Enameled diamond mold of high-speed large round wire horizontal enameling machine

A horizontal enameling machine, diamond technology, used in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of poor enameled wire quality, large amount of wire, card mold breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Present embodiment is a kind of grinding aid, and the preparation process of this grinding aid is as follows:

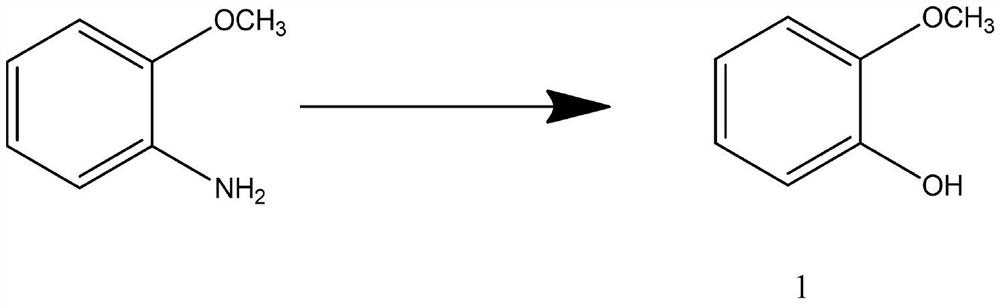

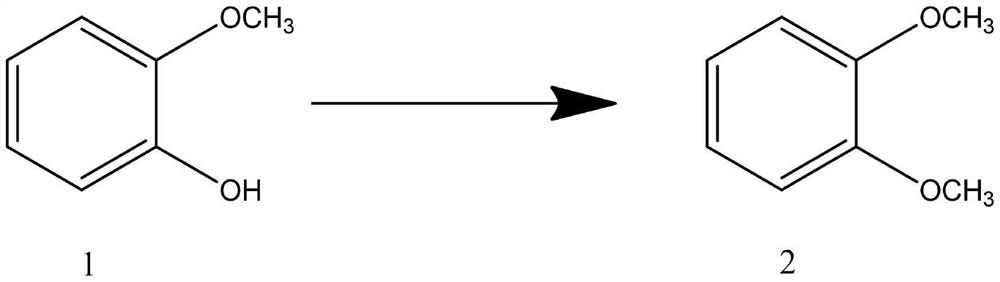

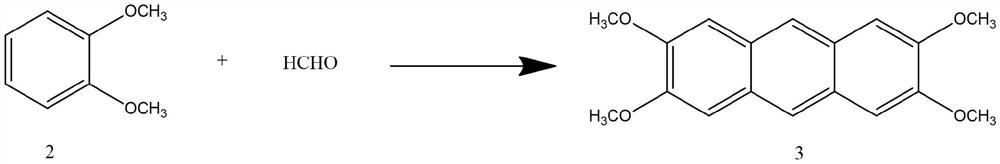

[0039] A1: Add sulfuric acid solution and anisole to a three-necked flask equipped with a thermometer, a reflux condenser, a constant pressure dropping funnel, and a magnetic stirrer, and then stir the reaction at room temperature and at a stirring rate of 100r / min After 30 minutes, cool down in an ice-water bath to below 15°C, add sodium nitrite solution drop by drop while stirring, control the dropping rate at 1 drop / s, continue stirring for 5 minutes after the addition is complete, then add urea, and then collect the reaction solution , add deionized water in the four-necked flask that thermometer, constant pressure dropping funnel and mechanical stirrer are installed, add concentrated sulfuric acid and anhydrous copper sulfate while stirring under the condition that stirring speed is 300r / min, then be warming up to 110 ℃, control the heating rate to 3 ℃ / mi...

Embodiment 2

[0045] Present embodiment is a kind of grinding aid, and the preparation process of this grinding aid is as follows:

[0046] A1: Add sulfuric acid solution and anisole to a three-necked flask equipped with a thermometer, a reflux condenser, a constant pressure dropping funnel, and a magnetic stirrer, and then stir the reaction at room temperature and at a stirring rate of 300r / min After 40 minutes, cool down in an ice-water bath to below 15°C, add sodium nitrite solution drop by drop while stirring, control the dropping rate at 1 drop / s, continue to stir and react for 15 minutes after the dropwise addition, then add urea, and then collect the reaction solution , add deionized water in the four-necked flask that thermometer, constant pressure dropping funnel and mechanical stirrer are installed, add concentrated sulfuric acid and anhydrous copper sulfate while stirring under the condition that stirring rate is 500r / min, then be warming up to 110 ℃, control the heating rate to ...

Embodiment 3

[0052]This embodiment is an enamelled diamond mold for a high-speed large round wire horizontal enamelling machine, which is prepared by the following steps:

[0053] Step 1: Perforate the diamond with laser, ultrasonically shape and polish it to the required hole shape and size to obtain the mold core;

[0054] Step 2: Add nickel, zinc, cobalt, molybdenum, copper, tungsten, and tin into a high-speed mixer, and mix and stir for 3 hours at a stirring rate of 500r / min to obtain a mixed raw material, which is mixed with the mixed raw material from the example The grinding aid in 1 is added to the ball mill for ball milling to obtain sintered powder;

[0055] Step 3: Fix the mold base with a graphite mold sleeve, place the mold core in the mold base, then add sintering powder between the mold base and the mold core, and then put it on a hot-press sintering machine for sintering processing, first at a temperature of 500°C , preheated at a pressure of 0.5MPa for 60s, then sintered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com