Patents

Literature

57results about How to "Improve fragility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot rolled wire rod for high-strength cut steel wires and production method of hot rolled wire rod

The invention discloses a hot rolled wire rod for high-strength cut steel wires and a production method of the hot rolled wire rod. The production method of the hot rolled wire rod comprises the work procedures of converter smelting, LF refining, continuous casting and steel rolling. The hot rolled wire rod comprises, by weight percentage, 0.79-0.85% of C, 0.15-0.30% of Si, 0.40-0.60% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S, smaller than or equal to 0.05% of Cr, smaller than or equal to 0.05% of Ni, smaller than or equal to 0.05% of Cu, smaller than or equal to 0.0015% of Alt, smaller than or equal to 0.0008% of Als, smaller than or equal to 0.0010% of Ti, smaller than or equal to 0.0020% of T.O, smaller than or equal to 0.0030% of N, and the balance Fe and inevitable impurity elements. The center segregation of the wire rod obtained through the method is smaller than or equal to the level 2, the grain size is smaller than the level 7, the sorbitizing rate is larger than or equal to 85%, the tensile strength ranges from 1050 MPa to 1250 MPa, the reduction of area is larger than or equal to 38%, and good drawing machining performance is achieved; inclusion has good deformation performance or fragility, the length-width ratio average value of the inclusion is larger than or equal to 6, and the maximum inclusion size is smaller than or equal to 15 microns; and the wire rod is used for a user to produce the 0.11-0.12 mm cut steel wires, and reaches the level that wire breakage is avoided when the length is 10000 km or above.

Owner:XINGTAI IRON & STEEL

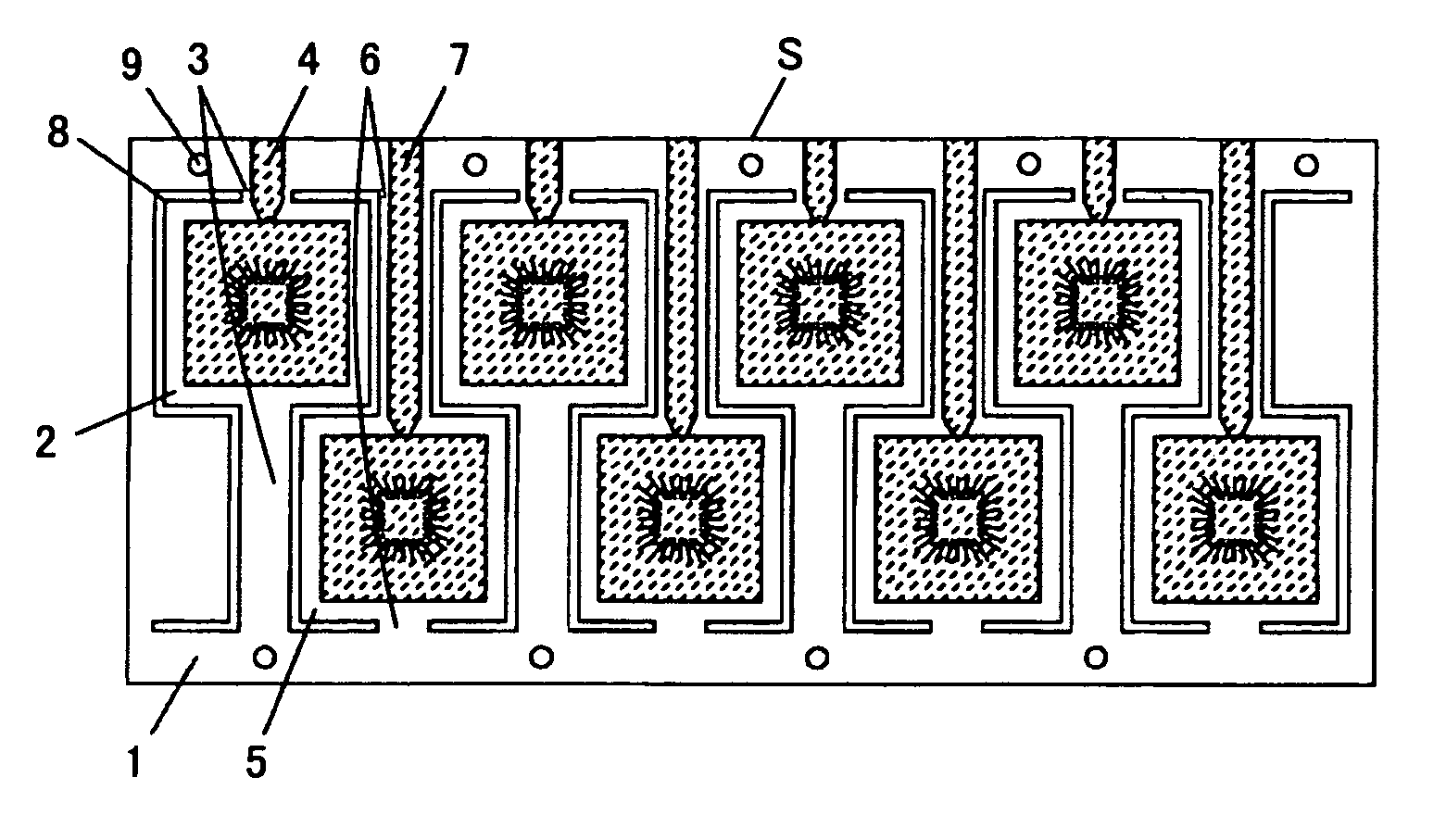

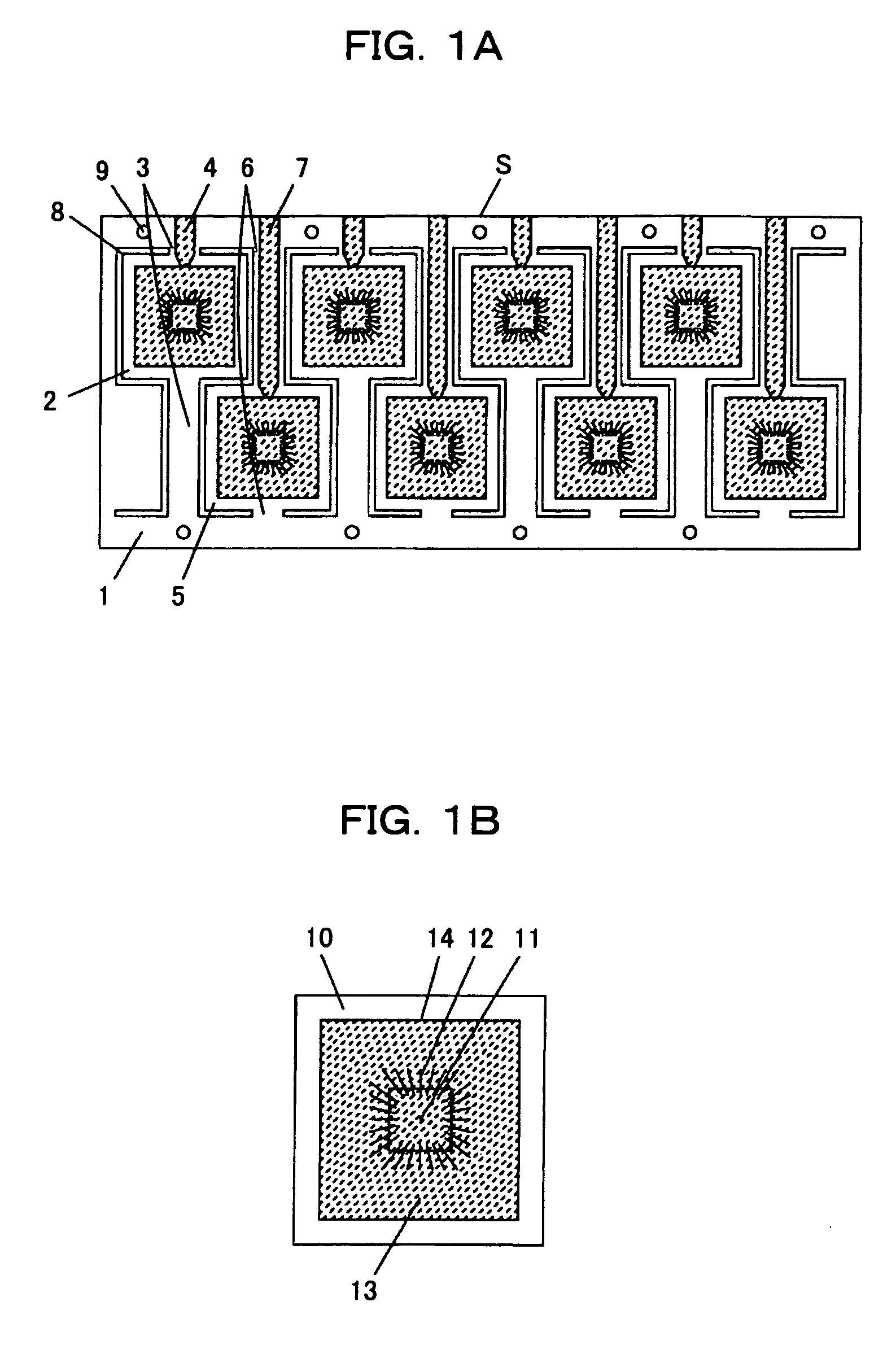

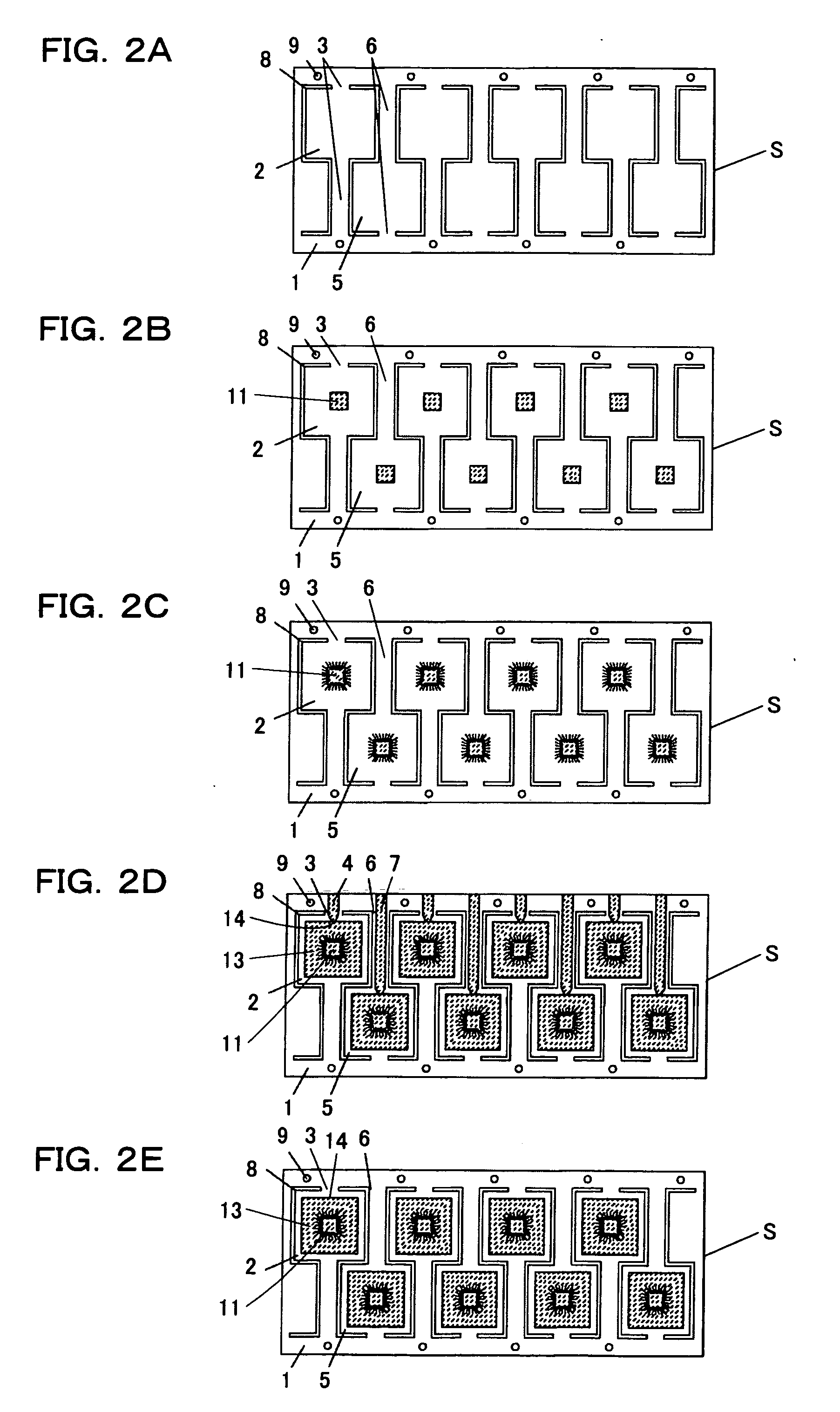

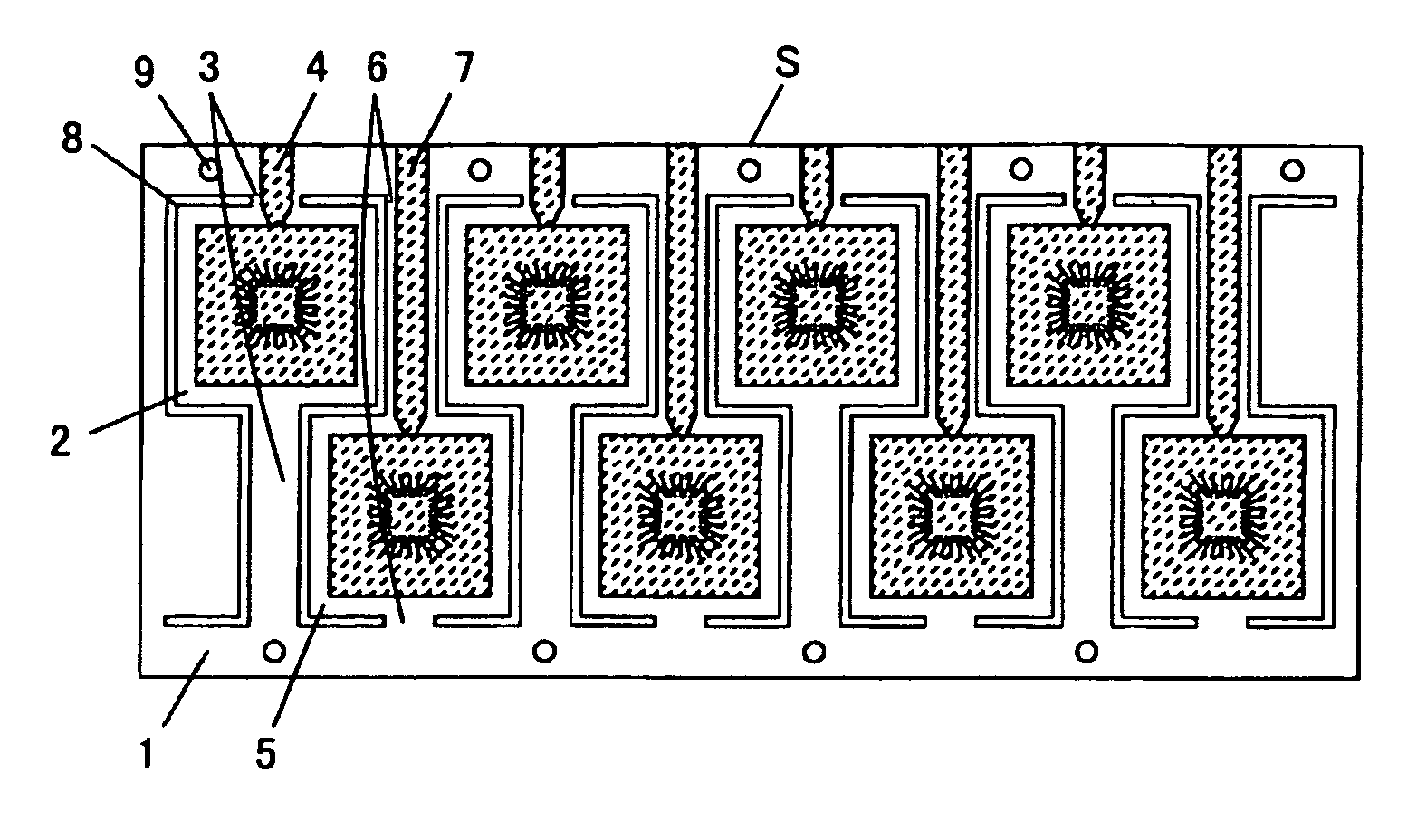

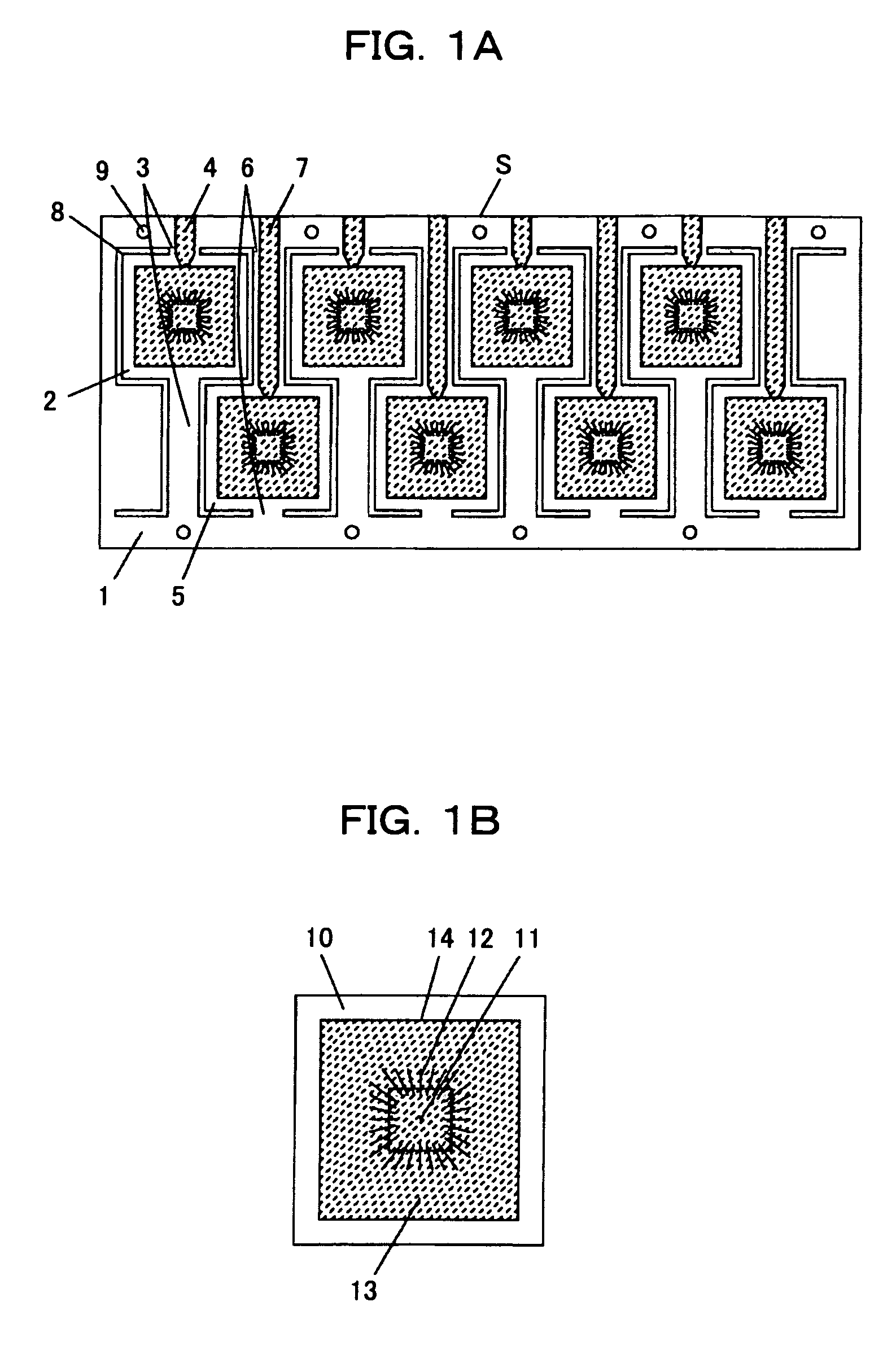

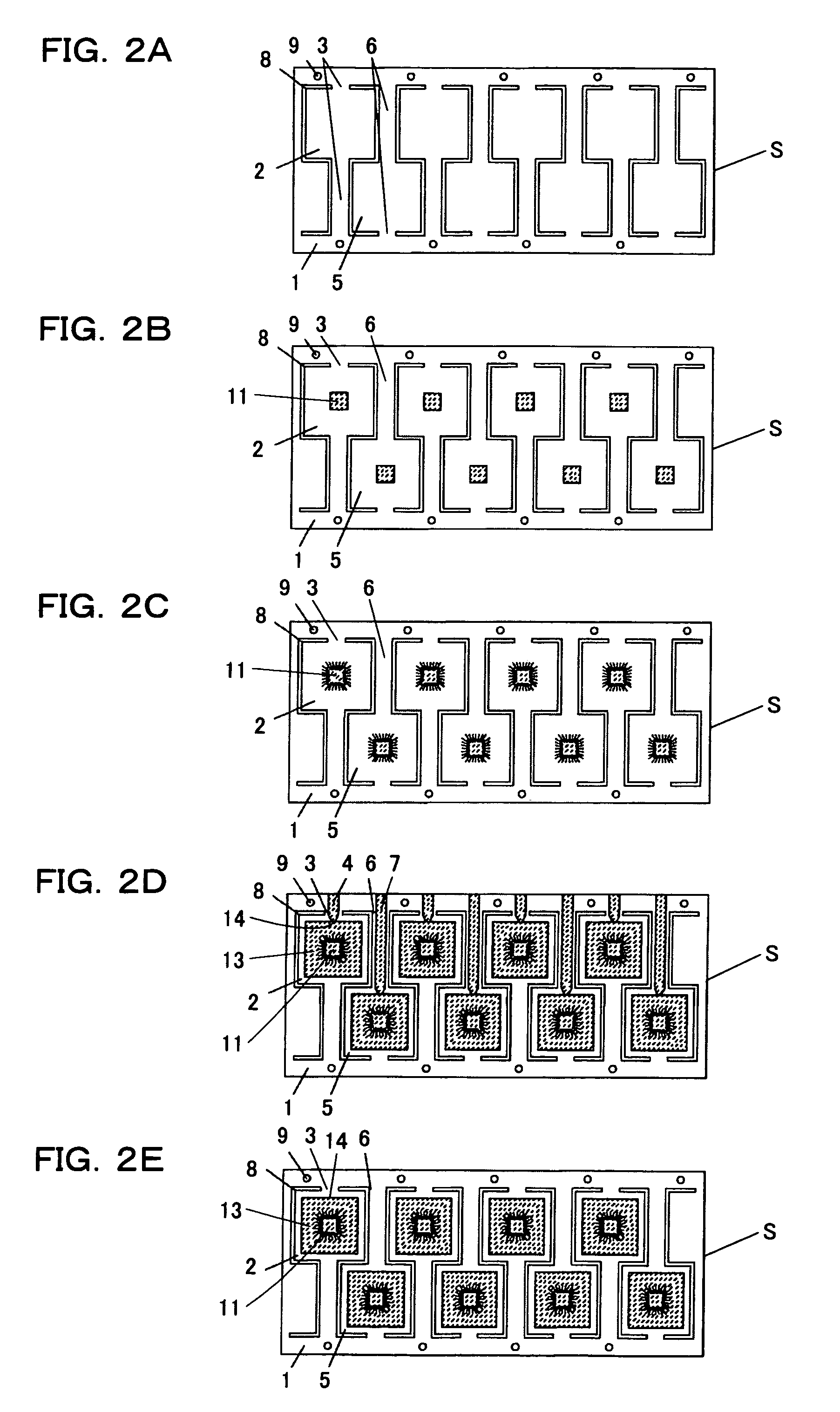

Semiconductor mount substrate, semiconductor device and method of manufacturing semiconductor package

InactiveUS20070090565A1Improved gate breakabilityAvoid it happening againSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor package

Owner:PANASONIC CORP

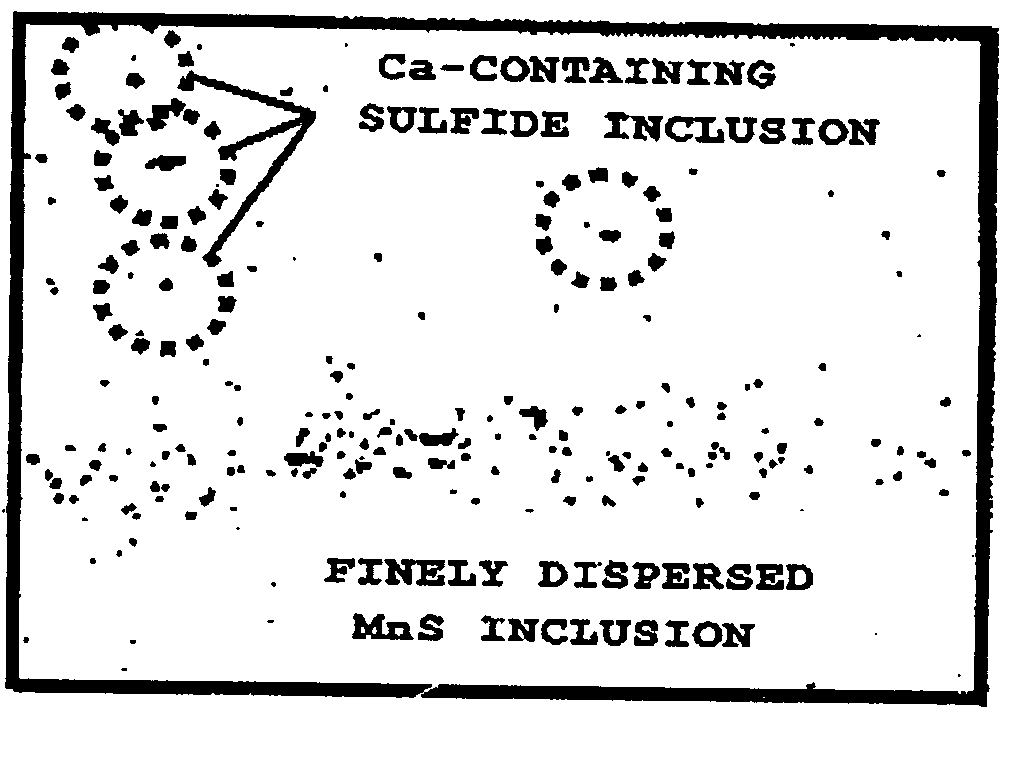

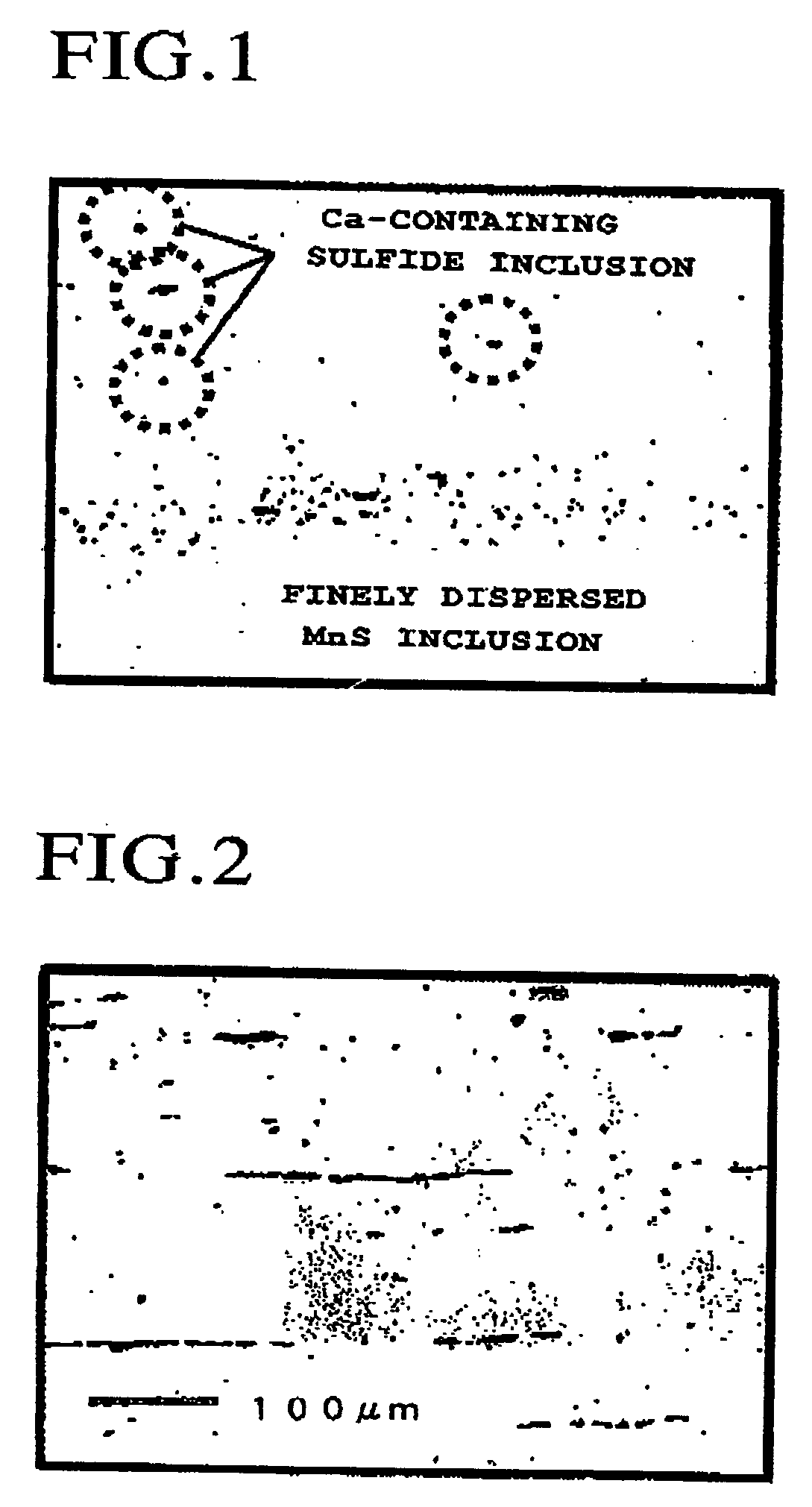

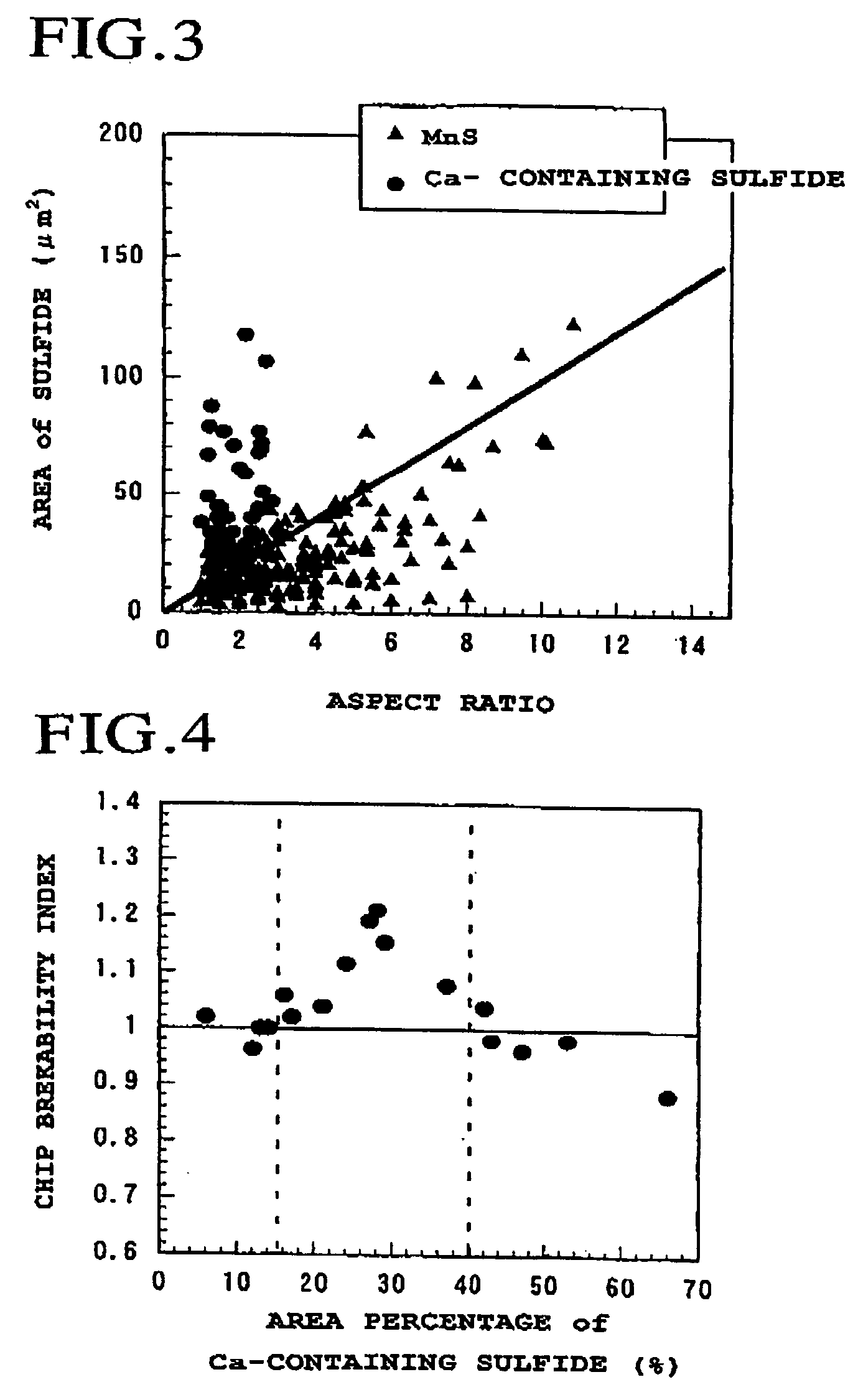

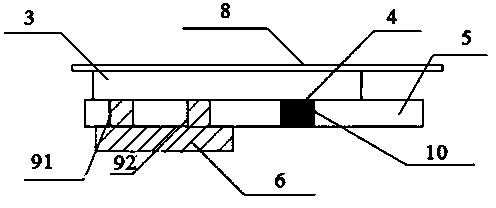

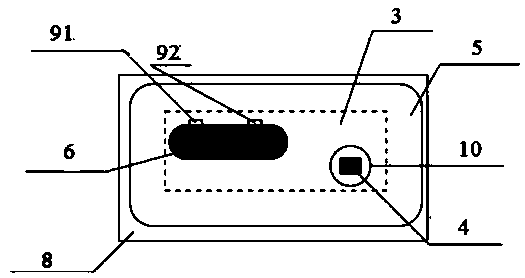

Steel for machine structural use excellent in friability of chips

Disclosed is a free cutting steel for machine structural use having excellent chip-breakability. The steel consists essentially of, by wt. %. C: 0.05-0.8%, Si: 0.01-2.5%, Mn: 0.1-3.5%, S: 0.01-0.2%, Ca or Ca+Mg; 0.0005-0.02%, Ti: 0.002-0.010% and / or Zr: 0.002-0.025%, O: 0.0005-0.010%, and the balance of impurities and Fe. At least five MnS inclusion particles having averaged particles sizes of 1.0 μm or more exists per mm2 per 0.01% of S-content in the steel. The steel satisfies the condition that, in the microscopic fields, (area[μm2] / aspect ratio)≧10, and that the the area percentage of Ca-containing sulfide inclusions containing at least 1.0 wt. % of Ca is in the range of 15-40% of the area of all the sulfide inclusions.

Owner:HONDA MOTOR CO LTD +2

Radio frequency identification label and manufacturing method thereof

ActiveCN103839099AFragile performance is goodGood anti-counterfeiting performanceRecord carriers used with machinesRadio frequencyAdhesive

The invention discloses a radio frequency identification label and a manufacturing method of the radio frequency identification label. The label comprises a surface mark layer, an upper adhesion layer, a fragile radio frequency identification layer and a lower adhesion layer, wherein the layers are sequentially and mutually combined. The fragile radio frequency identification layer comprises a release layer, a radio frequency identification antenna, a chip, an isolating layer and a conducting layer, wherein the isolating layer is provided with a chip hole and a vertically through bridge hole, the antenna is arranged on one side of the isolating layer, the conducting layer is located on the other side of the isolating layer, the chip is arranged in the chip hole, the isolating layer is provided with small holes communicated with the chip hole and the bridge hole, the conducting layer penetrates through the bridge conducting hole to be connected with the antenna, and the chip adheres to the radio frequency identification antenna through a conductive adhesive. The label is good in anti-fake performance and free of the problem that conducting is influenced by material rebounding and the like, so that the rate of finished products is greatly increased, and product cost is reduced.

Owner:SHANGHAI TECHSUN ANTI COUNTERFEITING TECH HLDG +1

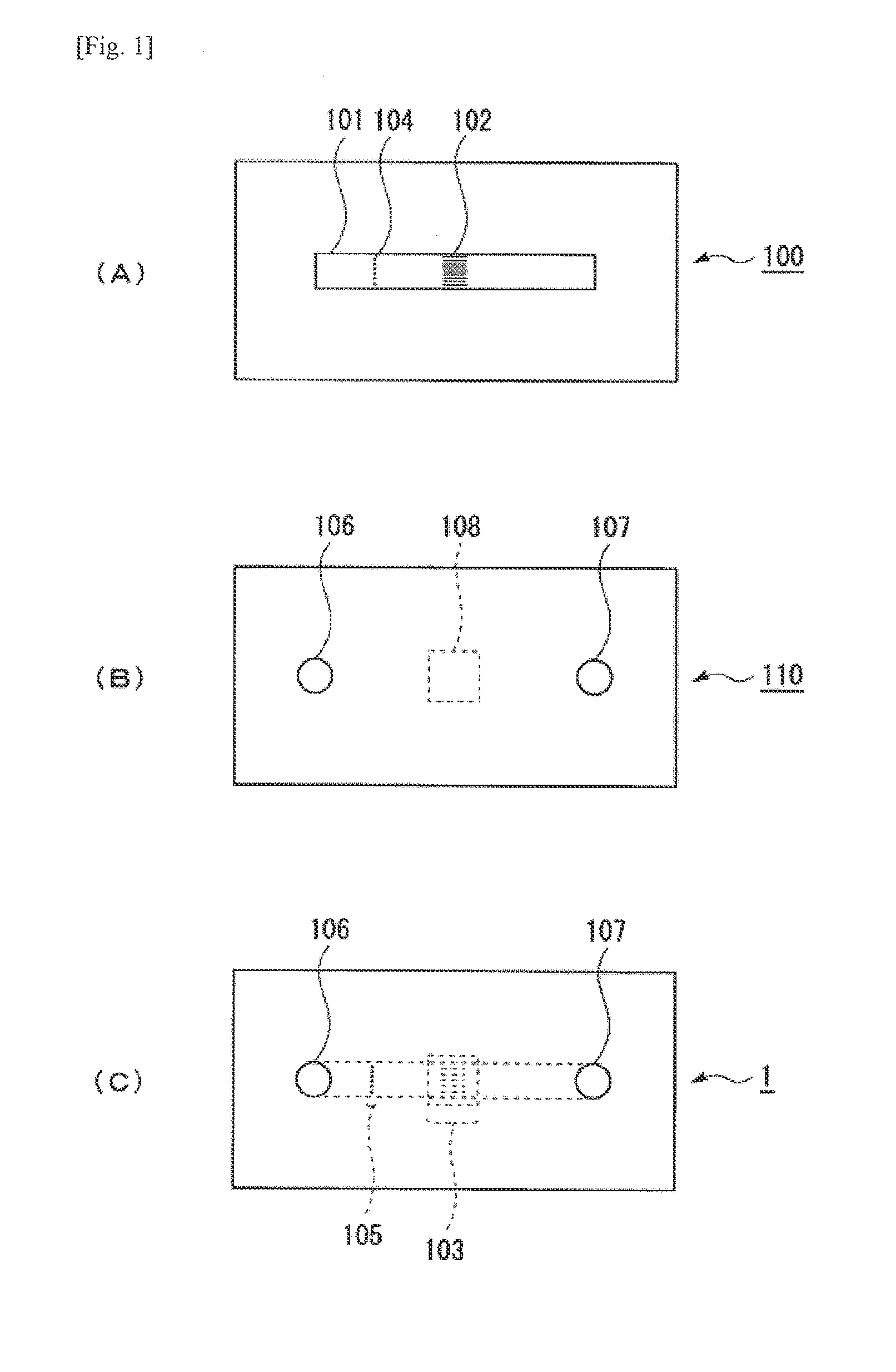

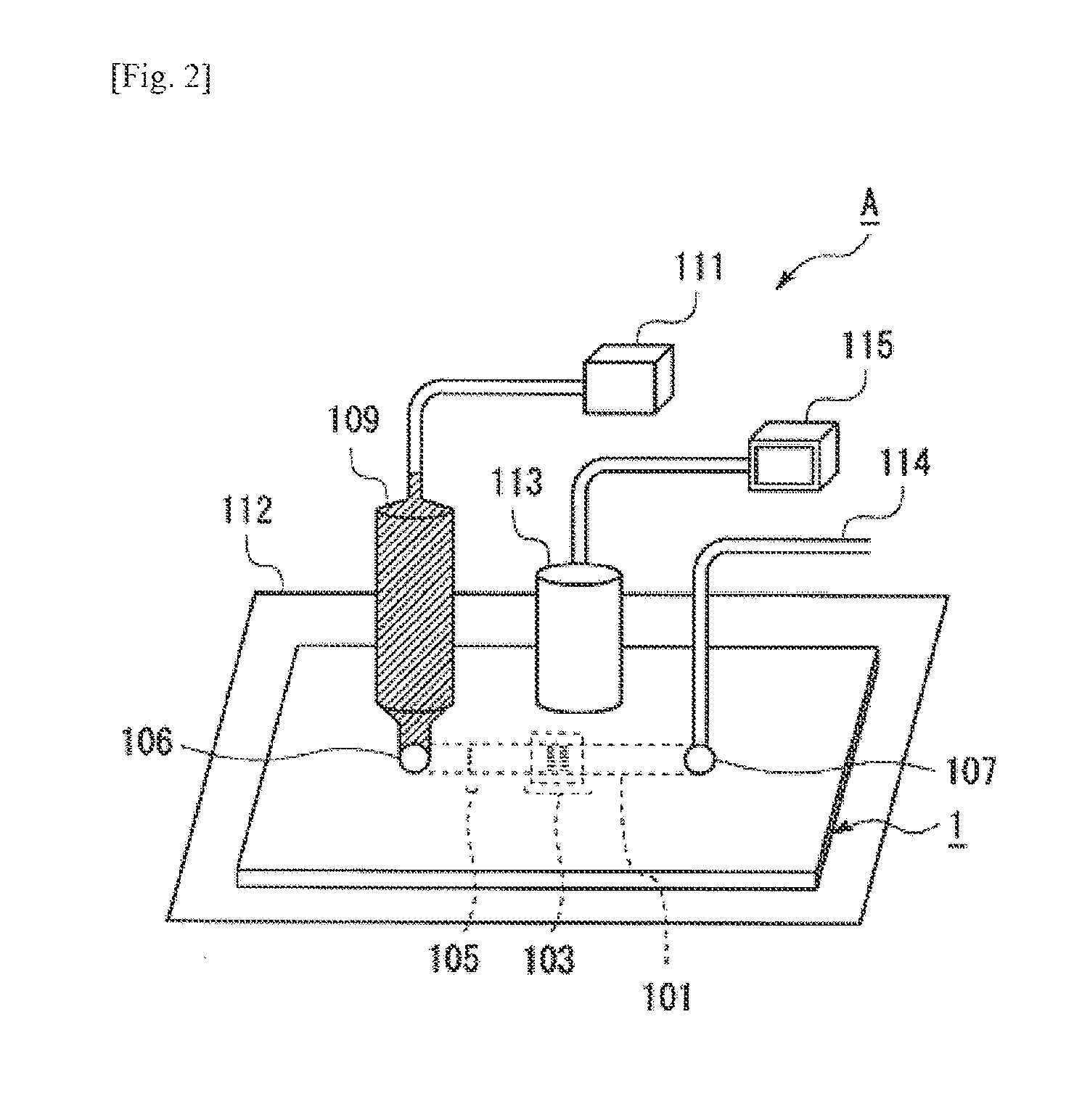

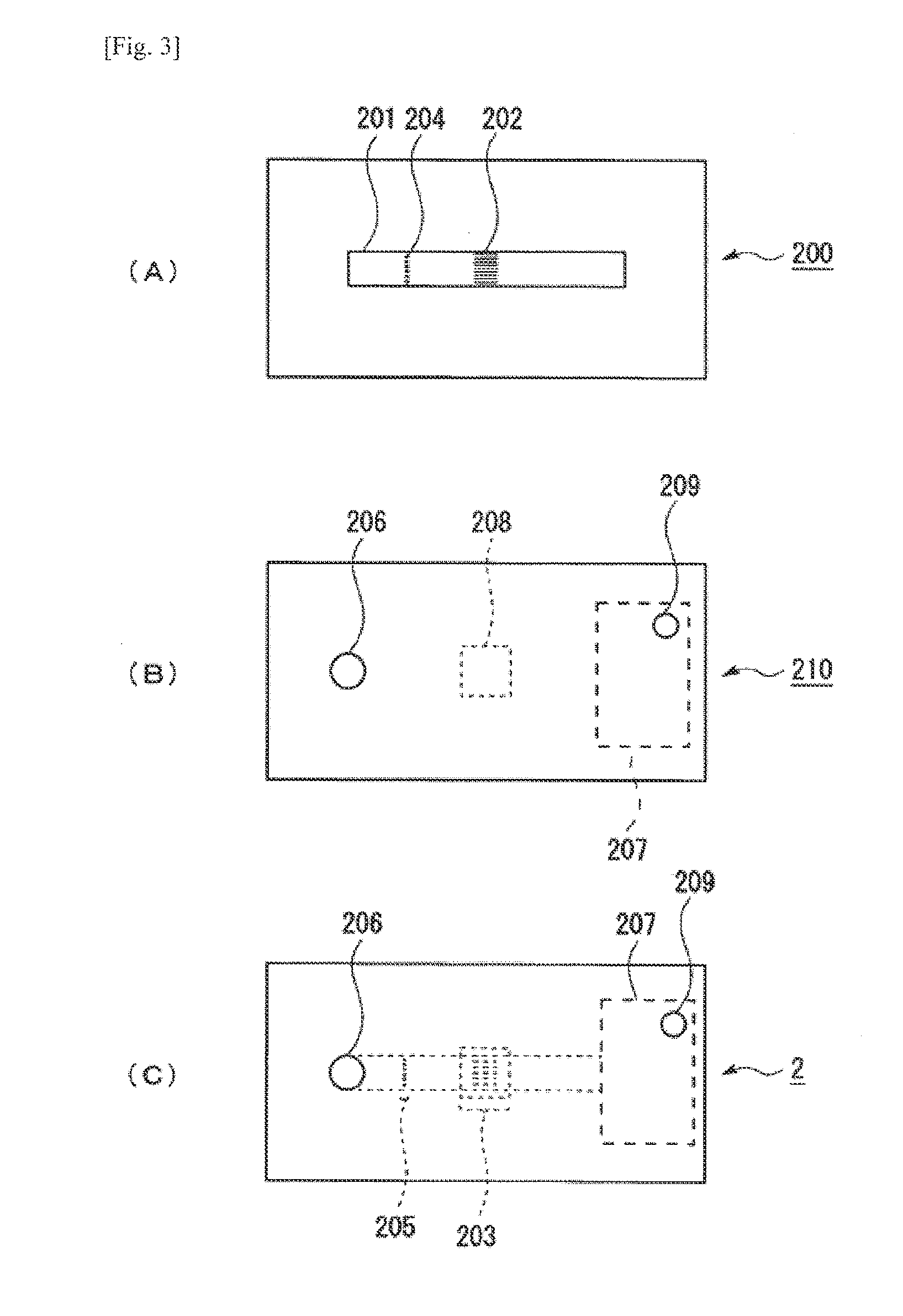

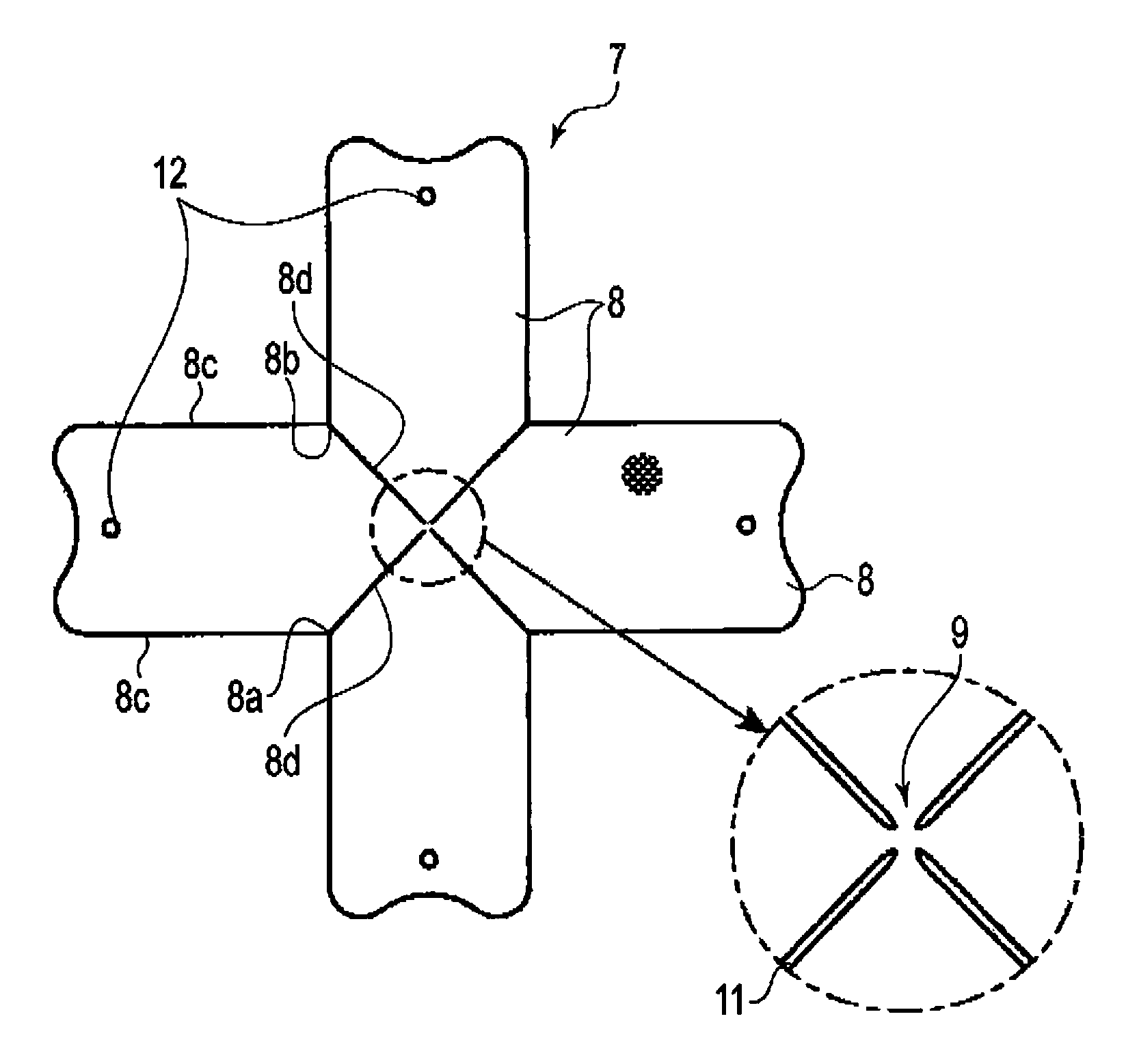

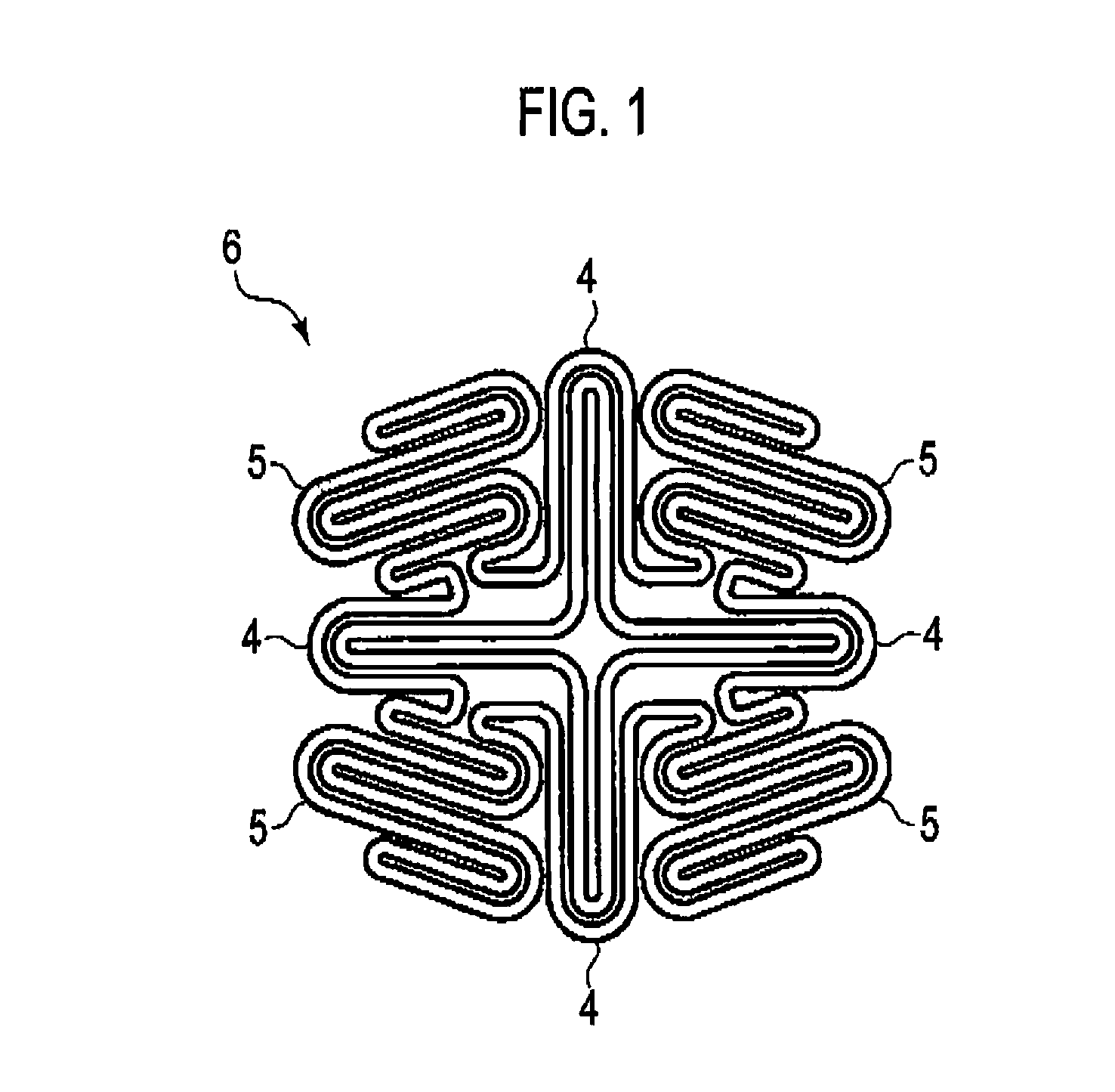

Microchip for Platelet Examination and Platelet Examination Device Using Same

ActiveUS20120301966A1Strong and stable pressure increaseOptimize dataLaboratory glasswaresDisease diagnosisMedicineSurface roughness

Owner:FUJIMORI KOGYO CO LTD

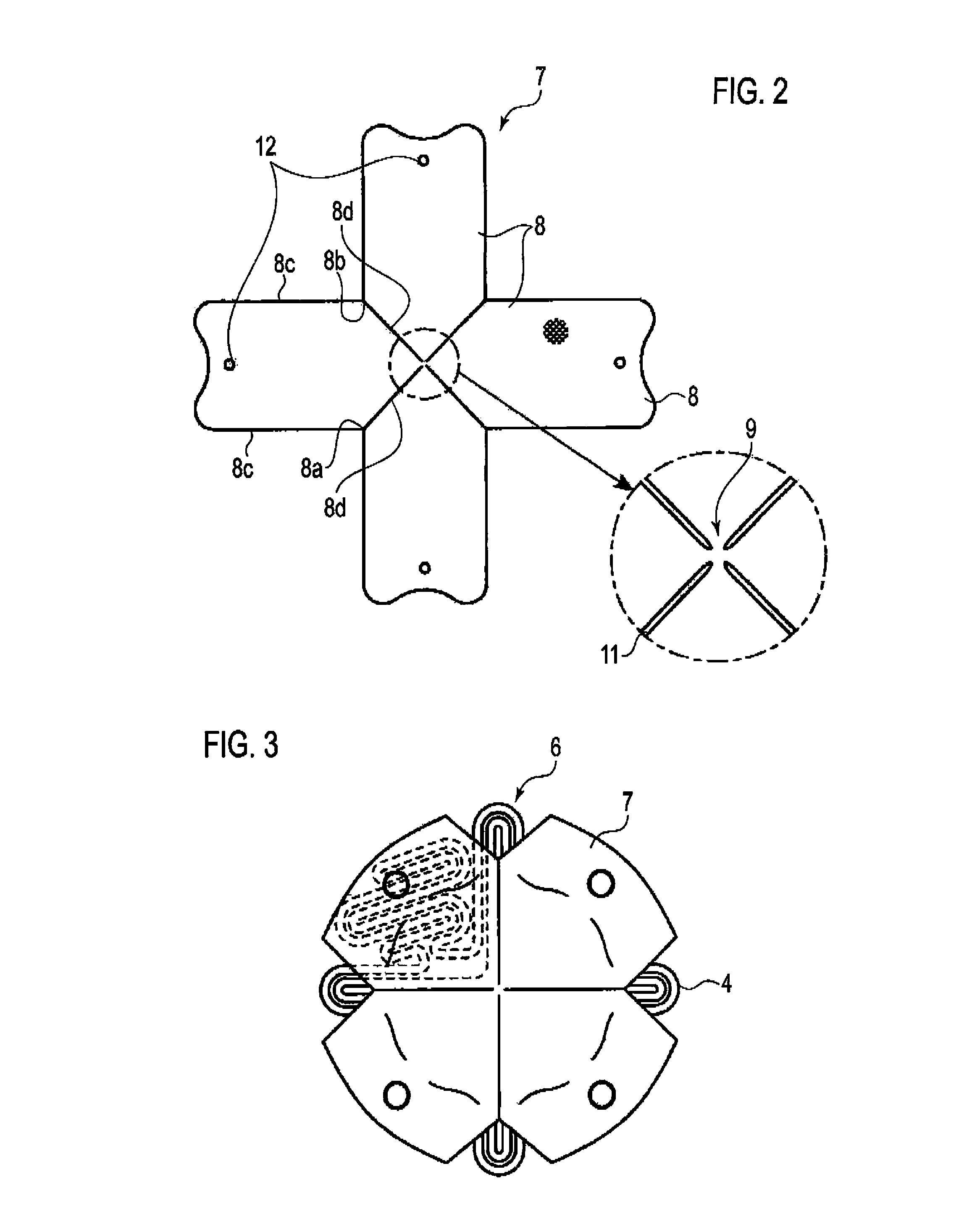

Airbag device

ActiveUS8789848B2Reduce the differenceImprove fragilityPedestrian/occupant safety arrangementAirbagEngineering

An airbag device includes an airbag folded into a shape having a base portion, an upper surface opposite the base portion, and a side portion surrounding a portion between the base portion and the upper surface, and a holding member configured to cover the airbag as folded by being laid over the airbag as folded. The holding member has a plurality of cloth piece portions and a single connection portion connecting the plurality of cloth piece portions to one another. The connection portion of the holding member is located at the upper surface of the airbag as folded.

Owner:NIHON PLAST CO LTD

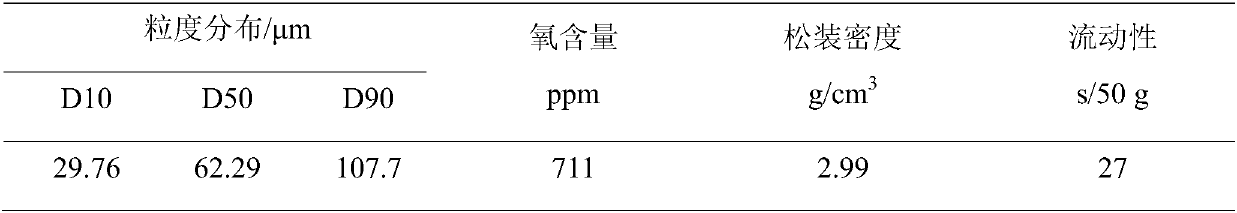

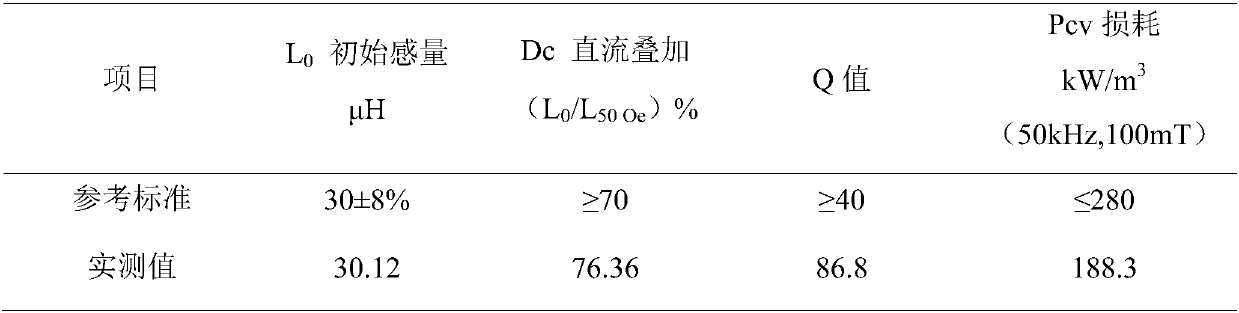

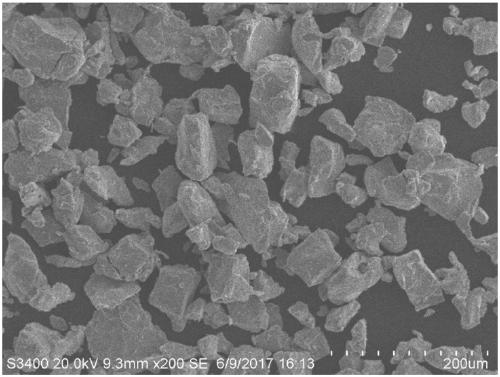

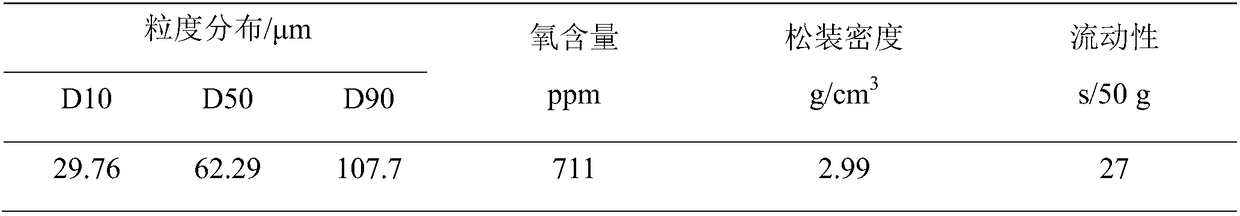

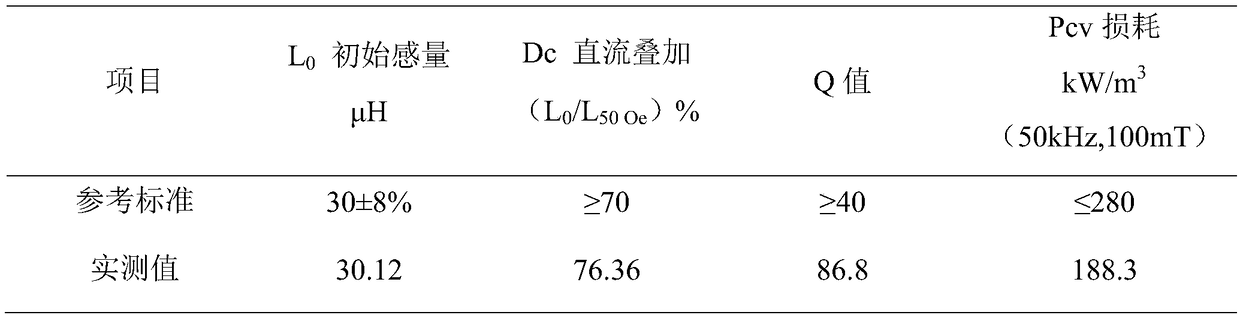

Metal soft magnetic iron silicon aluminum alloy powder and preparing method thereof

ActiveCN107675074AMany microscopic shapesReduce sharp cornersMagnetic materialsBall millInduction furnace

The invention relates to a preparing method of metal soft magnetic iron silicon aluminum alloy powder, and belongs to the technical field of metal soft magnetic material manufacturing. The preparing method comprises the steps that a furnace burden pure iron square billet, bulk metal silicon and a pure aluminum ingot are used as raw materials, and the raw materials are weighed according to the proportion; a non-vacuum medium-frequency induction furnace is used to induce, smelt and obtain alloy molten steel of the required components, and an alloy ingot is obtained after casting; the alloy ingotis crushed, and then a particle material with the particle size being below 5 mm is obtained; then fine powder of 180 meshes is obtained through a crushing ball mill technology; and finally, the ironsilicon aluminum alloy powder is obtained through annealing of 800-850 DEG C under nitrogen atmosphere and even mixing. The particle size distribution of the iron silicon aluminum alloy powder prepared by the method is narrow and adjustable, the shape of the powder is in a regular polygon, sharp corners are few, the effect of insulating coating is ensured advantageously, and the comprehensive magnetic properties of an iron silicon aluminum magnetic powder core after forming and pressing and sintering are excellent.

Owner:马鞍山新康达磁业股份有限公司

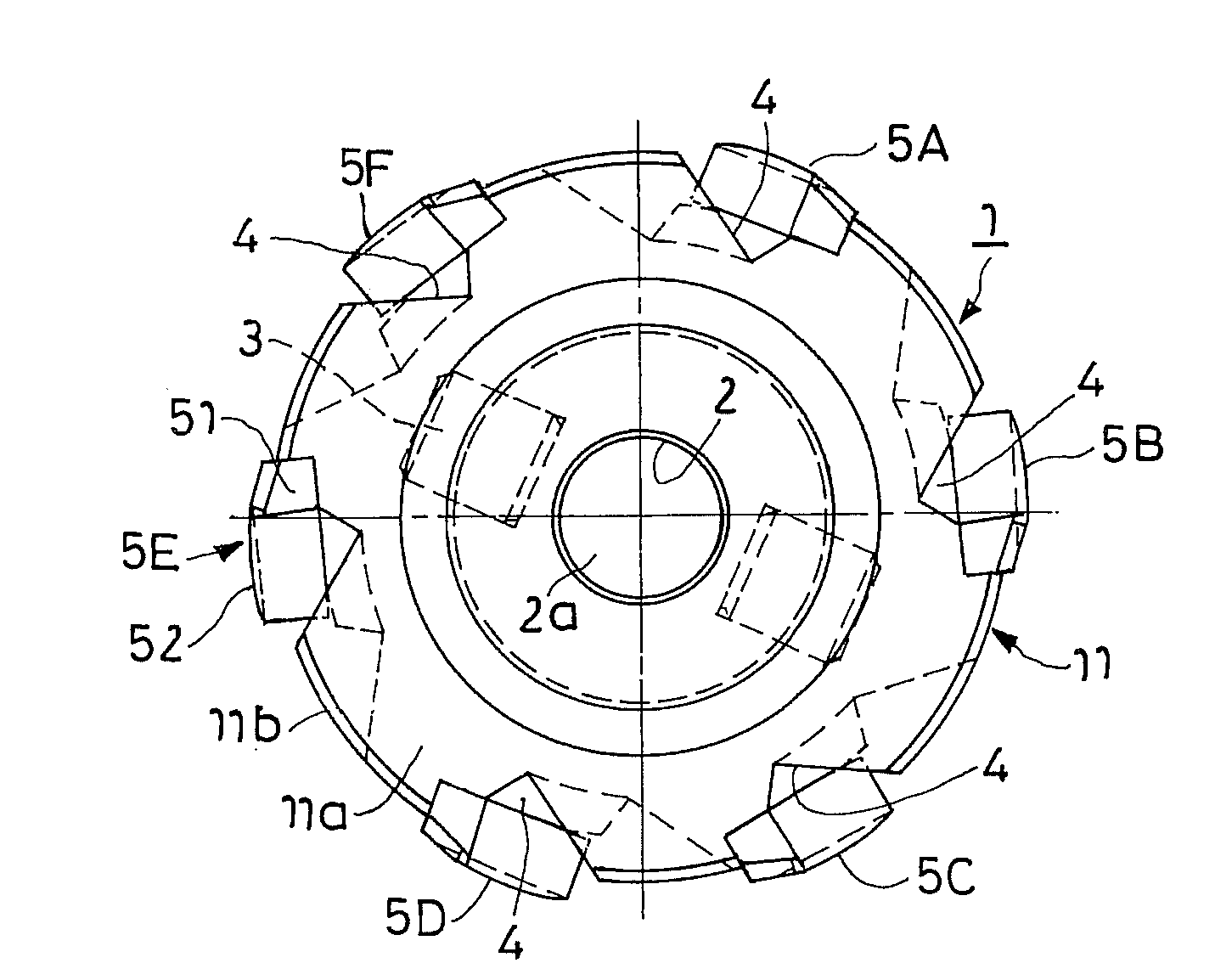

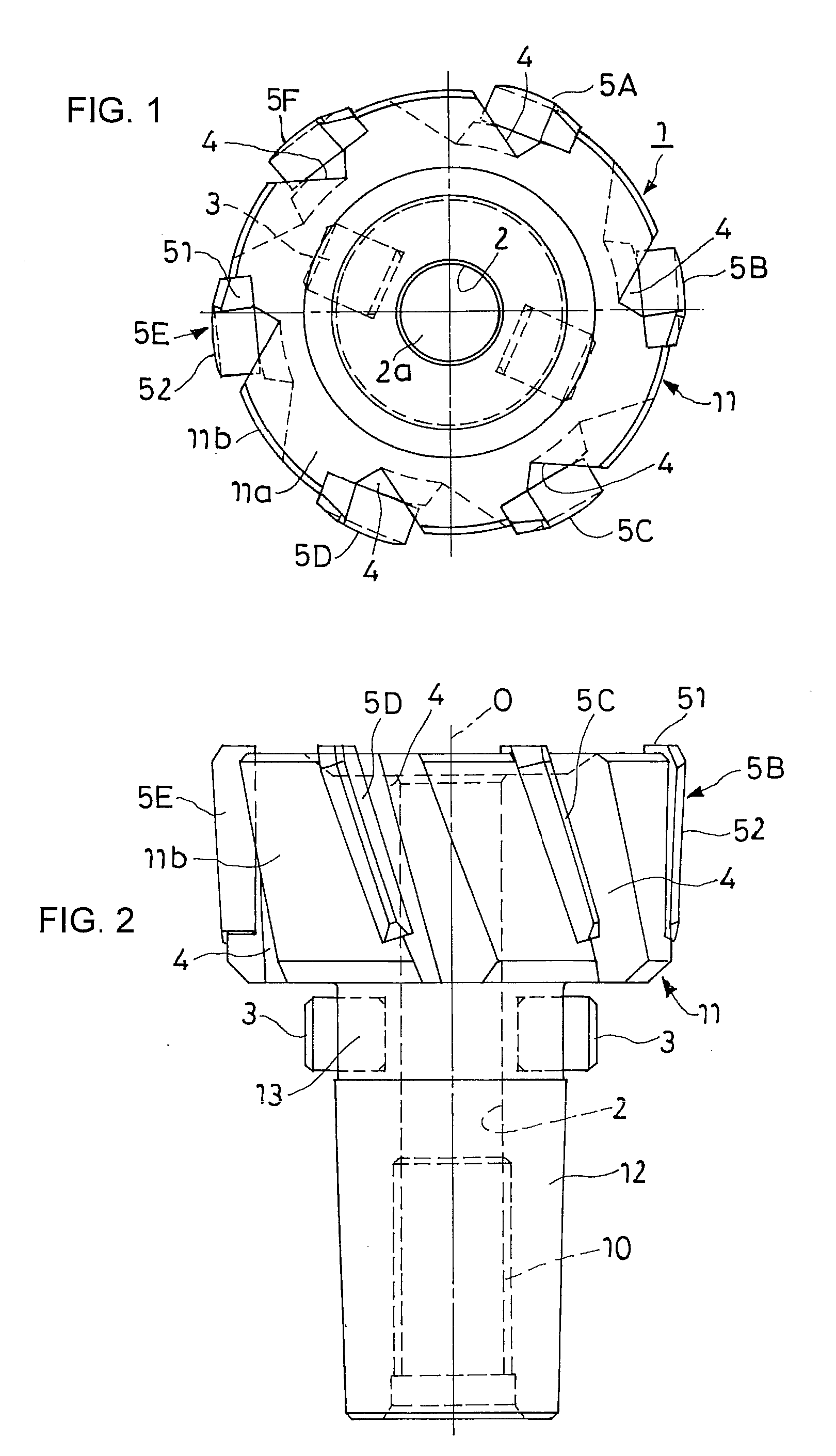

Machine reamer

ActiveUS20070237593A1Increased durabilityImprove machine performanceWood turning toolsTransportation and packagingEngineeringReamer

A machine reamer has blades to which a work material is not easily adhered by heat even if a cutting speed is increased, and hence high processing efficiency can be obtained. Additionally, the cutting edge of the blade is only slightly worn down even if heavy cutting is performed, and hence excellent durability and an extremely long machine life can be obtained. A plurality of slender blades is erected on the outer peripheral part of a reamer head body. Different kinds of materials are used to make the blades.

Owner:YUNITAKKU

Melt-in-mouth jelly and preparation method thereof

The invention discloses melt-in-mouth jelly and a preparation method thereof. The melt-in-mouth jelly comprises the following raw constituents in parts by weight: 75-85 parts of softened water, 0.2-0.4 part of starch, 0.1-0.2 part of konjac flour, 0.1-0.2 part of carrageenan, 16-22 parts of white granulated sugar, 0.1-0.4 part of calcium lactate, 0.1-0.4 part of citric acid, 0.1-0.4 part of malic acid, 0.1-0.4 part of sodium citrate and 0.1-0.3 part of food flavor. The preparation method comprises the following steps: cooking, emulsifying for cutting, concoction, filling, sealing, disinfection, cooling and drying. The melt-in-mouth jelly has the advantages that the dose of the starch is increased while the konjac flour and the carrageenan are used, so that the connections between the molecular bonds of the carrageenan and the molecular bonds of the konjac flour are weakened; as the process step of pipeline-type shear emulsification is added after the process step of cooking, parts of the meshed structures already formed between the carrageenan and the konjac flour are broken, the friability is improved as the gel elasticity is lowered, the gel strength is relatively low, and the taste can be smooth and soft. Therefore, the melt-in-mouth jelly has a melt-in-mouth taste.

Owner:LUOHE LIANTAI FOOD

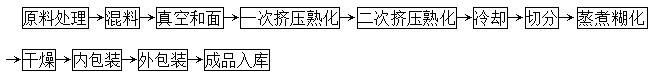

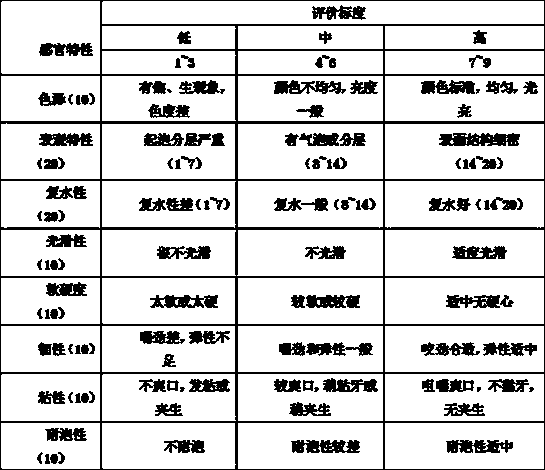

Hordeum Vulgare L. var. nudum Hook. F nutritive coarse cereal instant noodles and processing method thereof

InactiveCN108740757AWith bowel cleansing and detoxificationRegulate blood sugarFood ingredient as taste affecting agentFood ingredient as flavour affecting agentAmyrisCompound a

The invention relates to hordeum Vulgare L. var. nudum Hook. F nutritive coarse cereal instant noodles and a processing method thereof. In accordance with problems in the prior art, hordeum Vulgare L.var. nudum Hook. F is used as a main raw material, millet, whole potato flour and chenopodium quinoa willd are added to fill amino acids limited by the hordeum Vulgare L. var. nudum Hook. F, and thenutritive coarse cereal instant noodles based on the hordeum Vulgare L. var. nudum Hook. F are in continuous industrial production through performing vacuum dough mixing and compounding a starch modifier. The nutritive coarse cereal instant noodles based on the hordeum Vulgare L. var. nudum Hook. F made by the processing method disclosed by the invention have rich fragrance of the hordeum VulgareL. var. nudum Hook. F, and good mouth feel, sense evaluation is greater than or equal to 80 scores, the moisture content is smaller than or equal to 11%, the rehydration rate is greater than or equalto 1.6, and the rehydration time is 4-6min; a functional factor in the hordeum Vulgare L. var. nudum Hook. F, namely beta-glucan is reserved for 85% or above; through the processing of the raw material of the hordeum Vulgare L. var. nudum Hook. F, beta-glucanase is deactivated, so that the functional component in the hordeum Vulgare L. var. nudum Hook. F, namely the beta-glucan is reserved to themaximum extent; through the developed starch modifier, the gluten content of pure hordeum Vulgare L. var. nudum Hook. F dough can be improved, the porosity of a gluten net of the dough can be reduced,the forming of hordeum Vulgare L. var. nudum Hook. F cakes can be improved, the mouth feel of the hordeum Vulgare L. var. nudum Hook. F nutritive coarse cereal instant noodles can be improved, and the quality of the products can be improved.

Owner:四川东方主食产业技术研究院

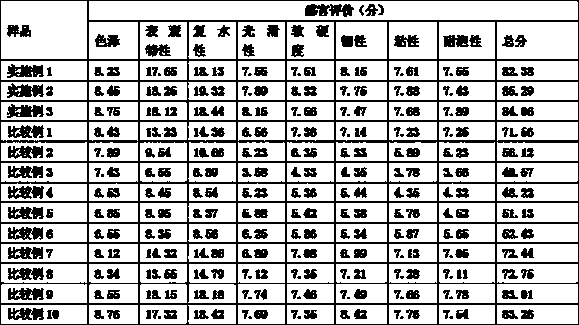

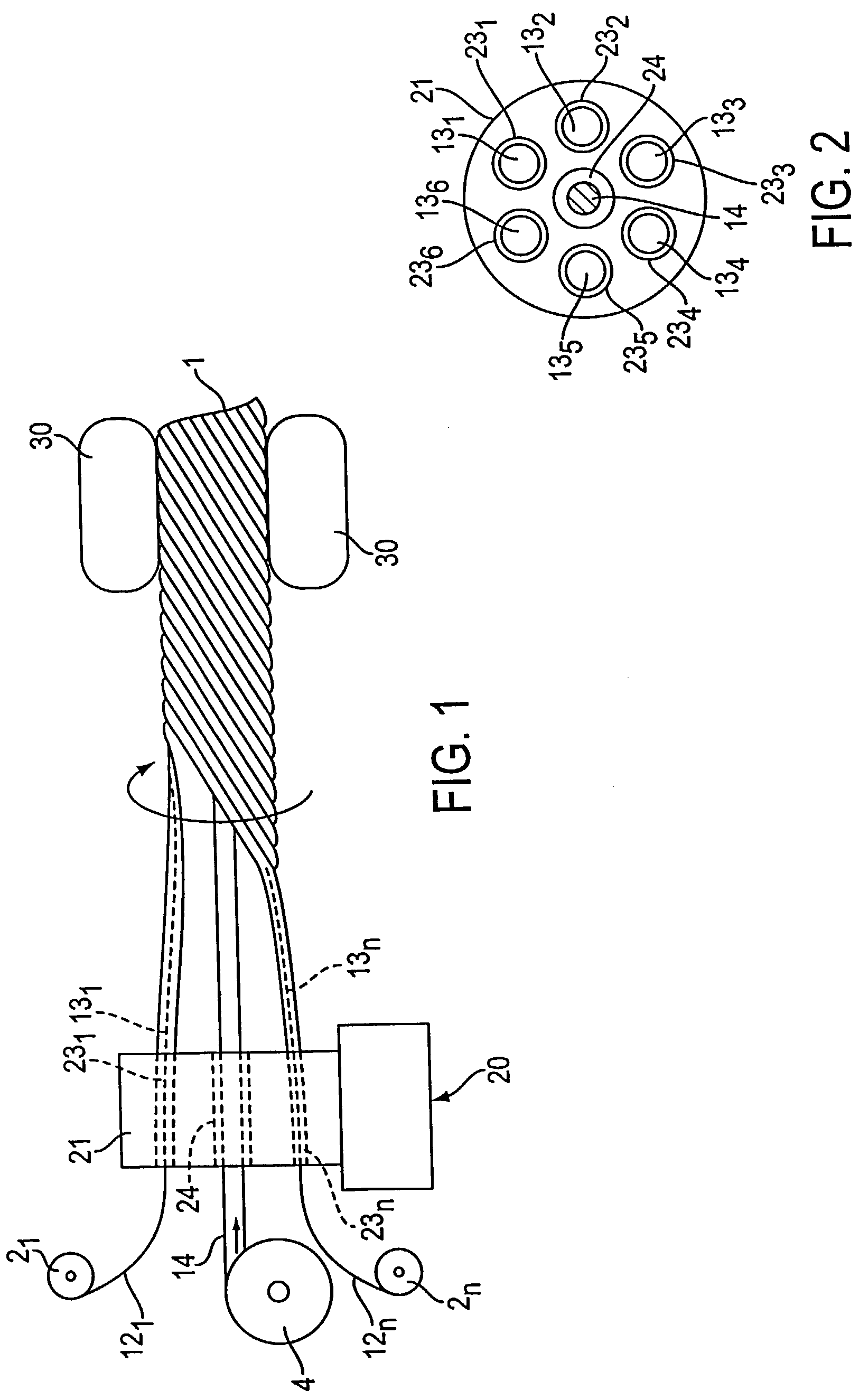

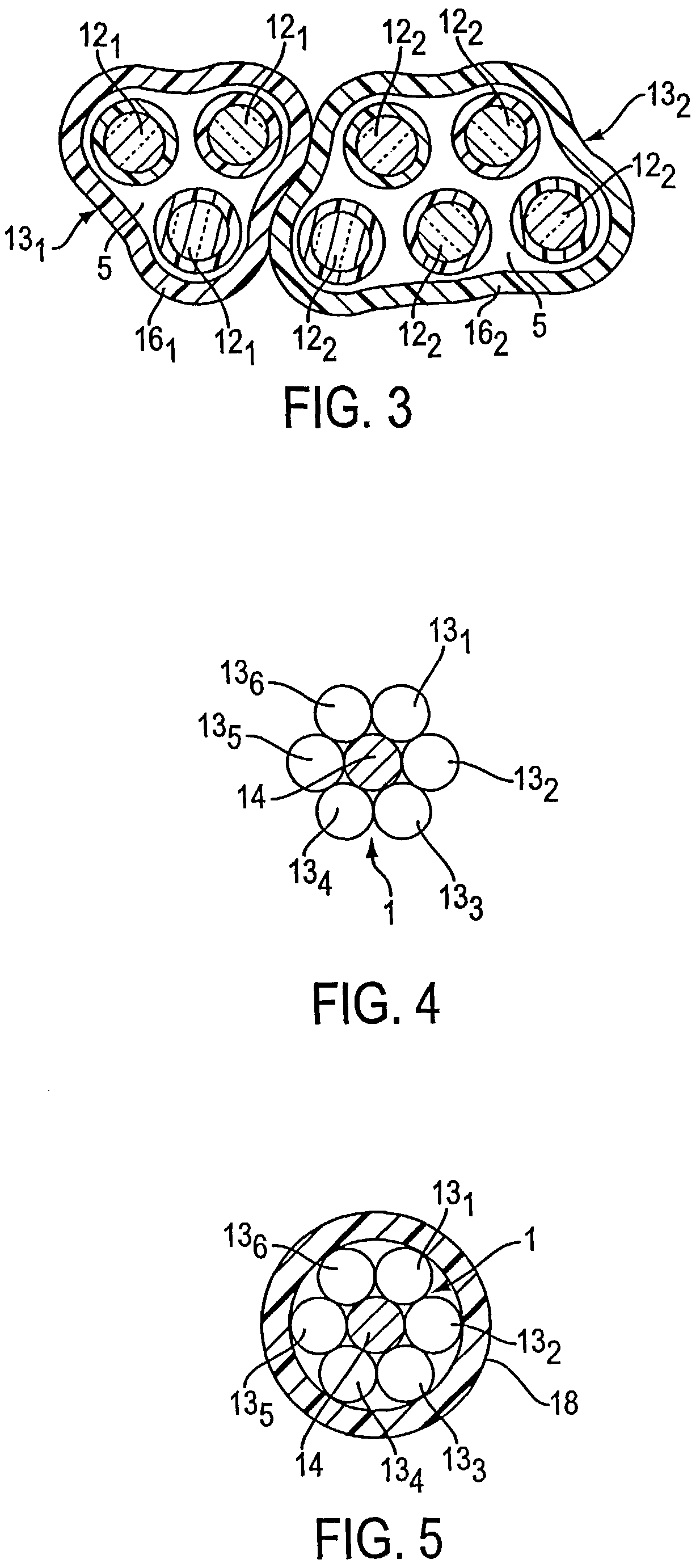

Method and apparatus for solid-stranding a flextube unit

InactiveUS7192541B2Increase line speedLow costHollow filament manufactureFilament/thread formingEngineeringCentral element

A solid-stranding method and apparatus for forming optical cables. Solid-stranding combines buffering and stranding operations, as well as performs the stranding operation while the flextubes are still hot so that they adhere together without additional binders. Optical fibers and / or wires are supplied to an extruder which forms flextubes around individual ones or groups of the optical fibers and / or wires. A central element may be supplied to, and go through, the center of the extruder. A rotating pulling device, such as a caterpillar, helically or in an SZ-manner solid-strands the flextubes around the central element—or solid-strands the flextubes to themselves when no central element is present—as the flextubes cool down. That is, solid-stranding includes buffering and stranding operations that are performed together without a water cooling stage therebetween. Thus, the flextubes adhere together, and may adhere to the central member, thereby forming a solid-stranded composite core. The solid-stranded composite core then may be jacketed by passing through another extruder, or may be used without a jacket, thereby forming a solid-stranded flextube unit from which individual flextubes easily may be split.

Owner:DRAKA COMTEQ BV

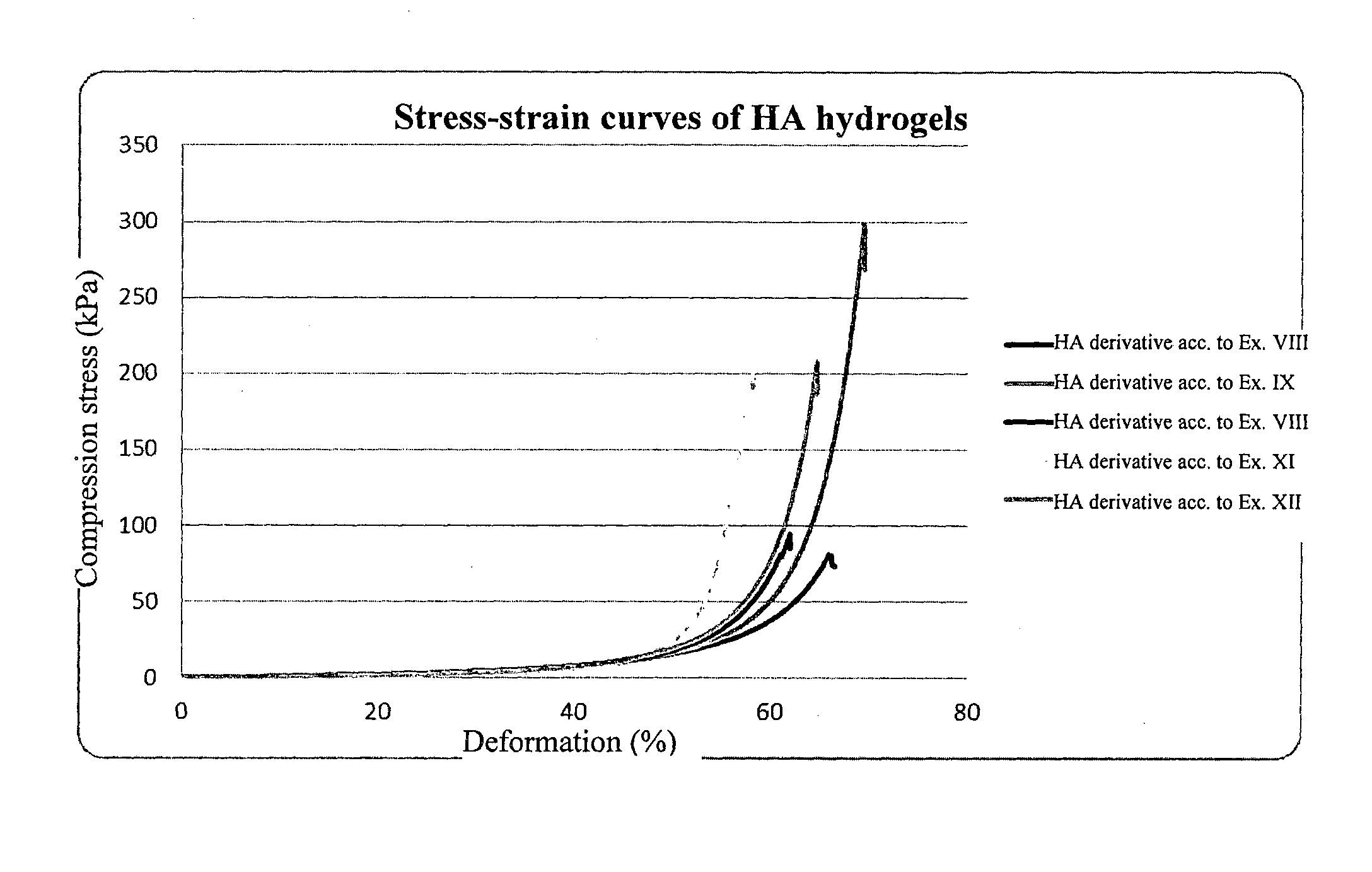

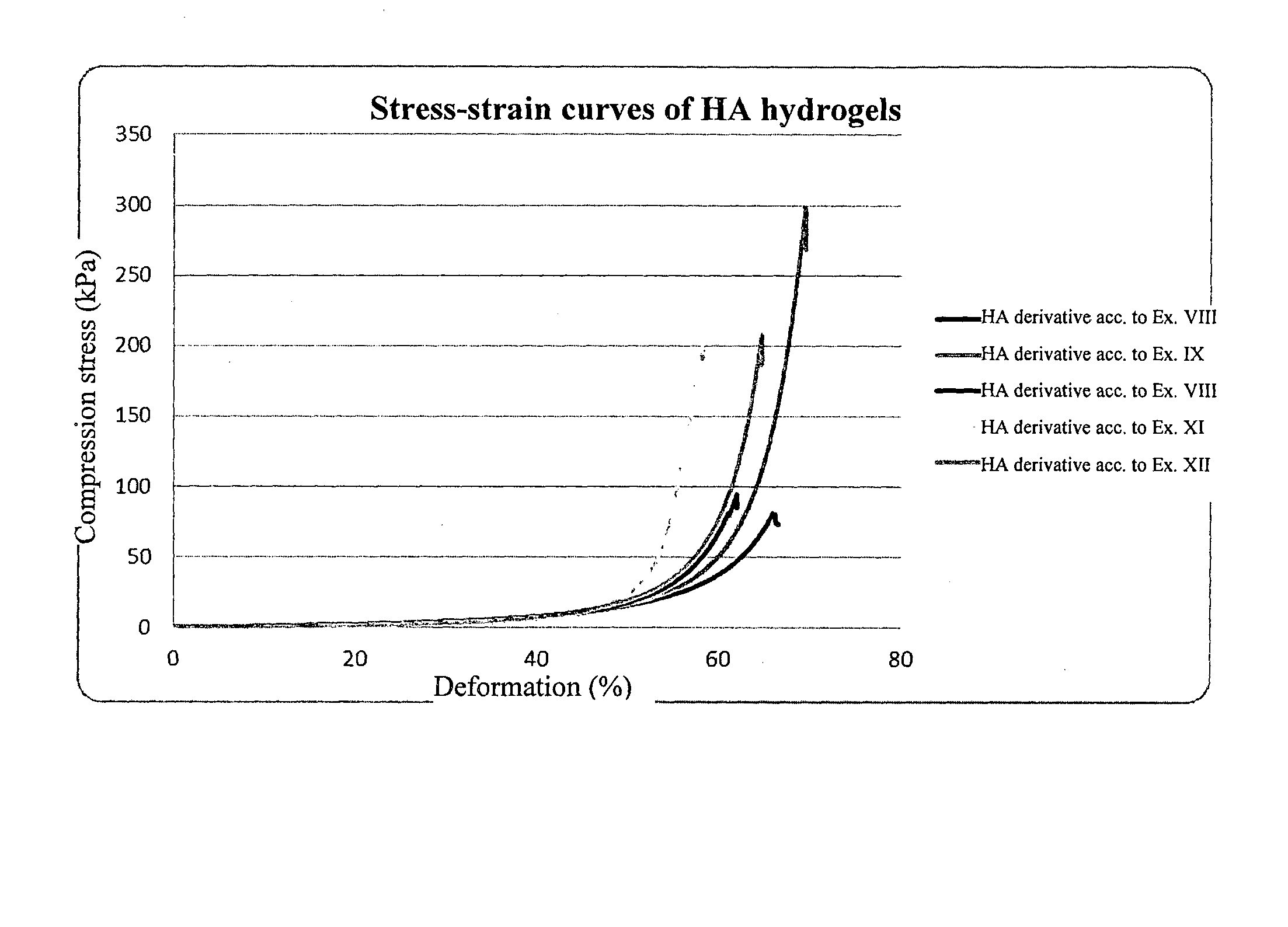

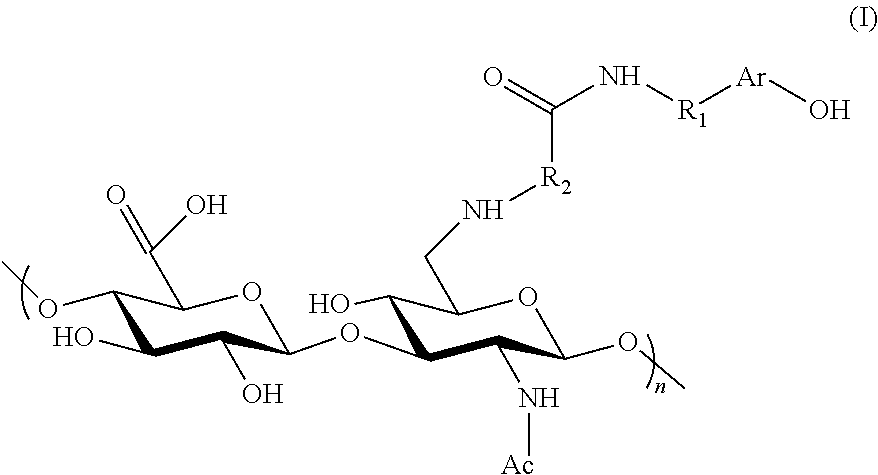

Derivatives of hyaluronic acid capable of forming hydrogels

ActiveUS9492586B2Limit possible usHigh strengthCosmetic preparationsToilet preparationsBone tissueHyaluronic acid

The invention related to hyaluronic derivative according to formula (I), methods of preparation thereof and a hydrogel prepared obtained from the derivative and methods of preparation thereof. The hydrogel can be used in tissue engineering, cosmetics, medicine or regenerative medicine such as the forming of scaffolds for the treatment of articular cartilage or bone tissue defects.

Owner:CONTIPRO AS

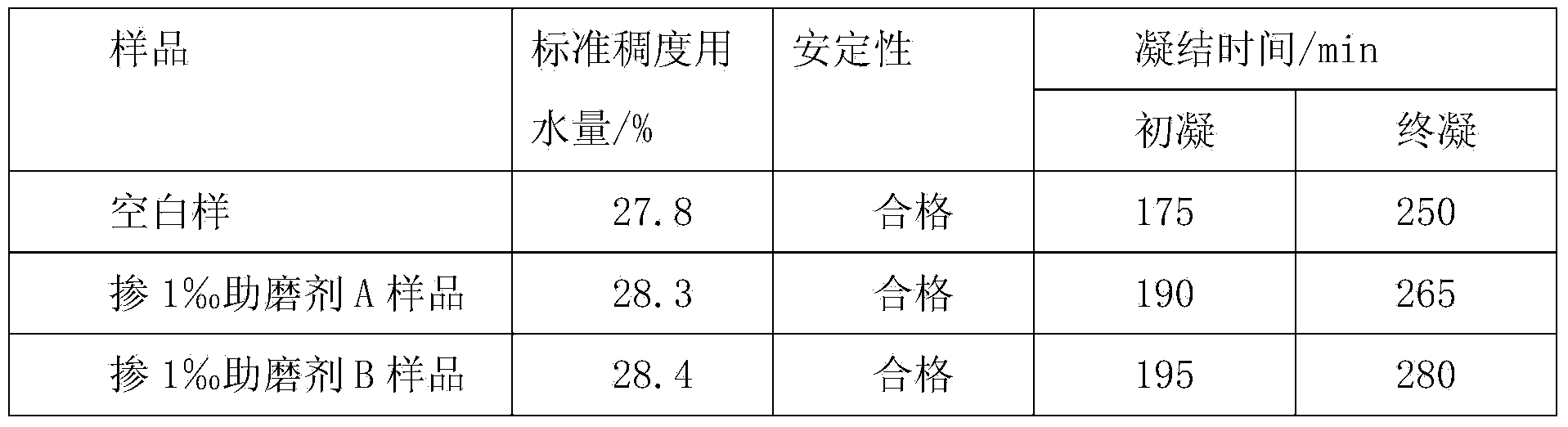

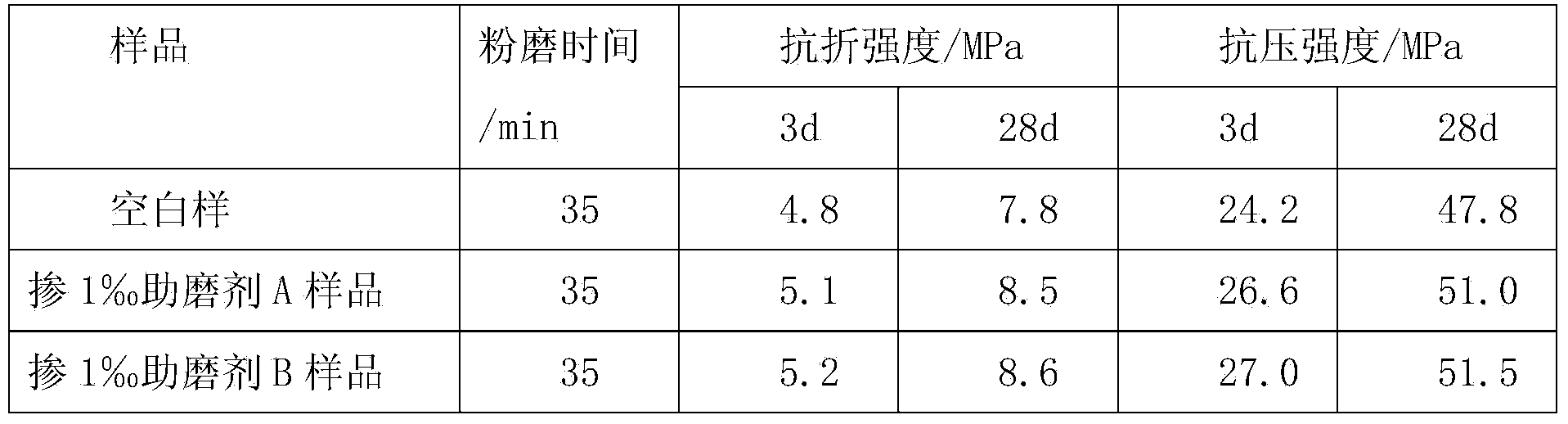

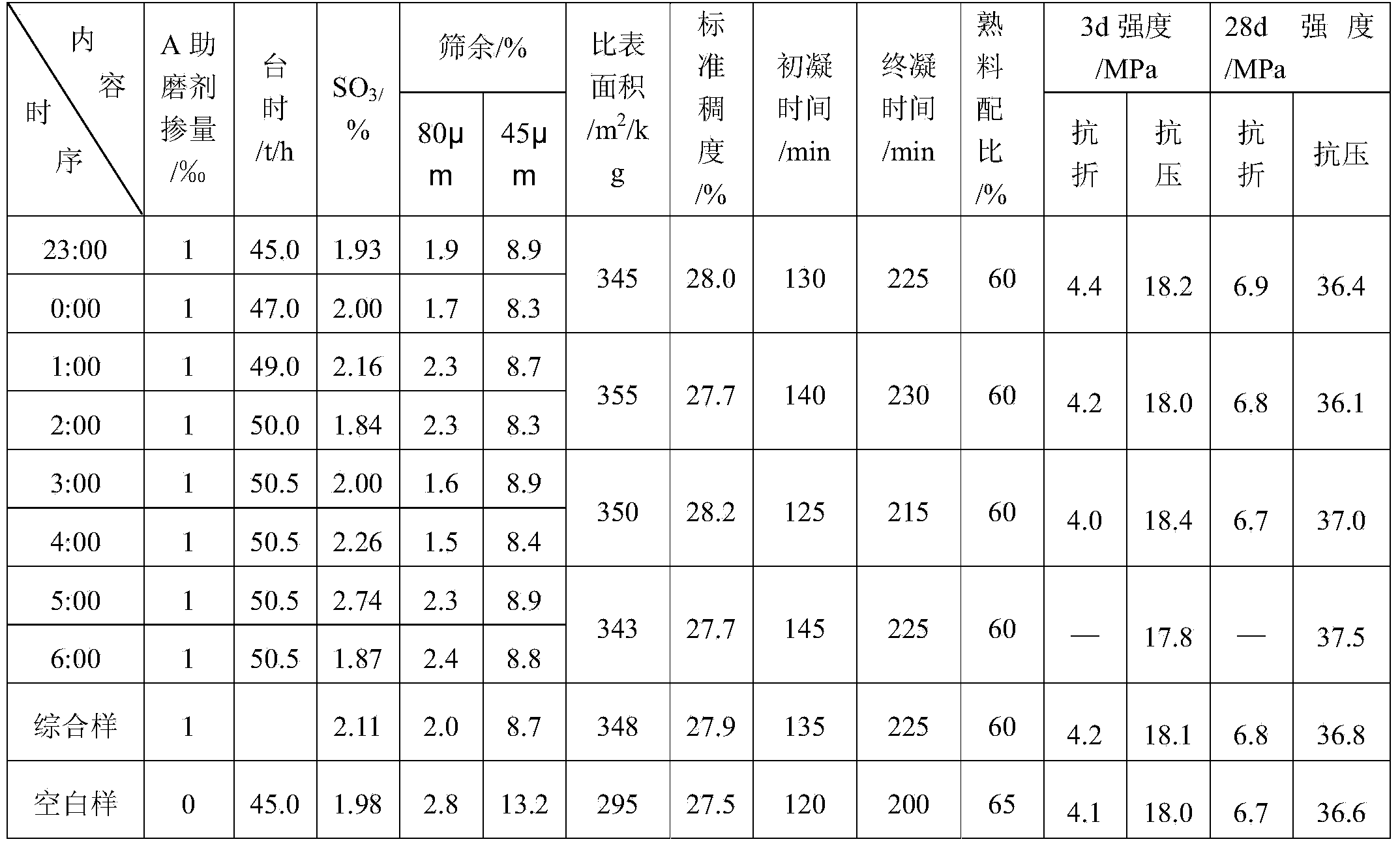

Reinforced cement grinding aid and preparation method thereof

The invention discloses a reinforced cement grinding aid. The reinforced cement grinding aid comprises the following raw materials by weight percent: 25% of mother liquor, 17.5% of sodium thiosulfate, 7.5% of industrial byproduct salt and 50% of water, wherein the mother liquor comprises the following components by weight percent: 45% of sulfonated triethanolamine salt, 20% of ethanediol, 20% of sugar dreg and 15% of water, the chemical formula of the sulfonated triethanolamine salt is (HOCH2CH2)N[(CH2CH2)NH(HO)SO2]2, the sulfonated triethanolamine salt is prepared from triethanolamine and sulphamic acid through sulfonation reaction, the chemical equation is as follows:(HOCH2CH2)3N+2[(NH2)(HO)SO2]->(HOCH2CH2)N[(CH2CH2)NH(HO)SO2]2+2H2O. The invention also discloses a preparation method for the reinforced cement grinding aid. The reinforced cement grinding aid has the advantages of low cost, better effect in assisting grinding, and improving the long-term strength of the cement.

Owner:安徽新创建材科技有限公司

Electronic seal protection method based on fragile watermark

InactiveCN102521787AImprove fragilityImprove integrityImage data processing detailsComputer graphics (images)Engineering

The invention discloses an electronic seal protection method based on a fragile watermark, which includes the following steps: 1, scanning an original seal image to a computer; 2, setting a mapping function f, enabling each pixel value of the image g obtained by scanning an original seal to be mapped into a two-value L, L (i, j) = fg (g (i, j)), wherein a value of the L is 0 or 1, and i and j are coordinates of image pixel points; and 3, embedding a watermark W in the seal scanning image g, wherein sigma is a positive integer which is as small as possible in a following formula. Each pixel value of the image g obtained by scanning the original seal is modified so as to enable a value of each pixel point in the modified image g to be the same as W after the value is calculated through the mapping function f. The electronic seal protection method based on the fragile watermark meets requirements of occasions which are hypersensitive to embedded images, and guarantees that as long as one pixel in a pattern embedded by a watermark is changed, the watermark can be damaged, thereby achieving verification and protection effects.

Owner:KUNSHAN BAIRUN TECH

Preparation method of biomass cement grinding aid

The invention relates to a preparation method of a biomass cement grinding aid, and belongs to the technical field of cement grinding aid. The preparation method comprises following steps: pine bark and bagasse are taken as raw materials, are crushed, and are subjected to steam explosion so as to obtain an explosion product; the explosion product is mixed with cellulase, pectase, and protease forenzymatic hydrolysis so as to obtain an enzymatic hydrolysis product; the enzymatic hydrolysis product is subjected to acid treatment, oxidation, and alkali treatment reaction respectively so as to obtain a reaction filtered residue; and at last, the reaction filtered residue is mixed with sodium sulfite for reaction, and vacuum freeze-drying is carried out so as to obtain the biomass cement grinding aid. The biomass cement grinding aid is excellent in grinding aid effect, and promising in application prospect.

Owner:张忠云

Novel cement grinding aid

A new cement grinding aid, which is made of the following raw materials in parts by weight: 4-7 parts of gypsum, 3-5 parts of sodium fluorosilicate, 2-6 parts of citric acid, 15-18 parts of stearic acid, fluorine 0.2-0.6 parts of sodium chloride, 2-4 parts of polyacrylamide, 3-6 parts of sodium silicate, 1.2-2.2 parts of preservative, 4-5 parts of accelerator, 8-16 parts of silica fume, 1.2 parts of organic early strength agent ‑2.5 parts, 1.8‑3.2 parts of phenyl salicylate, 1.2‑3 parts of guanidine hydrochloride, 1.2‑3.5 parts of sodium carbonate, 8‑23 parts of graphene. The beneficial effects of the present invention are: the novel cement grinding aid of the present invention effectively improves the friability and dispersibility of materials, improves the utilization rate of mechanical energy and reduces the cement production cost.

Owner:青岛特澳能源检测有限公司

Semiconductor mount substrate, semiconductor device and method of manufacturing semiconductor package

InactiveUS7525180B2Improve fragilitySuitable designSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

Owner:PANASONIC CORP

Machine-made charcoal processing method

InactiveCN105368469AHigh carbon contentIncreased graphite structureBiofuelsSpecial form destructive distillationCarbonizationGraphite

The invention provides a machine-made charcoal processing method, and relates to a machine-made charcoal baking method, which is the improvement of the current production technology and the process. According to the present invention, the main components of the wood rod comprise cellulose, wood fibers and water, the selected control temperatures respectively are 160 DEG C, 160-280 DEG C and 280-400 DEG C, the final carbonization temperature is increased to 510-630 DEG C, the early heating is slowly performed, the soil kiln heating time is 15 h, the machine kiln heating time is 2-3 h, and the early heating time is long so as to prevent the raw material rod from damping and cracking; and the kiln temperature control and the high temperature charcoal refining are performed, the residual volatile materials in the charcoal are discharged, the carbon content in the charcoal is improved, the graphite structure of the charcoal is increased, and the electric conductivity is enhanced.

Owner:邱宝全

Isomaltose hypgather tablet excipient, medicine tablet and preparation method

InactiveCN102671200AImprove emulsion stabilityGood thickening effectPill deliveryPharmaceutical non-active ingredientsIsomaltooligosaccharideMedicine

The invention discloses isomaltose hypgather tablet excipient, which consists of 88 percent to 96 percent of isomaltose hypgather, 1 percent to 5 percent of starch octenyl succinate anhydride, 1 percent to 5 percent of silicon dioxide and 1 percent to 5 percent of porcellanite in percentage by weight, and has the advantages that the mobility is good, the forming degree is good, the demolding performance is good, and isomaltose hypgather tablet excipient can be directly tableted with medicine and water for preparing medicine tablets. The invention also discloses a medicine tablet, which consists of 75 percent to 85 percent of medicine active ingredients, 5 percent to 15 percent of isomaltose hypgather tablet excipient and 5 percent to 15 percent of water raw materials in percentage by weight, wherein the isomaltose hypgather tablet excipient and the medicine active ingredients do not have incompatibility and reaction, in addition, the solvability is good, the flowability is good, and the medicine tablet is suitable for the direct tableting of various kinds of medicine. The invention also discloses a preparation method of the medicine tablet, which has the advantages that the preparation is simple, the implementation is easy, and the operation and the control are easy.

Owner:安吉东来药用辅料有限责任公司

Fructo-oligosaccharide tablet excipient, medicine tablet and preparation method of medicine tablet

InactiveCN102671206AImprove emulsion stabilityGood thickening effectInorganic non-active ingredientsPill deliverySolubilityAdditive ingredient

The invention discloses a fructo-oligosaccharide tablet excipient which includes, by weight, 88% to 96% of fructo-oligosaccharide, 1% to 5% of an octenyl succinic anhydride modified starch, 1% to 5% of silicon dioxide and 1% to 5% of kaolin. The fructo-oligosaccharide tablet excipient is good in liquidity, molding, and demoulding, and can be used for preparing medicine tablets with medicine and water through direct compression. The invention further discloses a medicine tablet which includes, by weight, 75% to 85% of an active pharmaceutical ingredient, 5% to 15% of the fructo-oligosaccharidetablet excipient and 5% to 15% of water. The fructo-oligosaccharide tablet excipient and the active pharmaceutical ingredient have no incompatibility and reaction, have good dissolubility and liquidity, and are suitable for direct compression of various medicines. The invention further discloses a preparation method of the medicine tablet. The preparation method is simple, and easy to implement, operate and control.

Owner:安吉东来药用辅料有限责任公司

A kind of metal soft magnetic silicon aluminum alloy powder and preparation method thereof

ActiveCN107675074BMany microscopic shapesReduce sharp cornersMagnetic materialsBall millInduction furnace

The invention relates to a preparing method of metal soft magnetic iron silicon aluminum alloy powder, and belongs to the technical field of metal soft magnetic material manufacturing. The preparing method comprises the steps that a furnace burden pure iron square billet, bulk metal silicon and a pure aluminum ingot are used as raw materials, and the raw materials are weighed according to the proportion; a non-vacuum medium-frequency induction furnace is used to induce, smelt and obtain alloy molten steel of the required components, and an alloy ingot is obtained after casting; the alloy ingotis crushed, and then a particle material with the particle size being below 5 mm is obtained; then fine powder of 180 meshes is obtained through a crushing ball mill technology; and finally, the ironsilicon aluminum alloy powder is obtained through annealing of 800-850 DEG C under nitrogen atmosphere and even mixing. The particle size distribution of the iron silicon aluminum alloy powder prepared by the method is narrow and adjustable, the shape of the powder is in a regular polygon, sharp corners are few, the effect of insulating coating is ensured advantageously, and the comprehensive magnetic properties of an iron silicon aluminum magnetic powder core after forming and pressing and sintering are excellent.

Owner:马鞍山新康达磁业股份有限公司

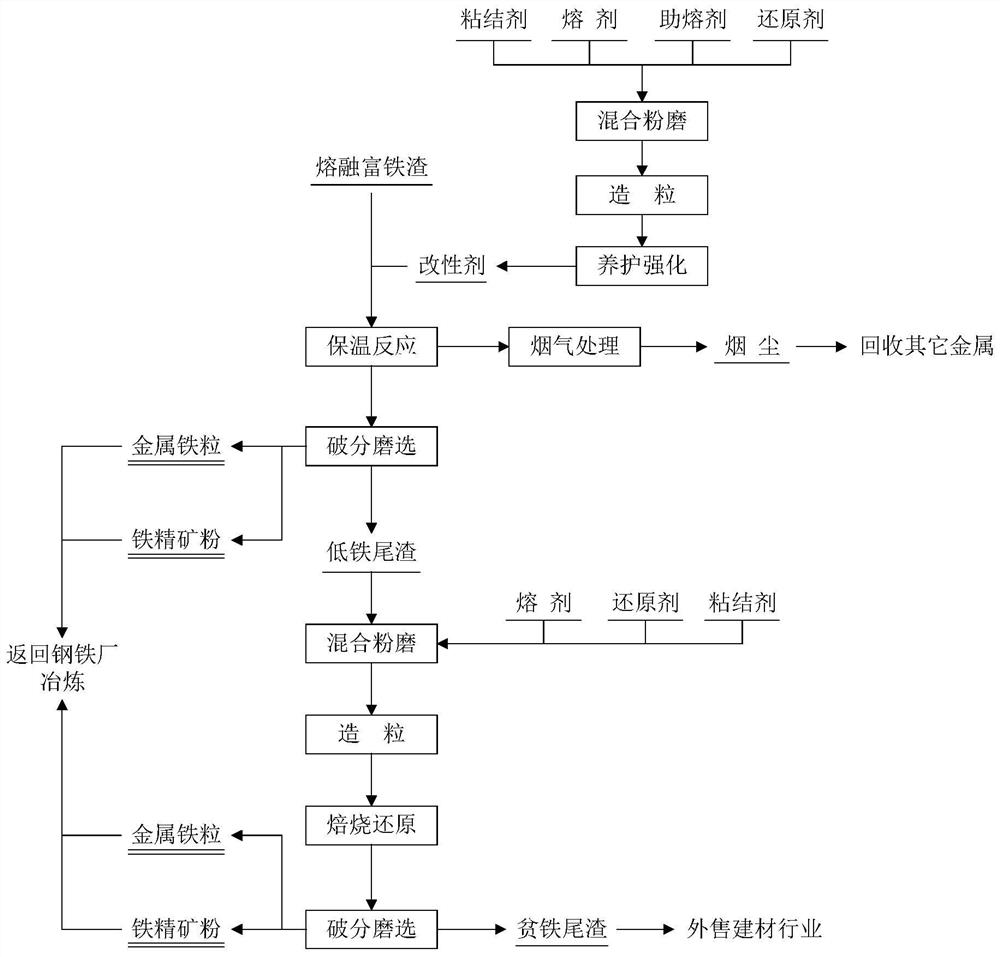

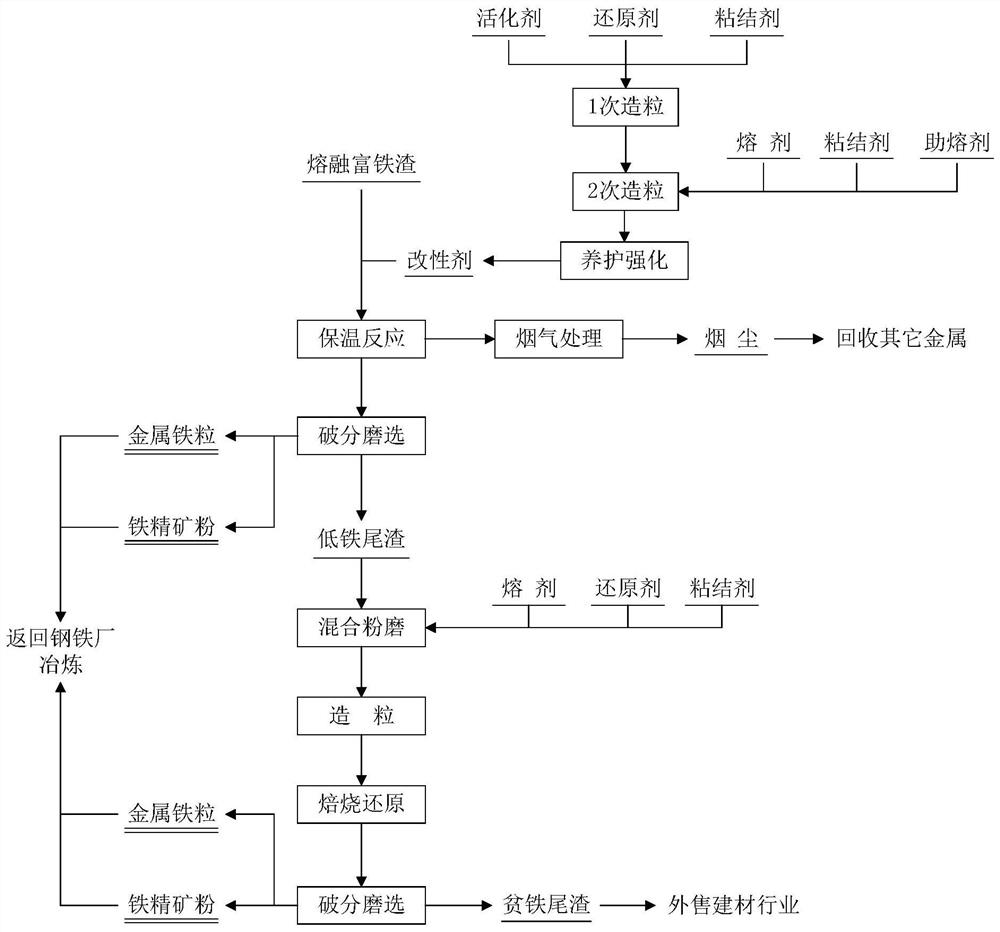

Slag modification reducer and preparation method thereof, and method for Fe recovery with slag waste heat

ActiveCN111763820AChange chemical compositionChange structureSolid waste managementSeparation technologyHeat conservation

The invention discloses a slag modification reducer. The slag modification reducer is shaped like spherical particles with a particle diameter of 10-30 mm and comprises 100 parts by weight of a fusionagent, 5-24 parts by weight of a reduction agent, 8-18 parts by weight of a binder and 0-10 parts by weight of a fluxing agent. The invention also discloses a method for Fe recovery with slag waste heat. The method comprises the following steps: (a) during a course when slag is discharged from a smelting furnace and poured into a heat-preservation container, the slag modification reducer is addedinto a slag flow, and a modified reduction reaction takes place; and (b) after the slag completes the reaction with the modification reducer, solid slag in the heat-preservation container is crushed,and metal Fe particles and / or Fe ore concentrate powder are obtained through magnetic separation. The method aims at the fact that the slag contains a lot of waste heat and residual Fe resources, directly conducts high-temperature waste heat modification of the slag, adjusts chemical components and a smelting temperature of the slag, reduces reduction potential energy of Fe oxides and then uses amiddle-low temperature roasting temperature and a grinding-separation technology to realize efficiency recovery of Fe in the slag.

Owner:CHINA ENFI ENGINEERING CORPORATION

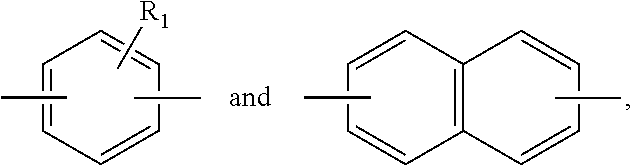

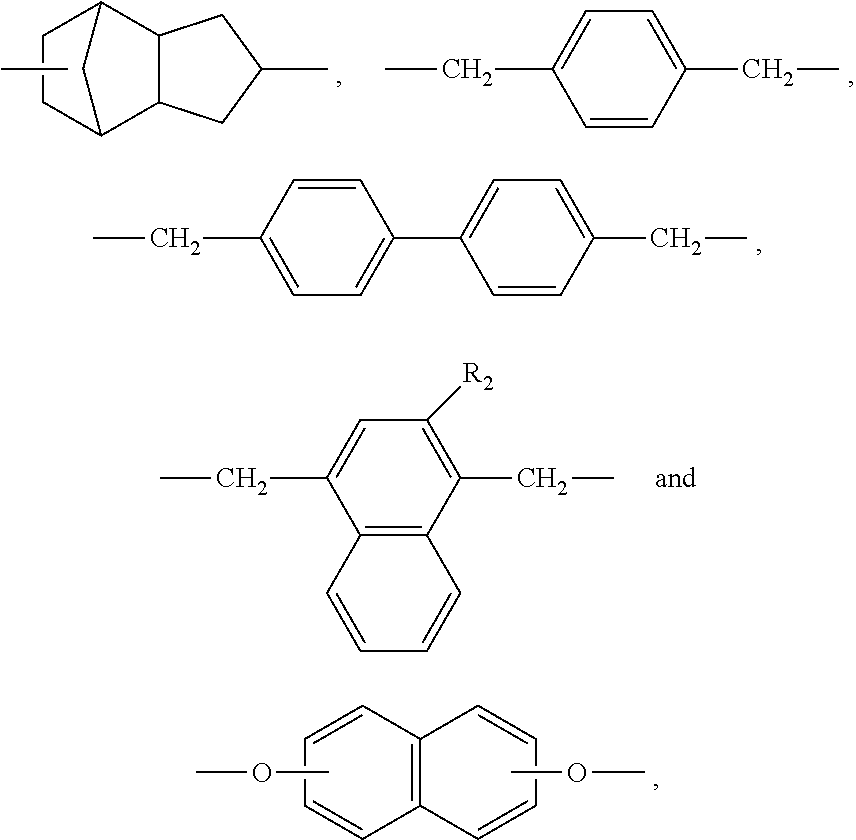

Halogen-free thermosetting resin composition, prepreg and laminate for printed circuit boards using the same

InactiveUS20180126701A1High in phosphorusEfficacy of halogen-free flame retardancySynthetic resin layered productsElectrical equipmentHalogenHeat resistance

The present invention relates to a halogen-free thermosetting resin composition, a prepreg and a laminate for printed circuit boards using the same. The halogen-free thermosetting resin composition comprises, based on 100 parts by weight of organic solids, (A) from 16 to 42 parts by weight of a halogen-free epoxy resin, (B) from 1.5 to 4.8 parts by weight of a compound containing dihydrobenzoxazine ring; (C) from 10 to 28 parts by weight of a phosphorus-containing bisphenol curing agent, wherein the phosphorus-containing bisphenol curing agent has a weight average molecular weight of 1000-6500, and (D) from 30 to 70 parts by weight of silicon dioxide. The prepreg and laminate for printed circuit boards prepared from the halogen-free thermosetting resin composition have high glass transition temperature, excellent dielectric performances, low water absorption, high heat resistance and better processability, and can achieve halogen-free flame retardancy and UL94 V-0.

Owner:GUANGDONG SHENGYI SCI TECH

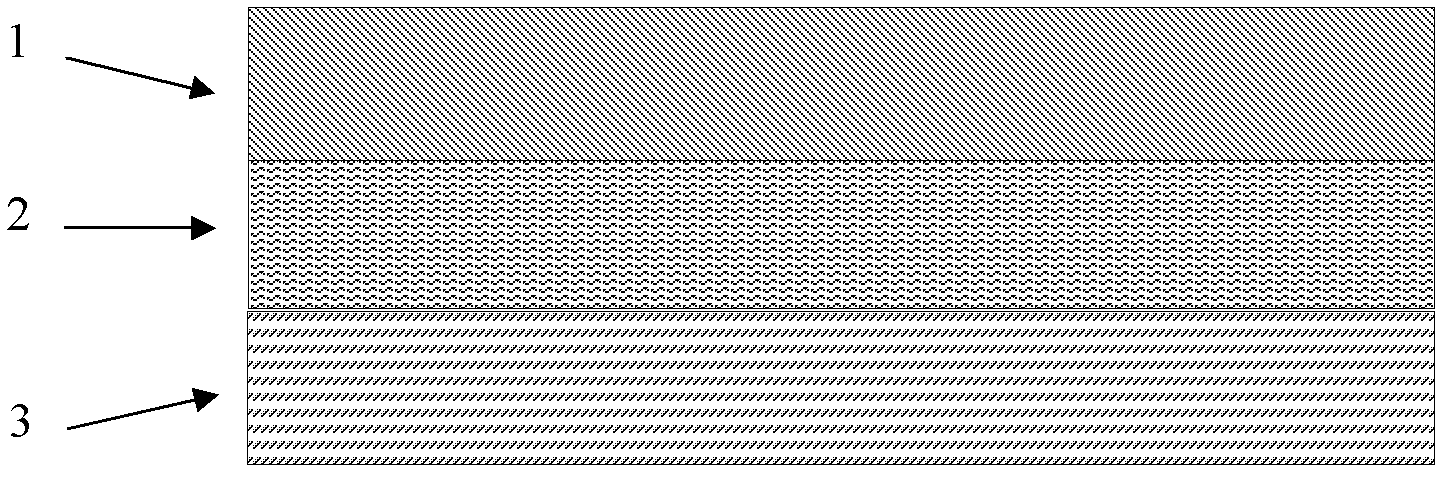

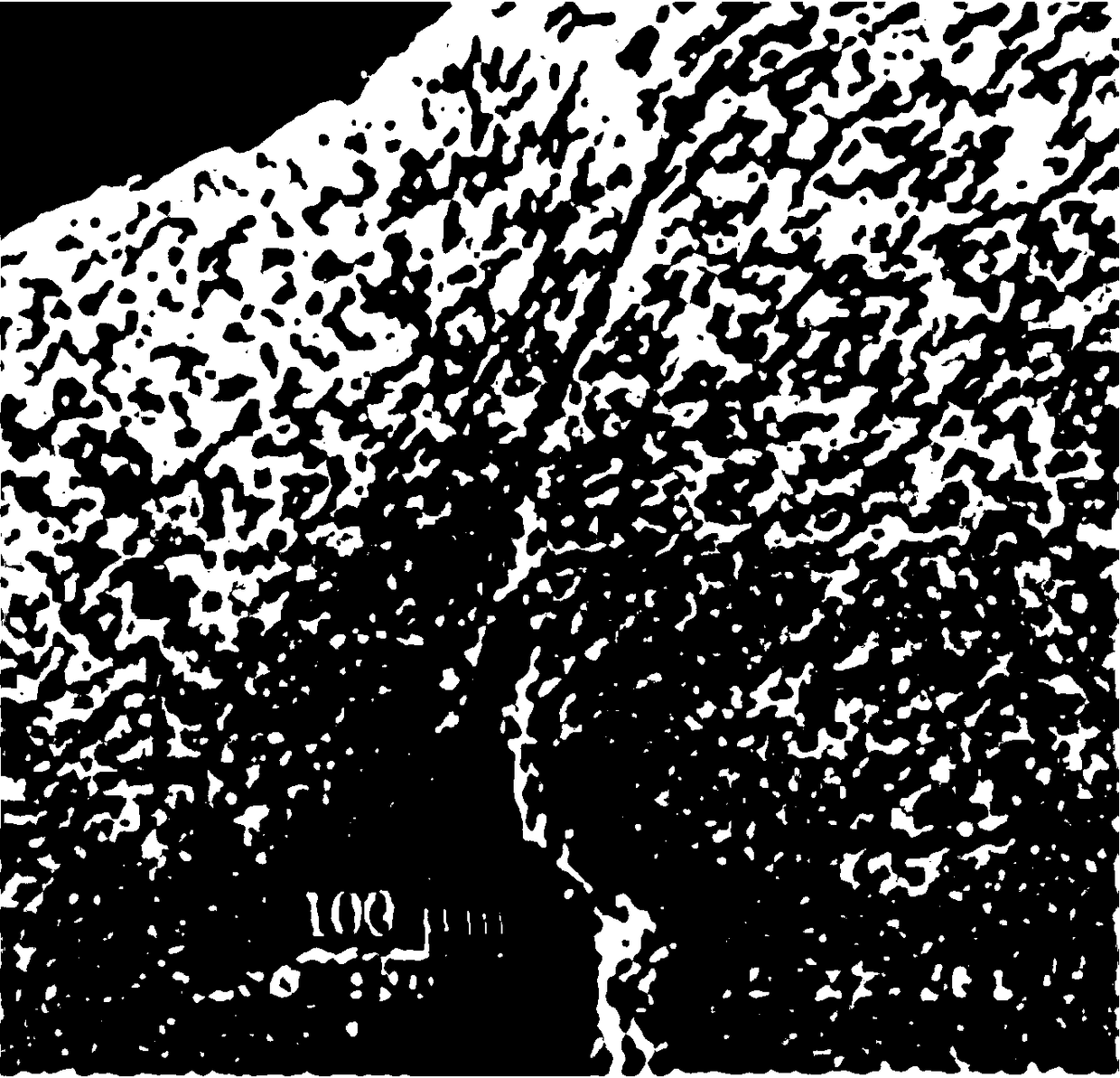

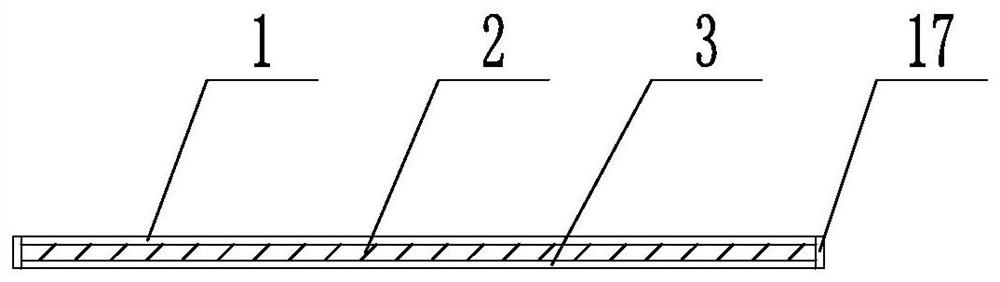

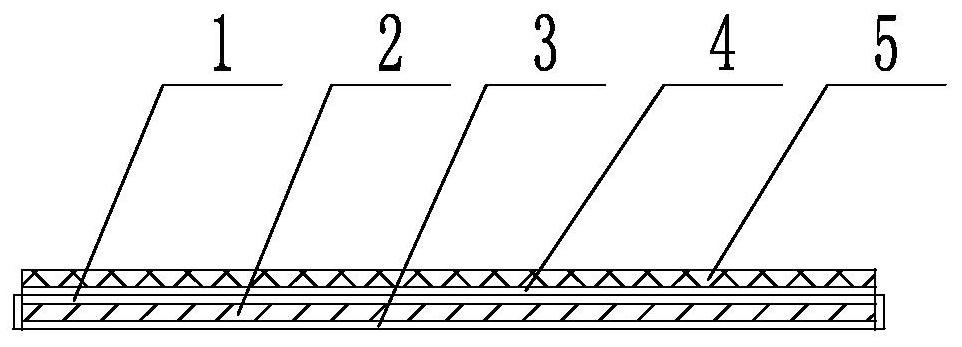

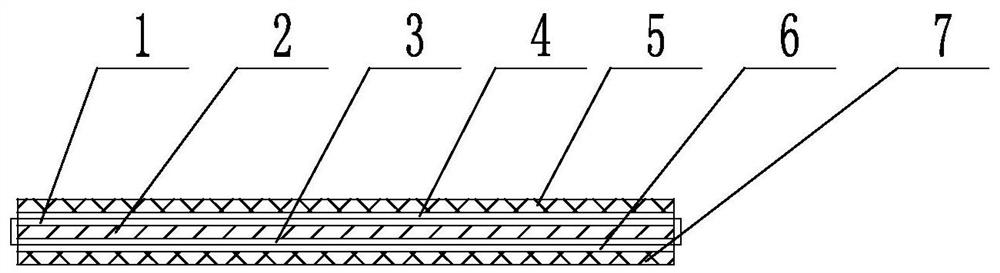

Brittle film

InactiveCN102529273AImprove fragilityImprove waterproof functionSynthetic resin layered productsThermoplasticSurface layer

The invention discloses a brittle membrane, which sequentially comprises an upper surface layer, a core layer and a lower surface layer from top to bottom, and is characterized in that: the upper surface layer, the core layer and the lower surface layer are of a co-extruded structure, and a material of the upper surface layer and the lower surface layer forming the co-extruded structures is thermoplastics; and a material of the core layer forming the co-extruded structure is a filled and modified material of the thermoplastics, and the filled and modified material is inorganics. The brittle film with a three-layer structure by a multilayer co-extrusion and extension process has the advantages of waterproof and easily breaking effects, simple manufacture, and reduction in production cost.

Owner:FOSHAN SUXING MASTERBATCH

Fragile armor-piercing shell W alloy and preparation method thereof

InactiveCN108425057AHigh strengthHigh densityTransportation and packagingMetal-working apparatusEffective solutionWax

The invention discloses a fragile armor-piercing shell W alloy and a preparation method thereof. The W alloy is prepared by mixing and sintering W powder, Ni powder, Fe powder and Re powder. The preparation method comprises the following steps: wet mixing; primary drying and screening; doping with wax; secondary drying and screening; shaping; dewaxing / pre-sintering; sintering; and heat treatment after sintering. The added Re powder serves as a more effective solution strengthening element, so that the density of the W alloy can be improved to a certain extent and the relatively high plasticitycan be kept; through the addition of Al2O3 powder of different grain sizes, the tensile strength can be reduced under the precondition that the dynamic compression strength and plasticity of the W alloy are guaranteed, and the fragility of the W alloy can be improved; and accordingly, fragments can be formed after the W alloy pierces armor, and then the purpose of secondary damage can be fulfilled.

Owner:江西澳科新材料科技股份有限公司

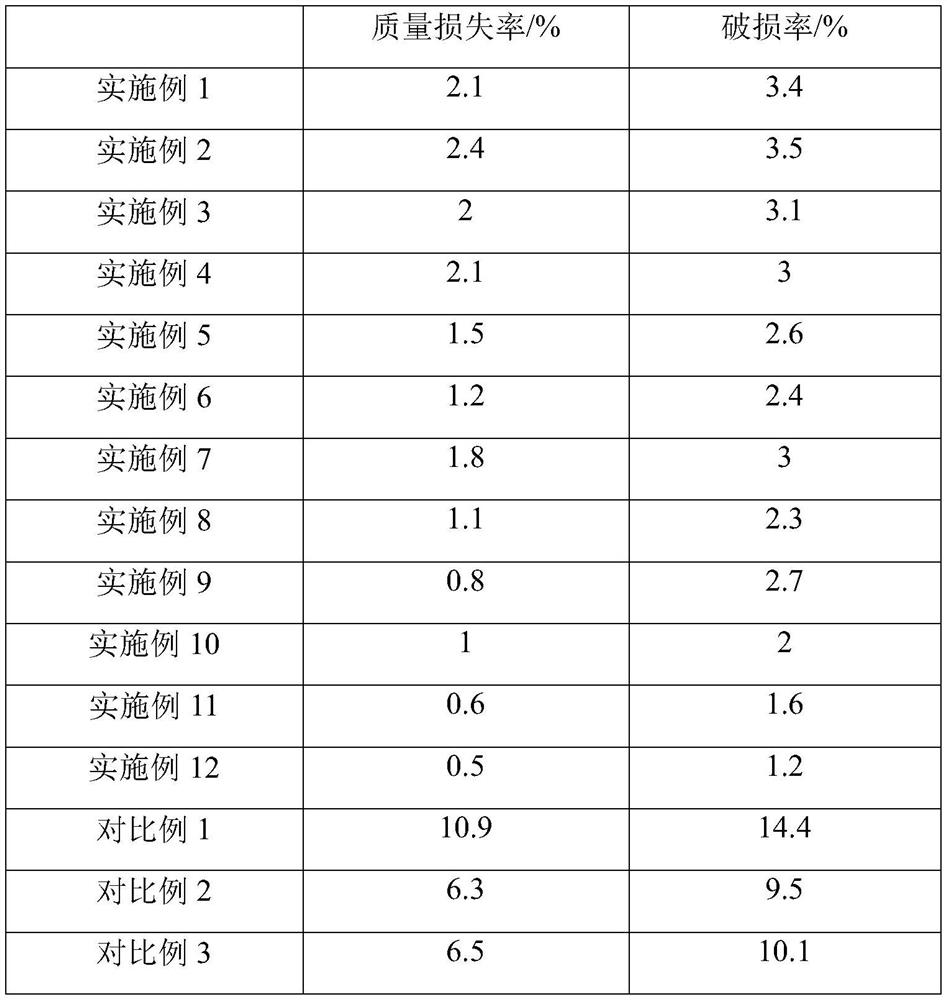

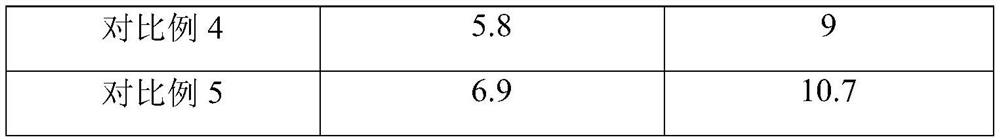

Preparation method of foam board with uniform plasmids

PendingCN114539598AImprove dispersion uniformityImprove diffusivitySodium bicarbonatePolymer science

The invention relates to the field of foam boards, and particularly discloses a preparation method of a foam board with uniform plasmids, which comprises the following steps: step 1, melting polyethylene resin, adding magnesium hydroxide composite agglomerated particles, and then extruding and granulating to obtain modified polyethylene particles; step 2, mixing and homogenizing the modified polyethylene particles prepared in the step 1 with a silane coupling agent, a foaming agent and a binder, and under circulation purging of nitrogen, adopting a vacuum heating mode and a positive pressure heating mode to circularly and alternately react for foaming to obtain a dry composite material; the foaming agent comprises tetrahydrofurfuryl alcohol, sodium dioctyl sulfosuccinate and sodium bicarbonate; and step 3, adding dimethylsilylated silica into the composite material, performing maintenance, and then performing curing molding to obtain the foam board. By adopting the preparation method provided by the invention, the fragile rate and breakage rate of the packaging plate after collision or falling in the transportation process can be effectively reduced, and the comprehensive performance of the foam plate is good.

Owner:慈溪市赞恩包装科技有限公司

Paper substrate radio frequency antenna and production method thereof

InactiveCN111786101AHigh strengthThe problem of achieving surface waterproofingAntenna supports/mountingsRadiating elements structural formsPlastic materialsElectronic tagging

The invention relates to a paper substrate radio frequency antenna and a production method thereof, and belongs to the technical field of radio frequency identification. The method comprises the following steps: (1) laminating: heating a plastic material, melting the plastic material into liquid, coating the surface of a paper substrate with the liquid, cooling, and curing to form a laminated layer; and coating two sides of the paper base material with films. (2) end surface waterproofing: coating the edge end surface of the paper base material with a waterproof material after film spraying; (3) compounding a metal film layer: coating the surface of the lamination layer with a compound adhesive layer and compounding the metal film layer; (4) printing protective gloss oil: printing protective gloss oil on the surface of the metal film layer; and (5) etching the antenna. According to the invention, the production cost of the antenna is reduced, and the environmental pollution caused by electronic tag products is reduced.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

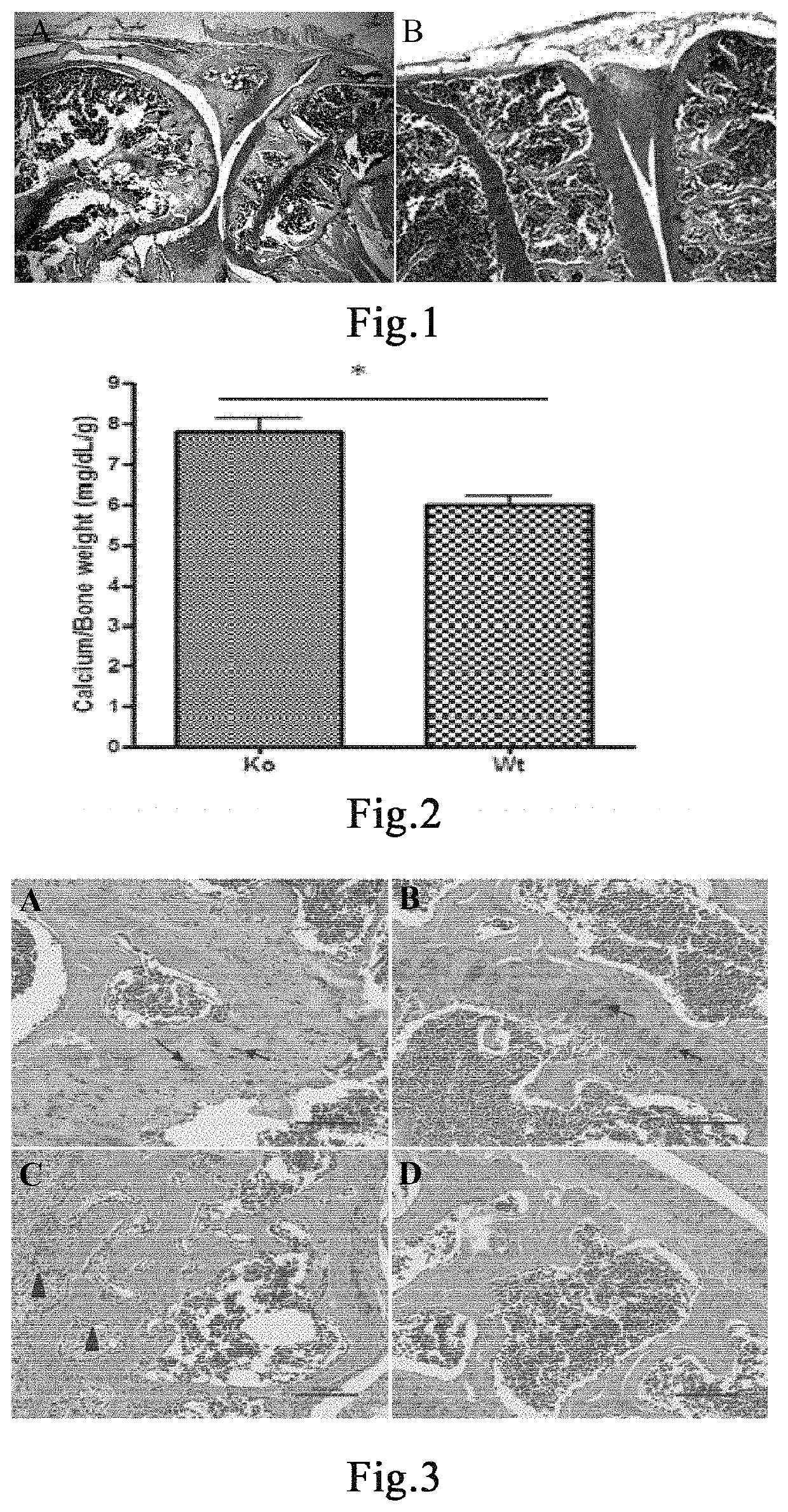

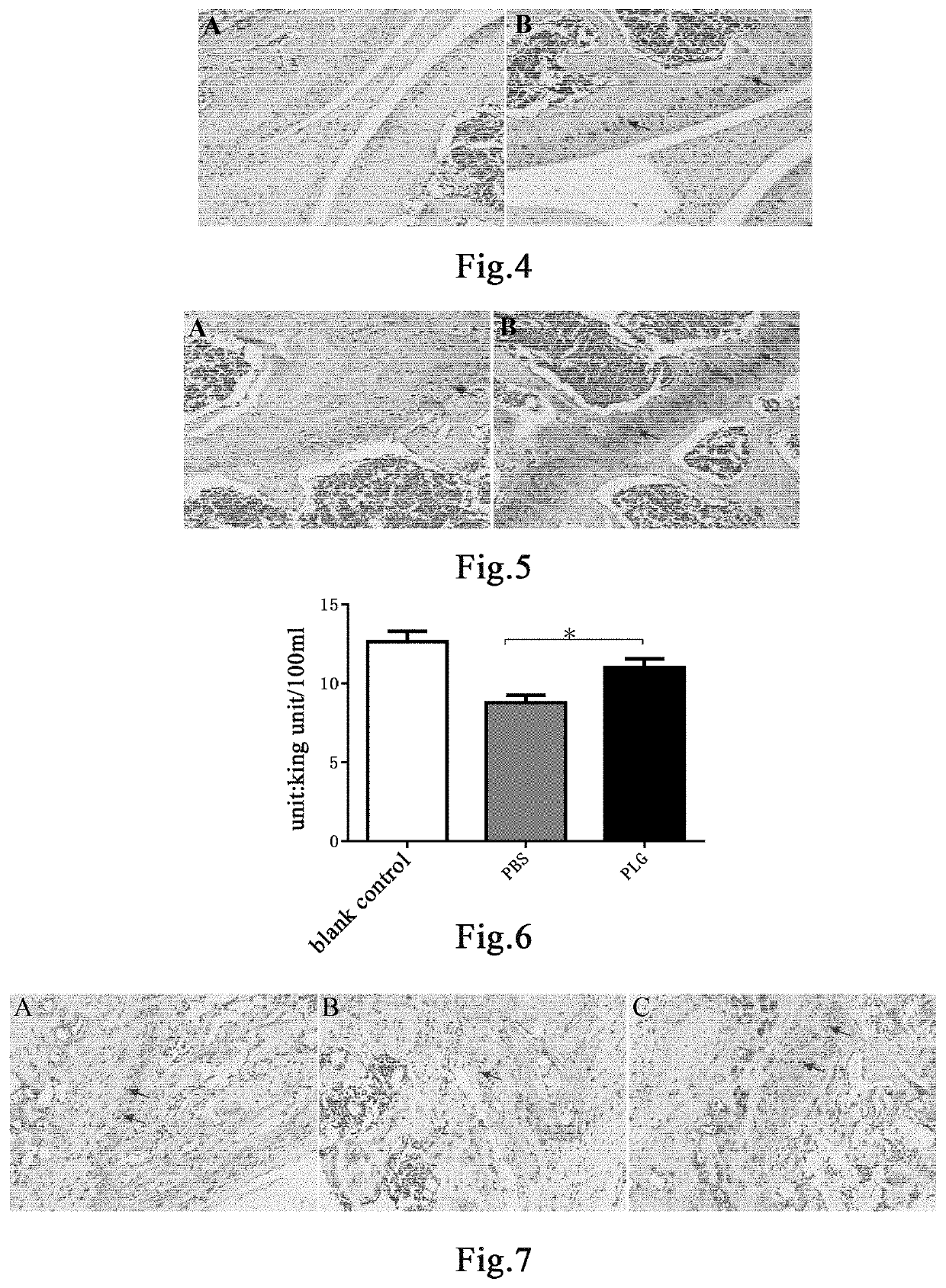

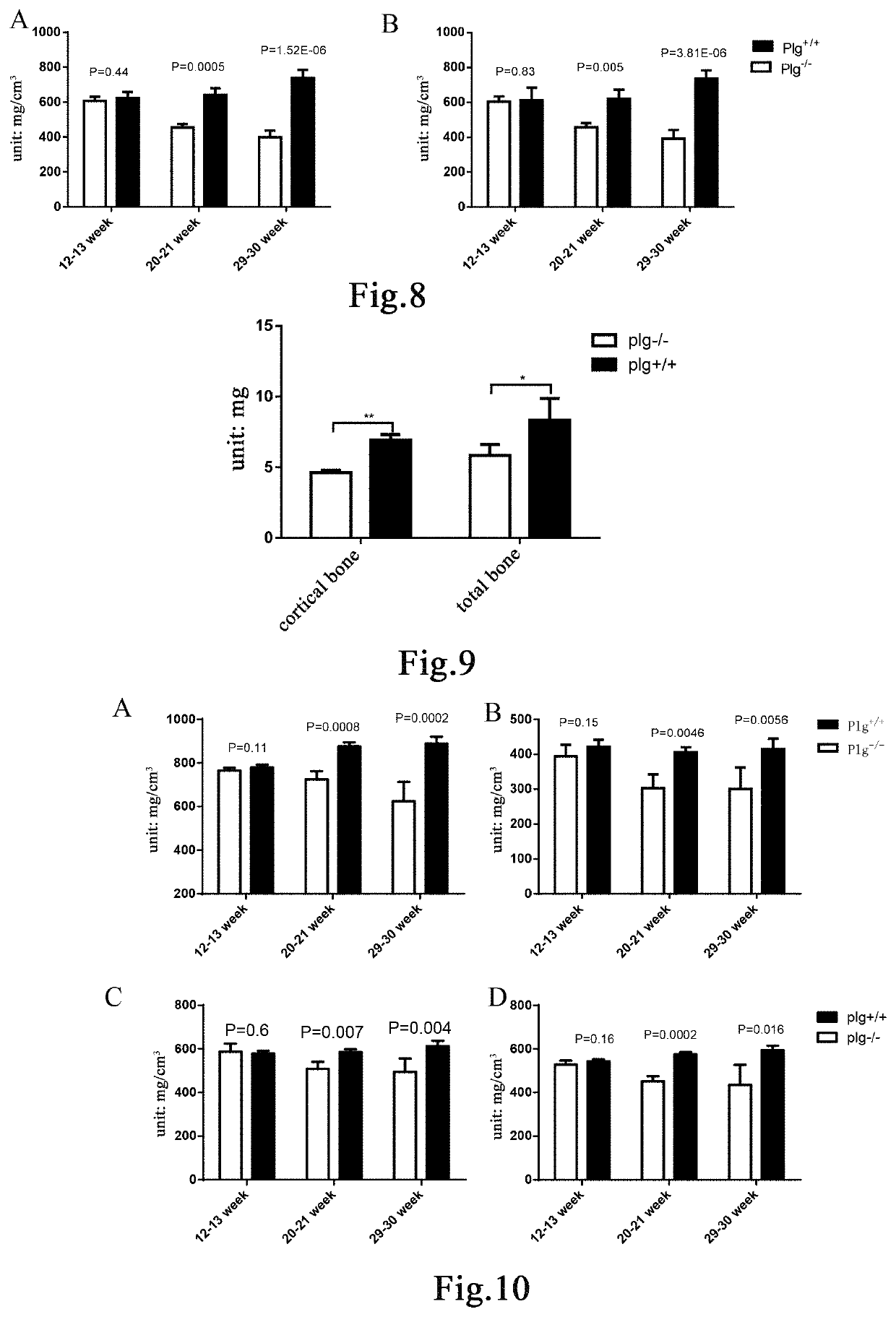

Drug for preventing and treating osteoporosis and uses thereof

InactiveUS20190365871A1Reduce quality problemsImprove fragilityPeptide/protein ingredientsSkeletal disorderDiseaseOsteopetrosis

The present invention provides uses of plasminogen in preventing and / or treating osteoporosis and diseases related to the osteoporosis. The present invention also provides a drug and a product for preventing and / or treating osteoporosis.

Owner:TALENGEN INTERNATIONAL LIMITED

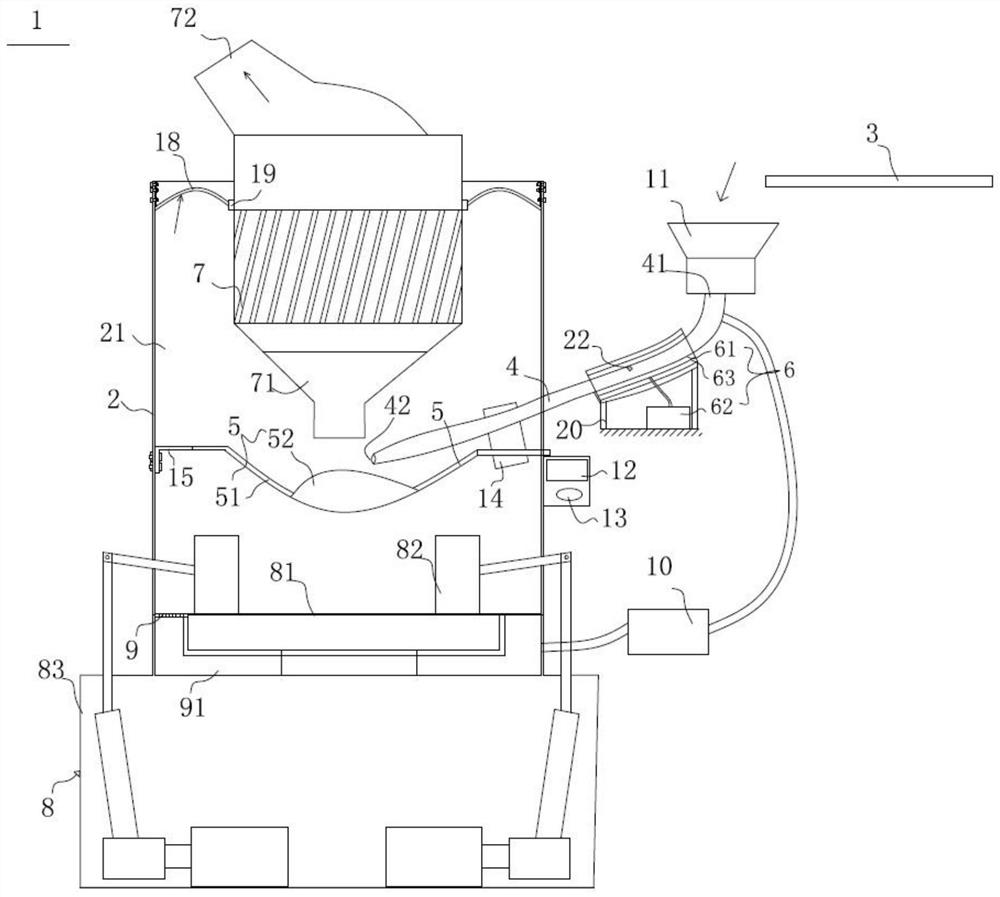

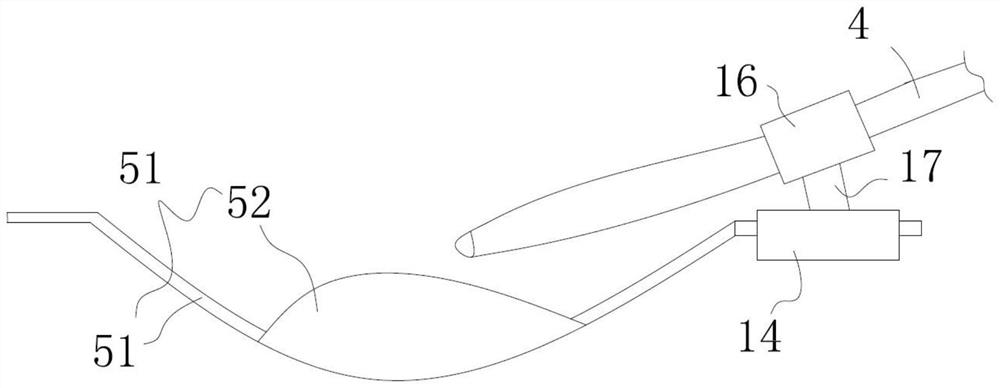

Circulating Grinding Cement Vertical Mill with Preheating Grinding Function

The invention relates to a circulating grinding cement vertical mill with a preheating grinding function, which is used for grinding cement materials, wherein the circulating grinding cement vertical mill with a preheating grinding function comprises: a cylinder body with an accommodating space; a conveying device for It is used to convey cement materials; the crushing device is connected with the conveying device, and the crushing device is used to crush cement materials; the feeding pipe, the feeding port is connected with the crushing device, and the discharge port of the feeding pipe passes through the cylinder and is set in the accommodation space The material distributing device is arranged in the accommodating space. The material distributing device includes a curved mesh structure recessed downward and a material guide cone arranged at the top of the center of the curved mesh structure. The curved mesh structure is arranged at the outlet of the feeding pipe. The bottom of the feed port, and the top of the guide cone is located directly below the discharge port of the feed pipe. When the cement material is ground in the present invention, the cement material is firstly preheated to ensure that the cement material has a certain degree of brittleness during grinding, and its brittleness is better when it is ground, thereby improving the grinding efficiency.

Owner:JIANGSU PENGFEI GROUP

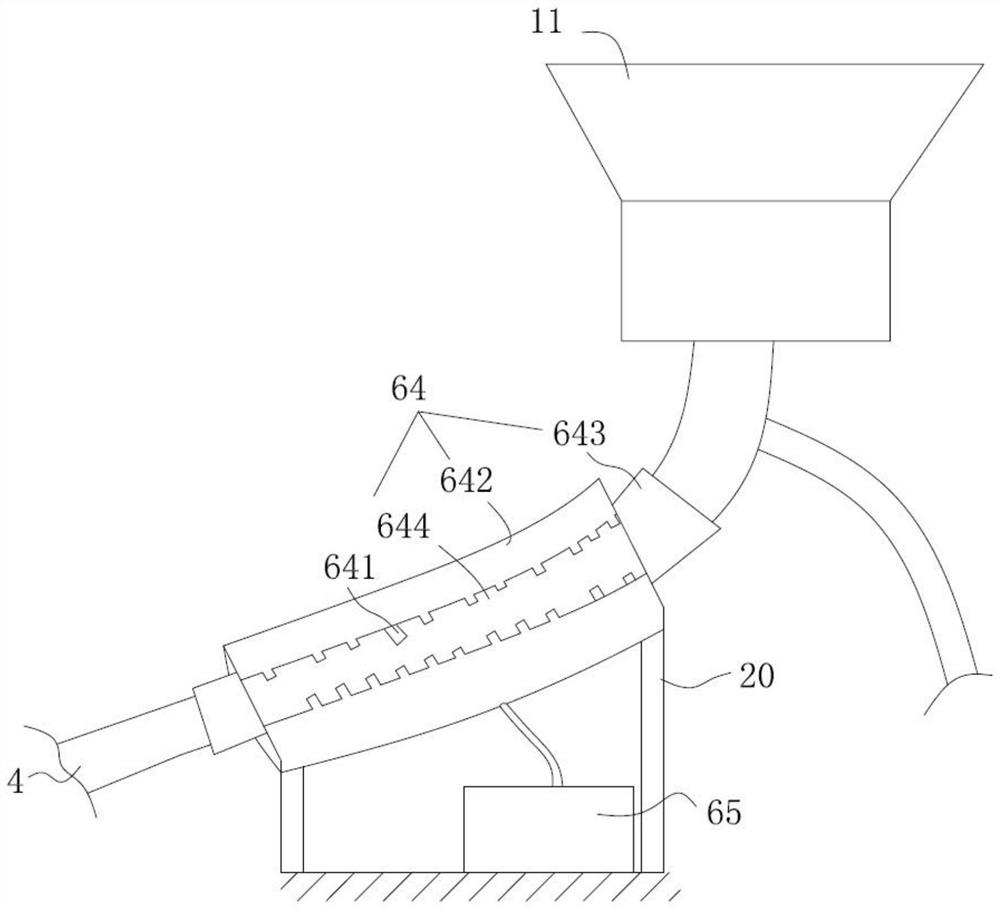

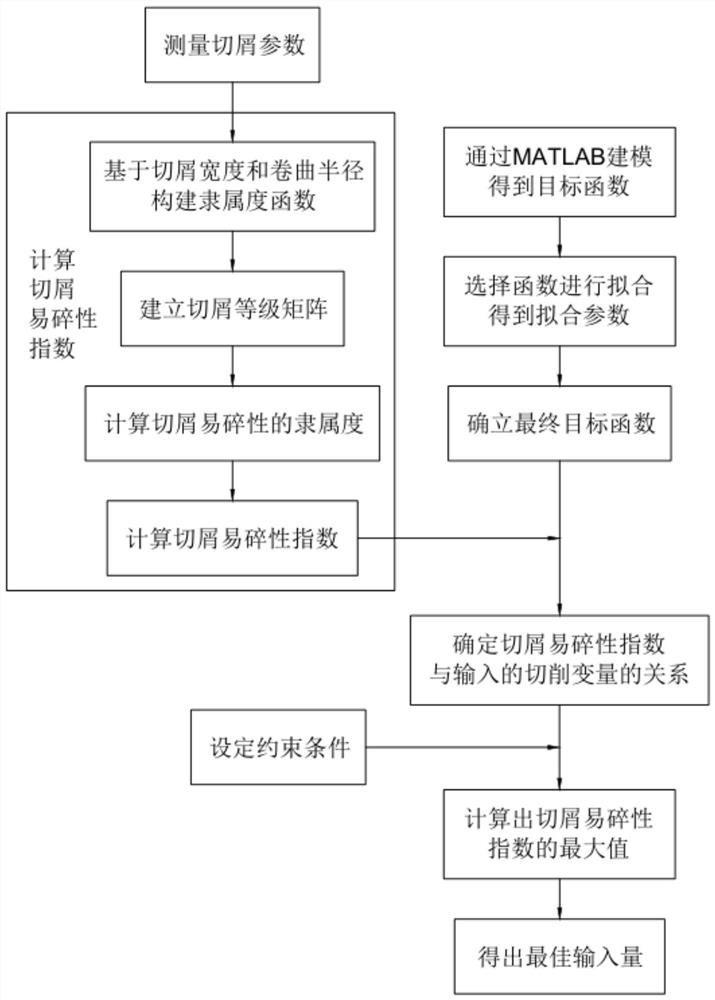

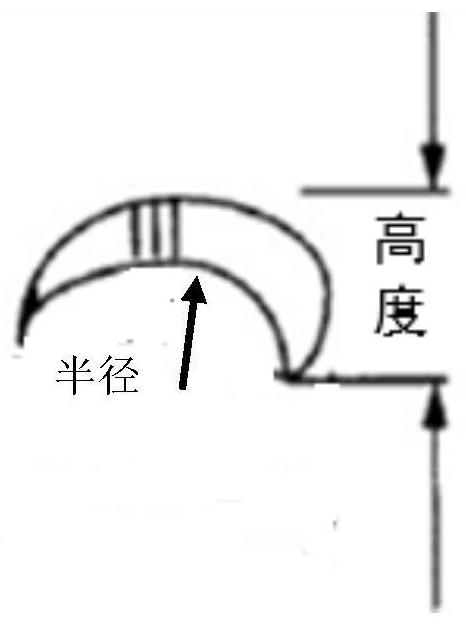

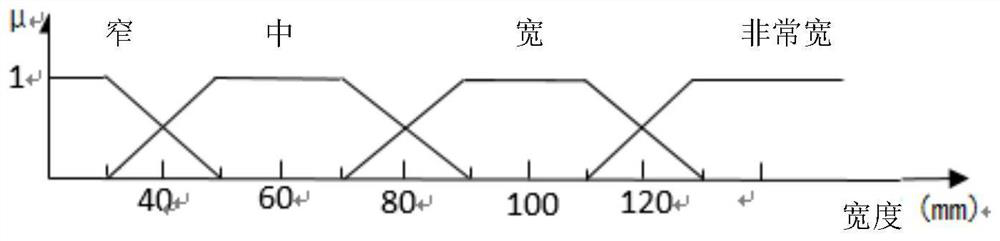

A Method for Optimizing Chip Fragility Based on Response Surface Modeling

ActiveCN109100953BChip friability optimizationAccurate calculationSimulator controlAlgorithmSurface construction

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com