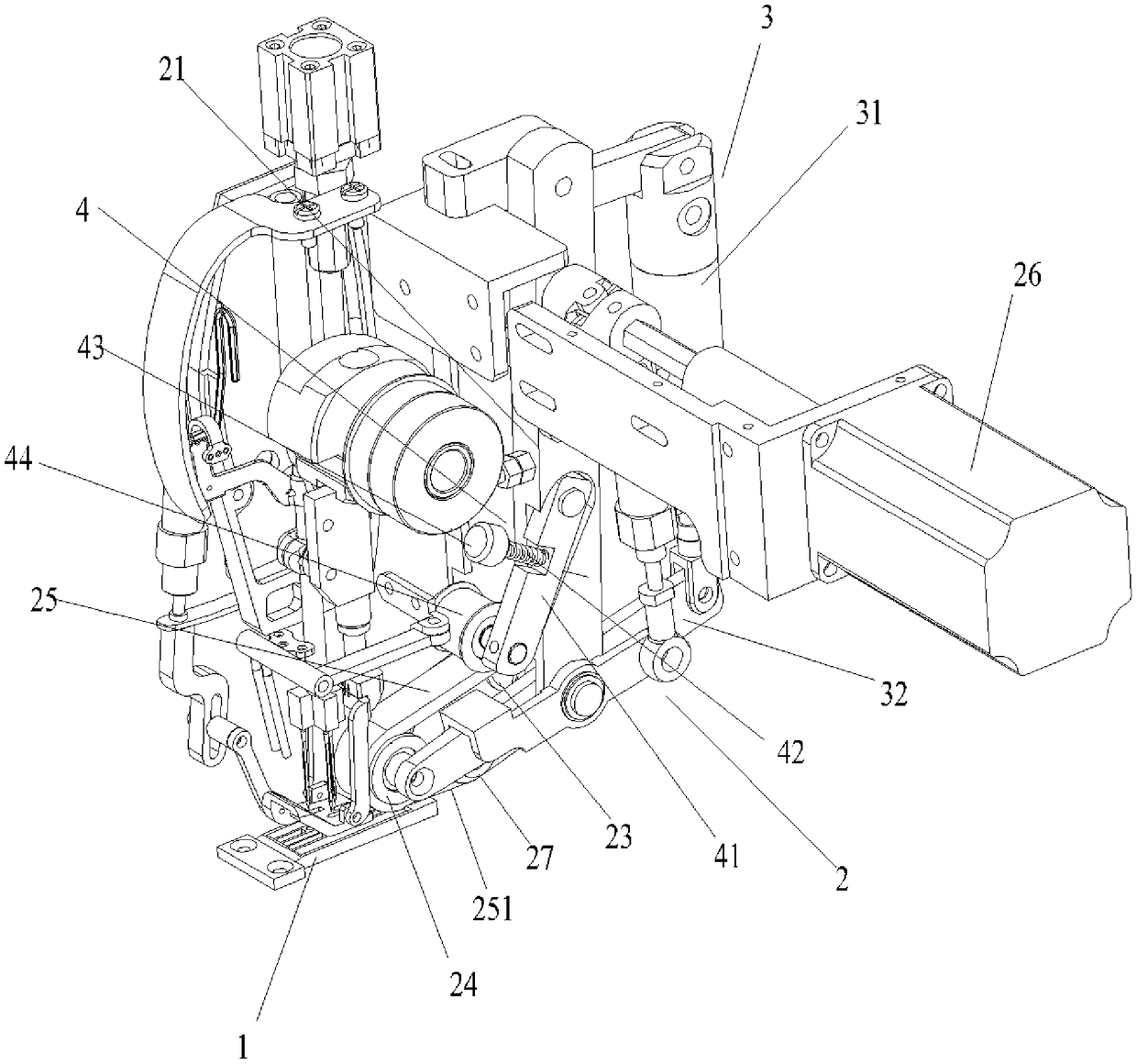

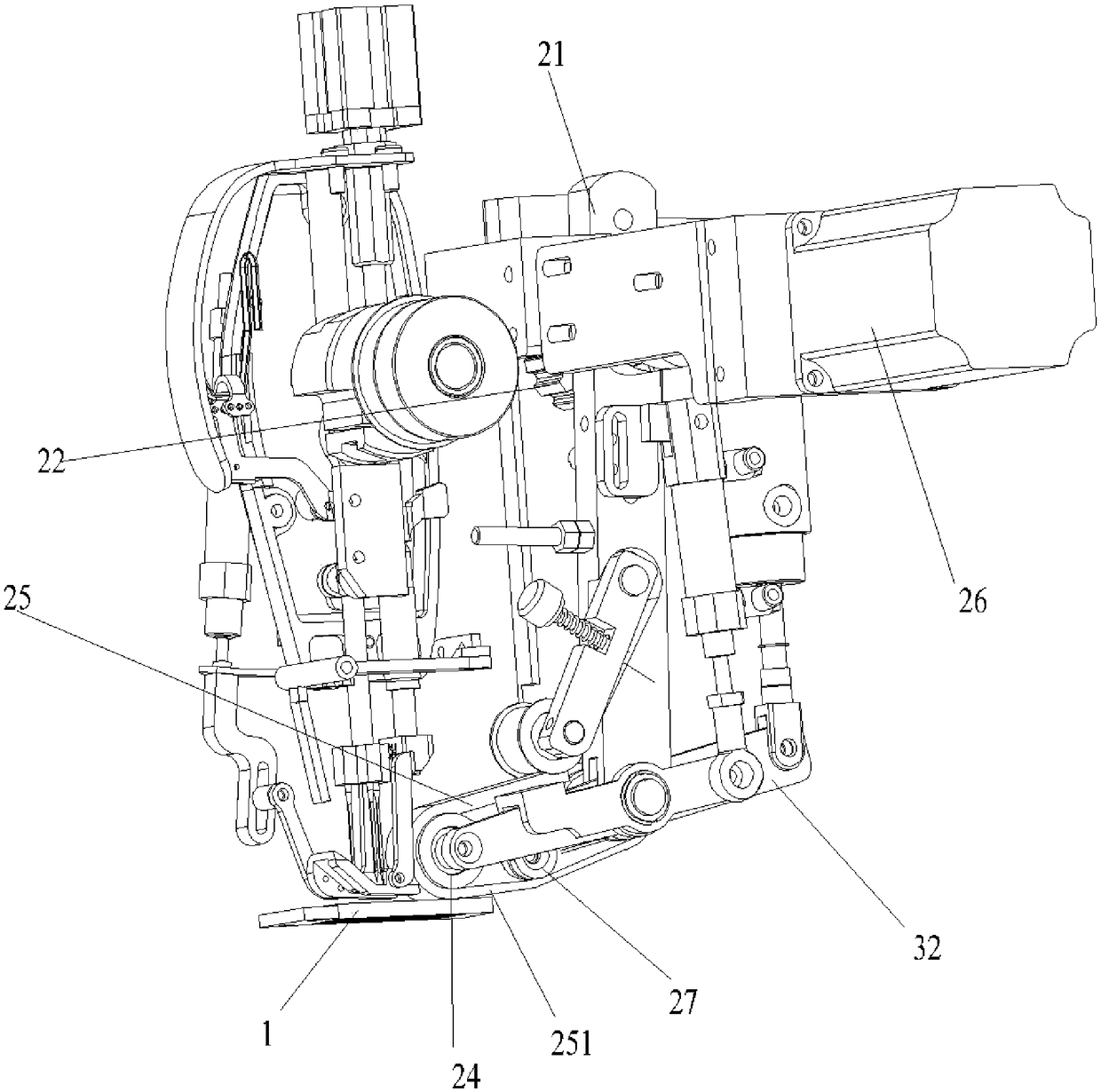

[0016] The present invention provides a sewing machine with smooth feeding, such as figure 1 and figure 2 As shown, it includes a sewing machine body (not shown in the figure), a needle cushion 1, a material pulling device 2 and a linkage mechanism 3, and the material pulling device 2 and the linkage mechanism 3 are all arranged on the sewing machine body, and the material pulling device 2 includes a mounting plate 21 , synchronous pulley 22, tension belt roller 23, pull material roller 24, pull material belt 25 and stepper motor 26, synchronous pulley 22, tension belt roller 23 and pull material roller 24 are arranged on the mounting plate 21 and draw material The belt 25 is tensioned, and the pulling roller 24 can rotate up and down centered on the tensioning roller 23, and the stepper motor 26 is connected with the synchronous pulley 22 and drives it to rotate; the linkage mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com