Manufacturing process ofmachine washable silk quilt

A production process and technology for silk quilts, applied in mechanical treatment, silk fiber production, non-woven fabrics, etc., can solve the problems of easy sticking of silk layers, affecting comfort of quilts, caking of silk layers, etc., to improve the degumming efficiency. And the effect of degumming, improving the service life, and not easy to run the wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

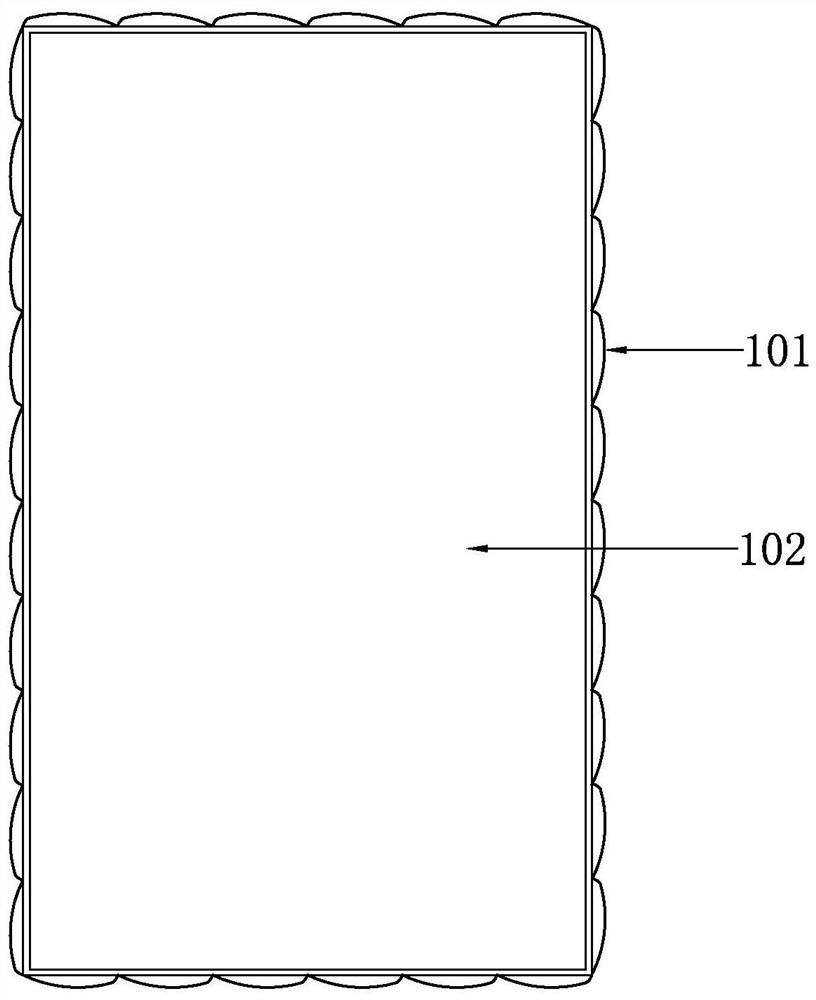

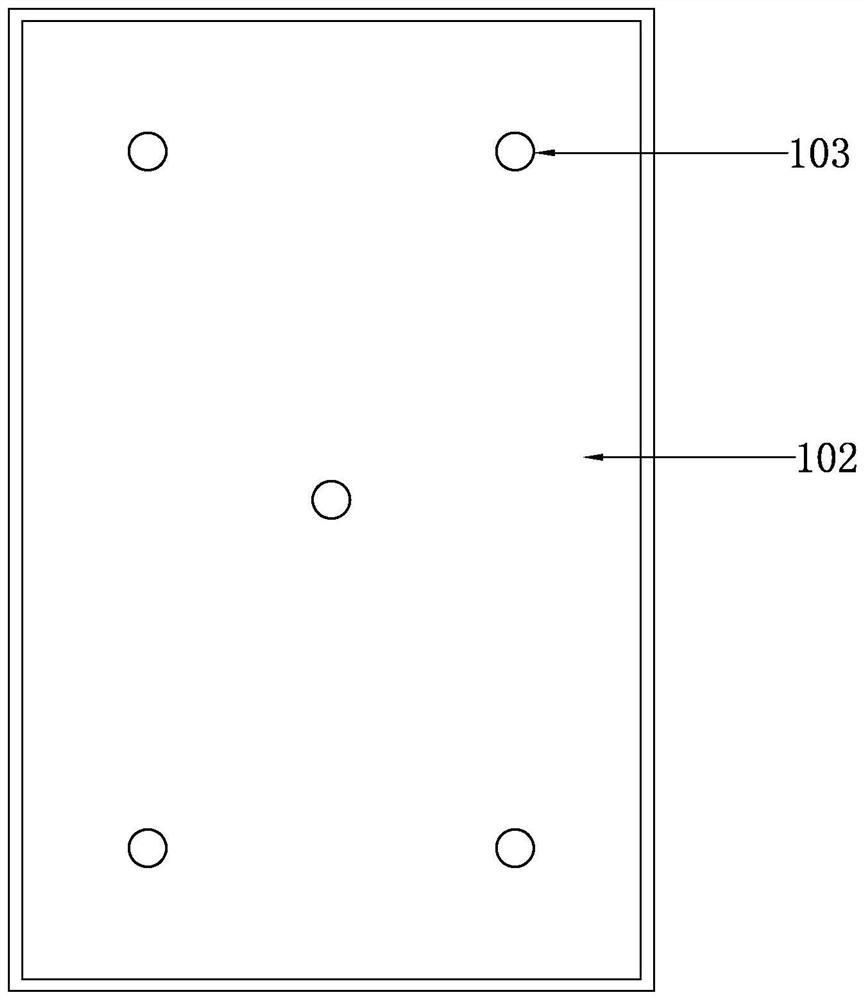

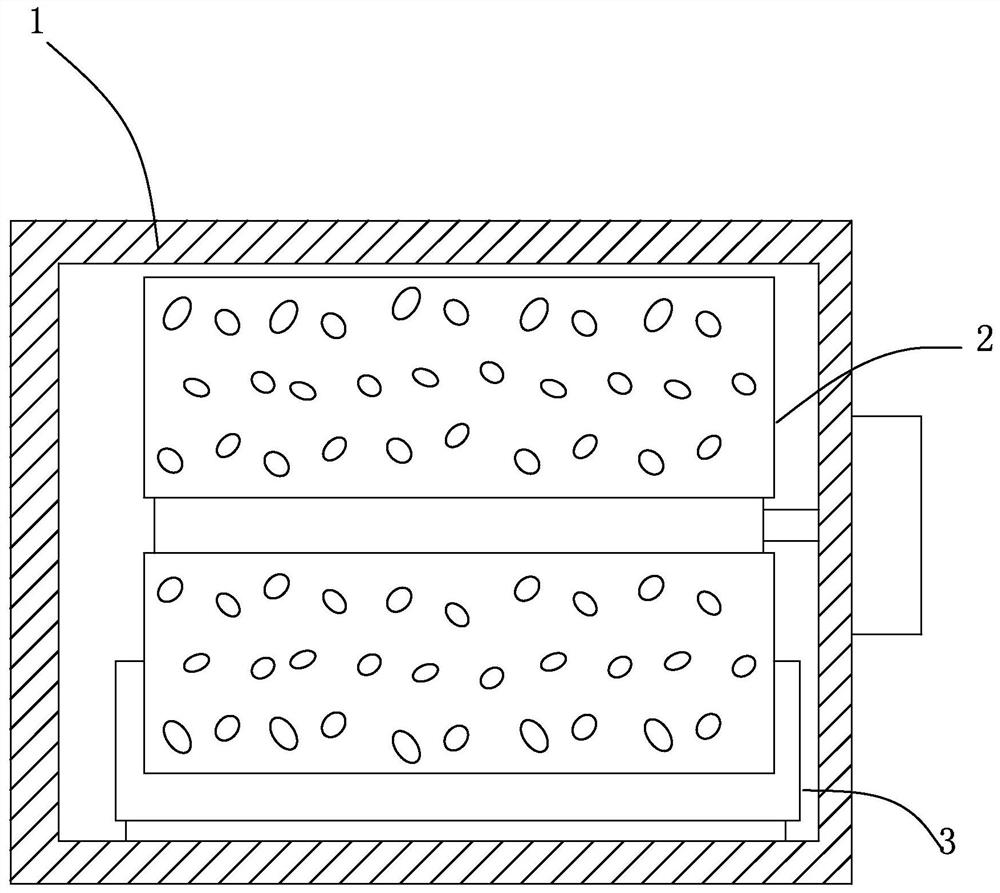

[0036] refer to Figure 1 to Figure 7 The embodiments of the present invention will be further described.

[0037] The invention relates to a production process which has a good degumming effect on silkworm cocoons and enables the produced silk quilt to be machine-washable.

[0038] Specific embodiments of the present invention:

[0039] The manufacturing process includes the following steps:

[0040] S1. Select cocoons, select double cocoons, and dry the selected double cocoons to become dry cocoons;

[0041] S2. Steaming the cocoon, placing the dried cocoon in water at a temperature of 90-100° C., adding baking soda accounting for 1% of the water weight in the water, and steaming the cocoon for 2 hours with steam;

[0042] S3, cocoon cooking, put the steamed cocoon in the cocoon cooking device, and cook for 1 hour with water at a temperature of 70-90°C and a hydrogen peroxide solution accounting for 2% of the water quality; the hydrogen peroxide solution is composed of hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com