Nuclear power plant large shielded main pump lower portion C-ring cutting device

A technology for cutting devices and nuclear power plants, which is applied in the direction of grinding/polishing safety devices, grinding machines, metal processing equipment, etc. It can solve the problems of not being able to meet the size requirements of the C-ring cutting space, the narrow and deep space of the C-ring, etc., and achieve structural stability, The effect of small displacement and deformation and controllable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

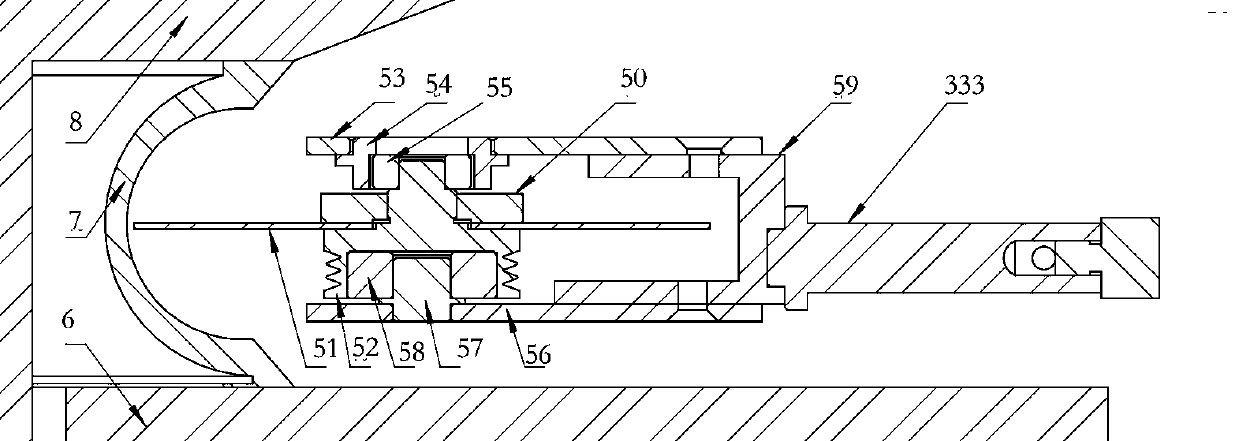

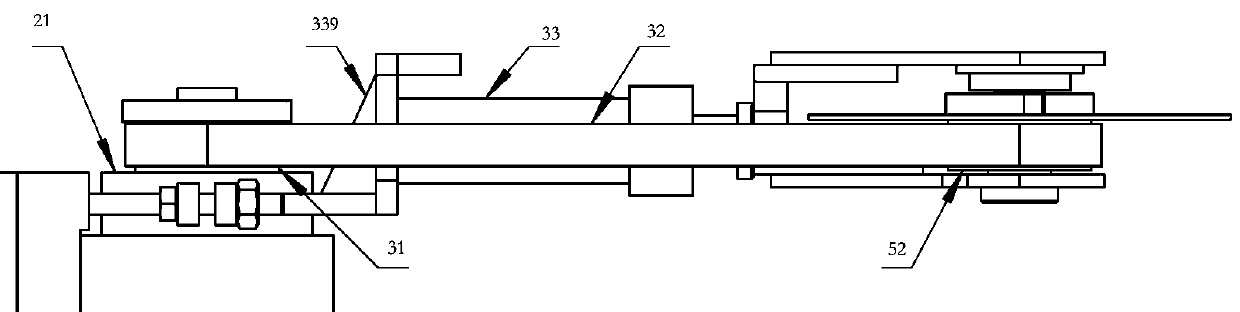

[0033] After the shielded main pump cancels the shaft sealing device, the welding seal of the whole pump body is realized by two upper and lower 304 stainless steel C-shaped sealing rings. In order to realize effective cutting in the narrow and deep C-ring space, the invention proposes a C-ring cutting device for a large shielded main pump of a nuclear power plant.

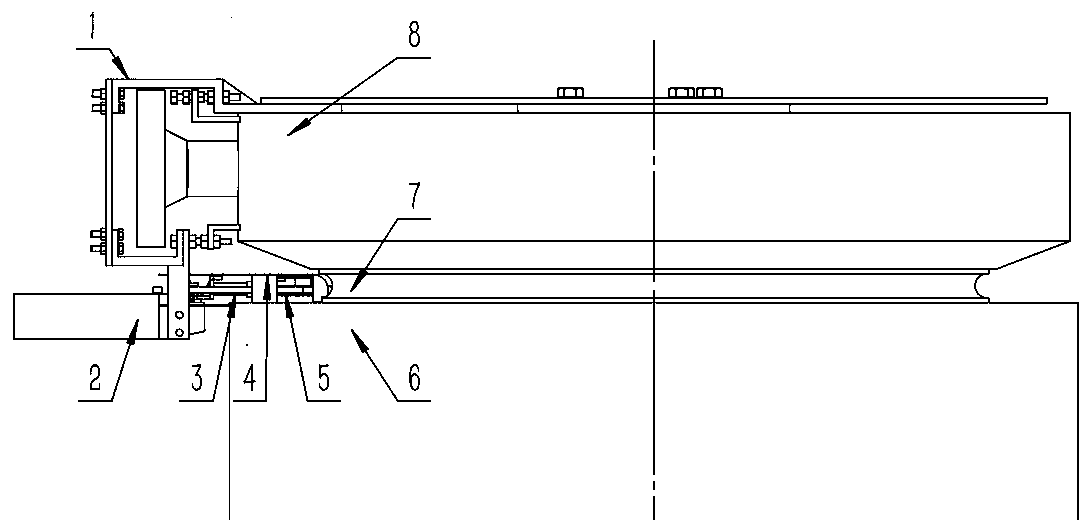

[0034] Such as figure 1 According to the present invention, a C-ring cutting device for the lower part of a large-scale shielded main pump in a nuclear power plant includes a wall-mounted assembly 1 and a cutting assembly. The wall hanging assembly 1 includes a pressing plate 11 and a wall hanging main body 12 . The pressure plate 11 is fixed on the end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com