Seamless line split joint structure and split joint method for clothing

A technology of seamless thread and clothing, applied in the direction of sewing tools, etc., can solve the problems of ineffective windproof, warm and rainproof, uneven fabric interface, uncomfortable wearing, etc., to achieve smooth seams and improve windproof , wearing comfortable effect

Inactive Publication Date: 2009-05-13

杭州福星工贸有限公司

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The interface of the fabric is not smooth, it is easy to directly rub against the skin, and it is uncomfortable to wear; in various harsh climates, such as severe cold at high altitudes, snowstorms, and heavy rains, because the clothing has pinholes, there will be gaps for wind and rain to penetrate, so it cannot Effective protection against wind, warmth and rain (water)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0027] The garment seamless splicing structure obtained in Example 1 is tested for seam fastness according to the ISO13935-2# method, and the test result is that the joint fastness is 410N, exceeding the qualified standard.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Login to View More

Abstract

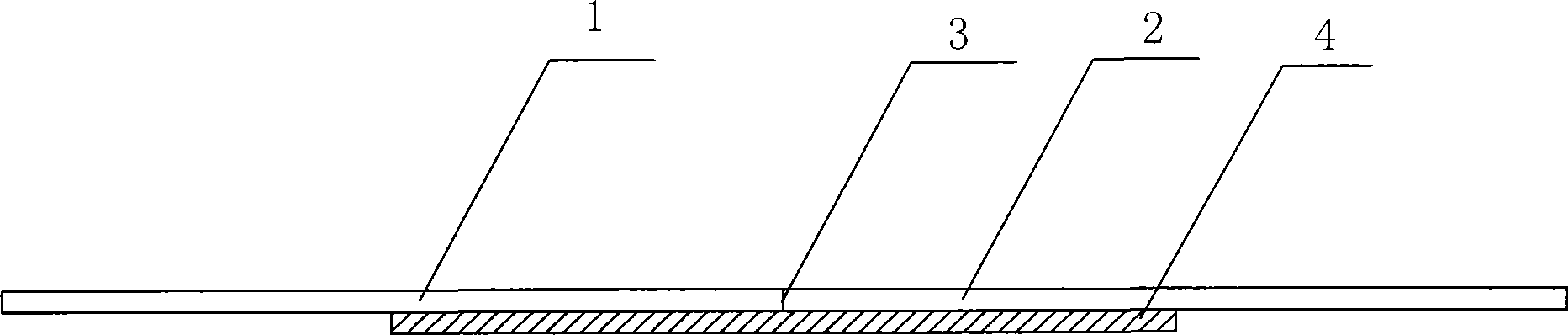

The invention relates to a seamless splicing structure of clothing, which comprises two pieces of fabric to be spliced, wherein the two pieces of fabric are molten at the spliced position and are connected with each other; and a one-side adhesive tape spun-bonded with the fabric is arranged on one side of the fabric at the spliced position. The splicing process of the seamless splicing structure comprises the following steps: (1) melting the two pieces of fabric to be spliced by ultrasonic thermal-melting process at the spliced position and connecting with each other; and (2) fixing a one-side adhesive tape on one side of the fabric by hot-press bonding process at the spliced position. The clothing with the seamless splicing structure has the advantages of wearing comfort, light weight, convenience, wind resistance, warmth retention, water tightness, etc.

Description

(1) Technical field [0001] The invention relates to a garment seamless splicing structure and a splicing method thereof. (2) Background technology [0002] Traditional clothing is all hand- or machine-sewn, and seams and sewing threads are left at the fabric splicing. The interface of the fabric is not smooth, it is easy to directly rub against the skin, and it is uncomfortable to wear; in various harsh climates, such as severe cold at high altitudes, snowstorms, and heavy rains, because the clothing has pinholes, there will be gaps for wind and rain to penetrate, so it cannot Effectively protects against wind, warmth and rain (water). (3) Contents of the invention [0003] The technical problem to be solved by the present invention is to provide a seamless stitching structure for garments with smooth seams, light and comfortable. [0004] The technical problem to be solved by the present invention is also to provide a splicing process for the seamless splicing structure...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A41H43/04

CPCB29K2313/00B29C66/729B29C66/43B29C65/5042B29C65/4815B29C66/1142B29C65/08

Inventor 赵军

Owner 杭州福星工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com