Full-fashioned hosiery production device and production technique

A technology of production device and production process, applied in the field of full-formed socks production device, can solve problems such as manual handling, and achieve the effects of saving production time, reducing working time and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

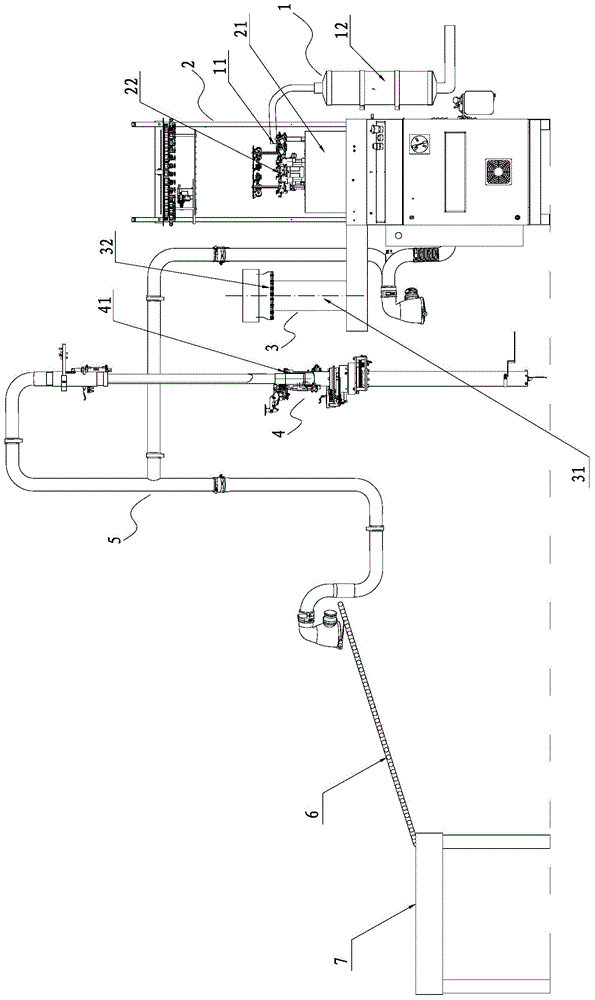

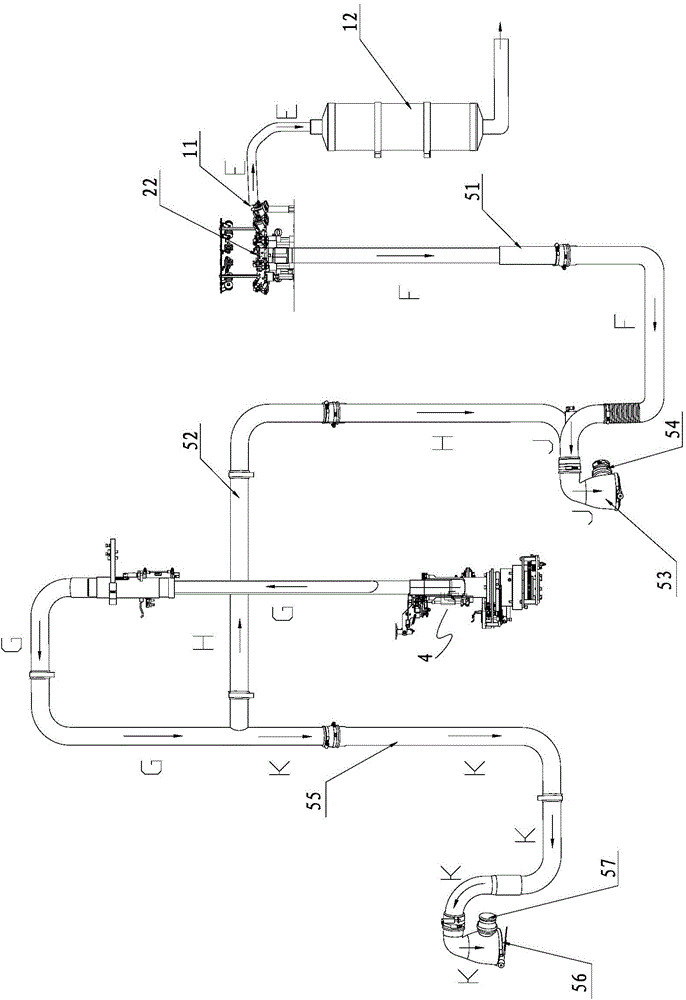

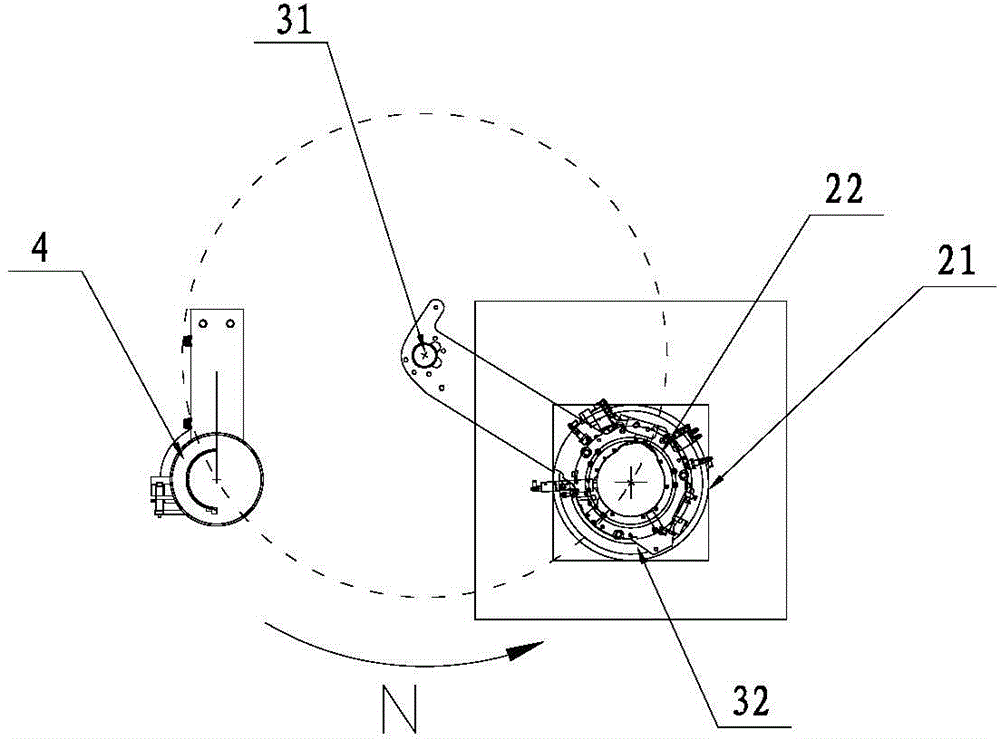

[0034] Such as figure 1 As shown, a fully formed sock production device includes a waste yarn storage mechanism 1, a knitting mechanism 2, a transfer mechanism 3, a sewing mechanism 4, and a transfer mechanism 6 installed in sequence on the production line, as well as a control device for controlling the operation of the entire production device mechanism, wherein, the knitting mechanism 2 includes a hosiery knitting machine 21, the knitting place 22 of the hosiery knitting machine 21 is provided with several pieces of knitting needles 23, and the knitting needles 23 are distributed in a circular shape; the waste yarn storage mechanism 1 The suction port 11 is located at the side of the knitting place 22 of the hosiery knitting machine 21, and is used to suck the yarn end and waste yarn generated when the sock knitting machine 21 is knitting into the storage bin 12 of the waste yarn storage mechanism 1 through the suction port. The transfer mechanism 3 includes a rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com