Electric vehicle beam structure

An electric vehicle and frame structure technology, applied in the direction of load-bearing body structure, superstructure, vehicle components, etc., can solve the problems of structural damage and hidden dangers of vehicle safety, avoid structural weaknesses, increase the load capacity, and reduce the sharp corner joints. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

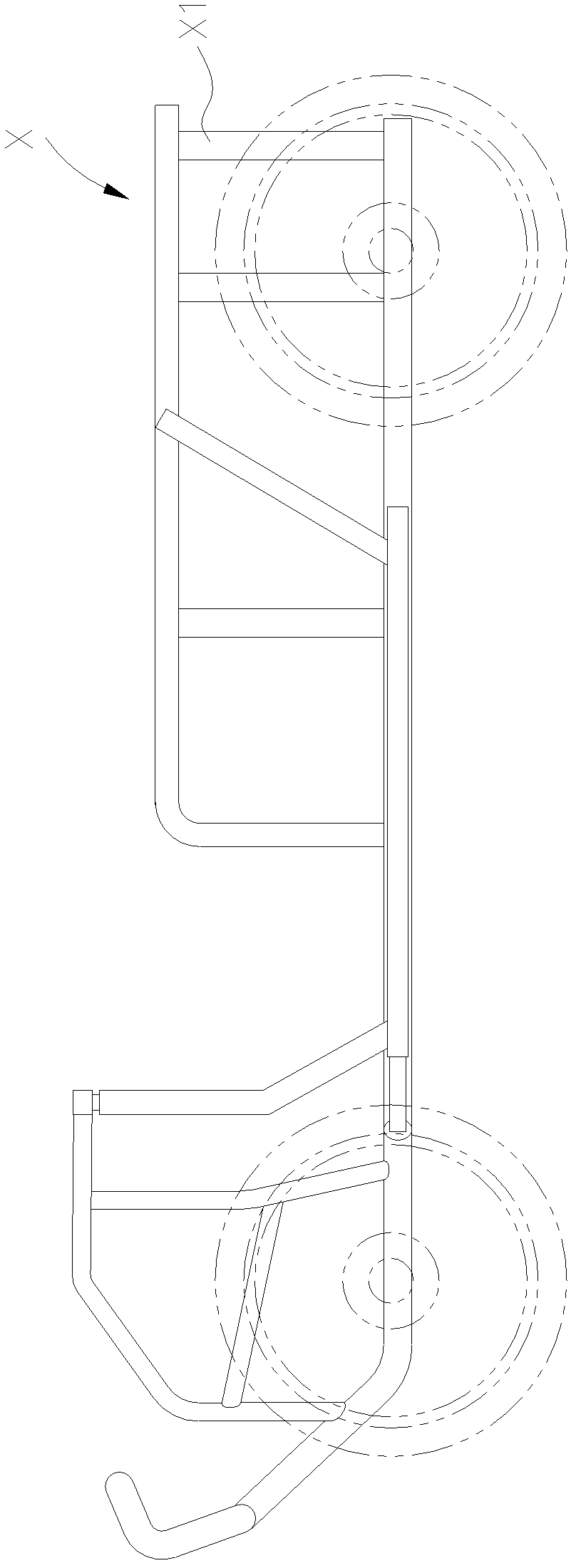

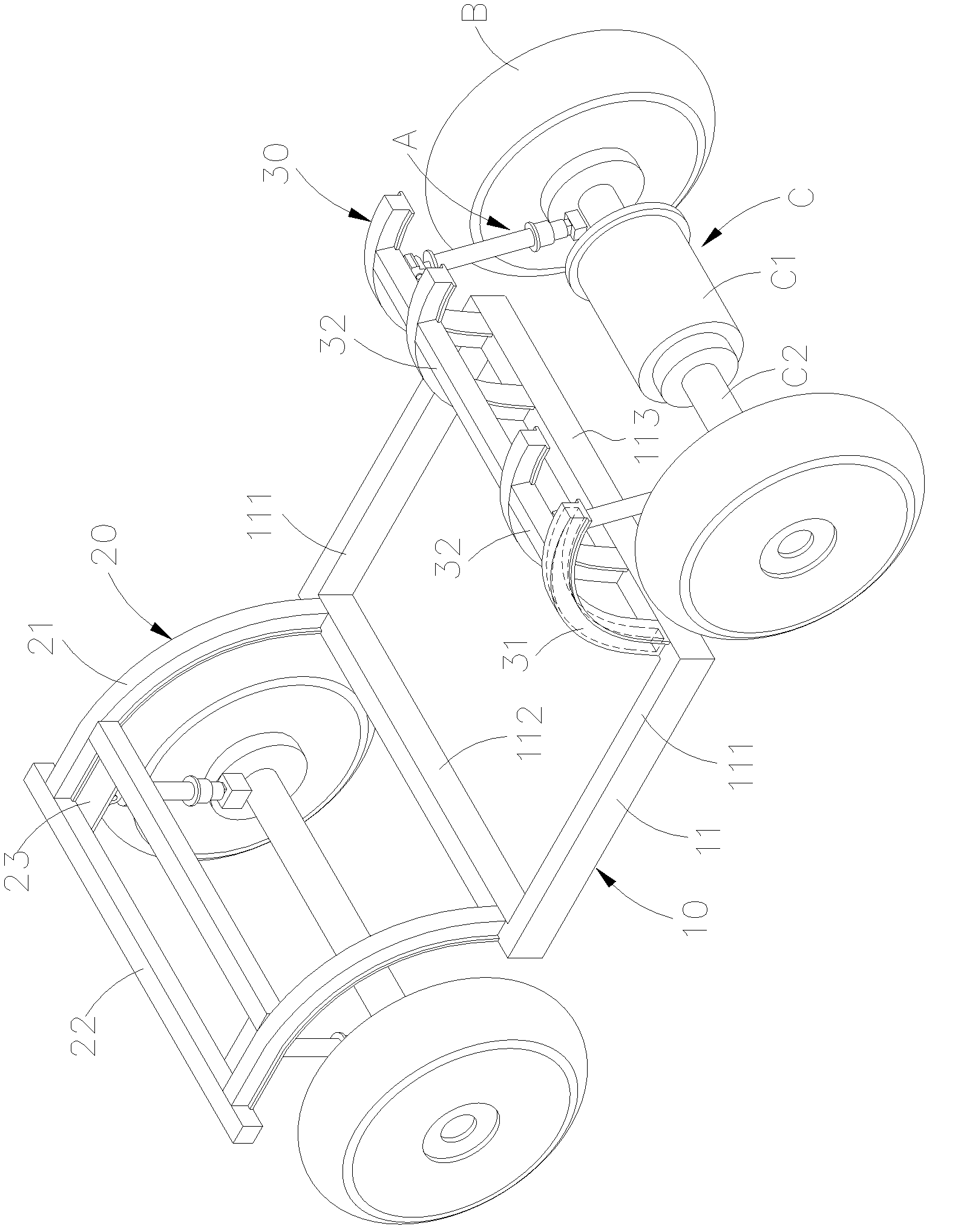

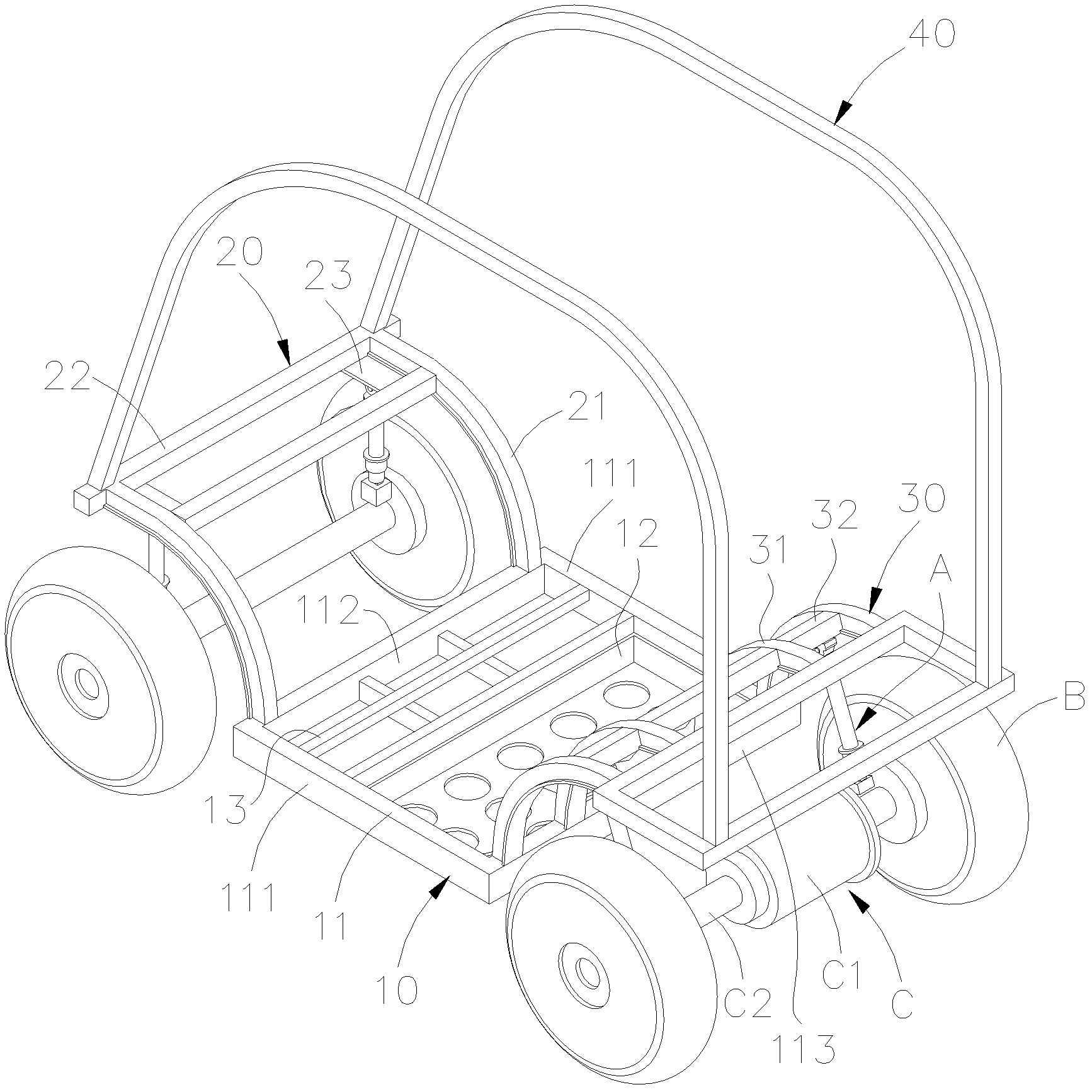

[0035] like Figures 2 to 4 As shown in the figure, the electric vehicle beam frame of the present invention includes a base frame 10, a front bracket 20, a rear bracket 30 and two side brackets 40;

[0036] The base frame 10 is surrounded by four frame sides 11 to form a four-corner frame structure, and the four frame sides 11 are respectively two side frame sides 111, a front frame side 112 and a rear frame side 113, and the front frame side 112 and the rear frame side 113 are respectively connected At both ends of the two side frame sides 111, a storage basket 12 is arranged in the base frame 10 to accommodate batteries, and a plurality of reinforcing pipes 13 are connected in the base frame 10 to improve the load-bearing capacity of the base frame 10;

[0037] The front support 20 comprises two front support arc tubes 21 and a front support connecting tube 22, and one end of the two front support arc tubes 21 is connected to the two ends of the front frame edge 112 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com