A kind of metal soft magnetic silicon aluminum alloy powder and preparation method thereof

A technology of iron-silicon-aluminum alloy and silicon-aluminum alloy, which is applied in the field of preparation of metal soft magnetic materials, can solve problems such as easy to pierce the insulating coating layer, difficult to obtain magnetic powder cores, and easy to segregate, etc., to improve the comprehensive magnetic properties, Effect of reducing damage and improving fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

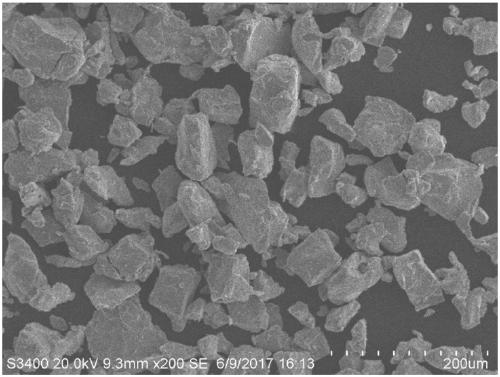

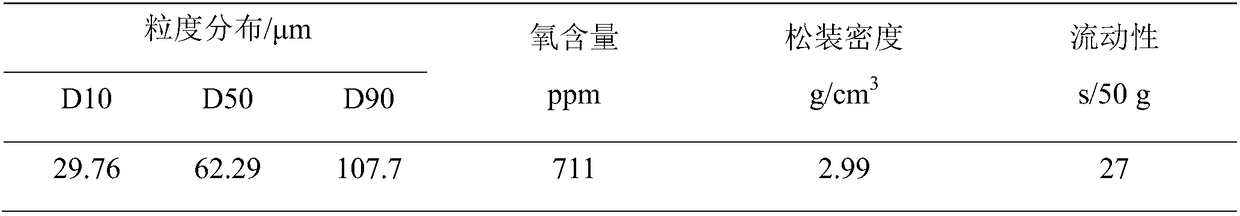

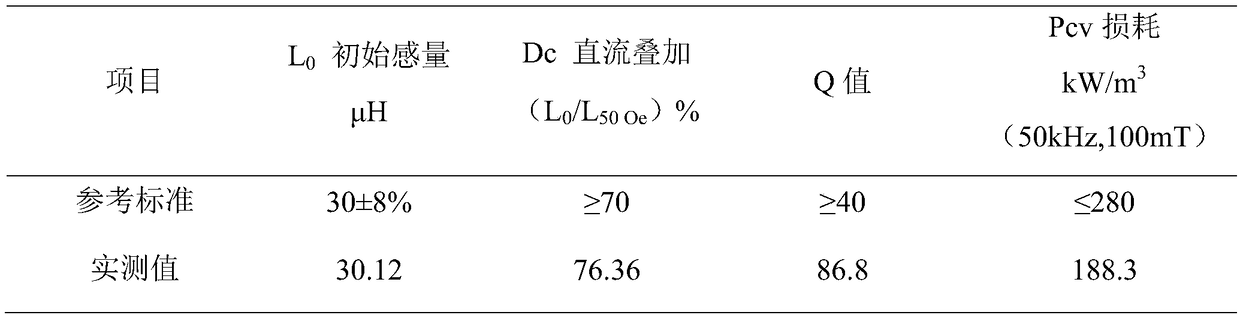

Image

Examples

Embodiment 1

[0038] The realization steps of the preparation method of the sendust aluminum alloy powder proposed by the present invention are:

[0039] Step S101, batching process: each raw material is weighed and batched separately, and the weight percentage of each raw material is: 84.65% of pure iron for furnace charge, 9.60% for bulk metal silicon, and 5.75% for pure aluminum ingot; the grade of pure iron billet for furnace charge is TISCO YT01, iron content 99.9%, manganese content 0.01%; bulk metal silicon grade 2202, silicon content 99.7%, calcium content 0.02%; pure aluminum ingot grade 997, aluminum content 99.9%, copper content 0.005%;

[0040] Step S102, smelting process: smelting the above prepared raw materials by non-vacuum induction heating, first put iron in the non-vacuum intermediate frequency induction furnace, set the induction power of the intermediate frequency induction furnace to melt the iron; after the iron is melted, adjust Low-medium frequency induction furnac...

Embodiment 2

[0052] The realization steps of the preparation method of the sendust aluminum alloy powder proposed by the present invention are:

[0053] Step S101, batching process: each raw material is weighed and batched separately, and the weight percentage of each raw material is: 84.65% of pure iron for furnace charge, 9.50% for massive metal silicon, and 5.85% for pure aluminum ingot; the grade of pure iron billet for furnace charge is TISCO YT01, the iron content is 99.9%, of which the manganese content is 0.01%; the grade of bulk metal silicon is 441, the silicon content is 99.2%, and the calcium content is 0.08%; the grade of pure aluminum ingot is Chalco 997, the aluminum content is 99.8%, and the copper content is 0.009%;

[0054] Step S102, smelting process: smelting the above prepared raw materials by non-vacuum induction heating, first put iron in the non-vacuum intermediate frequency induction furnace, set the induction power of the intermediate frequency induction furnace t...

Embodiment 3

[0067] The realization steps of the preparation method of the sendust aluminum alloy powder proposed by the present invention are:

[0068] Step S101, batching process: each raw material is weighed and batched separately, and the weight percentage of each raw material is: furnace charge pure iron 84.82%, bulk metal silicon 9.42%, pure aluminum ingot 5.76%; the grade of furnace charge pure iron billet is Taiyuan Iron and Steel Co., Ltd. YT01, iron content 99.8%, of which manganese content 0.02%; block metal silicon grade is 2202, silicon content 99.7%, calcium content 0.02%; pure aluminum ingot grade is China Aluminum 997, aluminum content 99.9%, of which copper content 0.006%;

[0069] Step S102, smelting process: smelting the above prepared raw materials by non-vacuum induction heating, first put iron in the non-vacuum intermediate frequency induction furnace, set the induction power of the intermediate frequency induction furnace to melt the iron; after the iron is melted, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com