A kind of reinforcement support structure of shear wall external formwork

A technology of supporting structure and external formwork, applied in the connection of formwork/formwork/work frame, formwork/formwork/work frame, building structure, etc., can solve the difficulty of formwork adjustment, high formwork pressure and construction difficulty Large and other problems, to achieve the effect of not easy to run the mold, simple structure, improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

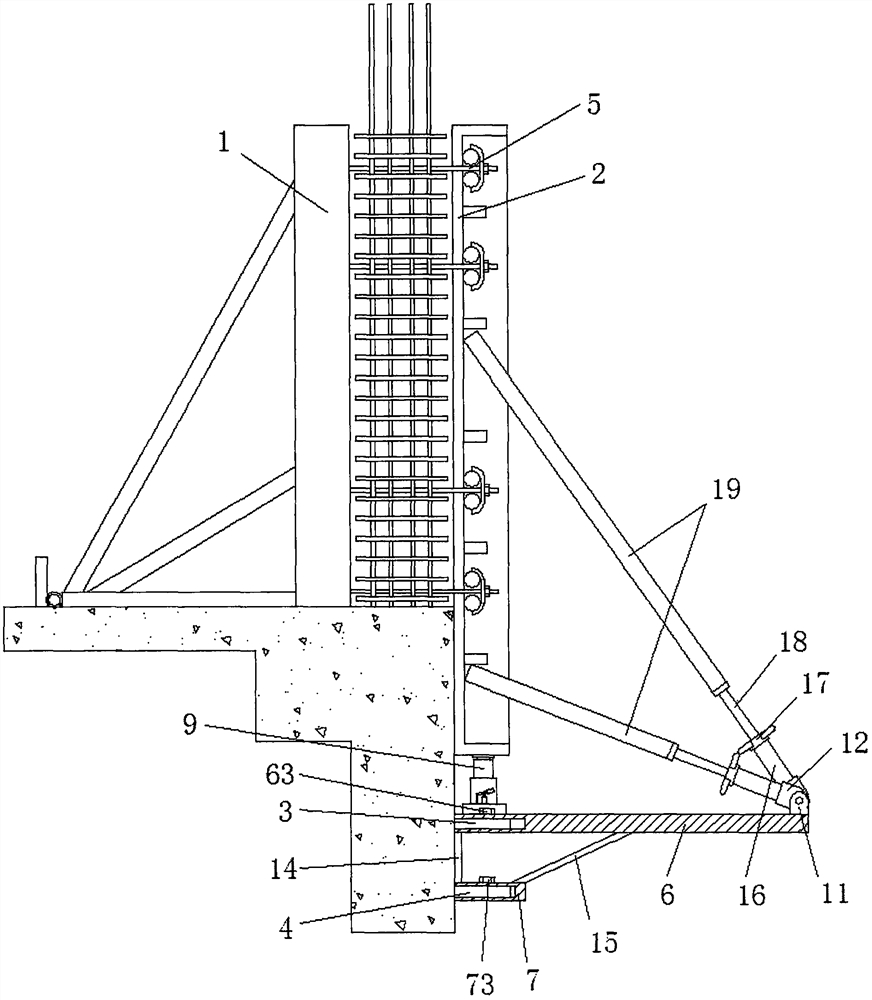

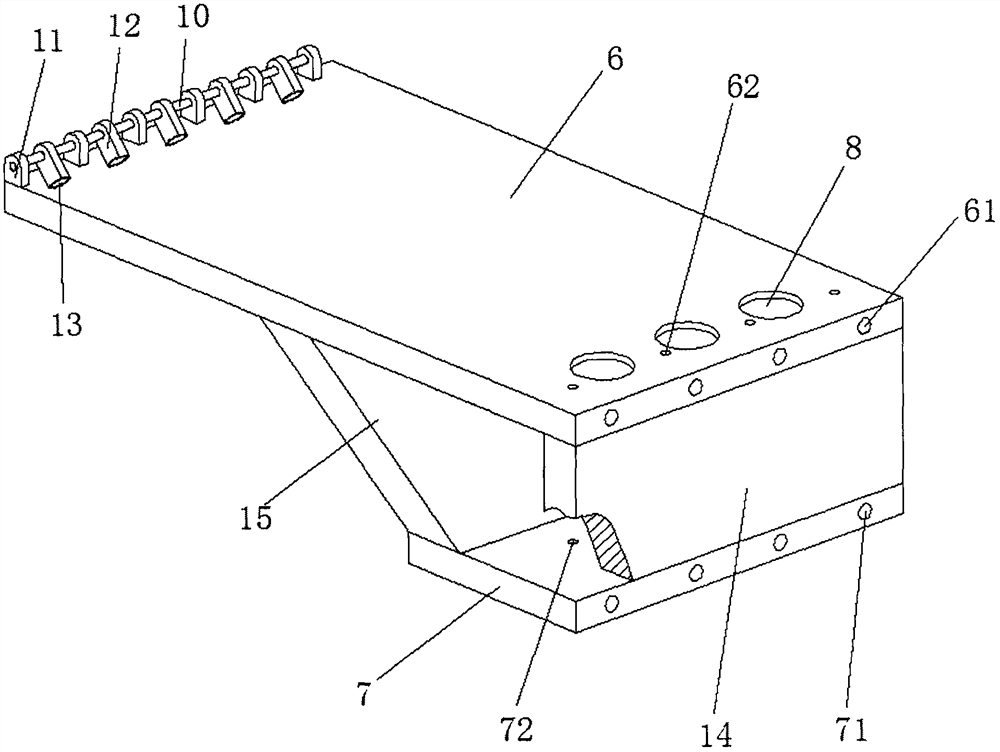

[0015] see Figure 1-2 , which includes the inner formwork 1 and outer formwork 2 located on both sides of the shear wall reinforcement that has been bound and accepted by the supervisor, and the upper row of support reinforcement 3 and the lower row of support reinforcement 4 that have been pre-implanted in the shear wall, The inner formwork 1 and the outer formwork 2 are connected and fixed into one body through screw rods 5, and a first positioning plate 6 which doubles as an operating platform is fixed on the outer side of the upper row of support bars 3, and the lower row of support A second positioning plate 7 is fixed on the outer surface of the steel bar 4, and several grooves 8 for placing jacks 9 are provided on the upper top surface of the first positioning plate 6, and the piston shaft ends of the jacks 9 are pushed against the outer formwork. At the lower bottom surface of 2, a pin shaft 10 is arranged on the upper top surface of the first positioning plate 6, and...

Embodiment 2

[0021] First, the first positioning plate 6 and the second positioning plate 7 are respectively docked with the upper row of supporting steel bars 3 and the lower row of supporting steel bars 4, and then the first bolts 63 and the second bolts 73 are tightened and locked respectively. In this state, the first Positioning plate 6 can also be used as operating platform;

[0022] Then insert the bottom of the hydraulic jack 9 into each corresponding groove 8, then adjust the piston shaft end of the jack 9 to a uniform level;

[0023] Then the inner formwork 1 and the outer formwork 2 are hoisted to designated positions respectively, wherein the outer formwork 2 is directly placed on the piston shaft end of the jack 9, and then the inner formwork 1 and the outer formwork 2 are initially fixed by means of the screw pull rod 5 In this process, the alignment of the screw holes of the outer formwork 2 and the inner formwork 1 can be adjusted through the jack 9 to adjust the height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com