Stone material seamless polishing construction method

A stone, grinding and polishing technology, applied in the direction of covering/lining, building, building structure, etc., can solve the problems of uneven joints of marble or granite plates, inability to reflect the stone effect well, and obvious plate divisions, etc. To achieve the effect of fast construction progress, short construction period, and smooth plate joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

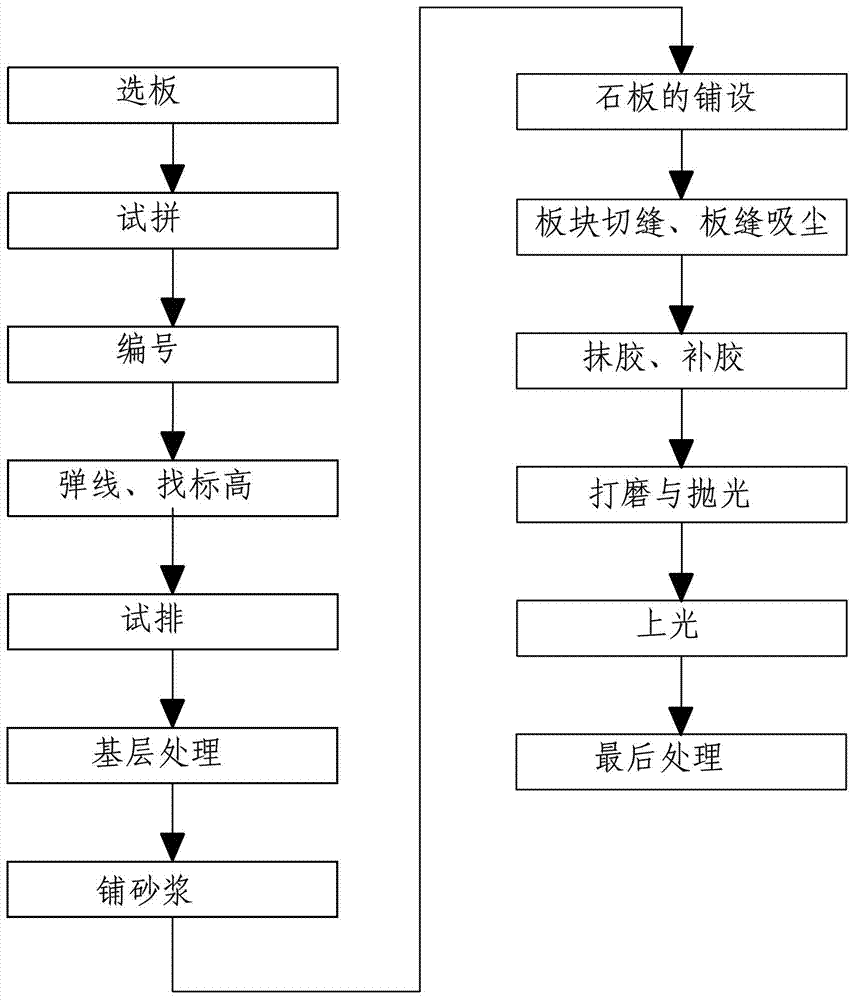

[0023] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 :

[0024] Stone seamless grinding and polishing construction method, including construction preparation and construction process, construction preparation includes: selection of stone boards, when selecting stone materials, pick out some warped, arched back, different widths and different squares , and use them in appropriate parts, soak the back of the stone with water, dry or dry it for later use; then carry out trial assembly, numbering, trial assembly according to pattern, color, and texture, and the gap between the plates is generally not greater than 1mm. After the trial assembly, number the stones according to their positions; then stretch the lines and find the elevation on the surrounding walls to control the thickness and flatness of the plaster; The width of the dry sand should be larger than that of the slabs, and the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com